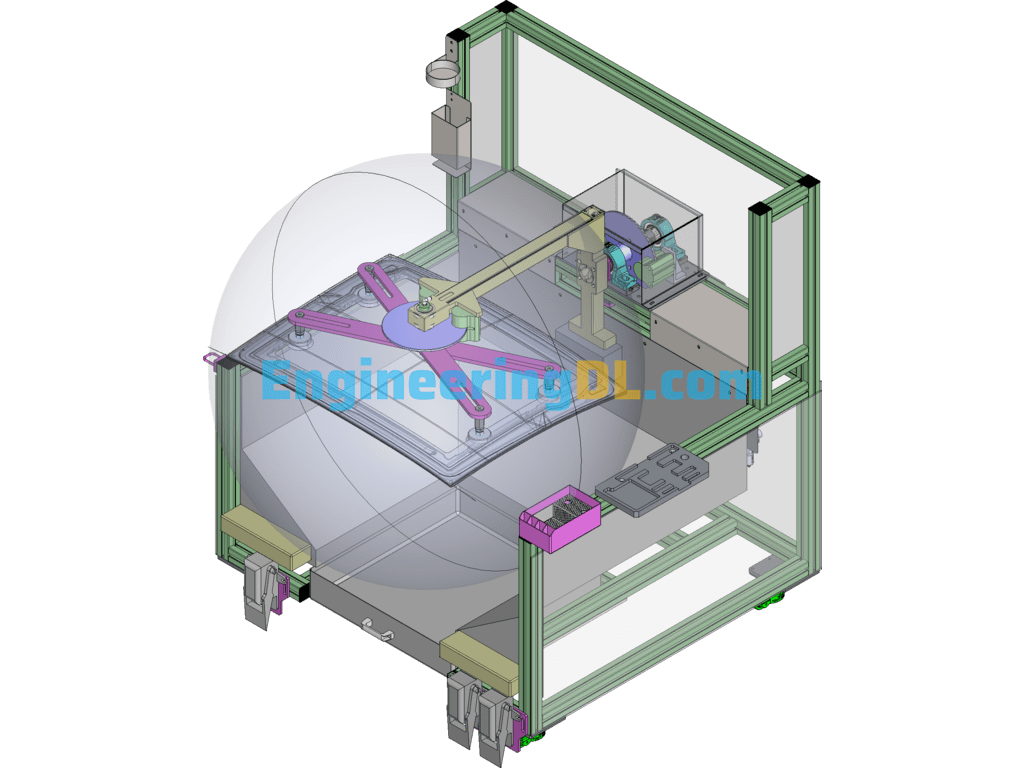

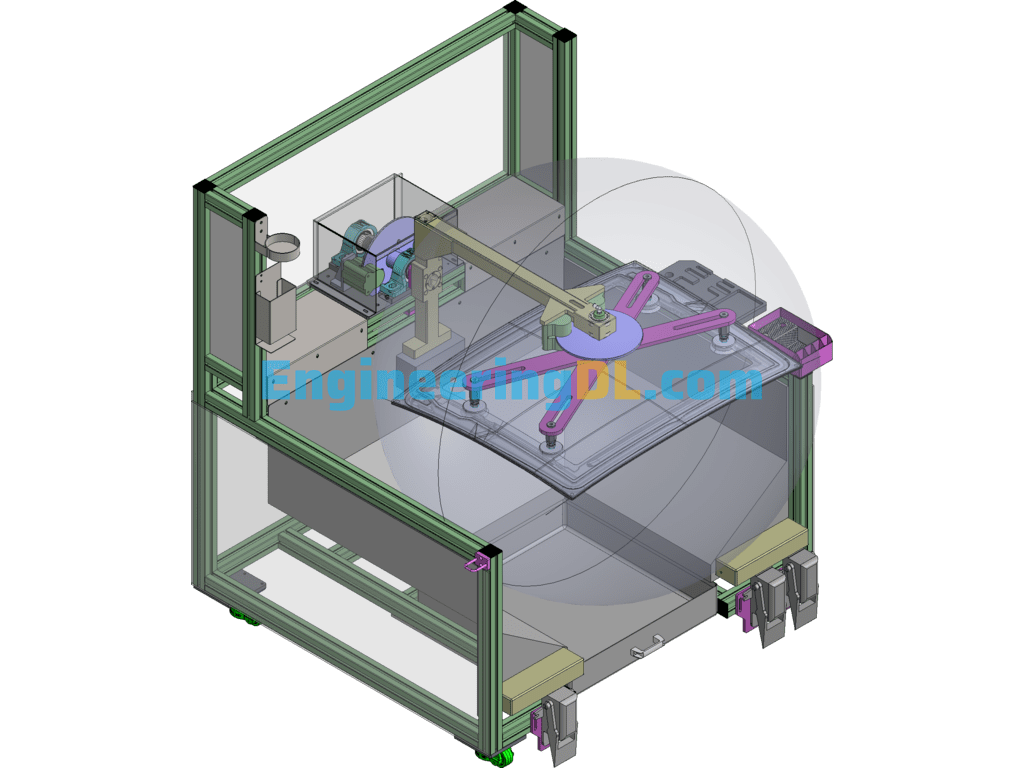

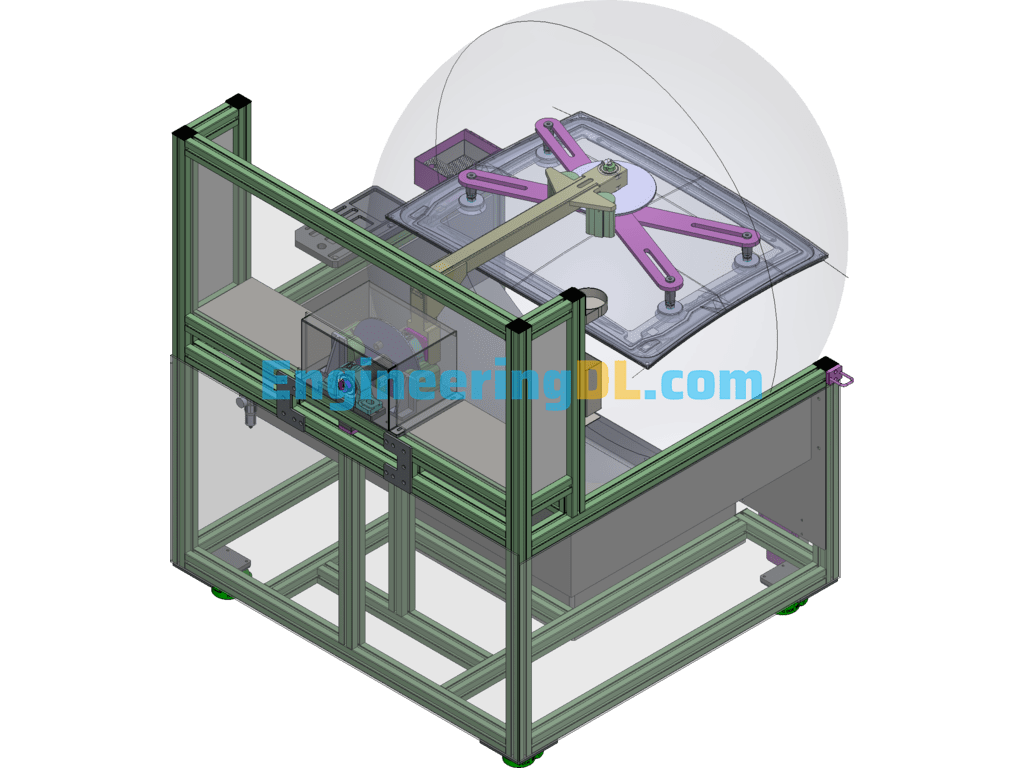

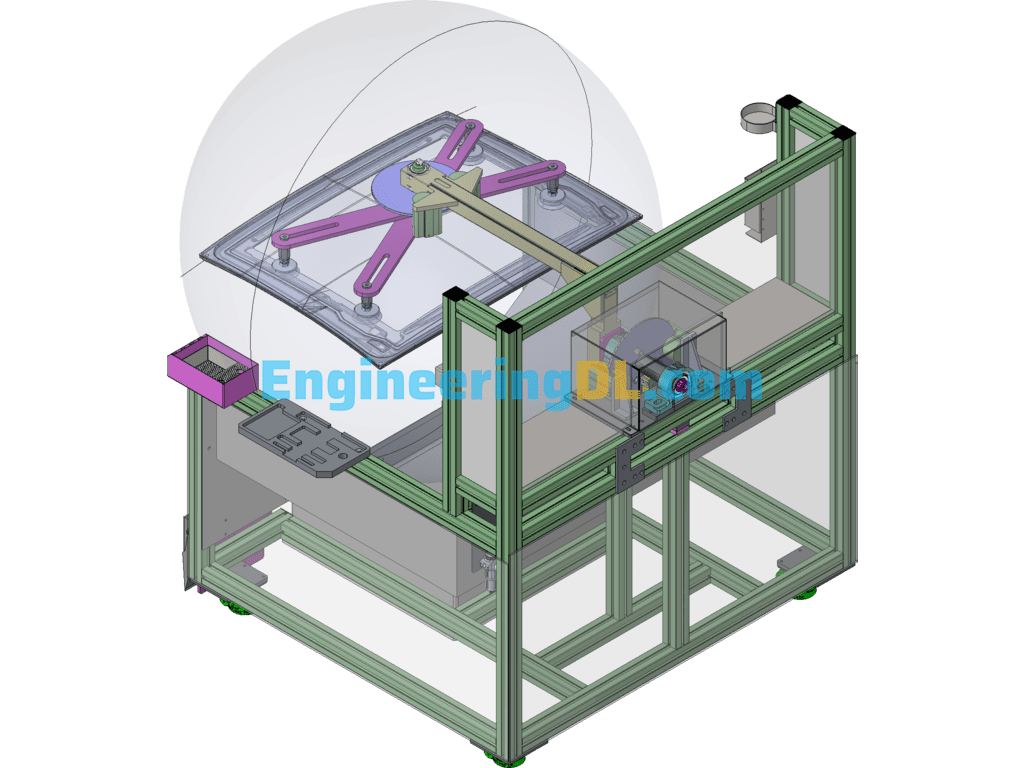

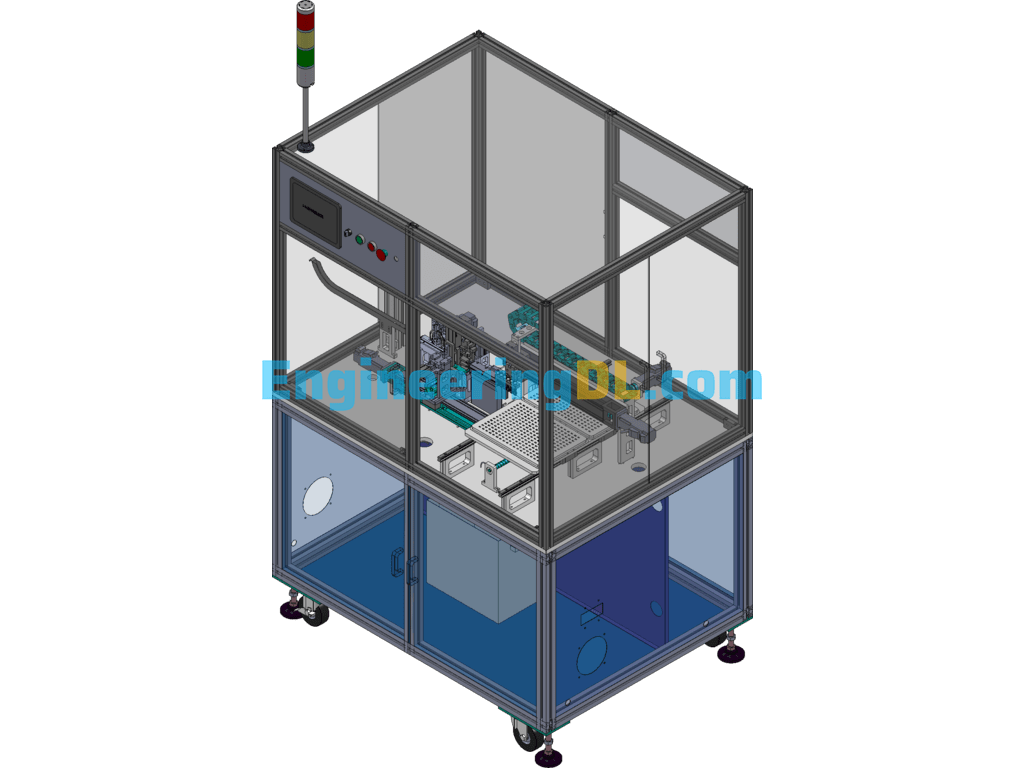

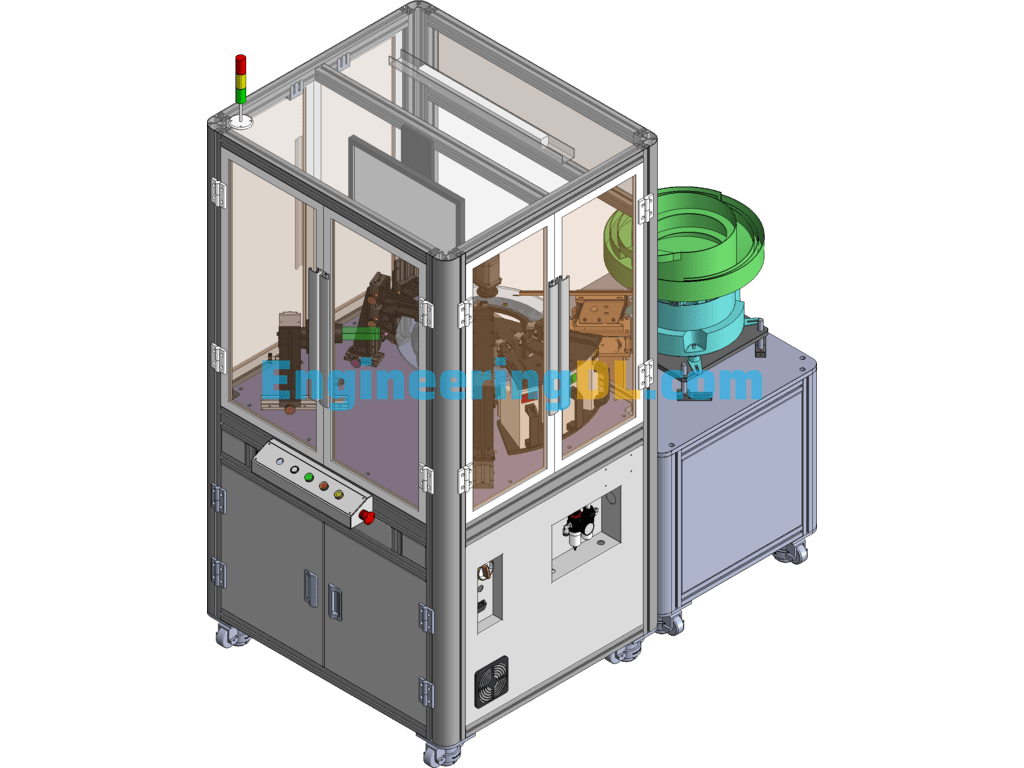

Auto sunroof GPA trimming and grinding workstation

