Function: Carrying the primed glass, one-way drive within the set time, easy to place and remove the glass, with exhaust/extraction interface

Error-proof function: the minimum drying time is limited to 20min, first-in, first-out

Number of operators: 1 person

Continuous use time:24H/day

Total cycle time:< 25 sec

Manual operation time:< 25 sec

Product switching tooling adjustment time:< 1 min (bearing width adjustment, glass support position adjustment)

Noise level: 70dB or less from 1m away

Technical description of structural

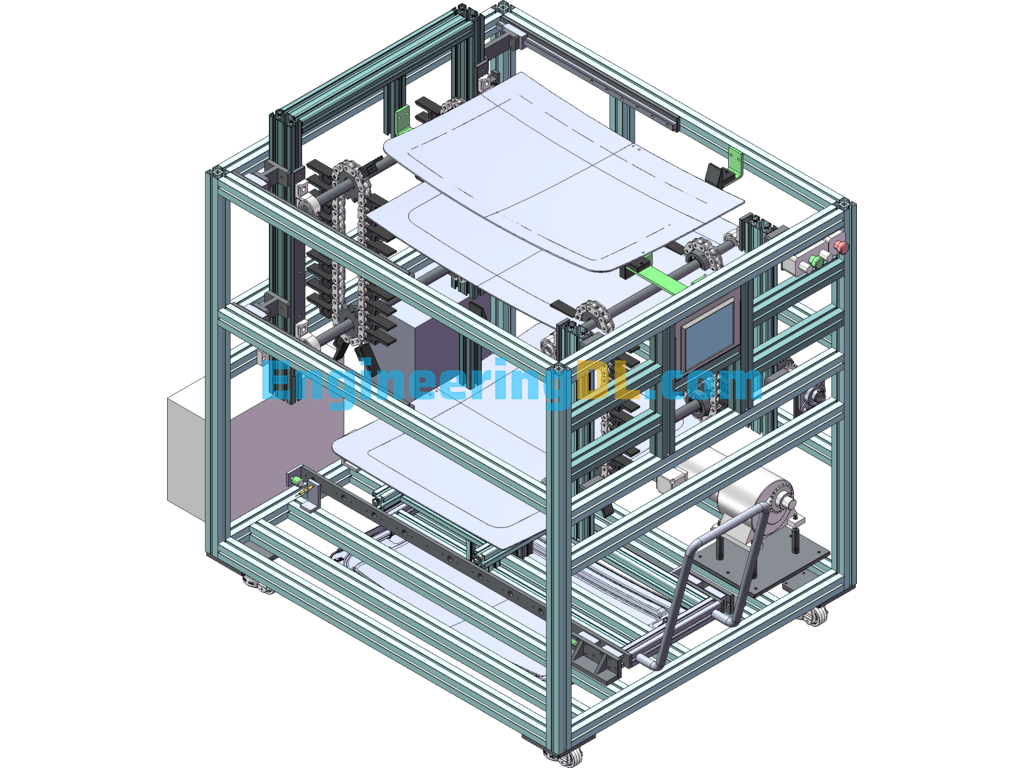

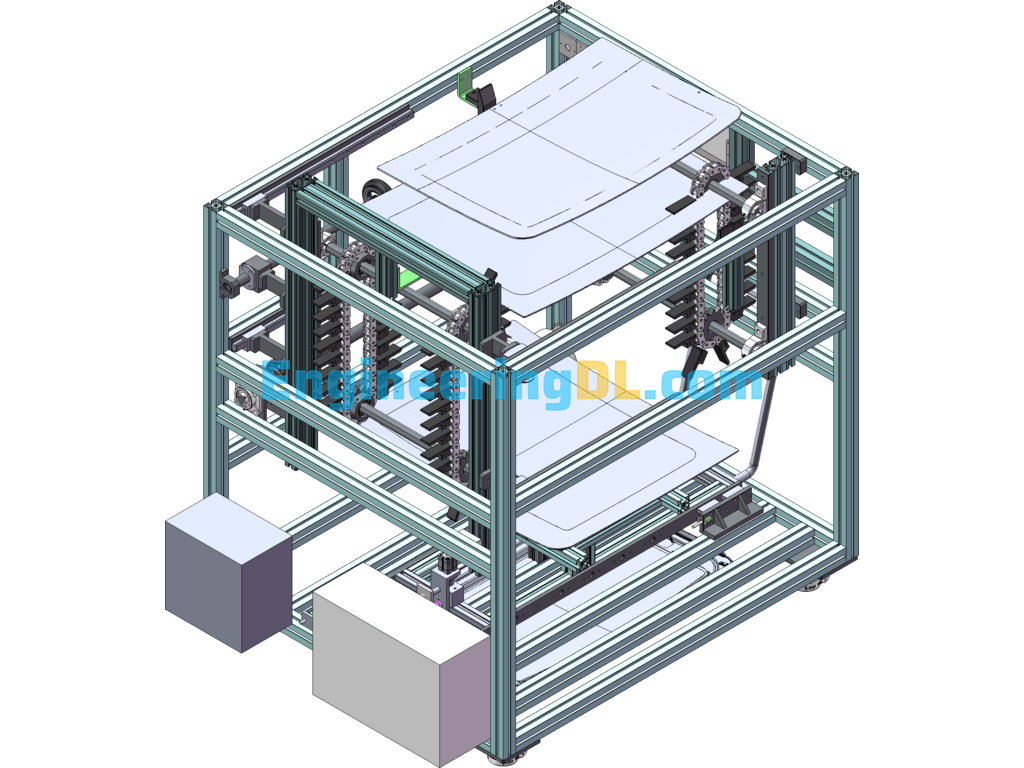

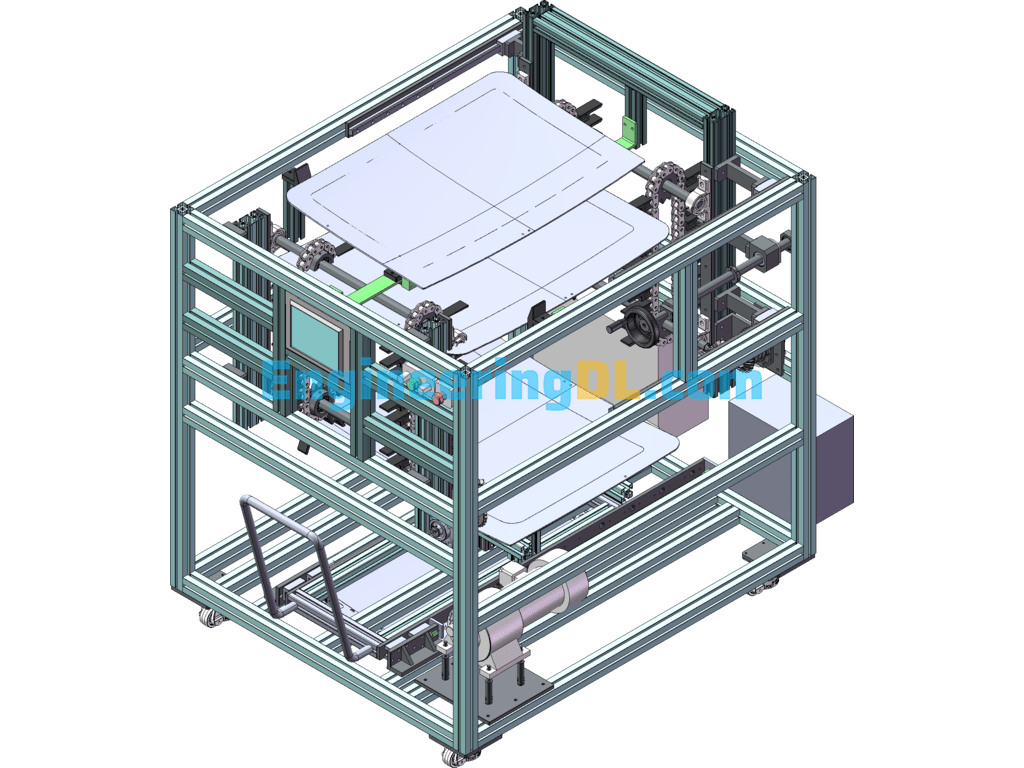

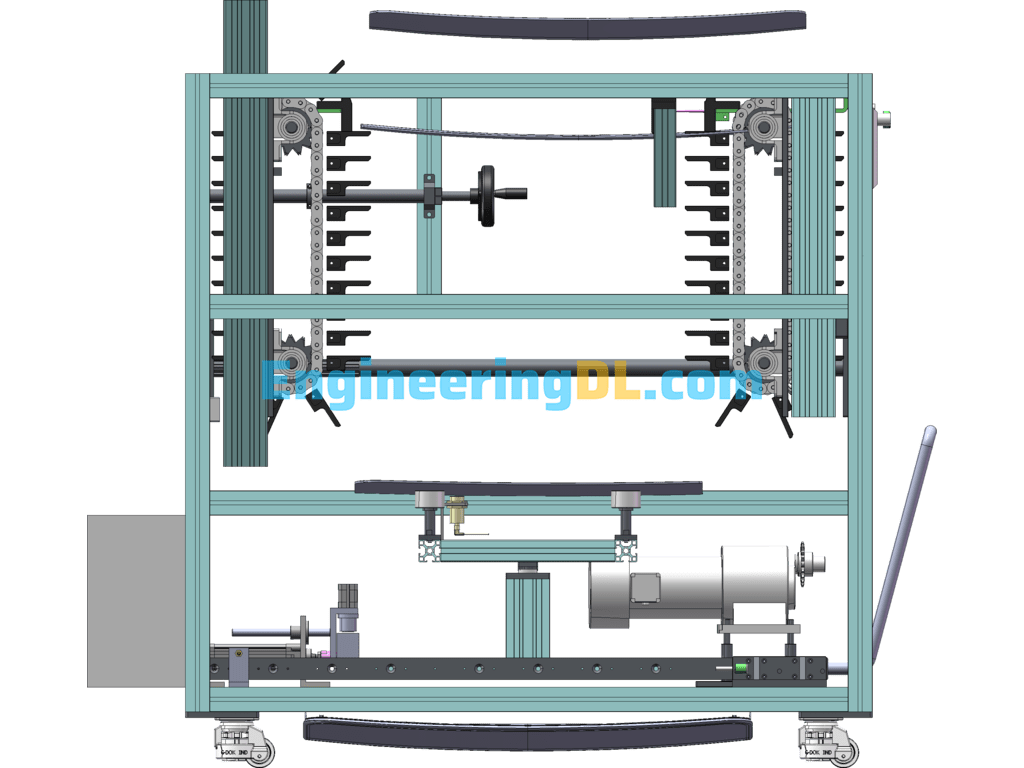

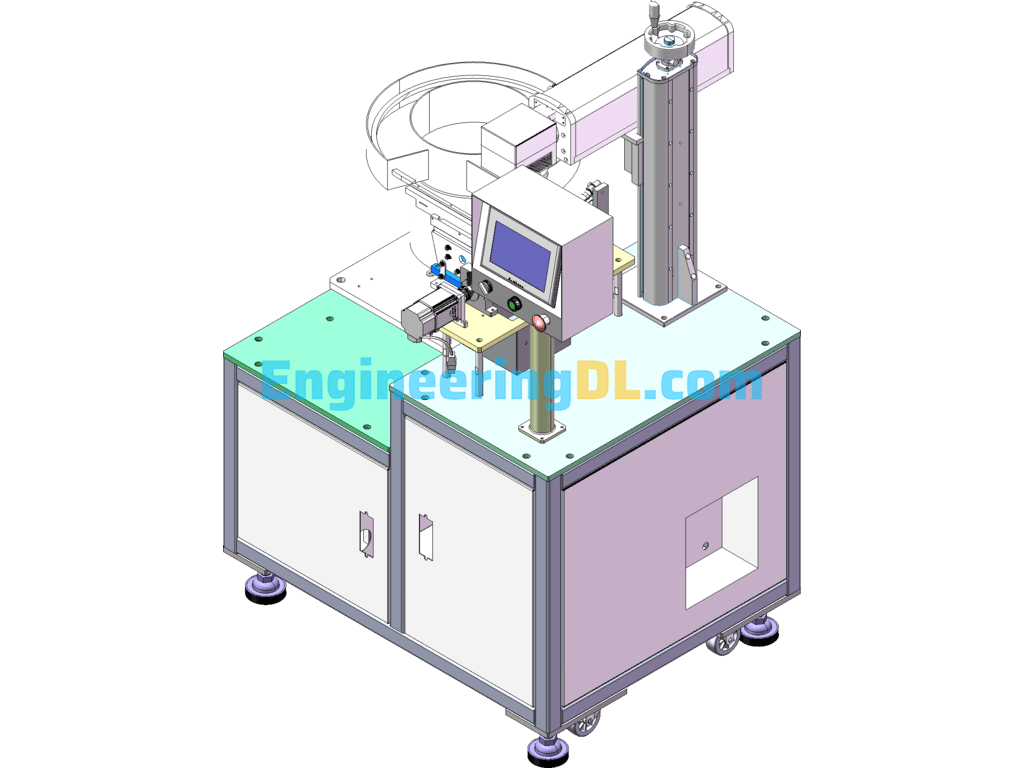

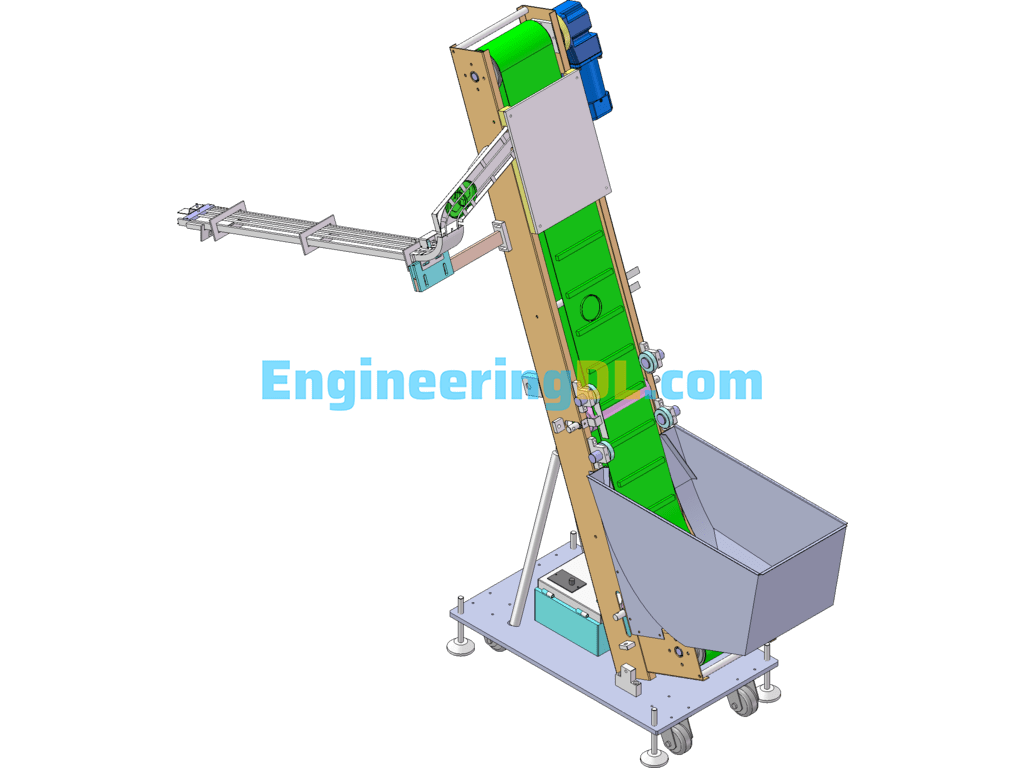

