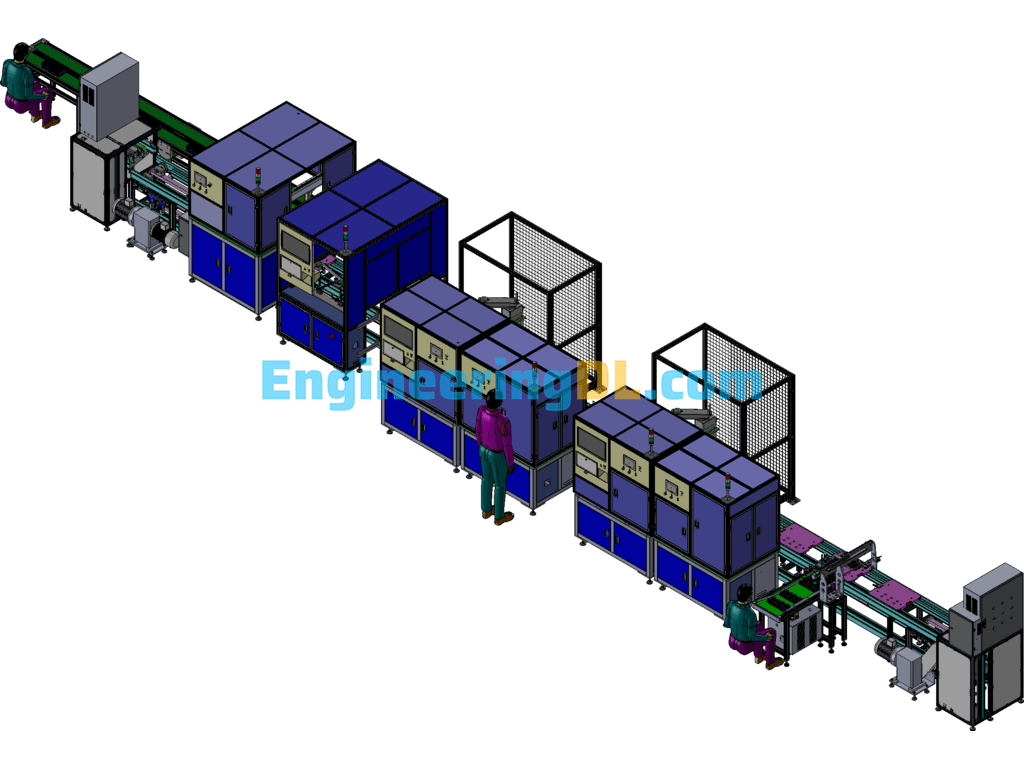

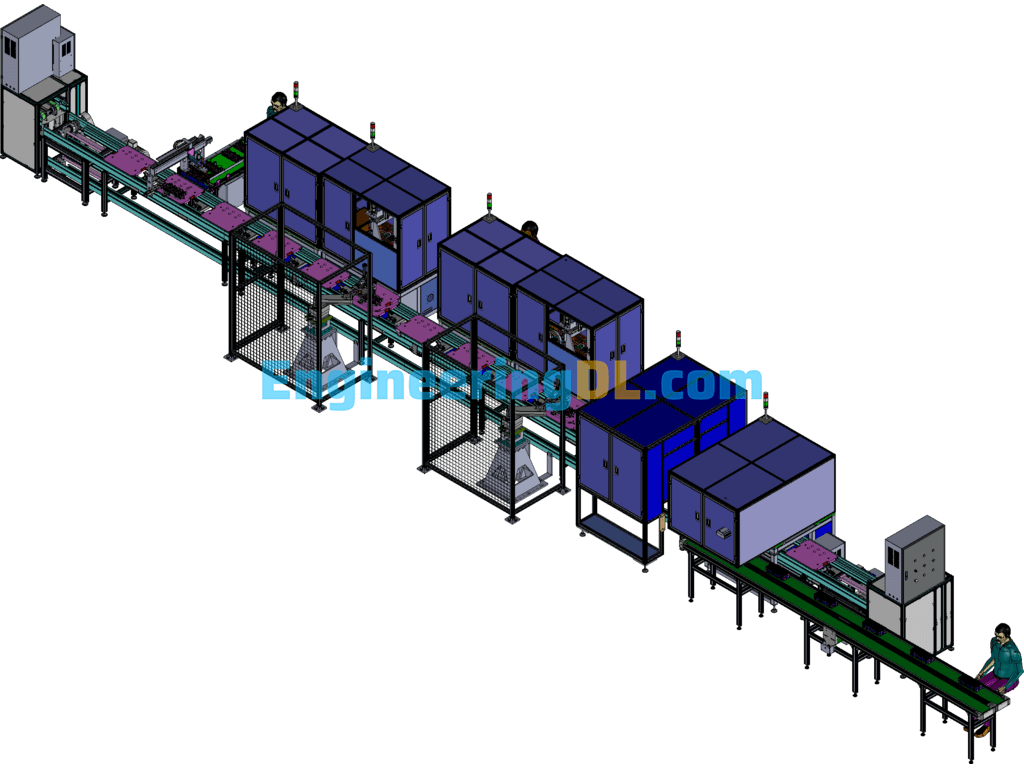

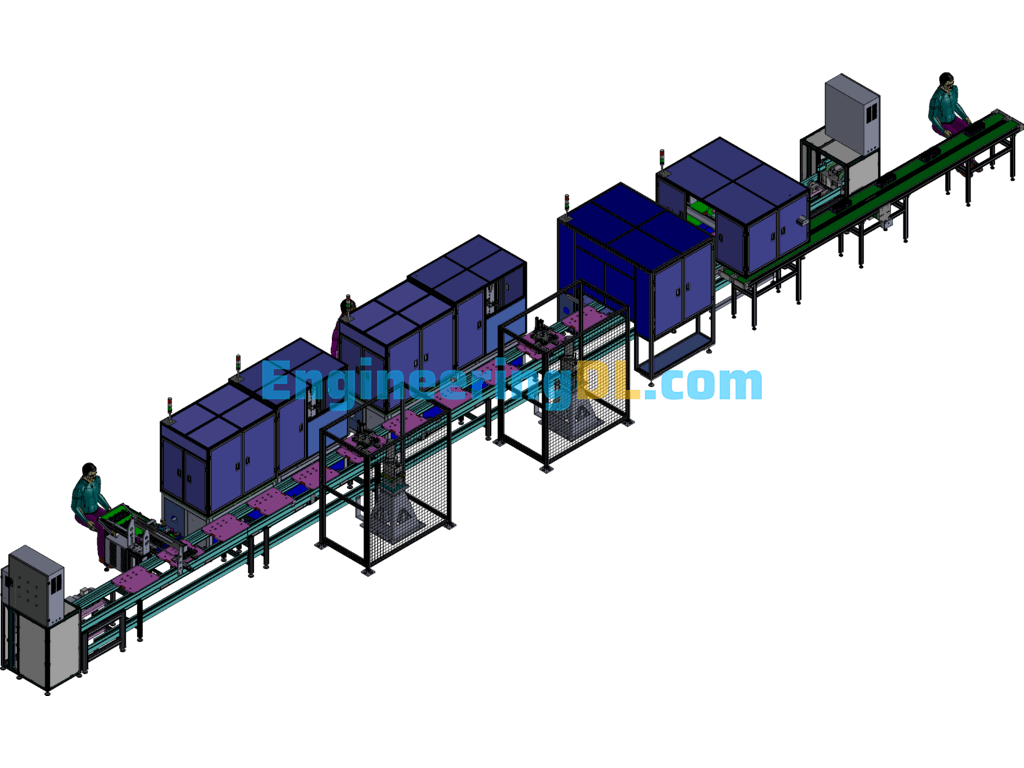

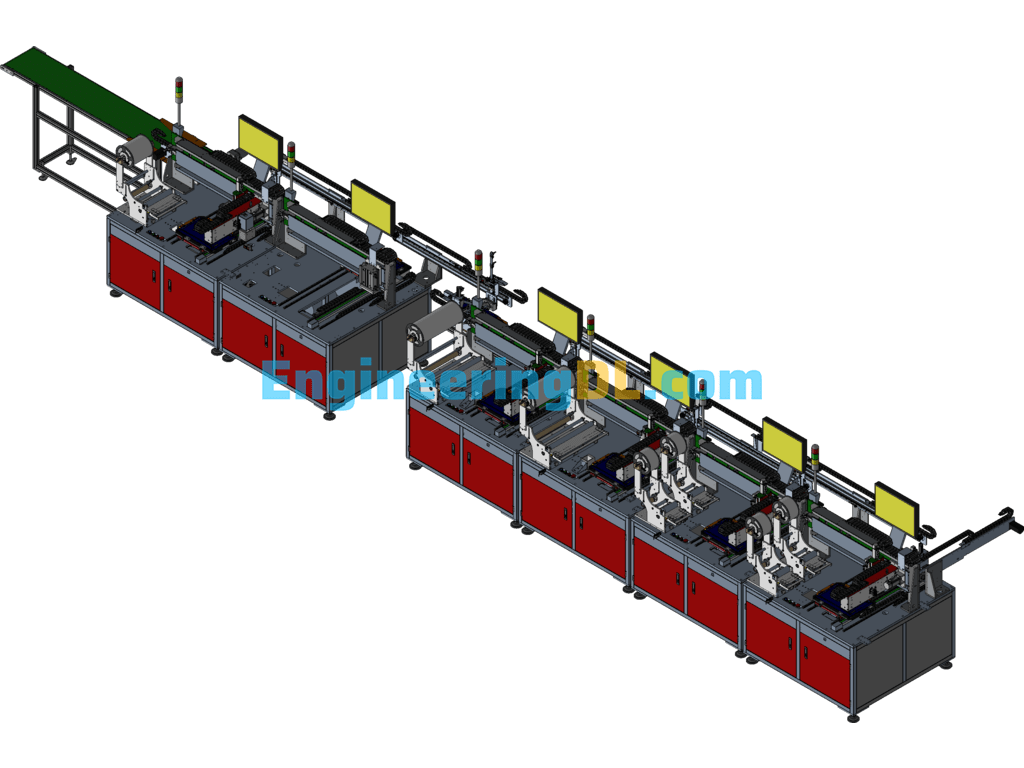

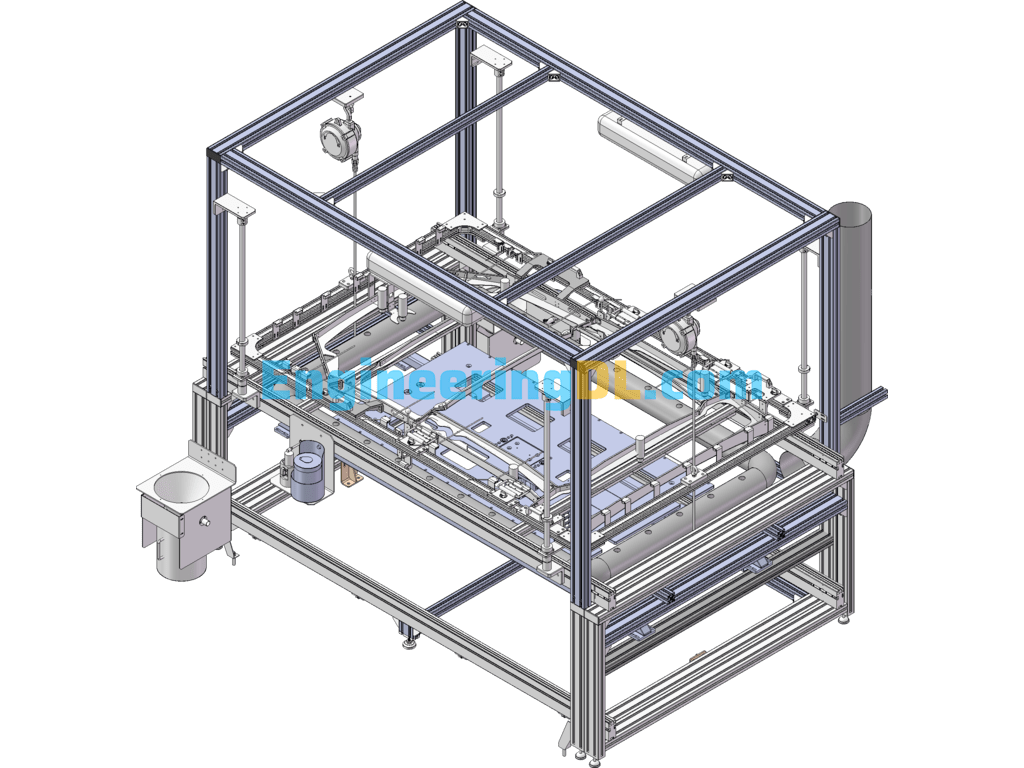

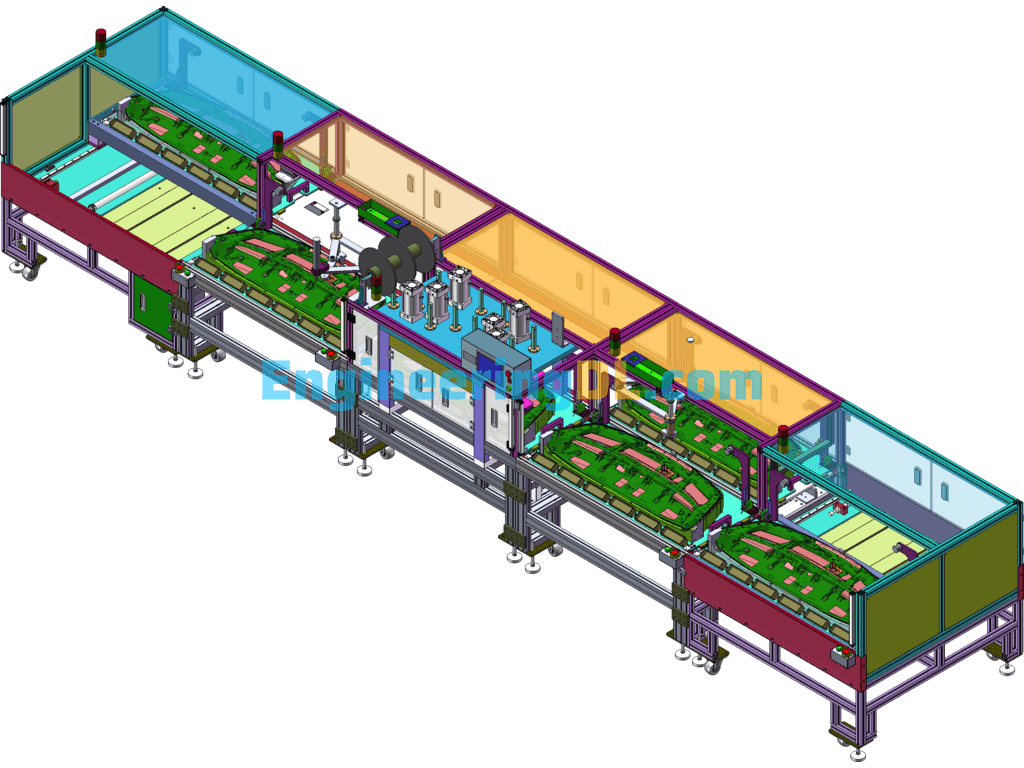

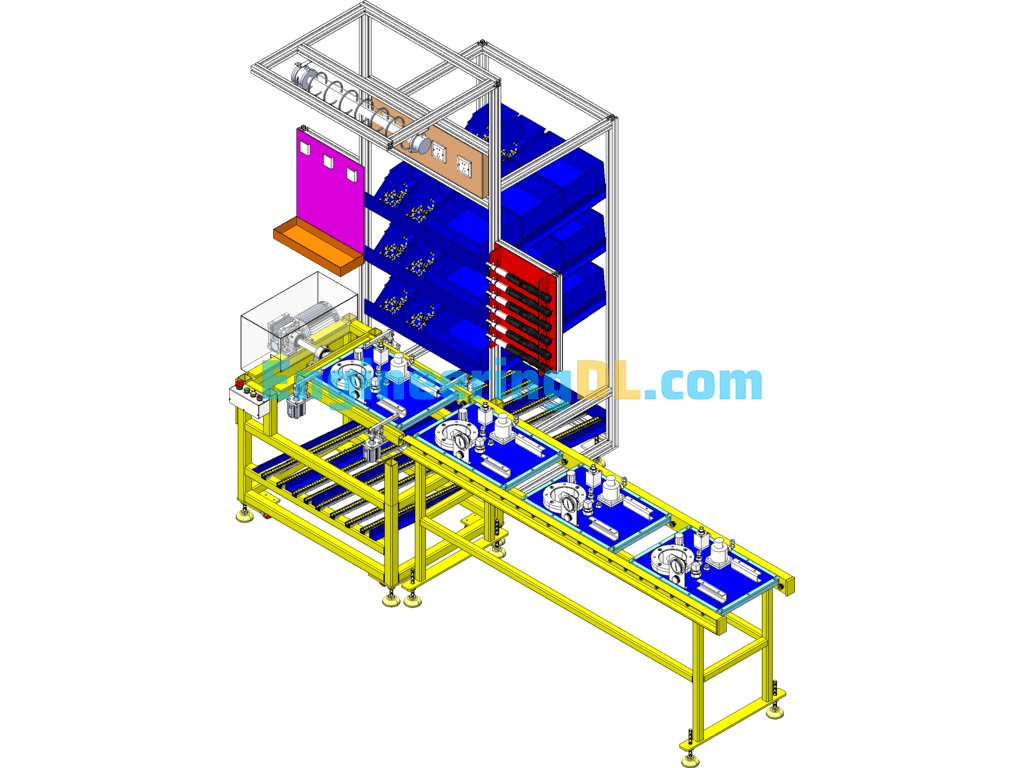

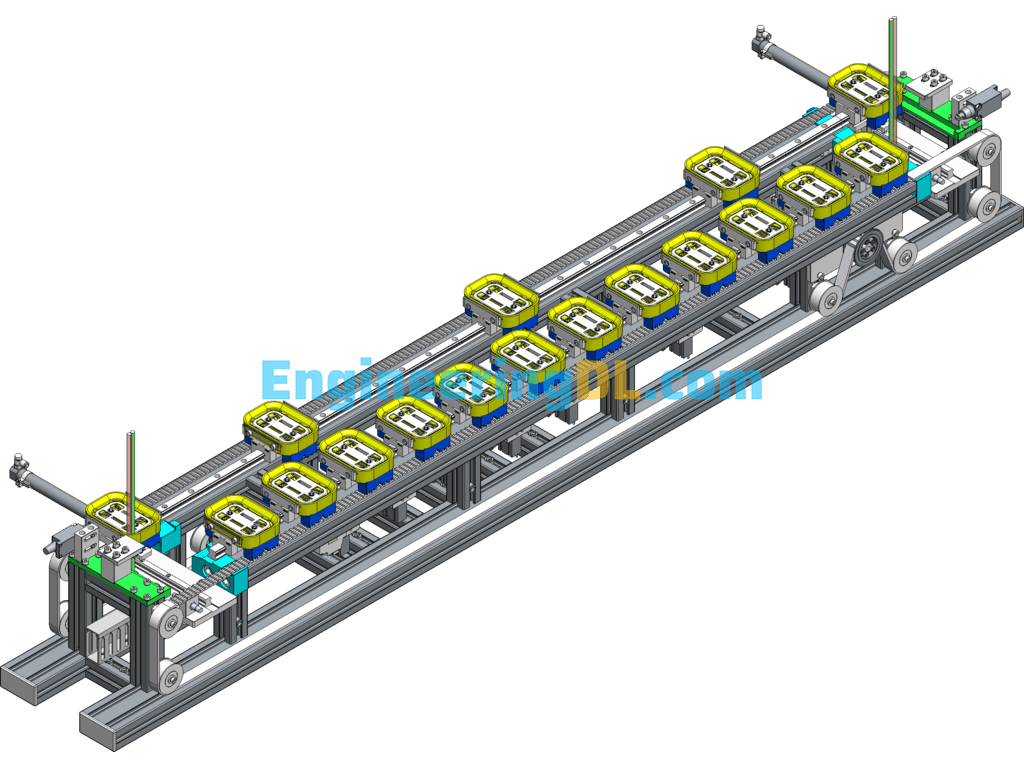

18650 cylindrical battery cell automatic assembly line I. Equipment Description Equipment description, 18650 battery cell automatic assembly line cylindrical battery lower bracket assembly This equipment is suitable for: 18650 battery cell, cylindrical mobile power battery, car power battery and other cylindrical battery cell assembly. The equipment is mainly a new energy power battery automatic assembly line: