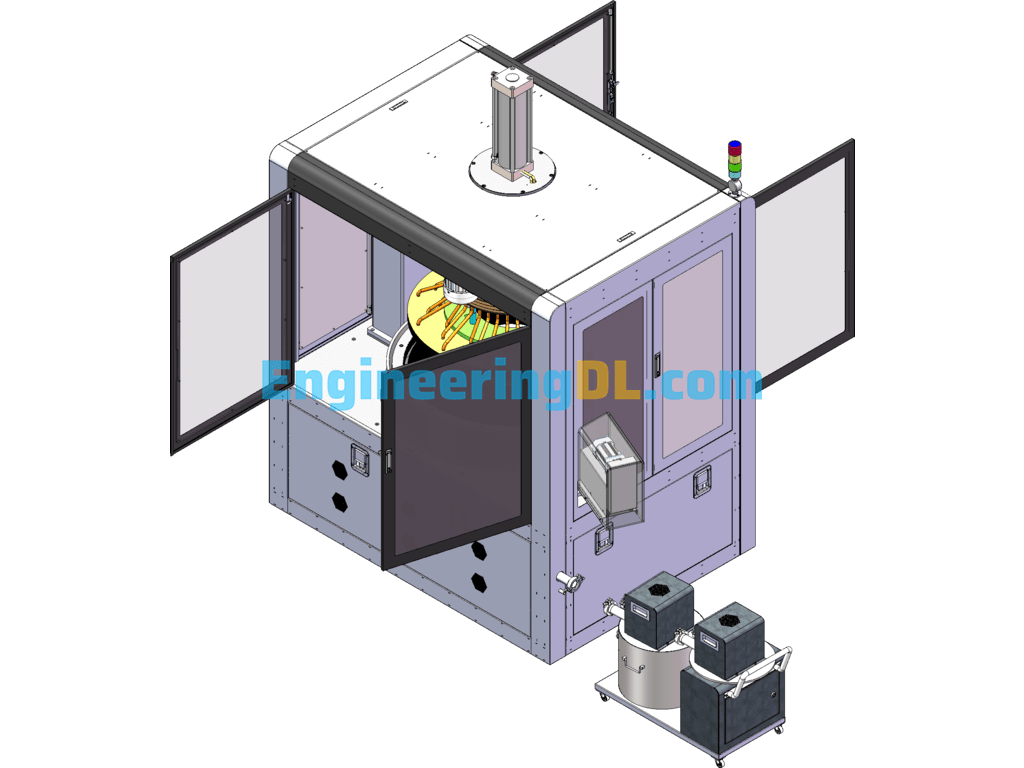

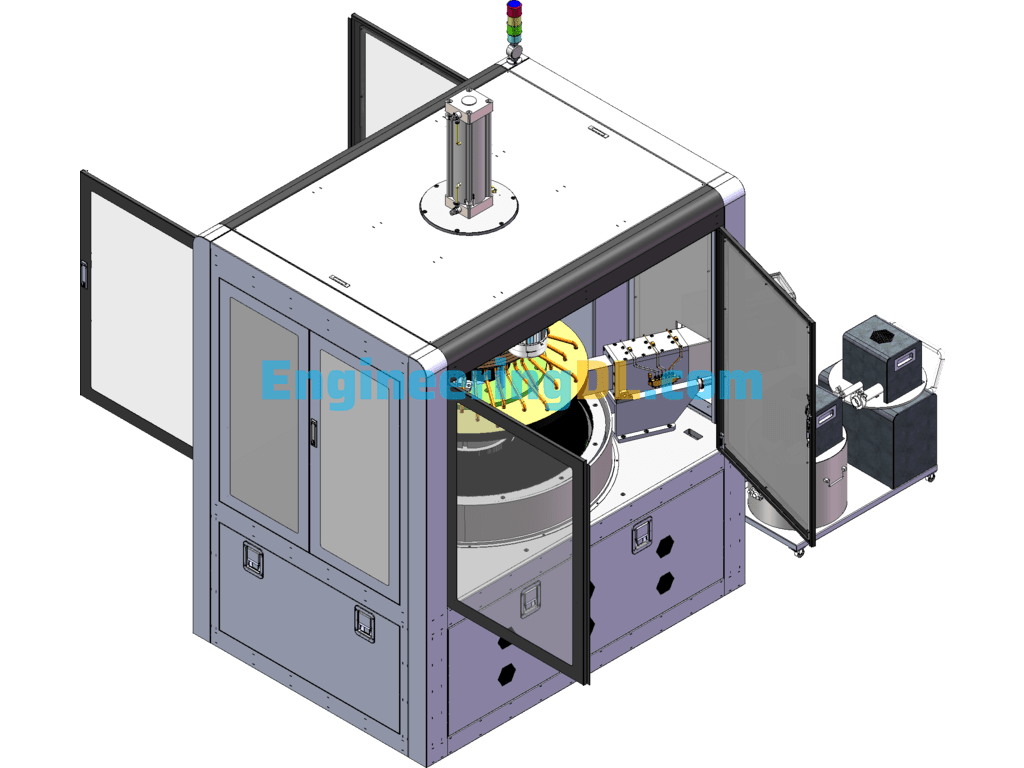

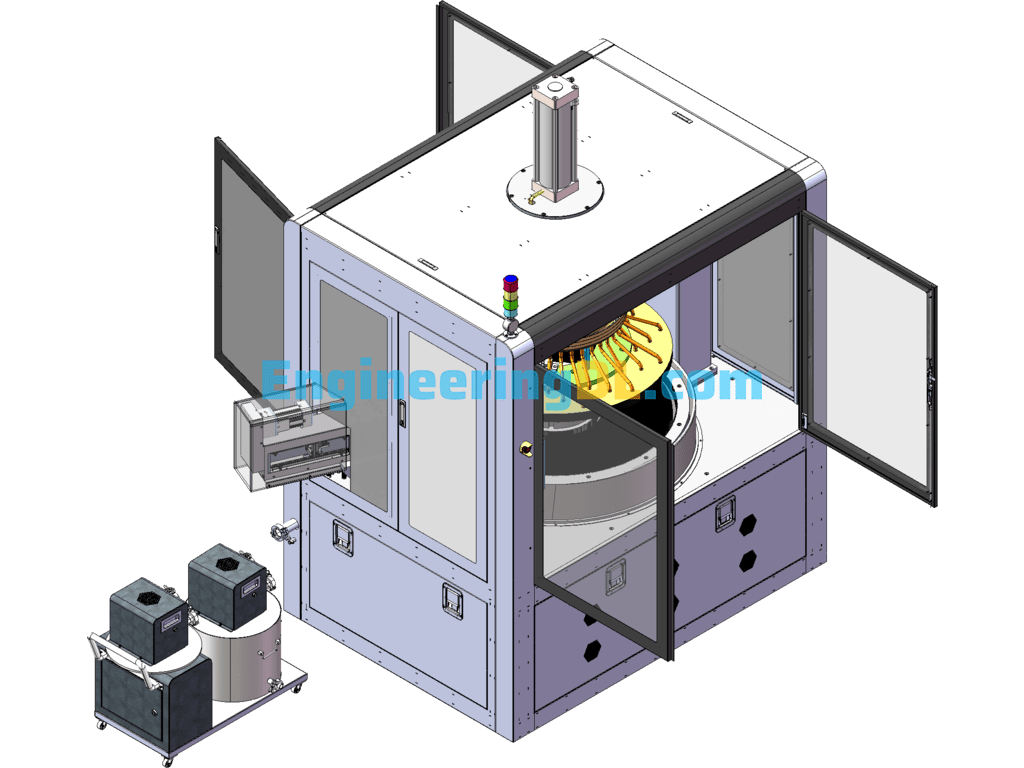

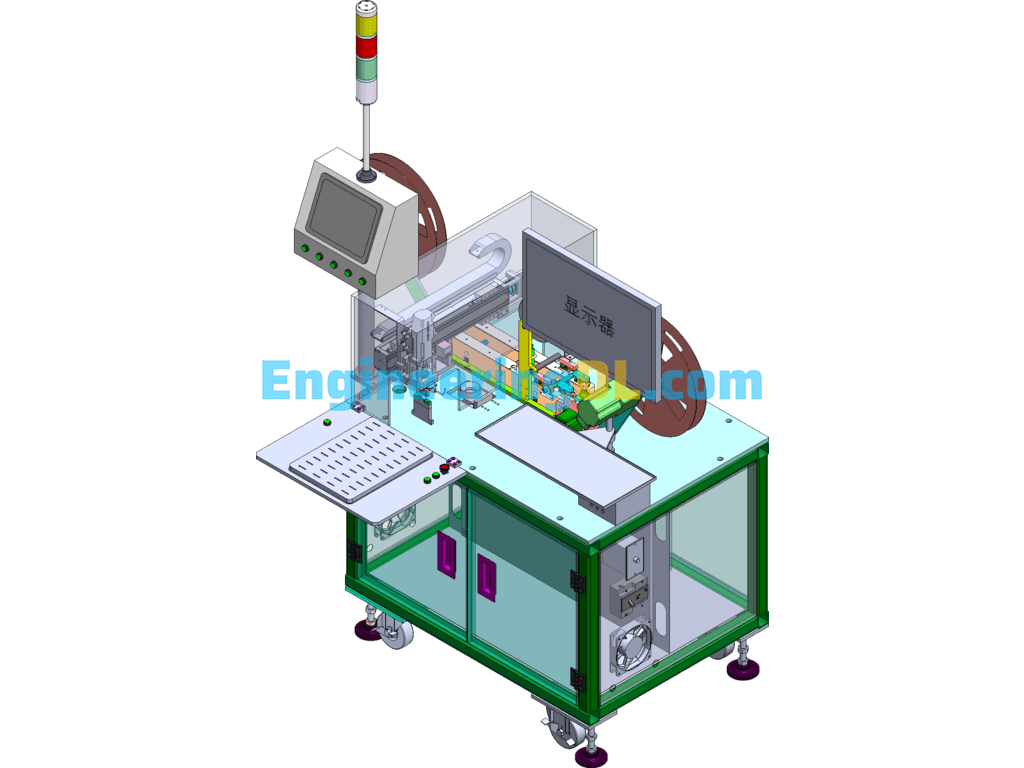

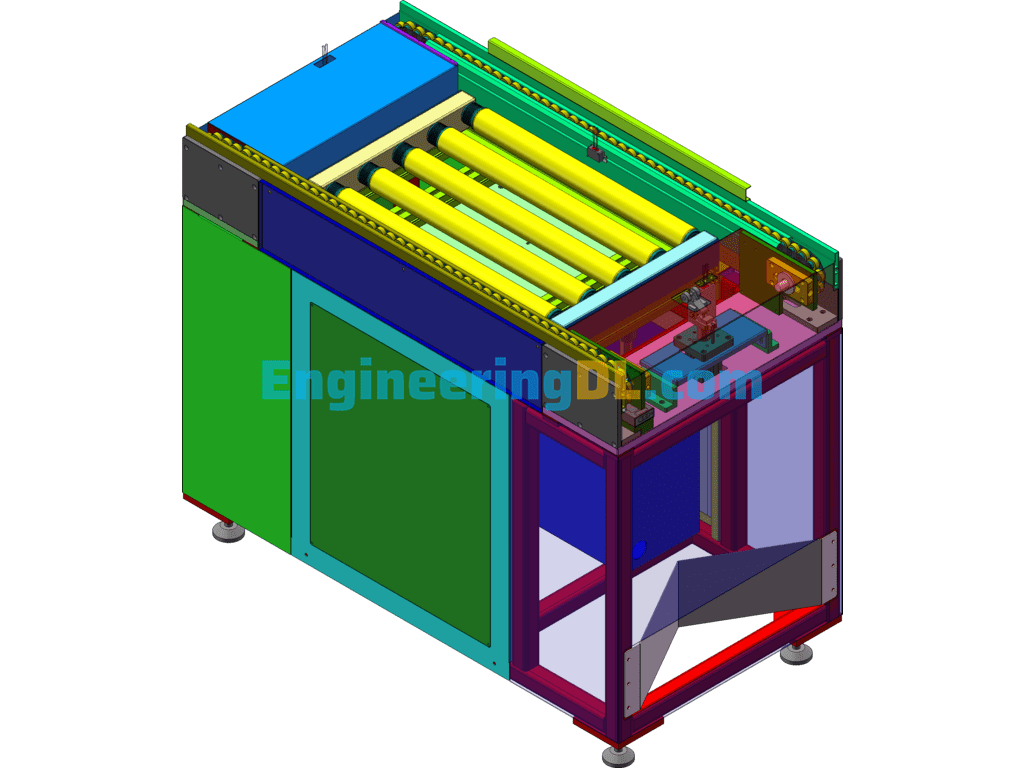

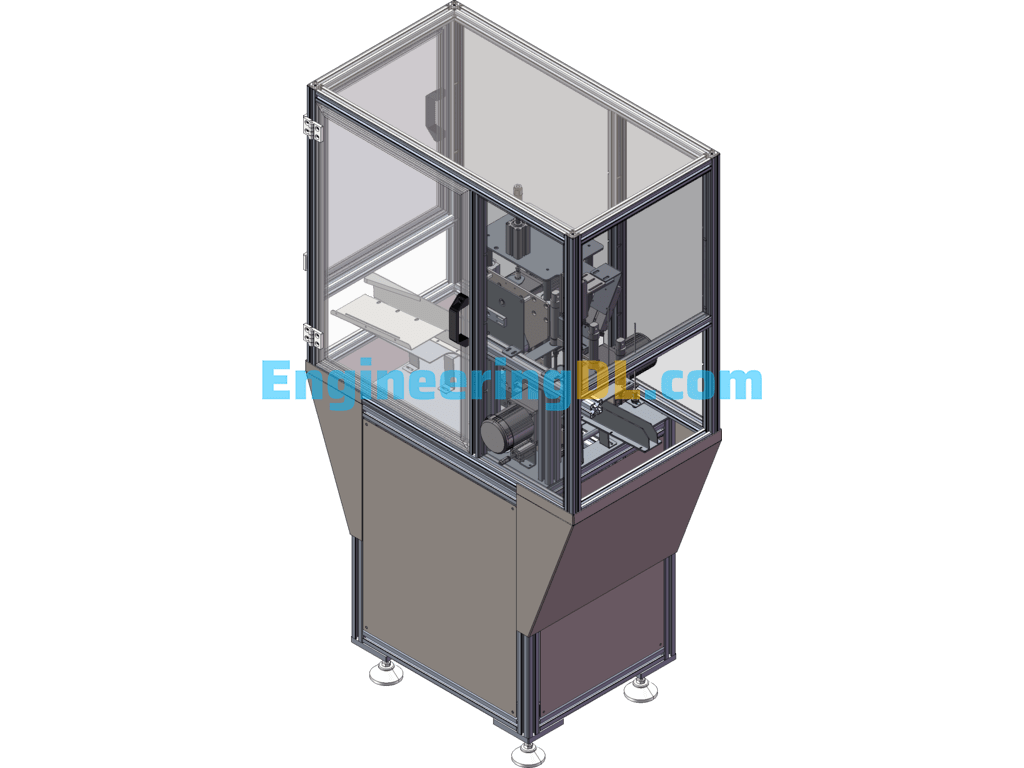

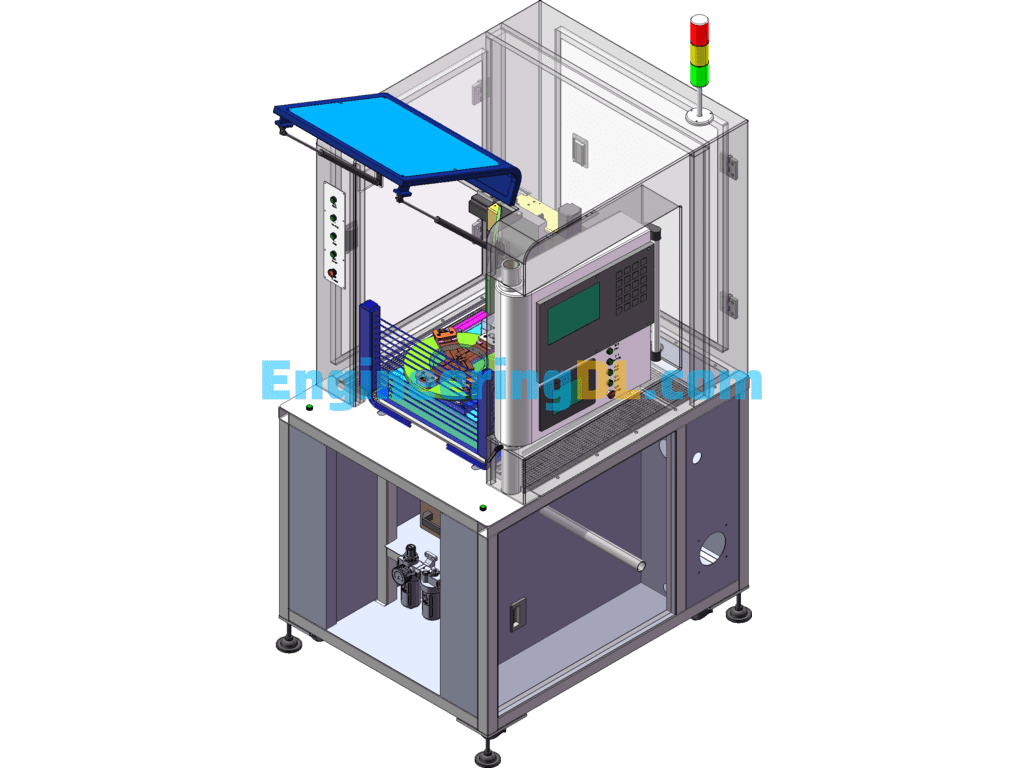

Double-sided grinding machine