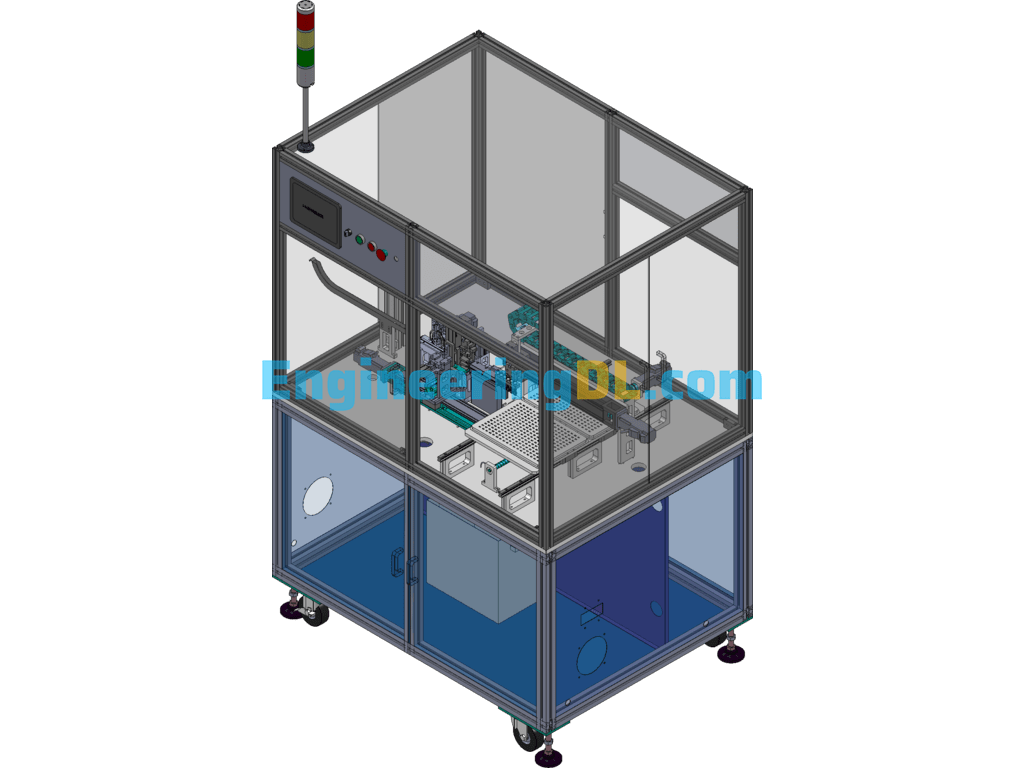

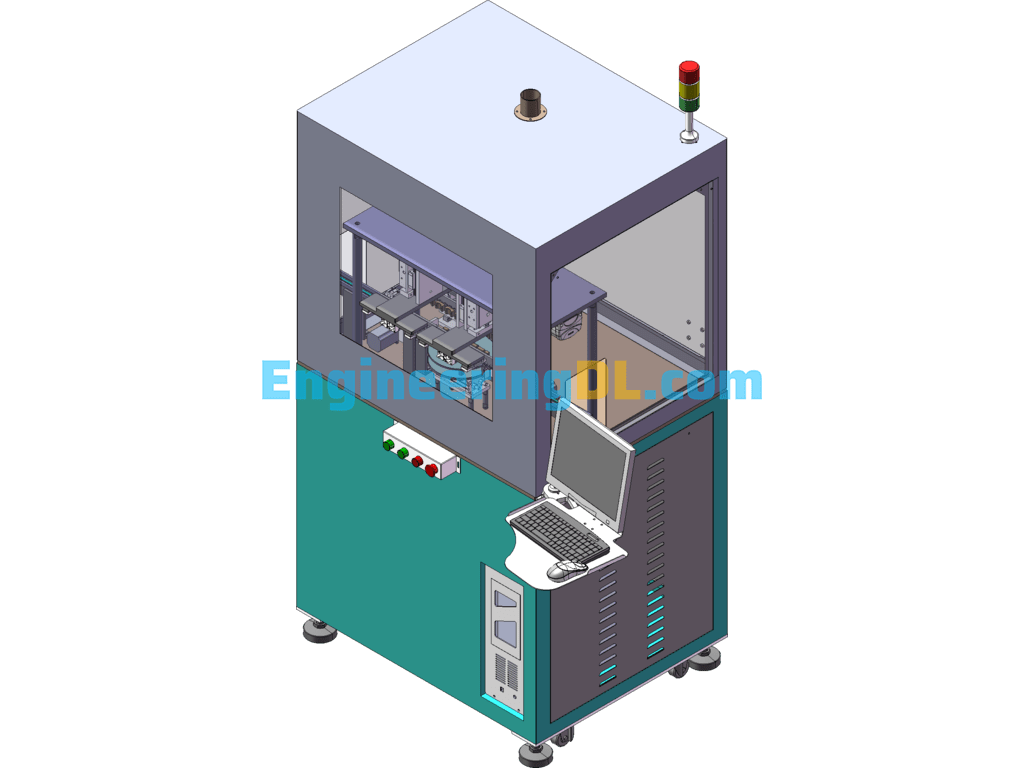

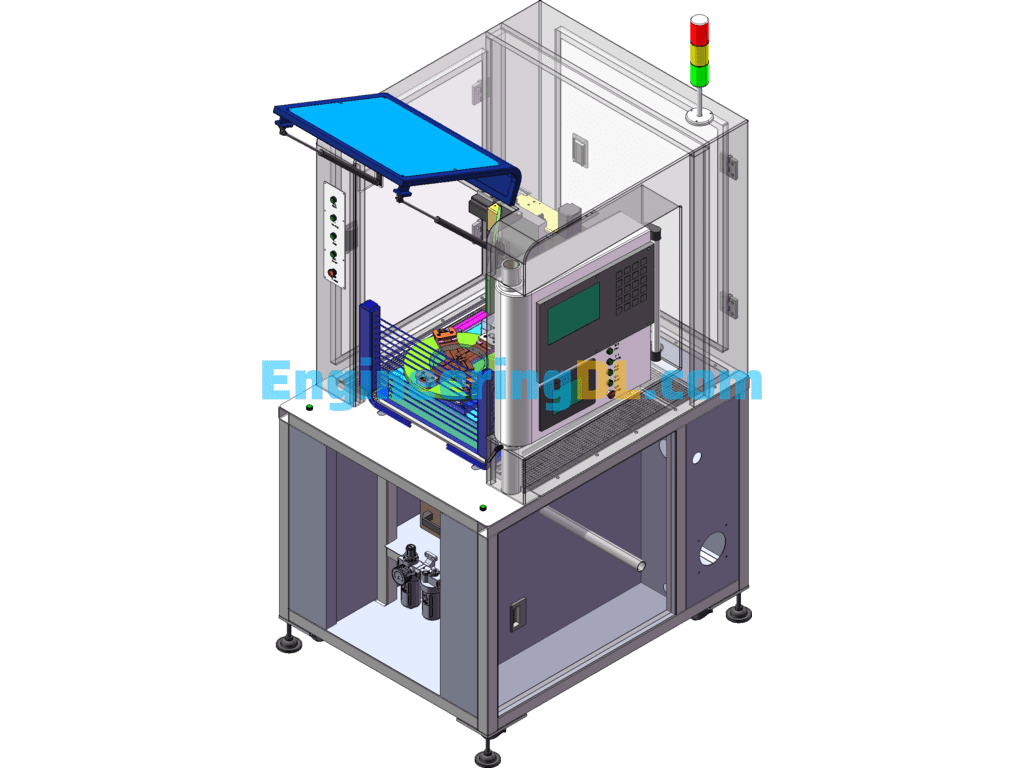

parts- The material frame is made of 50*50 Dr. aluminum profile with the following dimensions: W1500 ?? D1100 ?? H1500mm (maximum glass 800 ?? 1000). - The back side, left and right side and front side of the working table are equipped with plexiglass sealing plate; - The effective number of layers for drying glass is 12 layers, the layer spacing is 35~50mm, and the chain weight requirement is not less than 80KG (calculated according to the weight of glass). - The support of the glass is made of black nylon (flat) and black felt wool is applied to avoid scratching the glass. The support length is 65mm. - Pallet: The pallet frame