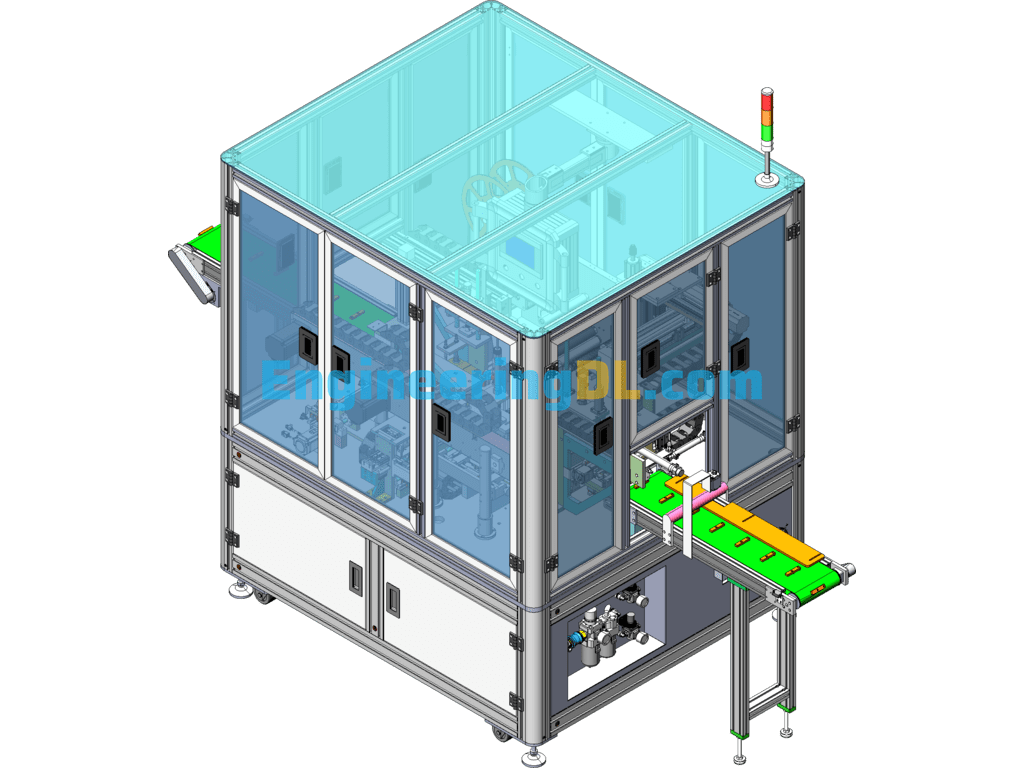

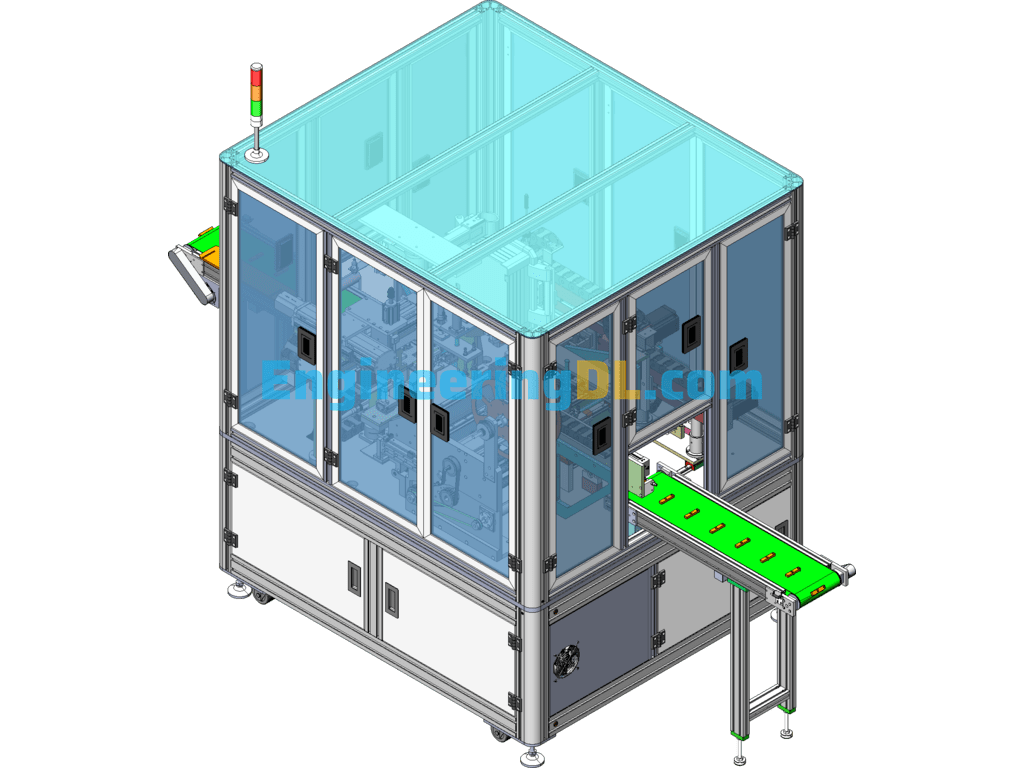

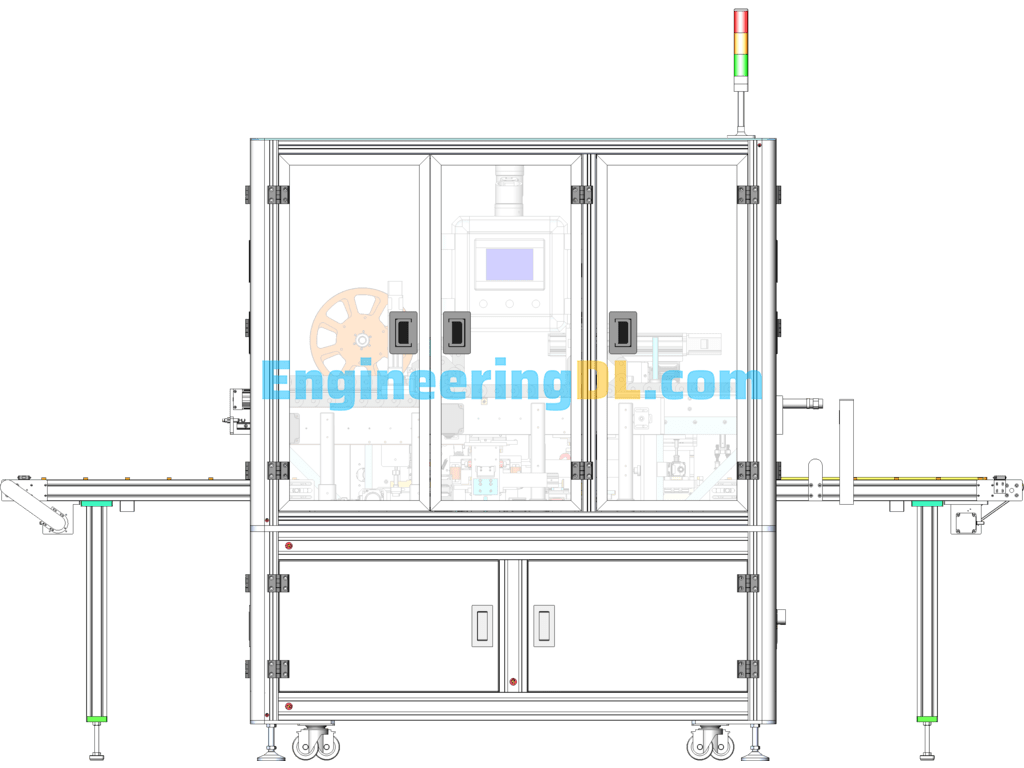

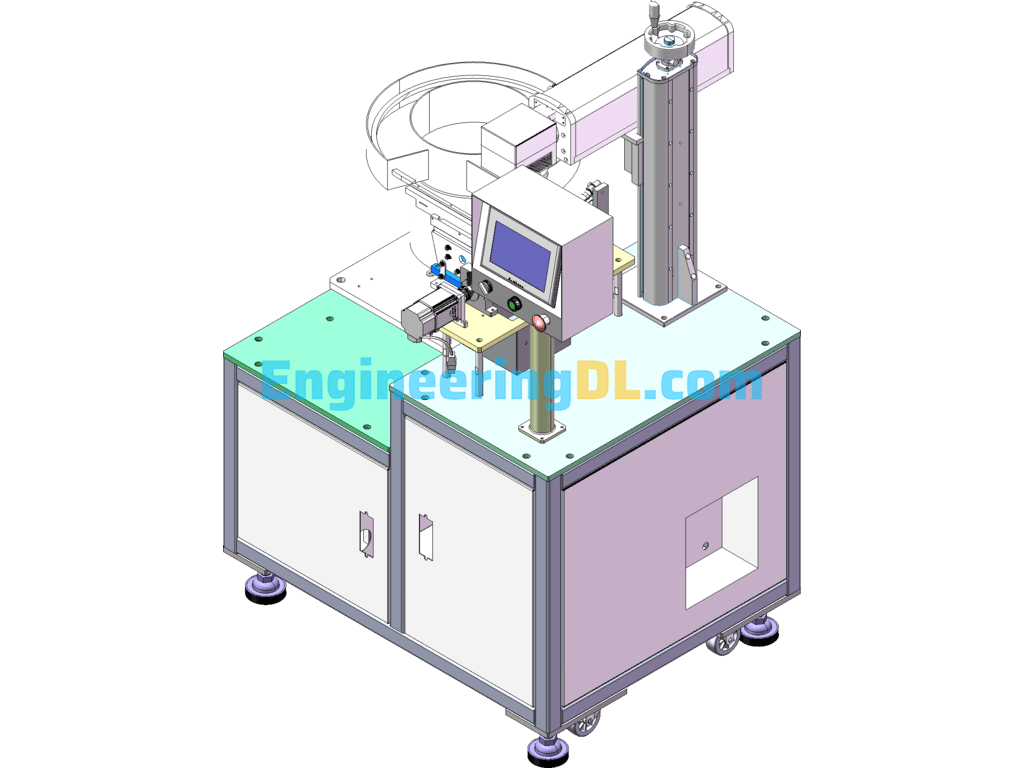

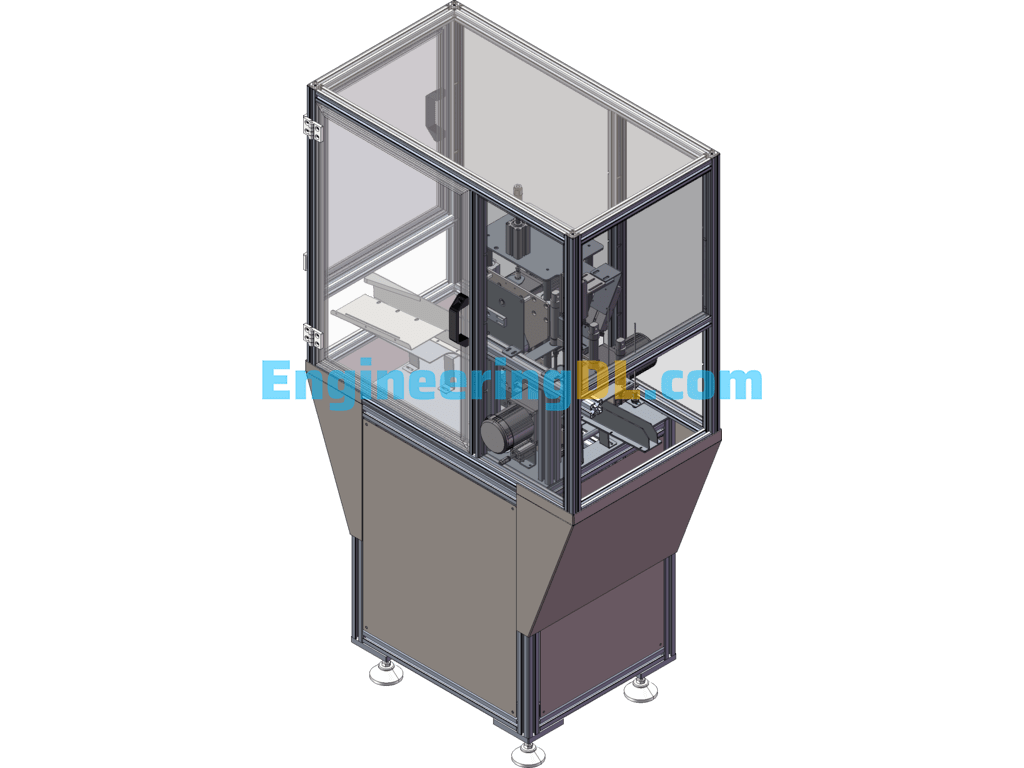

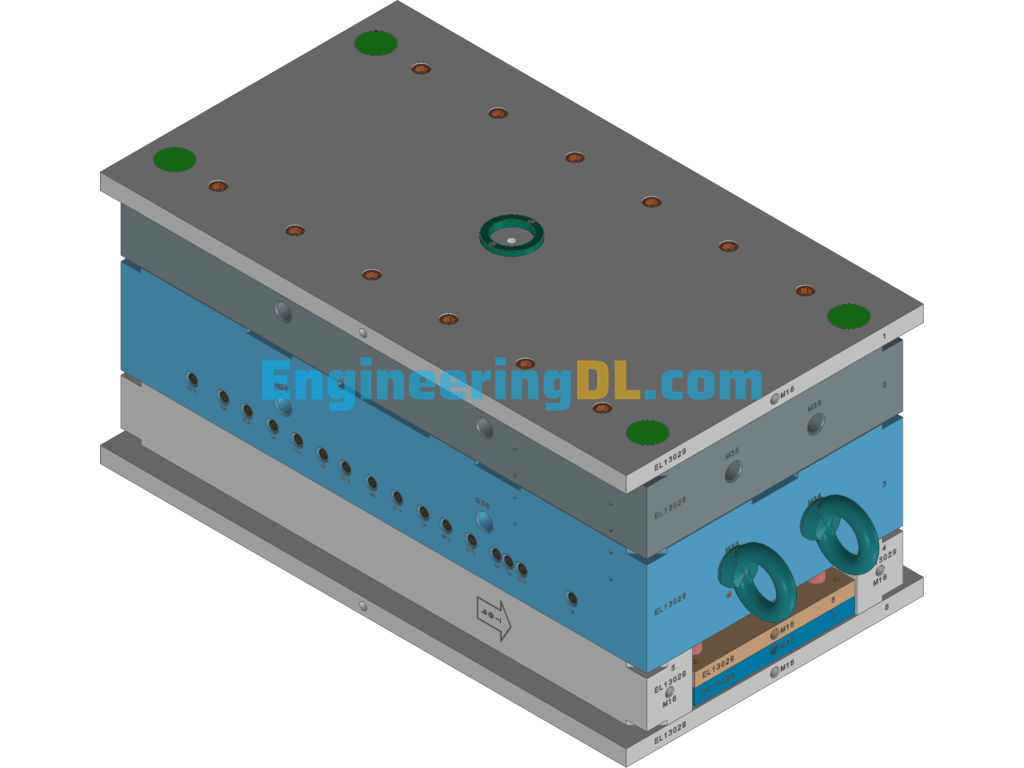

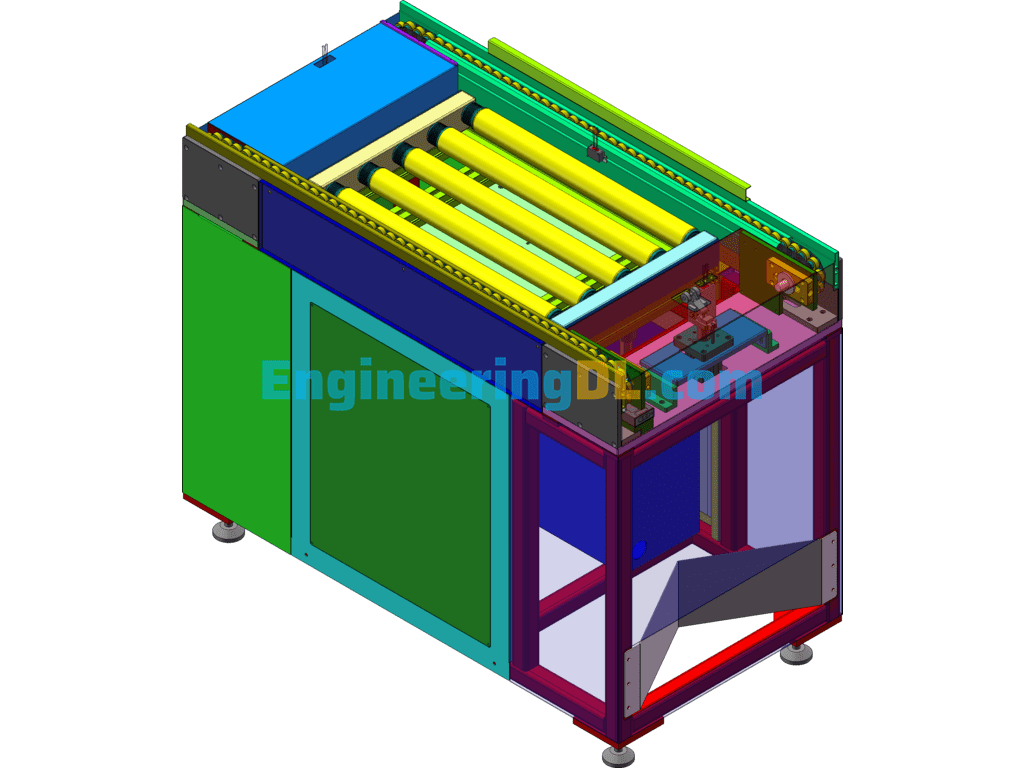

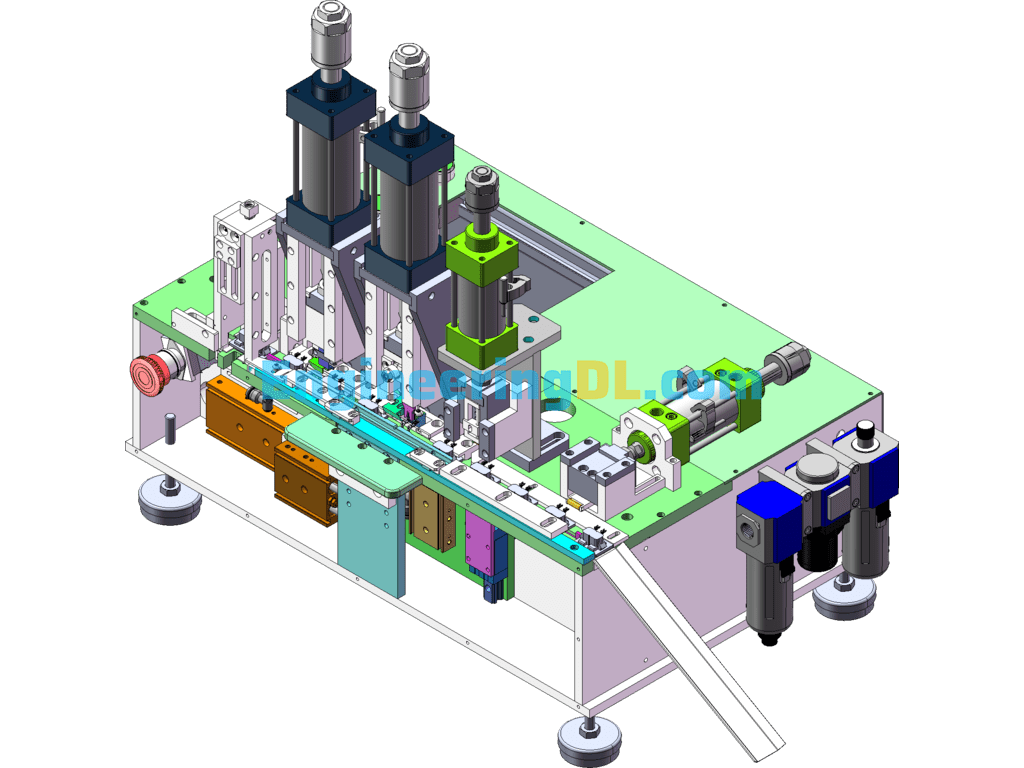

This equipment is for soft pack polymer battery shaping, pressing glue, labeling special