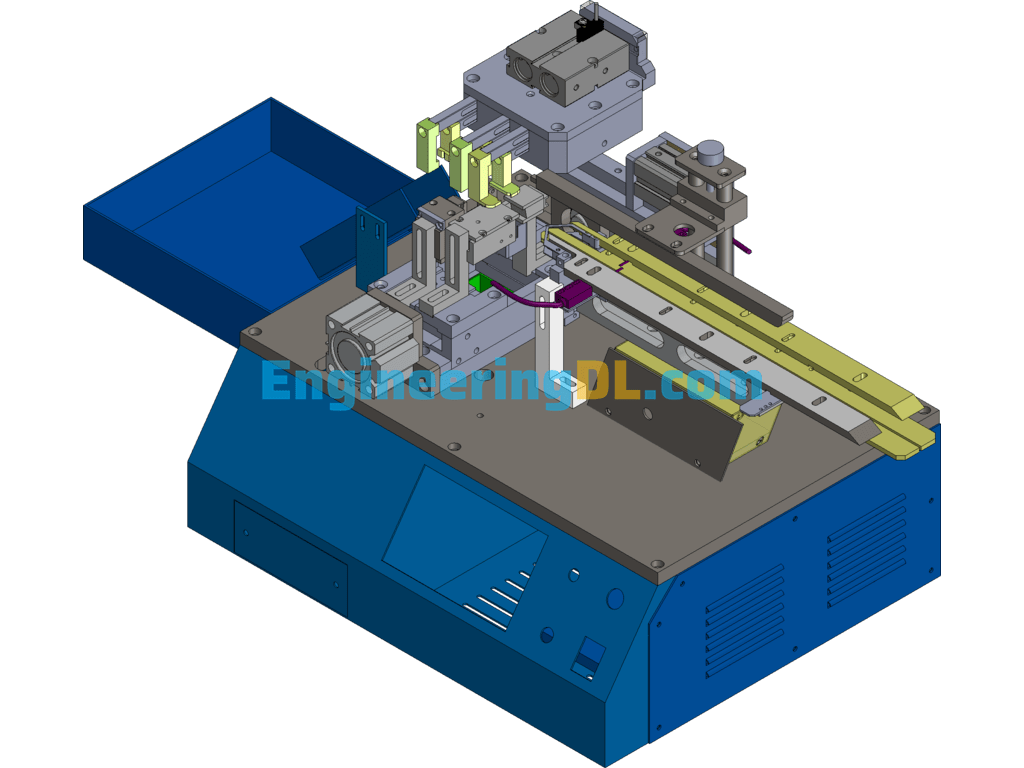

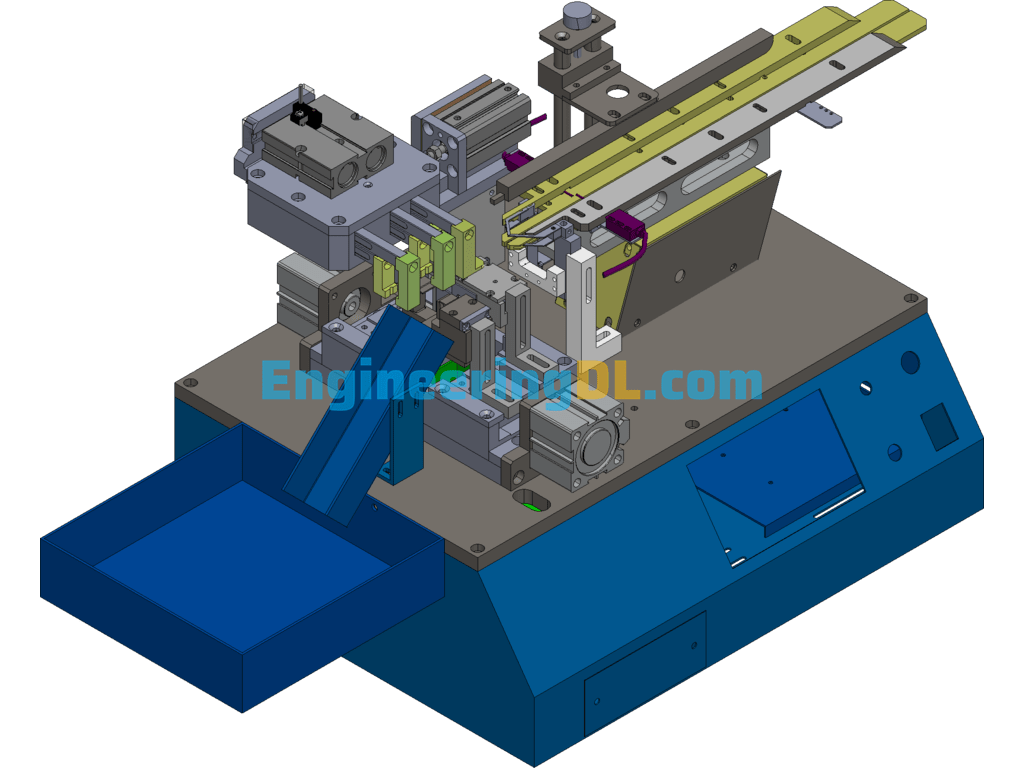

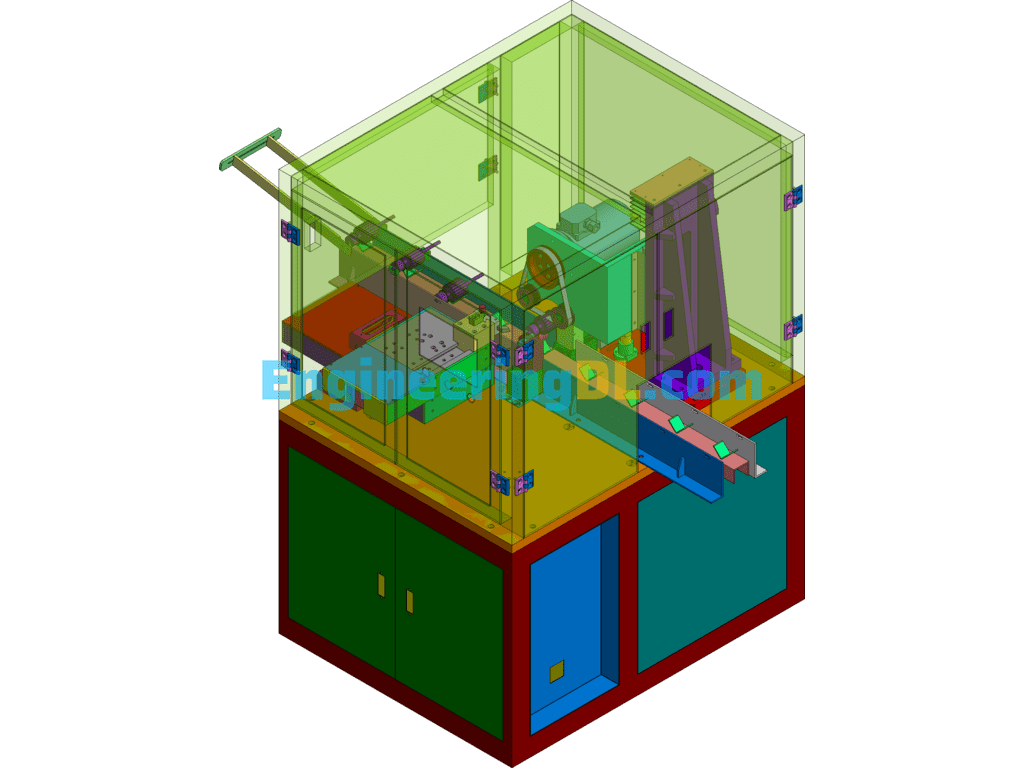

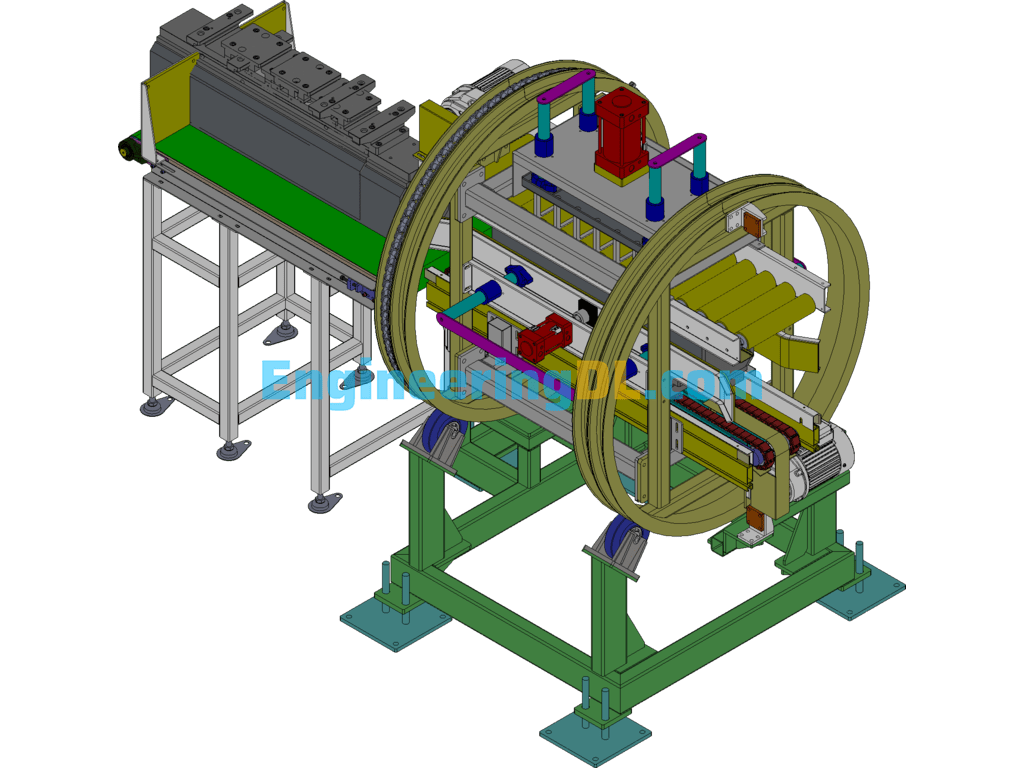

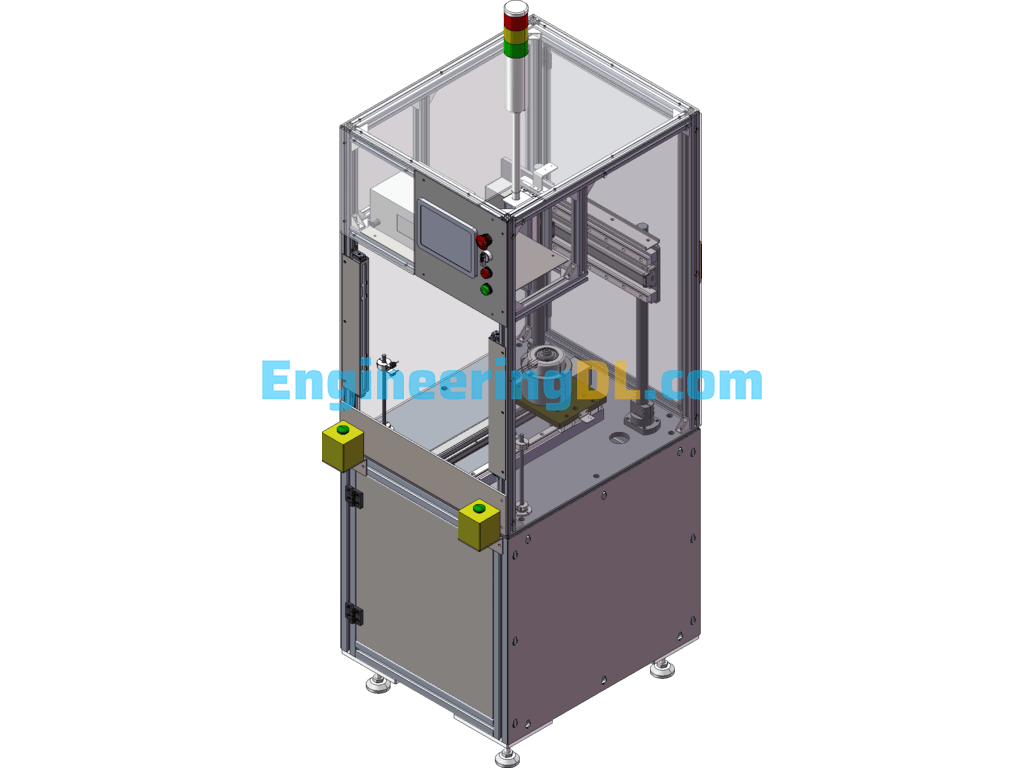

Pneumatic bulk capacitor forming machine equipment parameters

Power supply: 110V/200VAC 60HZ/50HZ

Size: L500 x W400 x H400mm

Speed: 4000pcs/h

Weight: 50kgs

Power???60W

Air pressure: 4-6kg/cm??

Equipment characteristics

This machine adopts Japan Sanlou PLC control system, equipped with human-machine dialogue interface touch loss screen, humanized design, simple operation.

