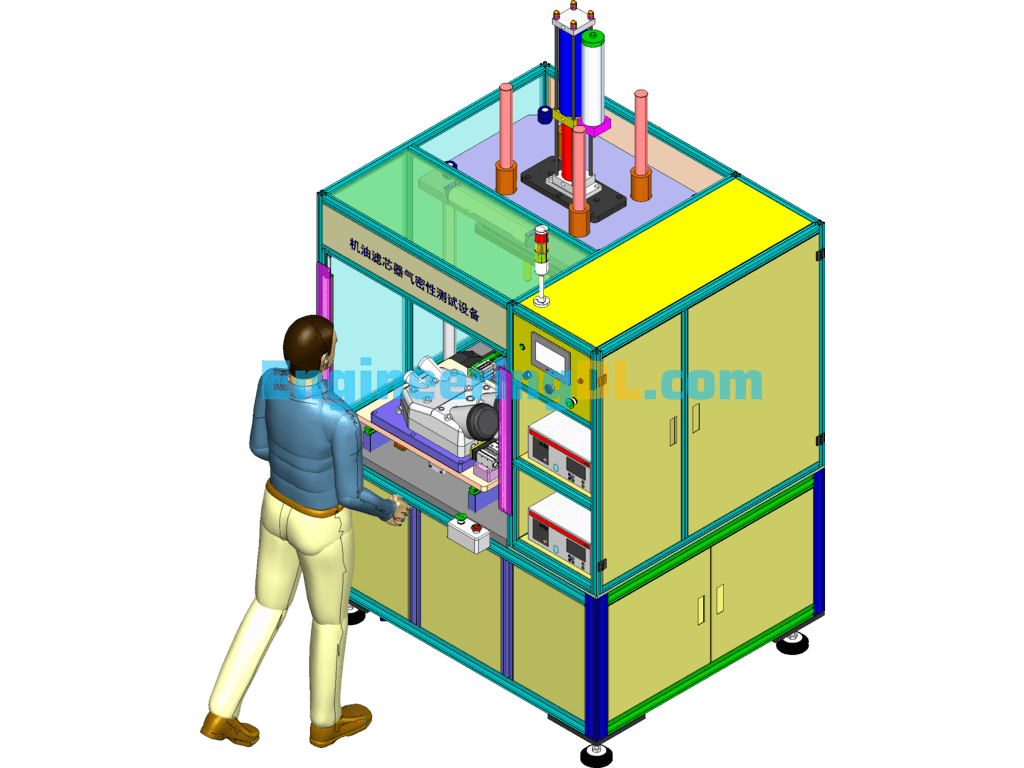

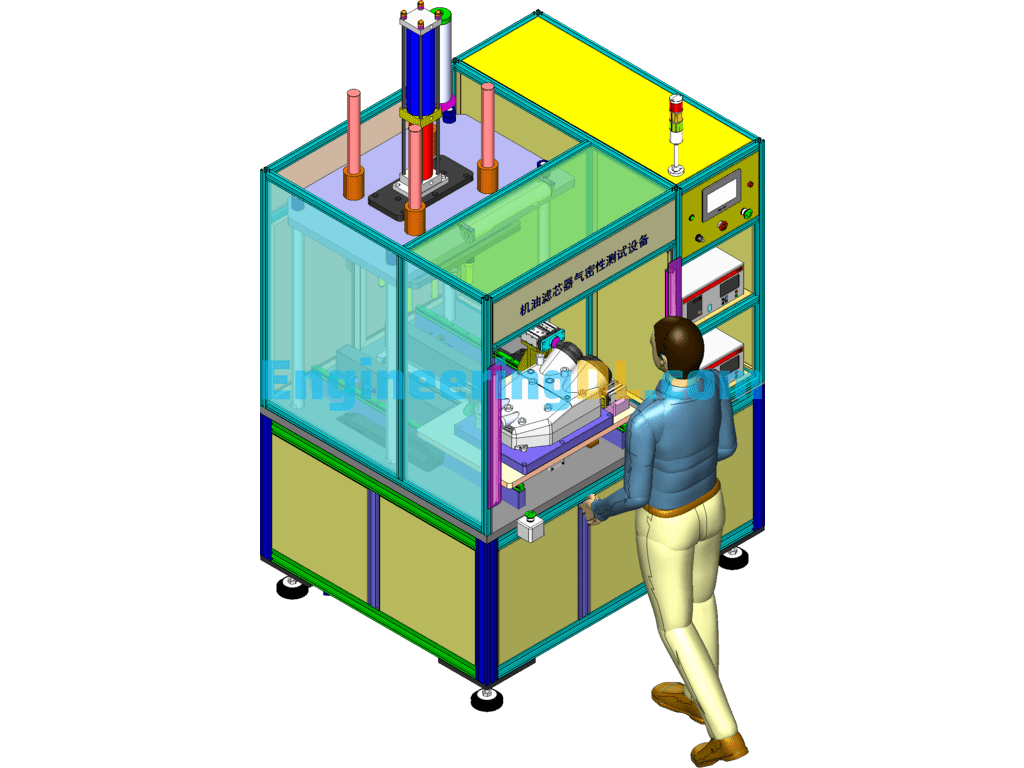