a full set of drawings decompression has more than 300MB, the bus has more than 1000 parts, the equipment is mainly through the lower bracket automatic loading, first by the manual core lower bracket into the feeding conveyor belt, robot grasps the lower bracket into the multi-speed chain of the tooling plate, multi-speed chain of fast and slow according to the production speed to adjust, multi-speed chain of tooling is also adaptable to The speed of the multi-speed chain is adjusted according to the production speed, and the multi-speed chain can also be adapted to multiple cell types, and the lower bracket enters the cell insertion station through the multi-speed conveyor. After the battery comes out from the sorting machine, it will be sticked with green paper, and after it is sticked, CCS will detect if there is no sticker, and this station will detect and discharge bad cells, and then the robot will suck the cell with good green paper into the belt line, and the cell will enter the loading machine through the belt line, and there is a set of feeding mechanism at the end of the conveyor belt, when the cell enters the tail, two sets of cylinders will push the cell into the material belt of the vertical loading machine respectively. When the vertical loading machine is pulled upward to the top, the core pushing and dividing cylinders push the cores into the material tube 4 cores at a time, the material tube is plastic bellows, the figure does not show the bellows outlet directly linked to the 4-axis robot discharge jig inlet, 4-axis robot core insertion accuracy of 0.1MM, the robot is responsible for inserting the positive electrode facing upwards 4 cores each time, after inserting into the A lower bit to insert the negative electrode of the cell, this cell insertion machine and robot has two, the front is inserting the positive electrode of the back is inserting the negative electrode, from the bus picture can also be seen, when the cell all inserted into the back of the polarity detection machine, using CCD visual inspection machine is mainly to detect whether there is inserted wrong, after the detection is complete into the lower bit which is all the cells have been inserted also detected, the lower