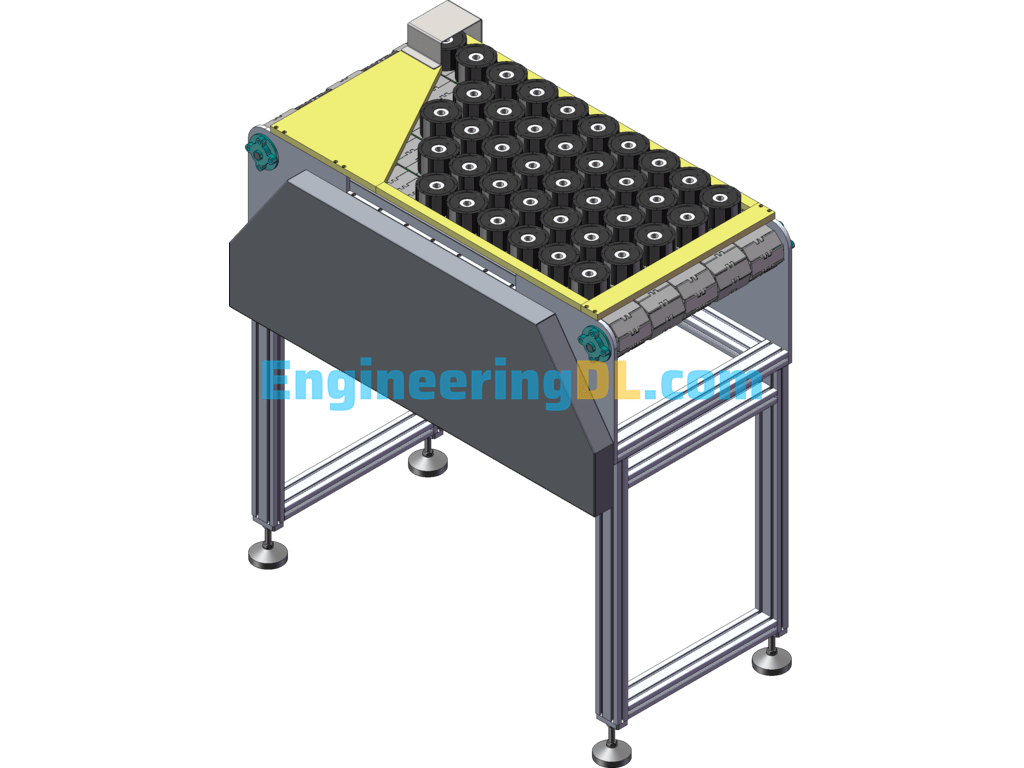

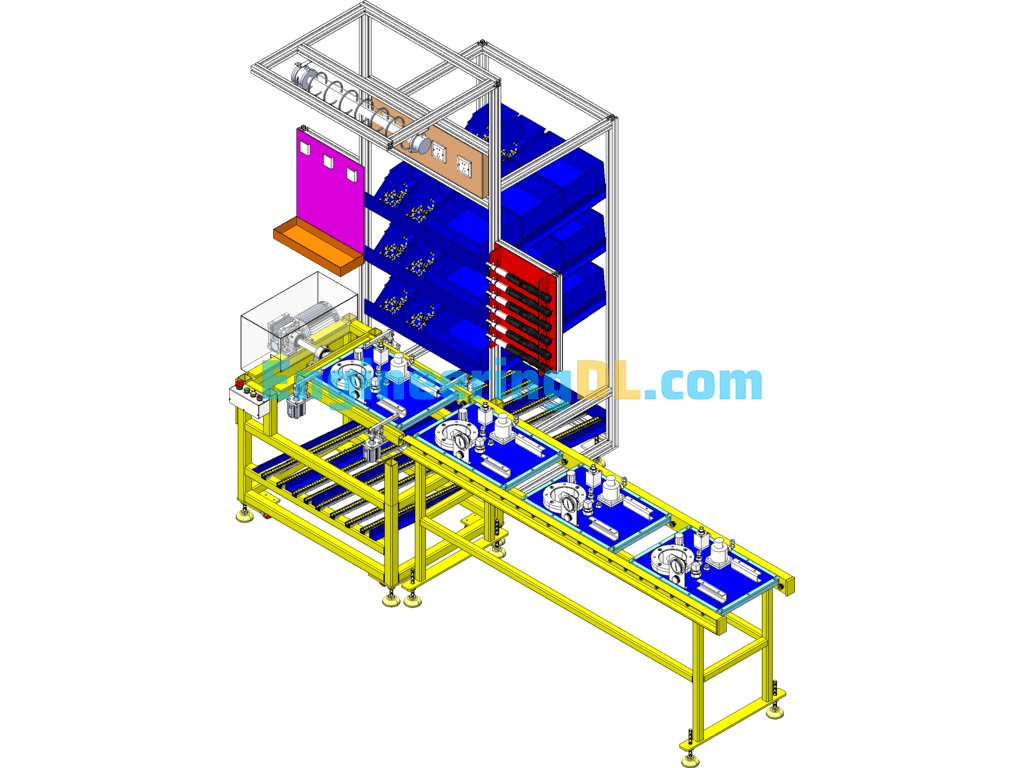

Suitable for LED, electrolytic capacitor, transistor, safety capacitor, metalized film capacitor, quartz pin body zun radial parts.

Imported cam drive mechanism, accurate and stable, durable and low noise, each spare part are special hardening treatment, long service life.

Forming shape: bend 90 degrees, internal bending, external bending, front and back bending, playing K, long and short legs, etc., can be customized according to customer requirements.

Vibrating plate automatically feeds, then through the process of clamping material, whole foot, polarity detection, steering, secondary testing, throwing material, cutting foot, forming and other processes completed at once, special requirements can also increase the corresponding process.

Adopting combined moulds, quick and easy to replace, each group of moulds is adjusted individually, and the tools and moulds are made of imported Japanese steel.

Flexible rack and pinion clamps, clamping material completely stable without hurting the parts themselves, and similar size parts do not need to replace the clamps

Specification: Pneumatic Bulk Capacitor Forming Machine SolidWorks

|

User Reviews

Be the first to review “Pneumatic Bulk Capacitor Forming Machine SolidWorks”

You must be logged in to post a review.

There are no reviews yet.