Main applications Mainly used for high-precision double-sided grinding/polishing of sapphire, blue glass, ceramic chips, crystals, semiconductors and other hard and brittle materials, especially for the processing of ultra-thin workpieces with obvious advantages.

Main features

1. Pressure precision control: PLC+PT+electrical proportional valve+low friction cylinder to achieve high precision pressure closed loop control;

2. Upper disk damping device: dynamic and static are applicable to vibration damping elastic connection;

3. Precision transmission system: high precision small gap full gear transmission;

4. Lower disk support: high precision plane fluid bearing support, large bearing capacity, stable operation, maintenance-free;

5. pin gear transmission: inside and outside teeth using pin gear transmission, prolonging the service life of the carrier, convenient maintenance, can also use involute gear transmission;

6. transmission system: three motor synchronous drag, upper disk, lower disk and gear ring, sun wheel (can be positive, can also be reversed) speed can be arbitrarily set, with recipe function.

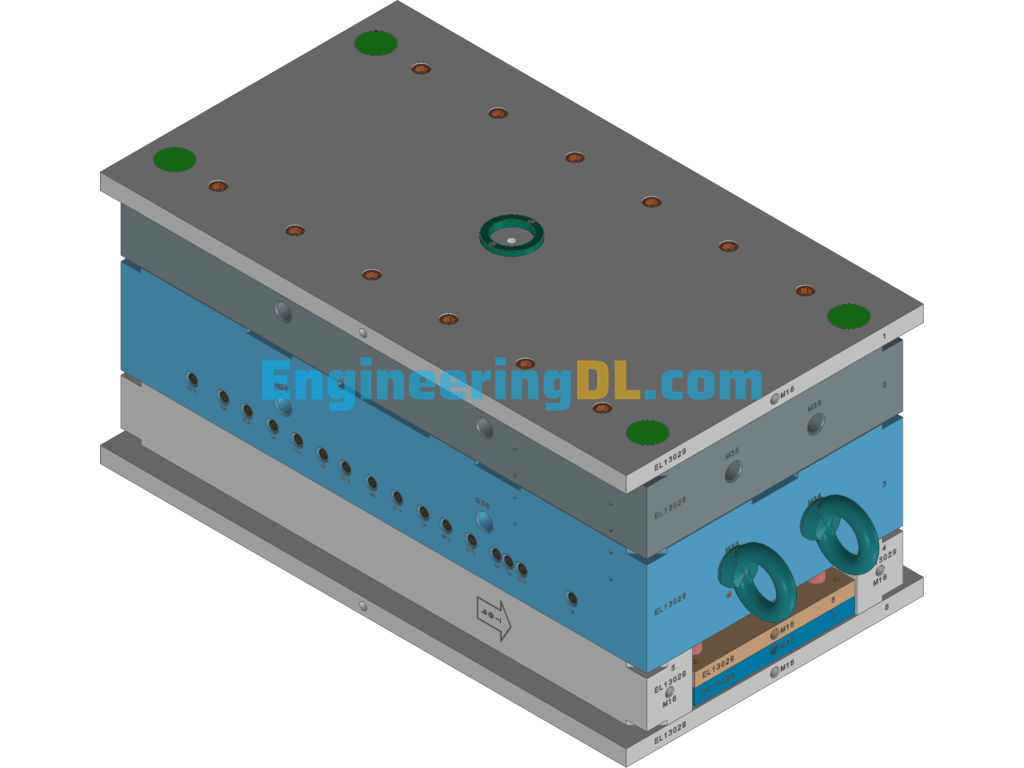

Specification: Glass Double-Sided Grinding Machine SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Glass Double-Sided Grinding Machine SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.