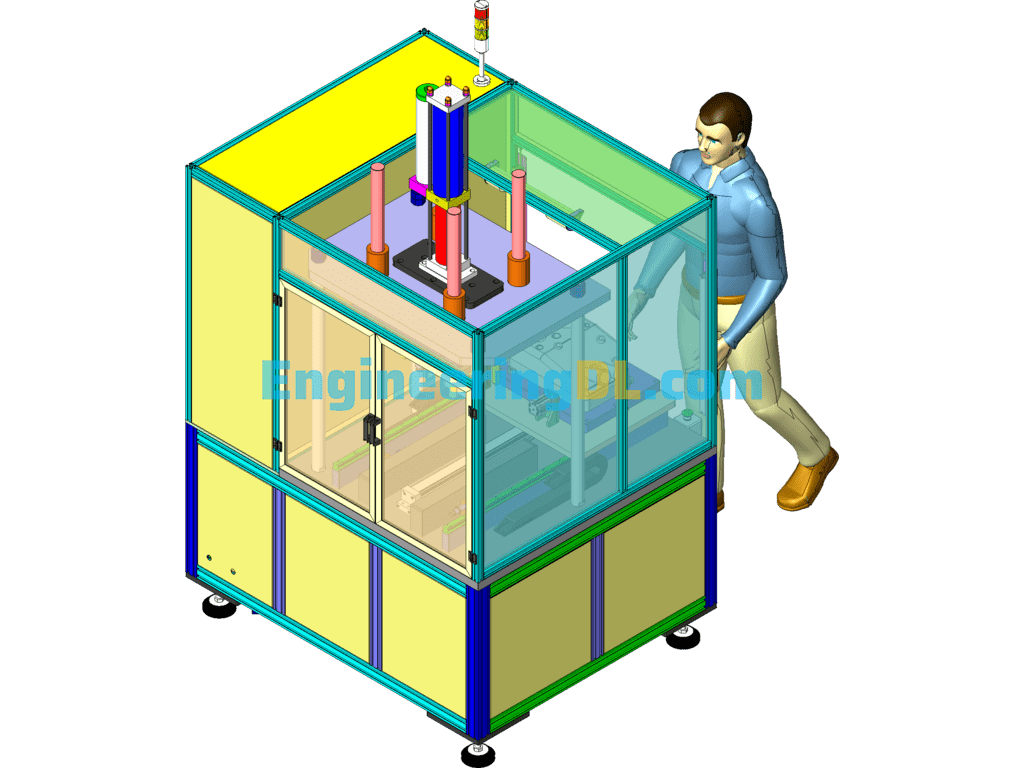

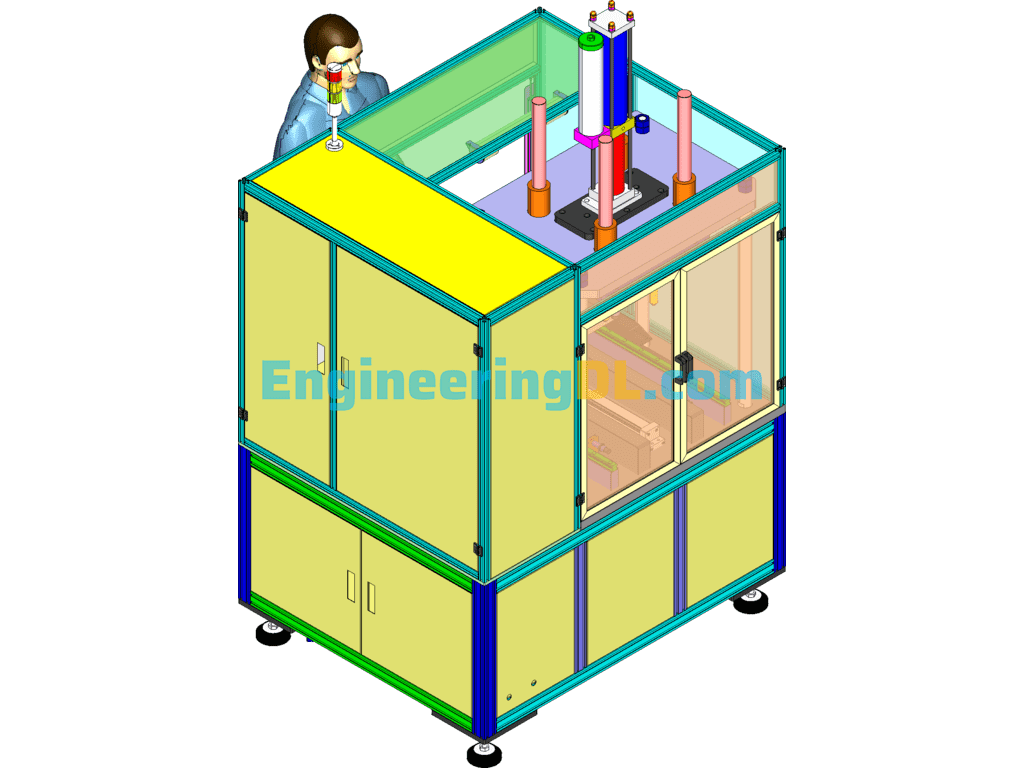

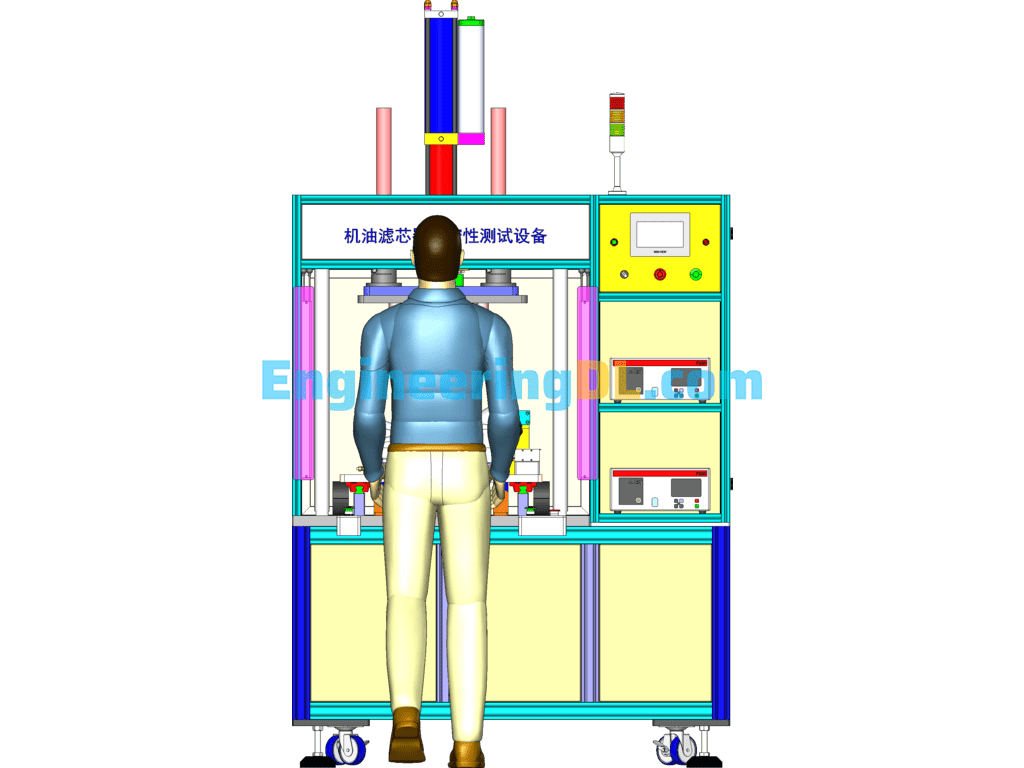

