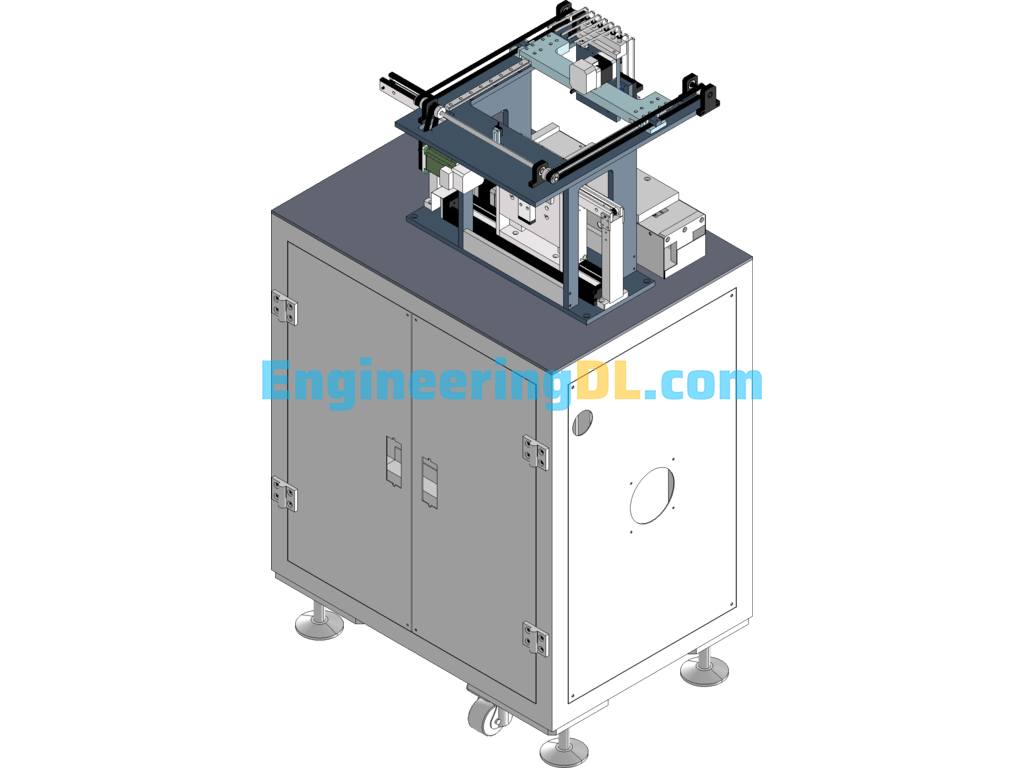

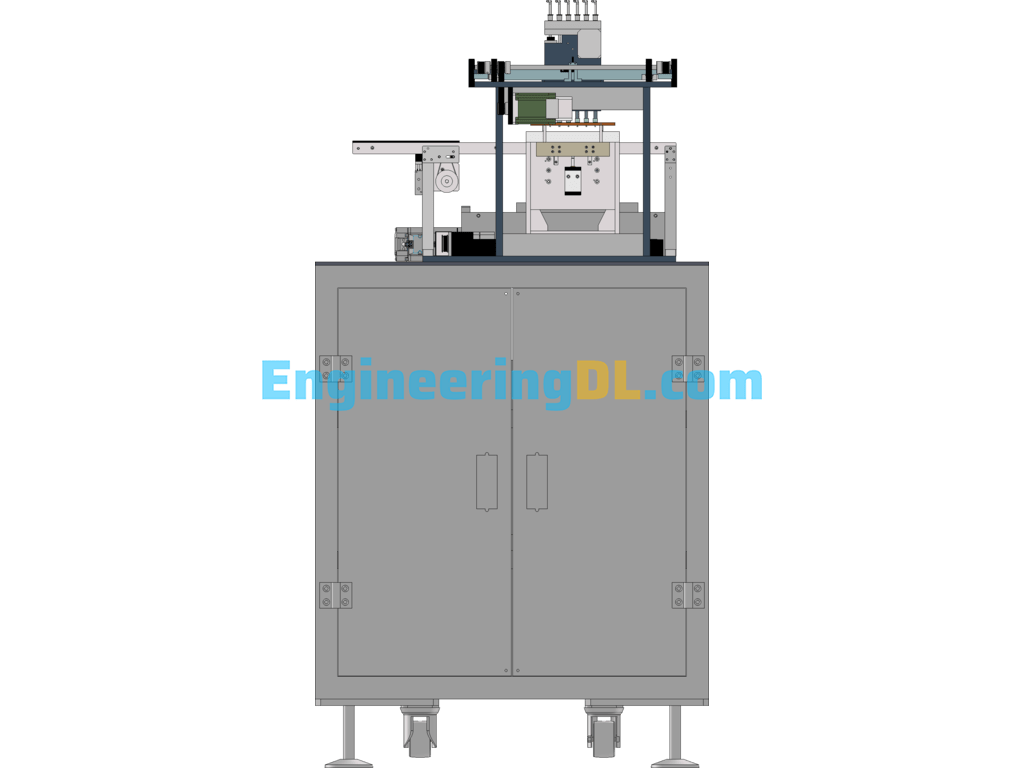

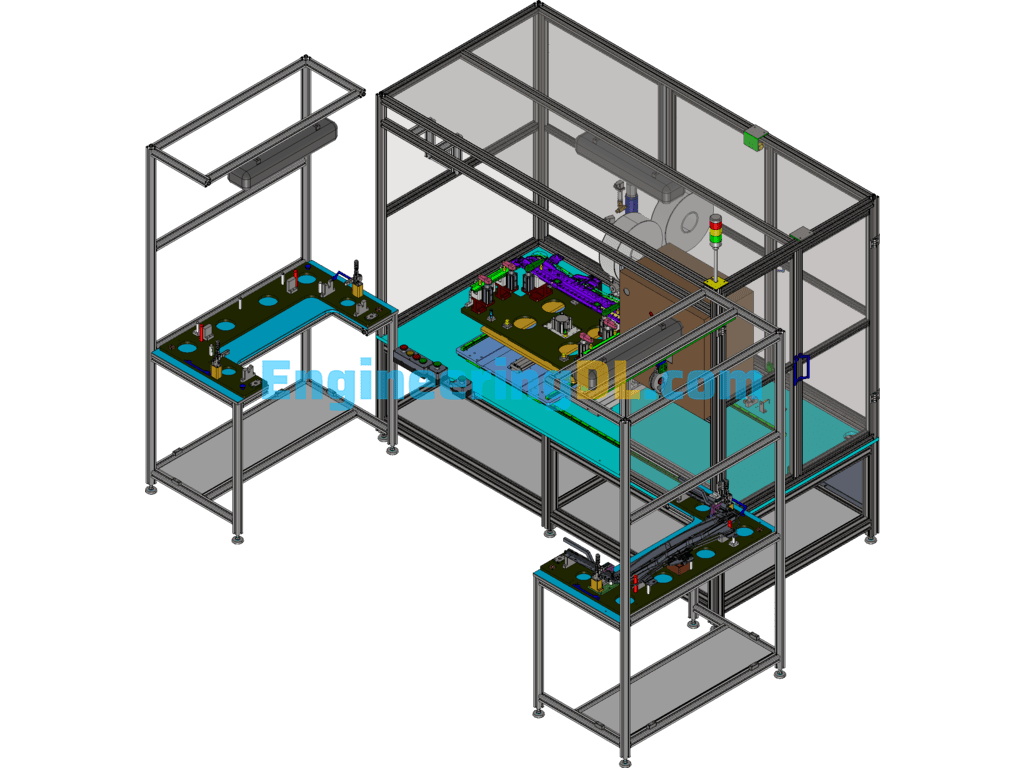

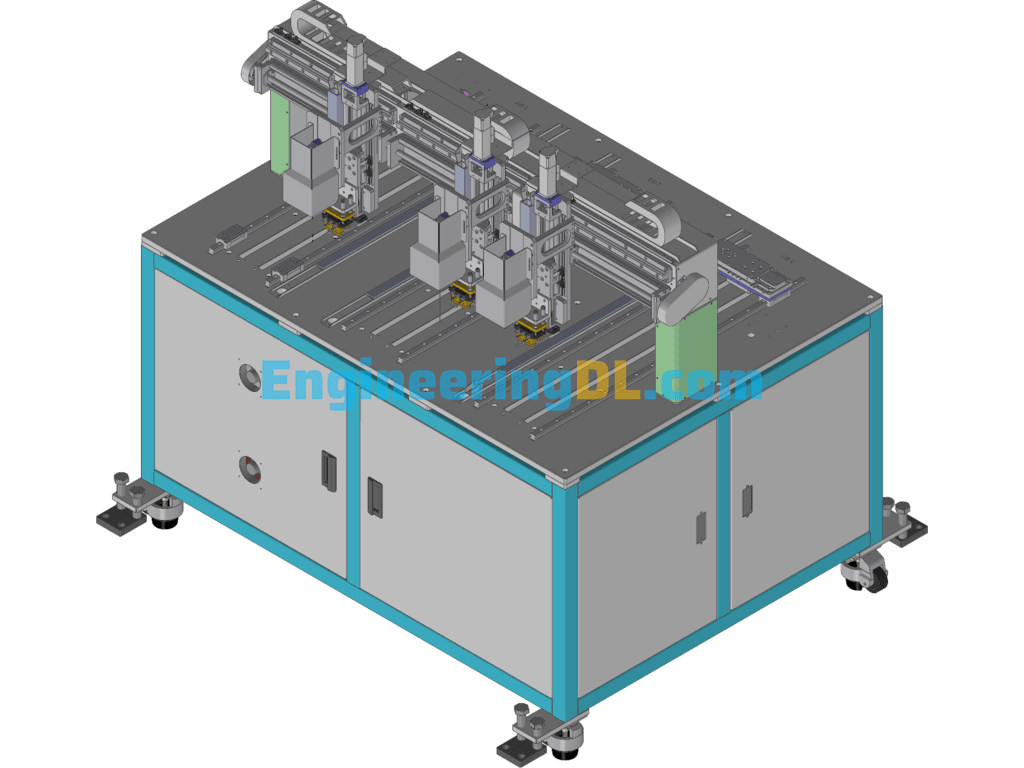

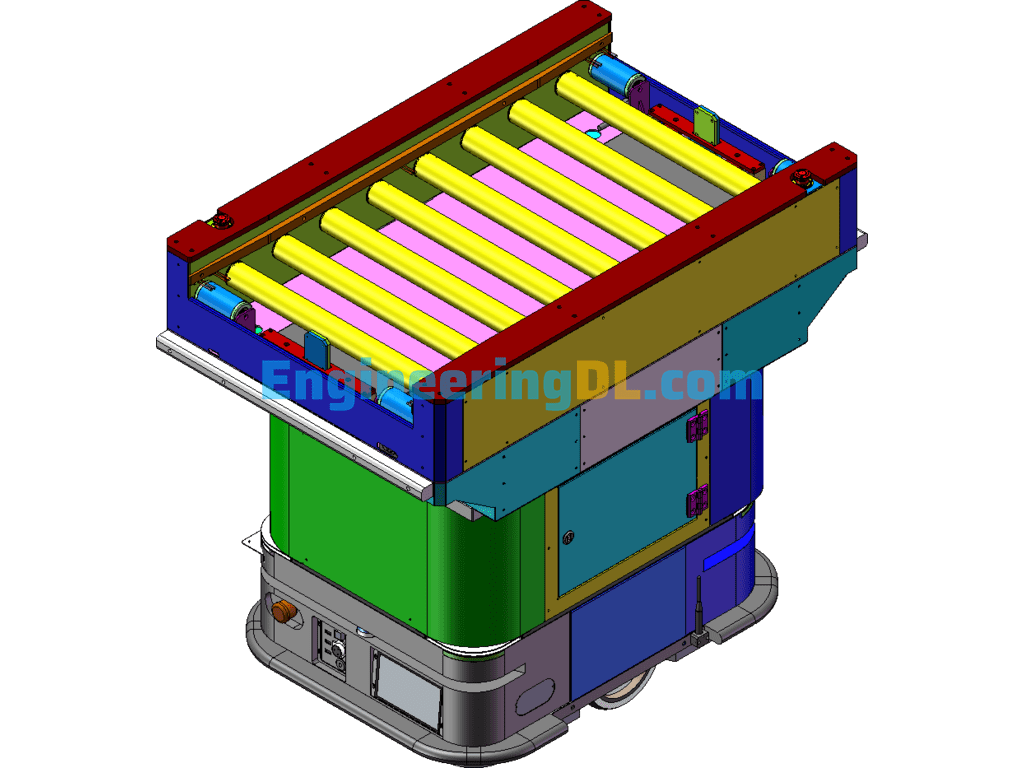

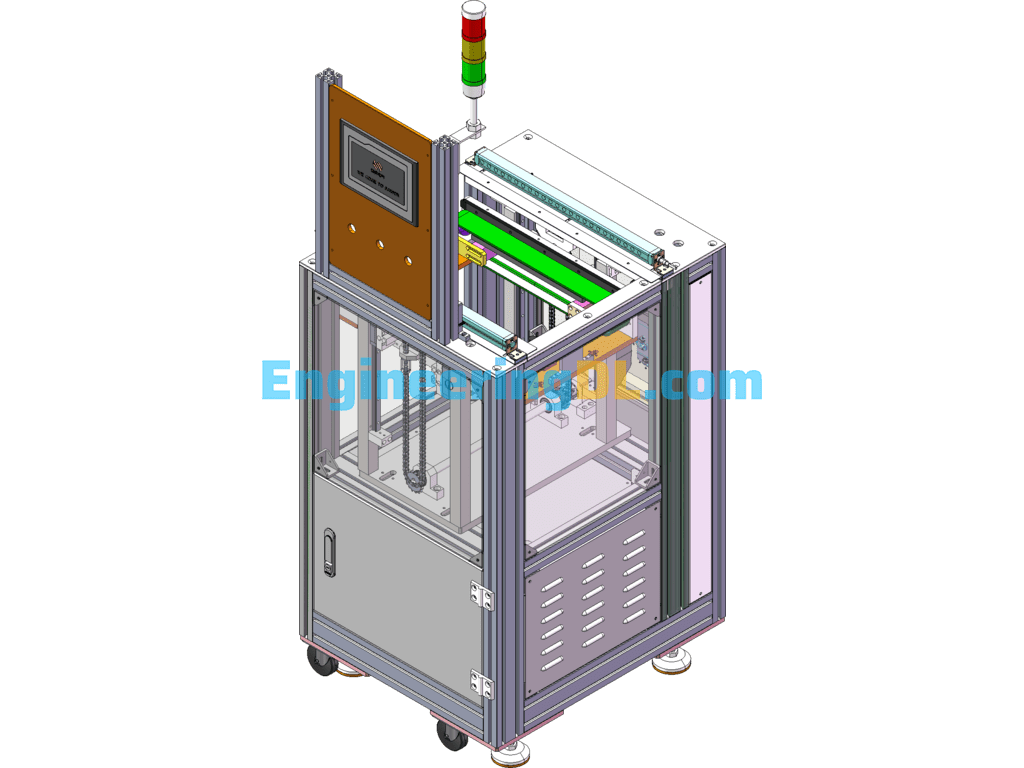

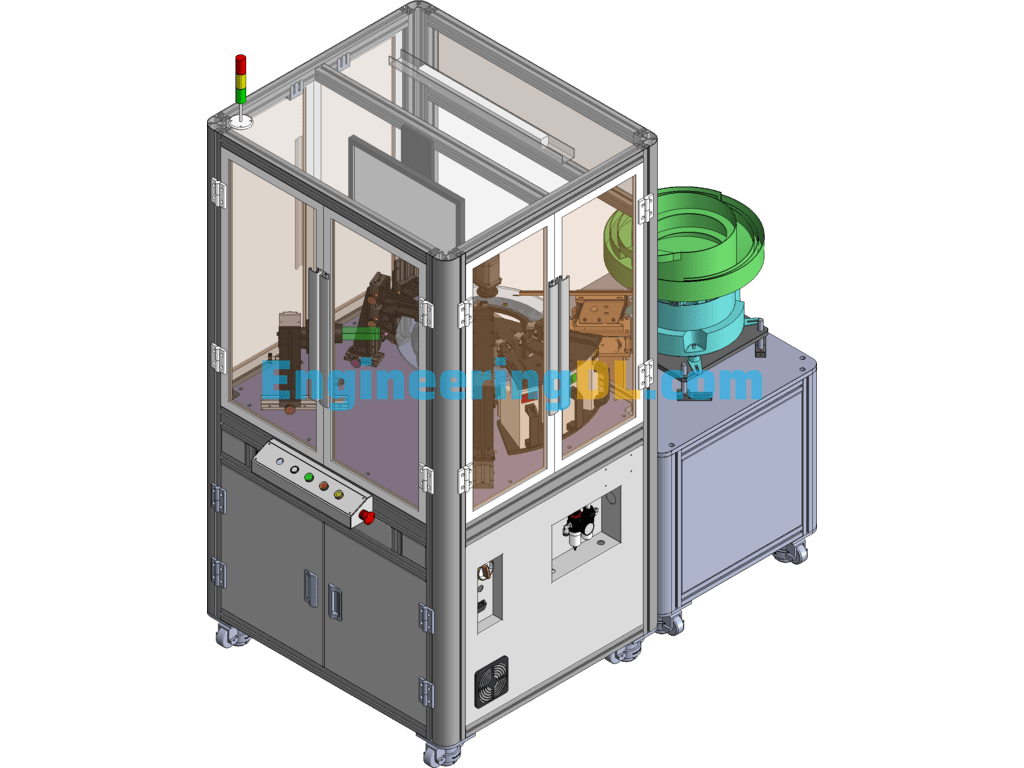

5-axis tabletop robot with xyzr + flip axis for gluing, 3-axis robot for handling parts batch input and batch output. Products need to be glued front and back. When inputting, personnel only need to put the whole board of palletized products into the input fixture, and select the type of gluing and parameters to be applied through the upper computer software. After the computer confirms, the input fixture is automatically put into the equipment, and the 3-axis robot clamps the product into the 5-axis robot flip fixture, and the 5-axis robot starts to apply glue to the front side of the product, and after it is finished, the flip axis drives the flip mechanism to flip and apply glue to the reverse side. After all finished, call the 3-axis robot to change the material. The 3-axis robot puts the glued products into the bottom outfeed tray, and then puts the new products from the infeed tray to the flipping mechanism. Until all products are glued, the machine automatically outputs the empty input trays and the bottom full trays to the loading and unloading position outside the machine.

Specification: Semi-Automatic Gluing Equipment SolidWorks

|

User Reviews

Be the first to review “Semi-Automatic Gluing Equipment SolidWorks”

You must be logged in to post a review.

There are no reviews yet.