Register to Download

Just 2 Minutes

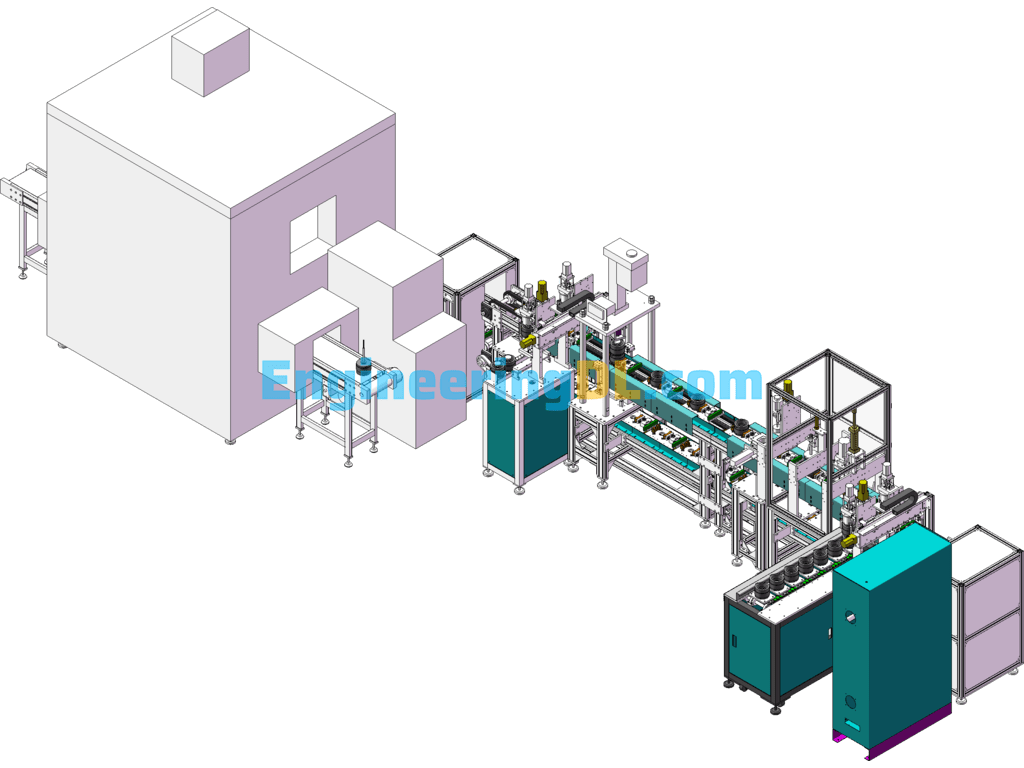

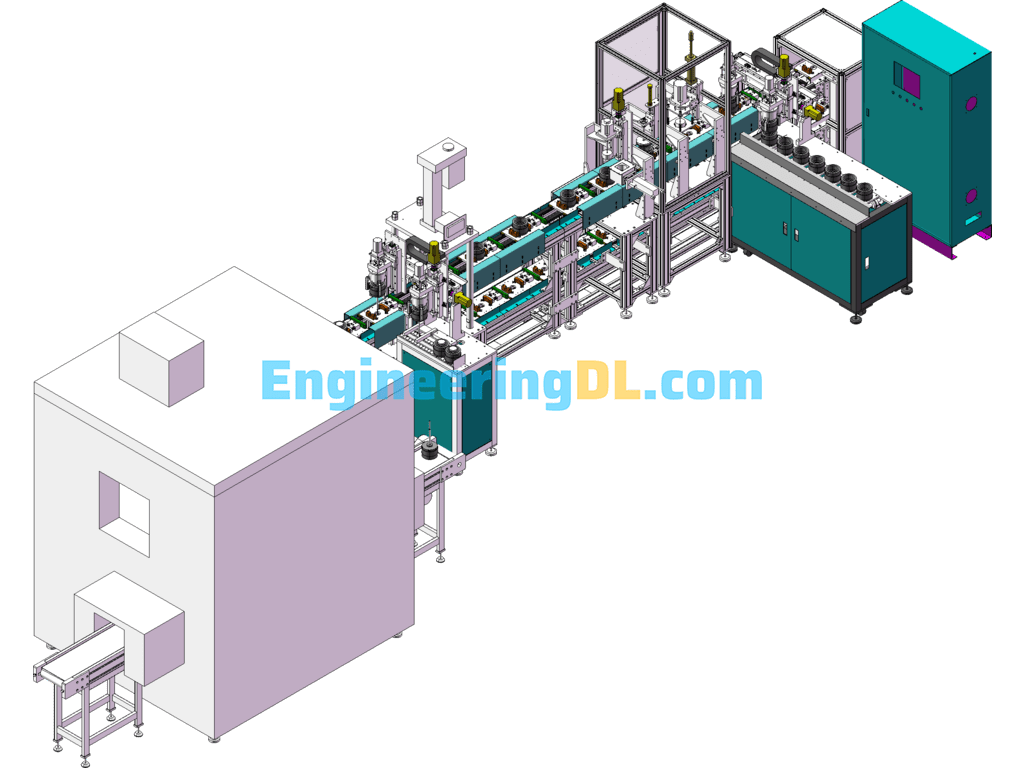

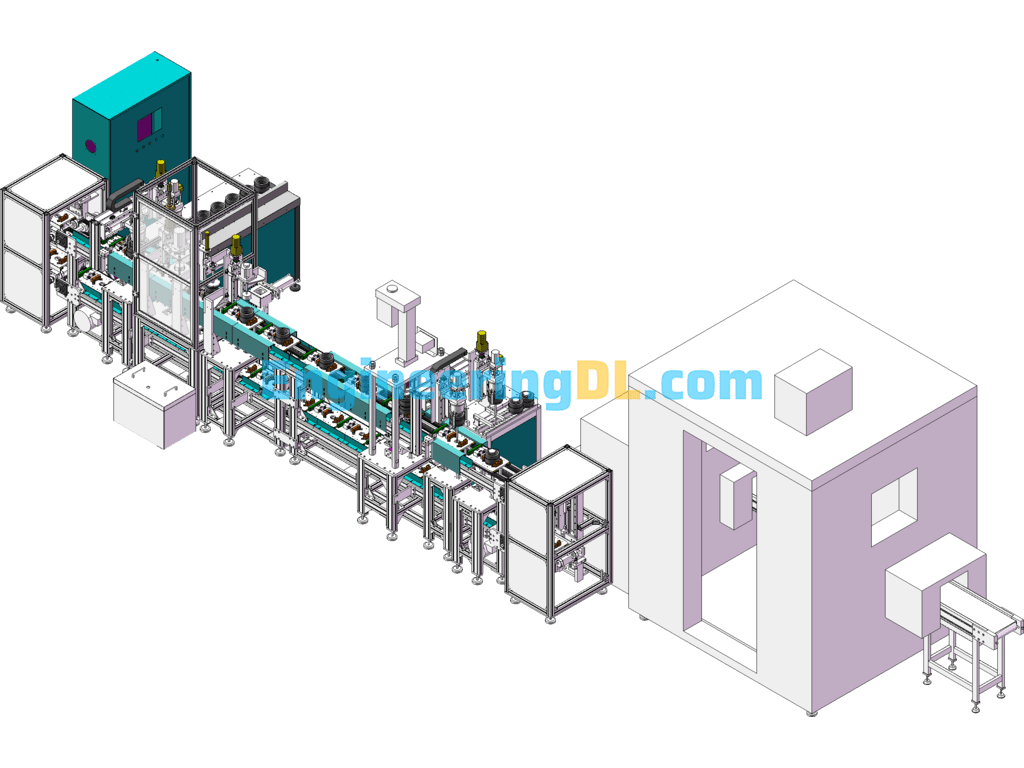

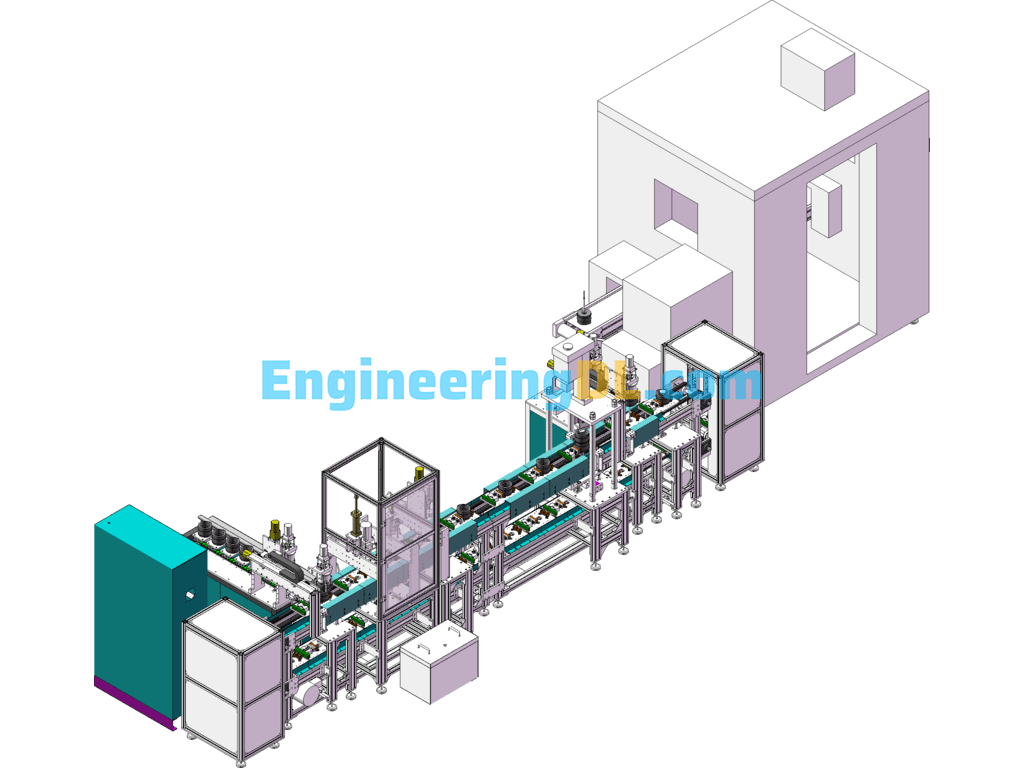

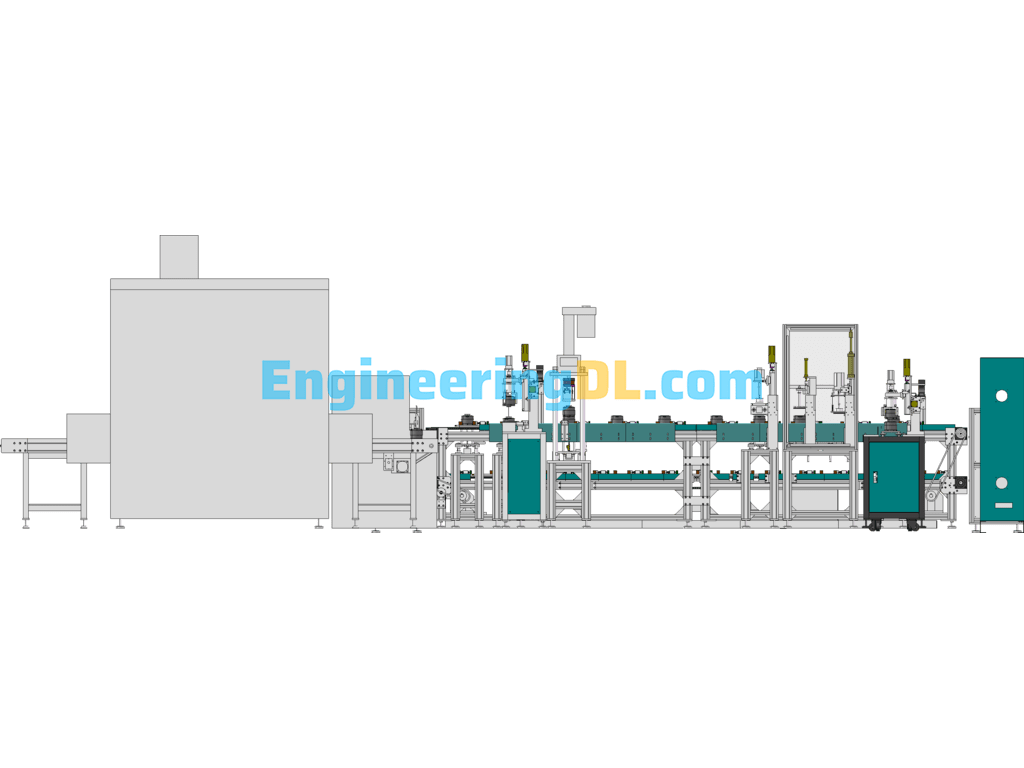

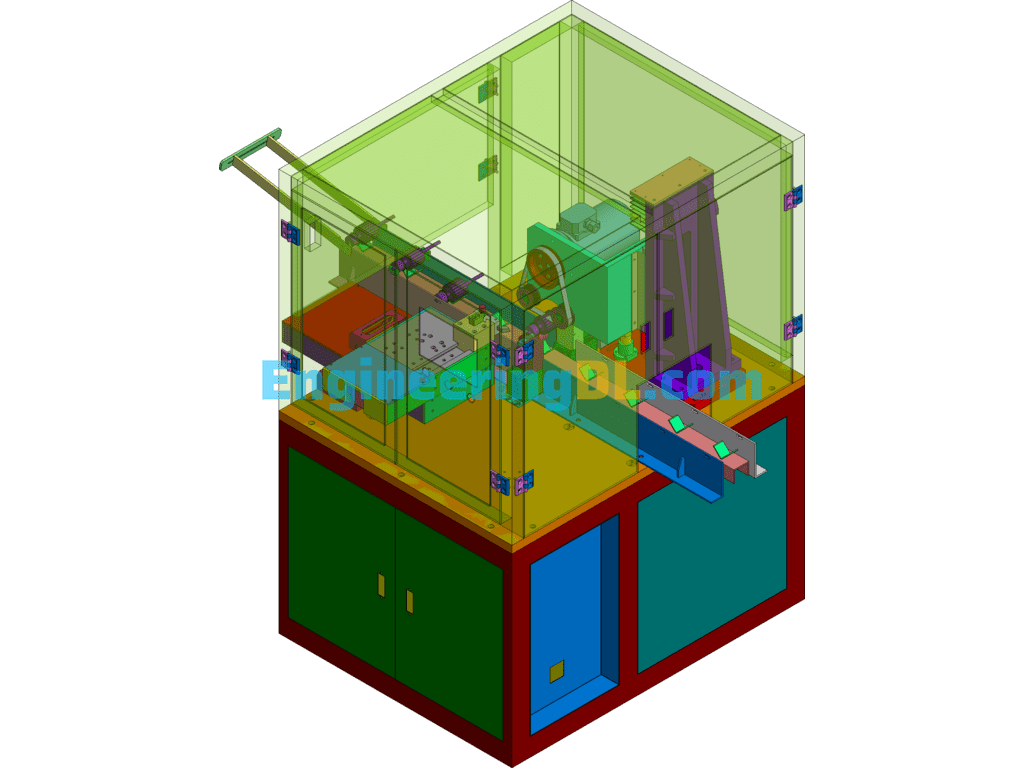

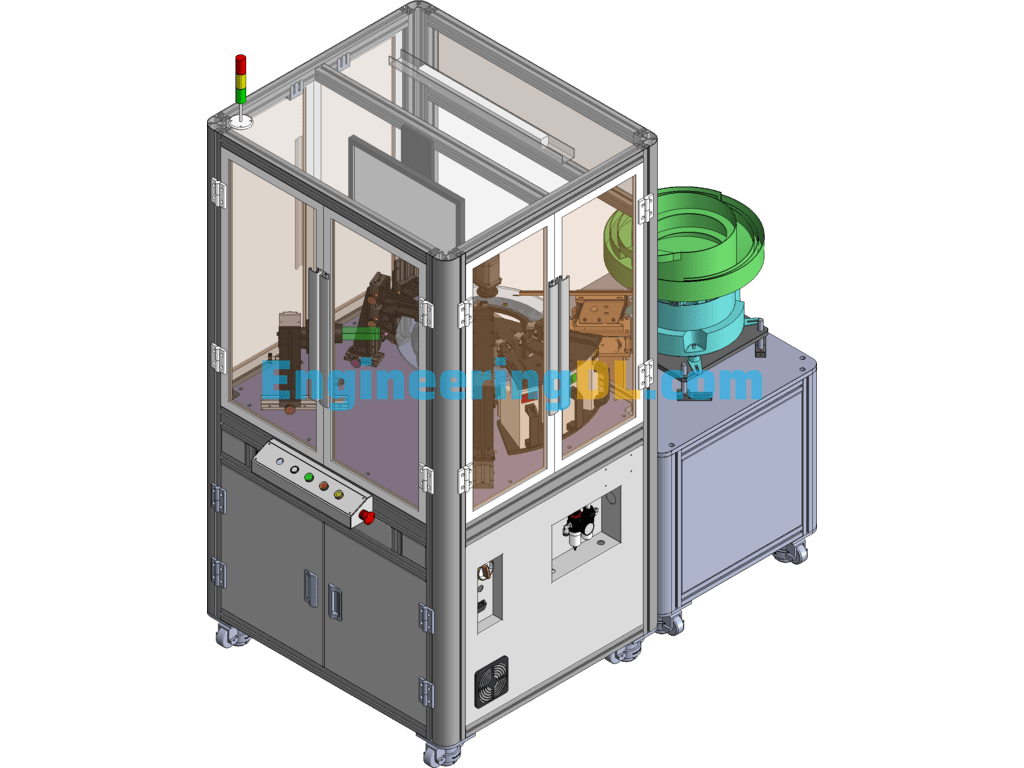

RP high-power plastic motor assembly and processing line automation line complex equipment – original drawings (with a complete set of engineering drawings within) the full length of the line body on one side of the motor power line dragging slot, the slot using SUS304 stainless steel manufacturing, the requirements throughout the smooth, line body dragging the power line in the slot to move shall not cause any form of mechanical damage to the power line, the slot should be set to enable the duplex stator automatically pressed into the machine The power line of the stator should be able to automatically enter the power line of the stator in the slot without causing damage to the power line. The line body power cord and air tube are not mixed and placed, and encapsulated with a special line slot. Easy to repair and maintain, lights, fans, sockets main power zero and fire wires are to be controlled separately with 2P leakage switch, every 10 lights are controlled by a small switch on the light frame, 3-phase sockets are wired separately, while there are 2 mains sockets every 1.5M under the line body. There is a gas source triplex and a 1″ solenoid valve for control at the main interface of the gas pipe (the control line can be shared with the total switch of the lamp).