equipment, artificially put the battery on the pull line and press the start button, the equipment starts to enter the battery anti-reverse CCD test station, CCD test if normal directly through the dust removal mechanism into the equipment. The battery is put on the reverse equipment alarm manual battery correction re-press the start button battery through the dust removal mechanism flow into the equipment. The loading and unloading robot absorbs the battery and moves it to the shaping mechanism for CCD testing after shaping both sides of the battery, and then takes it to the positioning labeling jig, the motor drives the jig to move back and move to the labeling position. The label feeding flyer peels out the label, the X, Y, Z, W four-axis robot absorbs the label, and the CCD vision detects the label position. The information is transmitted to the system, and the system instructs the X,Y,Z,W robot to correct the deviation position. The robot moves to the labeling position. The label is applied to the battery. The shaping station returns to the designated point position, the labeling mechanism jig releases the Z cylinder to lift the battery upward, the rollers on both sides of the face wrap up the battery, and the bending robot grabs the battery and transfers it to the bending station. First, use the rollers to flatten the battery lugs, and then fold the lugs after the CCD visual inspection is OK, then fold the bottom two ears and finally fold the bottom edge. SOLIDWORKS 2018 design

Specification: Polymer Battery Shaping And Labeling Machine SolidWorks

|

User Reviews

Be the first to review “Polymer Battery Shaping And Labeling Machine SolidWorks”

You must be logged in to post a review.

There are no reviews yet.