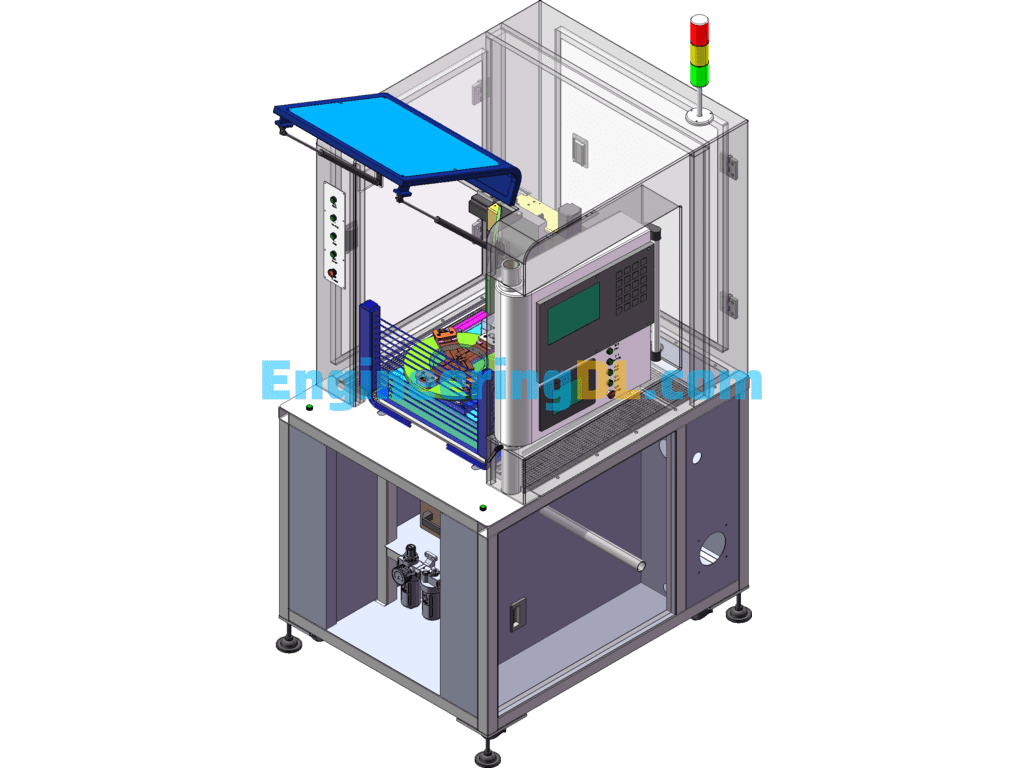

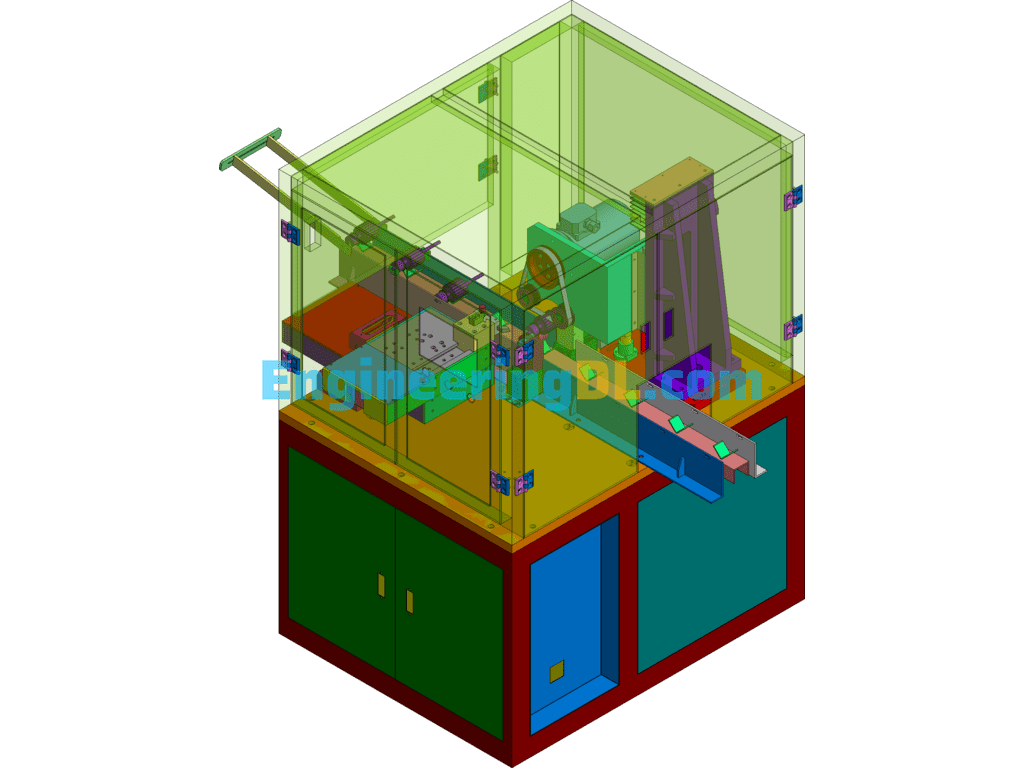