machine for the three-axis Manipulator clamping the entire battery pack under the material, under the material conveyor belt there are two a good product delivery, the other used to put CCD detection bad, good product delivery out by the manual behind the pulling belt to collect the material, the above is the battery cell insertion line of all the action process and assembly process, of course, want to understand more according to the body of the structure design, you need to download and slowly learn to study, a full set of drawings complete, if you need or interested friends Welcome to download and learn. IV. The main technical parameters: Category specifications parameters machine size: 15350 * 1220 * 1700MM (L * W * H) input voltage: AC-220V50Hz or AC-380V 50Hz www.sanweimoxing.com optional machine maximum power: 0.9K W (220V) input gas pressure: 0.4-0.6 Mpa gas consumption: 1.5 L/min productivity (C/T): ???1.0 S / four equipment loading rate: ???95% processing mode: automatic detection, automatic insertion of the core, automatic discharge programming mode: touch screen parameter modification

Specification: Lithium Battery Cell Automatic Assembly Line 18650 Cell Assembly Cylindrical Battery Lower Bracket Assembly Equipment 3D Exported

|

User Reviews

Be the first to review “Lithium Battery Cell Automatic Assembly Line 18650 Cell Assembly Cylindrical Battery Lower Bracket Assembly Equipment 3D Exported”

You must be logged in to post a review.

There are no reviews yet.