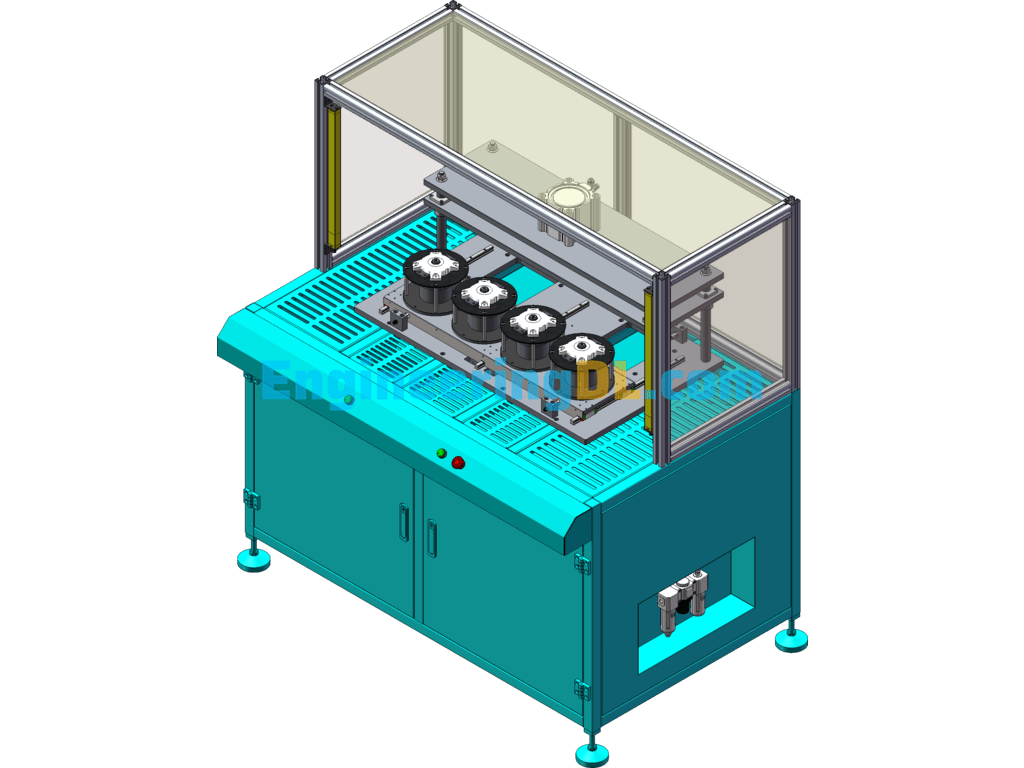

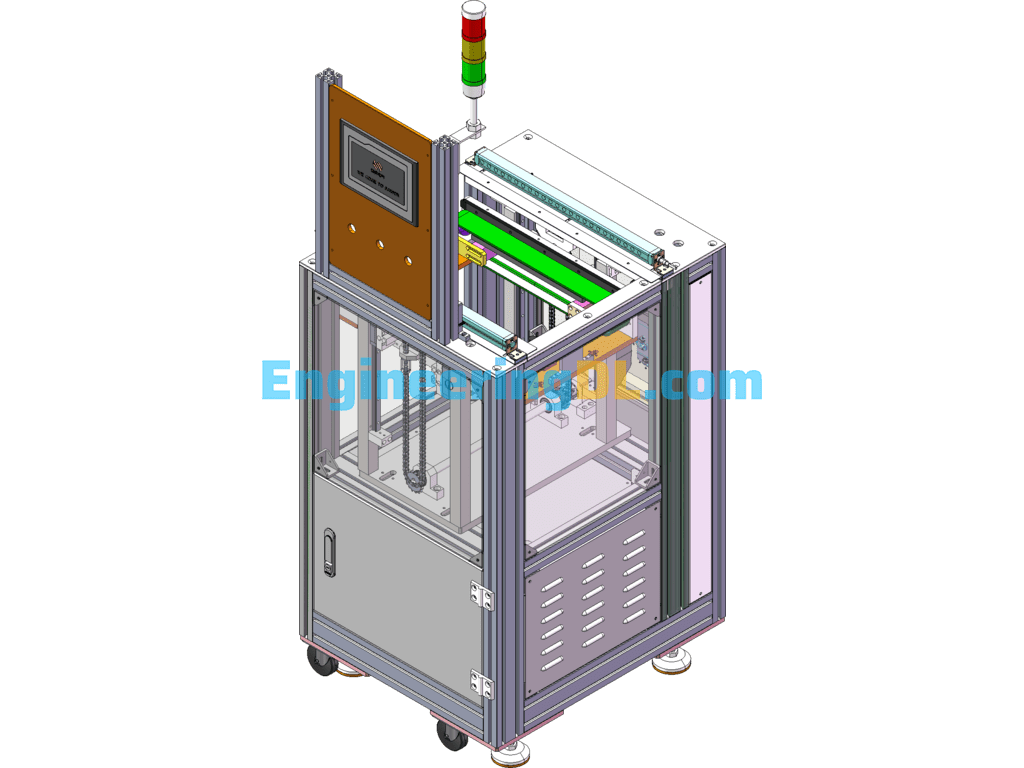

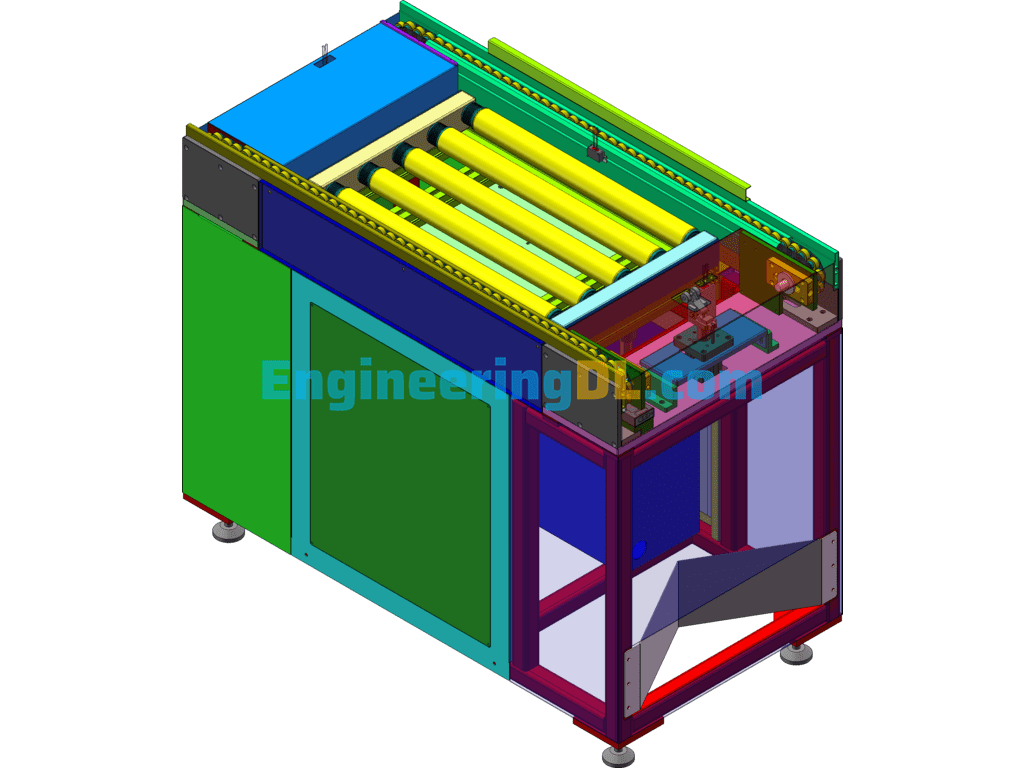

The RP high-power plastic sealing motor assembly and processing line automation line is suitable for manual and automatic mixed assembly of high-power plastic sealing motor. 1. Function: It is suitable for manual and automatic mixed assembly of 95 and 110 high-power plastic sealing motor series motors (motor shaft is unilateral shaft extension, the maximum length of the shaft is 150mm from the end cover to the shaft head on the side of the shaft, see motor shape diagram for details); the motor is vertically on the horizontal plane The shaft head is mounted on the tooling plate upward. 2, Working principle and action sequence: A, Special tooling plate enters the tooling plate stack storage area from the lifting platform. B, When the tooling plate where the BMC stator is placed is empty, the tooling plate enters the work station from the stack storage area. (The blocker blocks the plate and the plate stops, same below.) The robot will put the BMC stator (2 sets) into the corresponding position of the special plate, step down the foot switch, the plate goes down and enters the next stacking area. C. When placing rotor, PG plate and BB cover work station is empty, the tooling board will automatically enter the work station, then