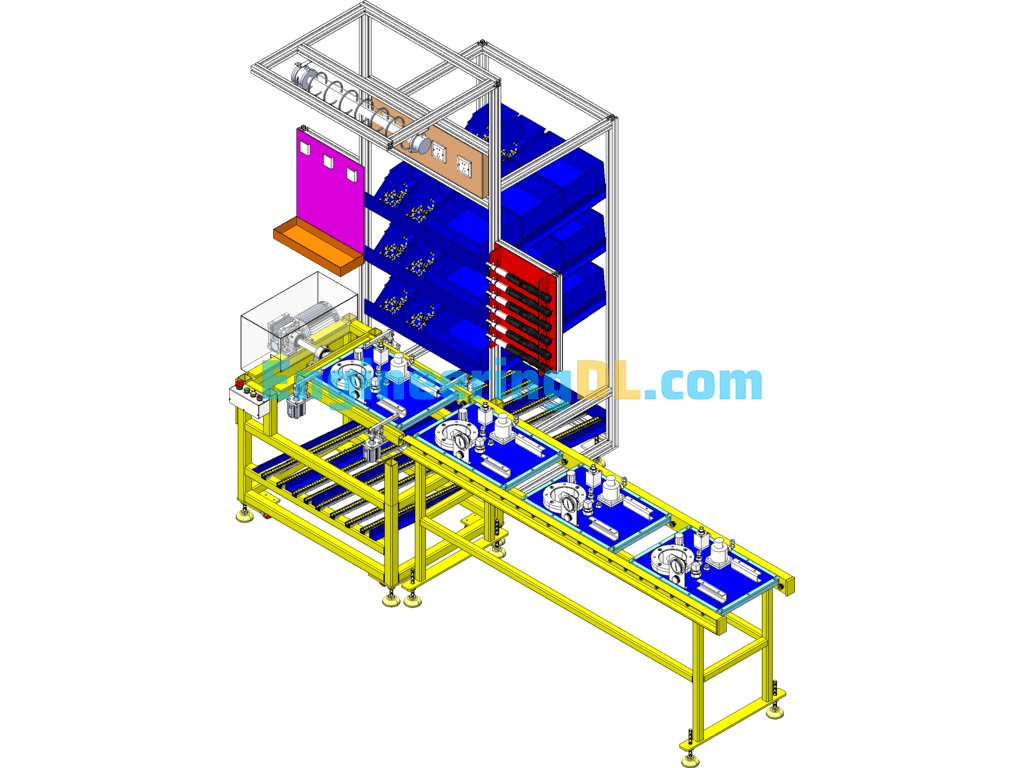

! Auto oil filter air tightness testing equipment including 3D model + engineering drawings + PDF working principle description + detail description