is I-beam (350X450), and the cylinder is installed on the lower side (with adjustable running speed), which is used to run the glass back and forth. 4 suction cups (FESTO brand, ??80) are installed on the pallet, and the position can be adjusted manually. When the button is pressed manually, the conveying frame is extended with a piece of original glass, after the glass is extended, the ejector is activated and the glass is ejected (the height is not less than 600), then it is tilted inward (about 30 degrees), after the glass is taken away, the ejector automatically drops and retracts, then the chain drops one frame; - the chain is fixed on the left side and adjustable on the right side, the adjustment range is 300mm. - The control display is installed in the upper left position on the front side (the top is installed on the profile), and the screen is equipped with a plexiglass shield outside. - Transmission mechanism. Composed of inverter + drive motor + reducer. - Electric cabinet and external cables are connected using quick connectors, and the control cabinet is placed at the bottom left, which can be pushed and pulled out for easy maintenance. - Transmission mechanism requires chain tension adjustment (to prevent loosening in the transmission process), and adjustable in the axial direction.

PLC control system: Start of production: The glass finished with primer coating is put into the top layer of the delayed material shelf from the top end, the top sensor senses the glass, press the "drop one frame" button, the chain will drop one frame; then the chain will drop automatically after the glass is put in; take out the glass. When the glass is dropped to the tray and the set time is reached, press the "In/Out" button, the tray will hold the glass at the bottom level and extend; the barcode scanner will scan the barcode information during the extension process, and if the barcode is not read, the red light will alarm, and the reset button can be used to reset until the barcode is scanned; the operator can remove the glass from the tray. (the ejector device automatically drops and retracts); - glass removal buttons ??? are installed on the top of the left and right sides (2), the button box is flush with the side of the profile, and the buttons extend. - The buttons on the control panel (from left to right): mode knob ???, control button ???, drop one frame ???, reset ???, emergency stop button ???, see the table below for the model. - Tricolor light is installed on the right side profile (near the rear 1500 high profile). - (Electrical control cabinet is placed on the lower left rear side, and the size of electrical cabinet is 400X600). - The rear and side need to do limit (material is black nylon sheet, 2 at the rear and 1 at the side), and the front of the glass for safety protection.

Specification: Auto Glass Delay Shelf Equipment 3D Digital Model + BOM + Design Manual SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Auto Glass Delay Shelf Equipment 3D Digital Model + BOM + Design Manual SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.