step on the foot switch, the tooling board will automatically run to the next work station staging area. D, When the BB cover press station is empty, the tooling board automatically enters the station and automatically presses the BB cover to detect the tampering amount, etc. After pressing, the foot pedal switch is pressed and the tooling board automatically runs to the next station for temporary storage. E. When the performance testing station is empty, the tooling board automatically runs to this station and manually detects the performance, after the performance testing is finished, then step on the foot switch, the tooling board automatically runs to the tooling board lifting platform stack storage area. F. Execute the next cycle. 3, The total length of the line body is 5.5 meters (including the lifting table at both ends), the total width is 300mm (excluding the protruding part of the lifting table at both ends), the height of the upper layer containing the workpiece plate is 800 mm, and the height between the two layers is 400mm. The height of the supporting stand of the line body is adjustable, with an adjustment range of ??30mm. 4, The line body adopts a double layer back to the plate structure, the upper layer is for the motor transmission, and the lower layer is for the workpiece plate fast Back to the plate with. a, the line body with roller chain drive; with independent power drive. b, The whole lower layer of the line body is driven by roller chain. c, The frame of the line body is made of high-strength aluminum alloy profile, with an overall load-bearing capacity of 300kg/1000mm. d, The line body can accept the control signal sent by each process machine and produce the corresponding process action. 5, The upper and lower chains should use independent power system and the speed of the lower return plate is 20% higher than the upper speed, the chain speed of the upper and lower layers is steplessly adjustable, and the adjustment range is 0-15m/m12, The design of the work plate should fully consider the impact and impact, and there should be no metal surface contact when the work plate is running and stopping. In any area of the line, in the work station where there is manual manipulation and placement of parts, and in the work section where there is a possibility of falling into the chain, protective covers should be added above the upper and lower chains.

Specification: RP High-Power Plastic Motor Assembly And Processing Line Automation Line SolidWorks, 3D Exported

|

User Reviews

Be the first to review “RP High-Power Plastic Motor Assembly And Processing Line Automation Line SolidWorks, 3D Exported” Cancel reply

You must be logged in to post a review.

There are no reviews yet.