Equipment working principle & step by step instructions :

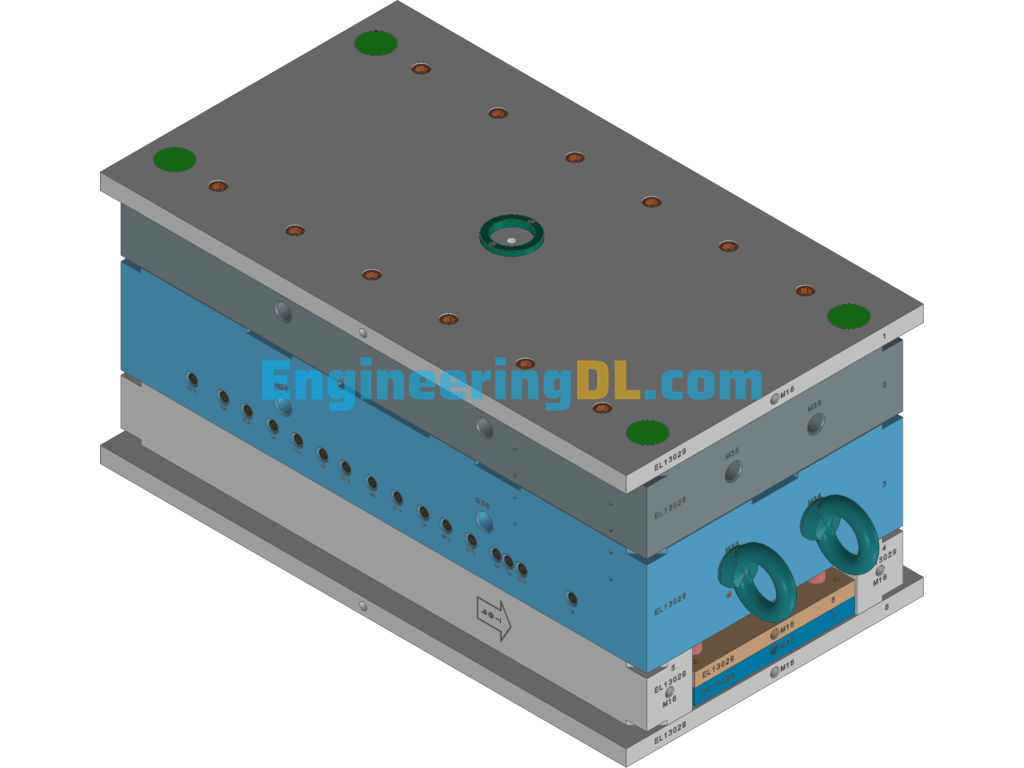

1. Put the product to be tested into the equipment Holder (positioned by round Pin and diamond Pin);

2. After the photoelectric sensor on the holder detects the product, the OP starts the button with both hands (the holder & product automatically enter the pressed position through the rodless cylinder drive);

3. After the Holder&products reach the pressed position, the press head (spring press head & blocking head) will be automatically pressed down;

4. After the press head is pressed into place, the back blocking & side blocking cylinder is ejected.

1#&2# air tightness leak detector start to detect respectively; after the detection is completed, the blocking cylinder retreats, and the pressure head (spring pressure head & blocking head) rises automatically;

5. After the pressure head is in place, the Holder& product is automatically pushed out of the original position by rodless cylinder drive;

6. OP take out the product which is OK for testing; (this cycle operation)

Specification: Auto Oil Filter Air Tightness Testing Equipment (With 3D Model + + Detail Description) SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Auto Oil Filter Air Tightness Testing Equipment (With 3D Model + + Detail Description) SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.