I. Basic functions.

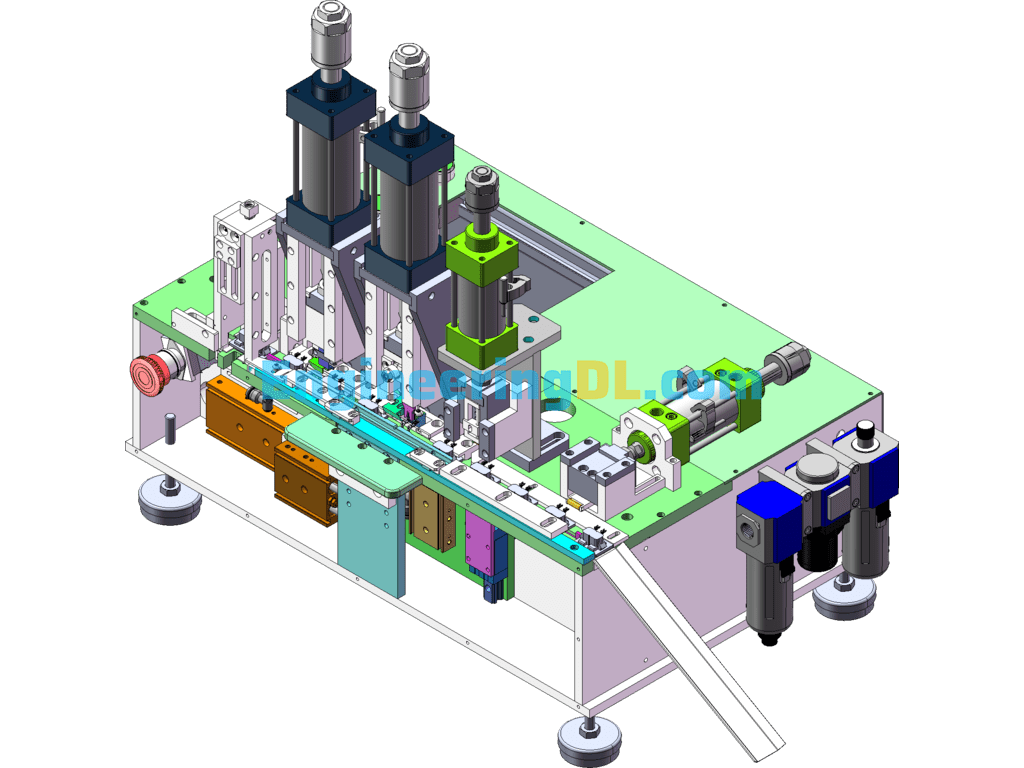

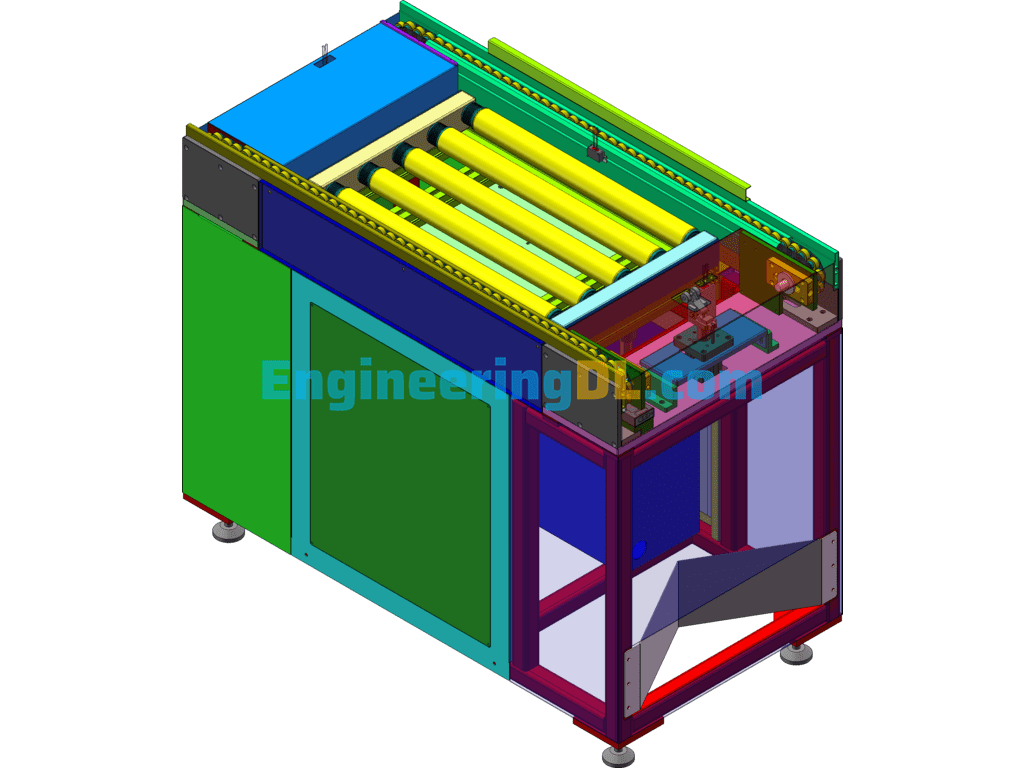

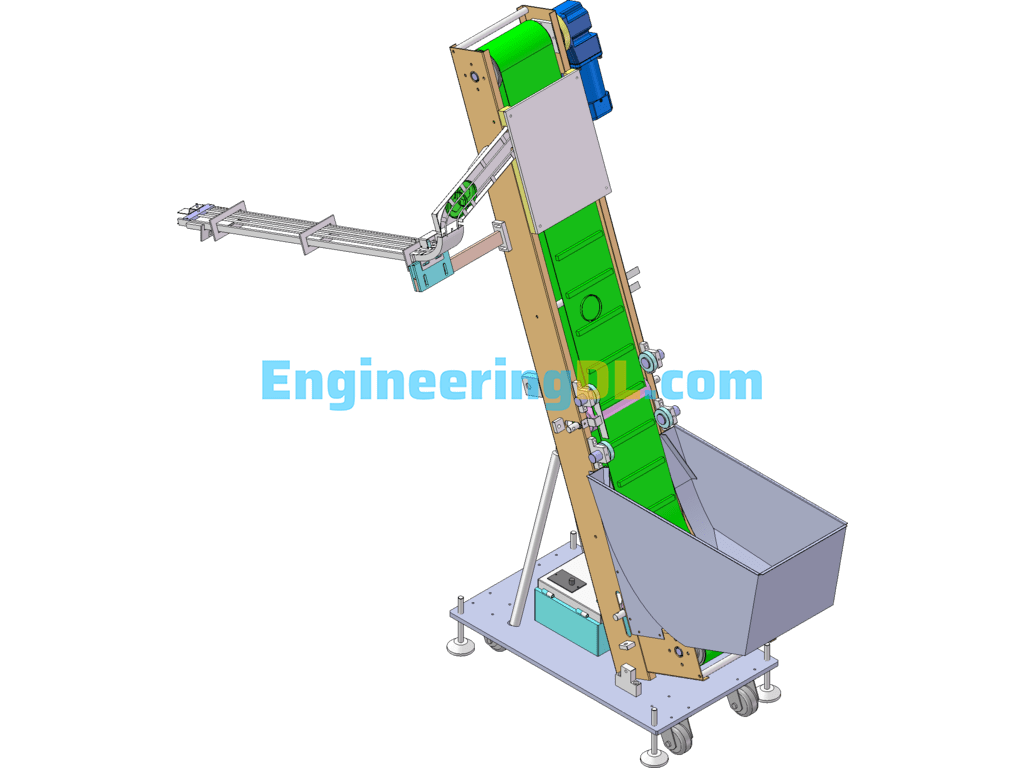

Placement of automotive sunroof GPA and trimming grinding, cleaning inspection, seal installation operations, glass can be freely rotated horizontally, flip flop (axial 180 degrees), and all with brake function

Second, the error-proof function: no

Operators

1. Number of operators 1 person

2.

Durability

1. continuous use time – 24H/day

2. durability years – more than 10 years

V.

Capability1.Total cycle time –

NA2.Manual operation time –

<60sec3.Product switching tooling adjustment time - <1min (suction cup position adjustment only) Working environment 1. Noise level - 70dB or less from the place of noise generation to 1m away 2. Stimulating gas - butanone and other chemical gases from the air duct Power specification 1.Power specification-3 phase 380V 50Hz or single phase 220V 50Hz2.Air source specification-6??1Kg/cm2 Eight, quality 1. Failure rate-No unexplained equipment problems caused by the bad occurrence. 2. Accuracy requirements-form factor requirements ??? ?? 10mm

Specification: Auto Sunroof GPA Trimming And Grinding Workstation 3D+Engineering Drawings+BOM+Instructions SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Auto Sunroof GPA Trimming And Grinding Workstation 3D+Engineering Drawings+BOM+Instructions SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.