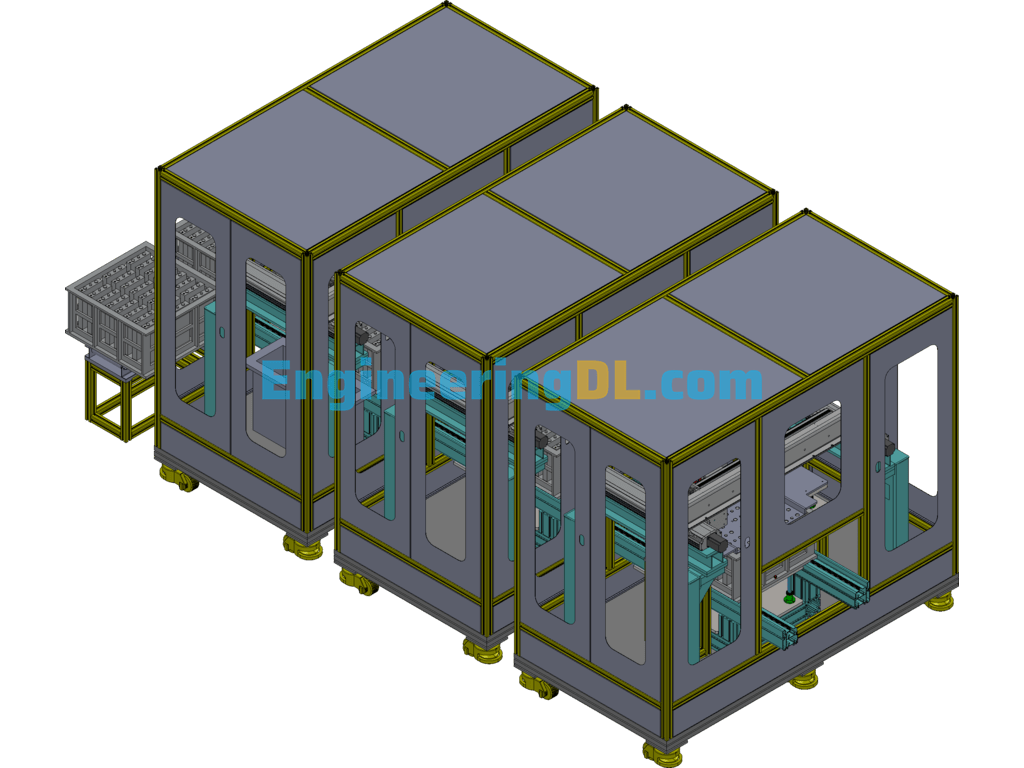

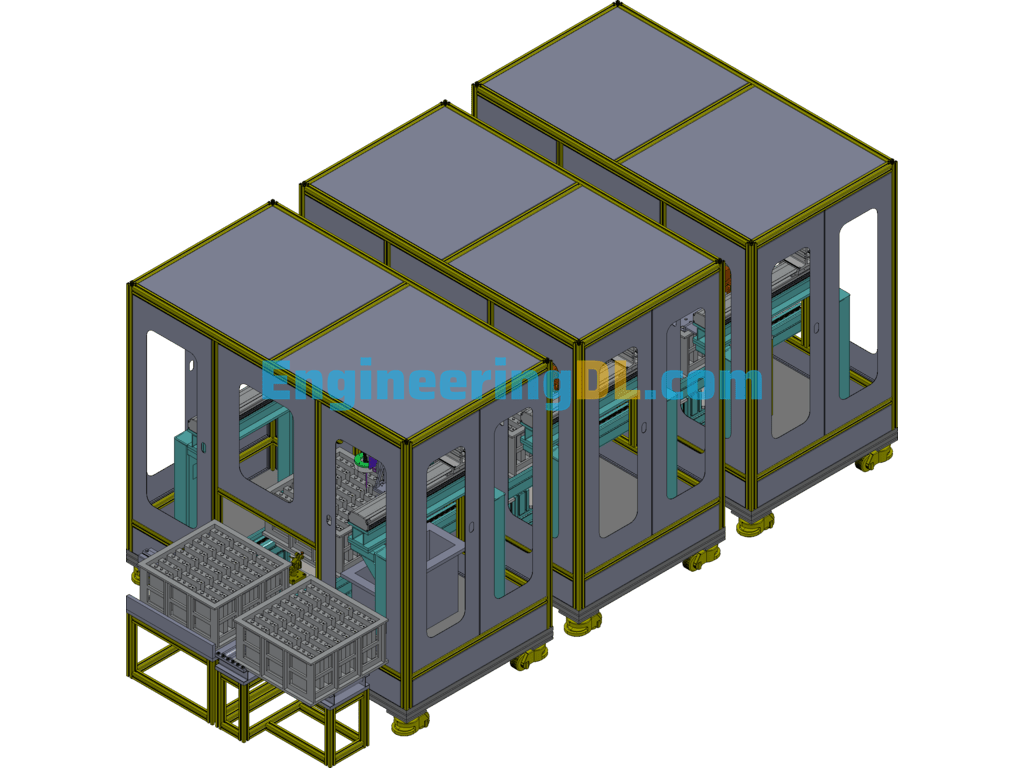

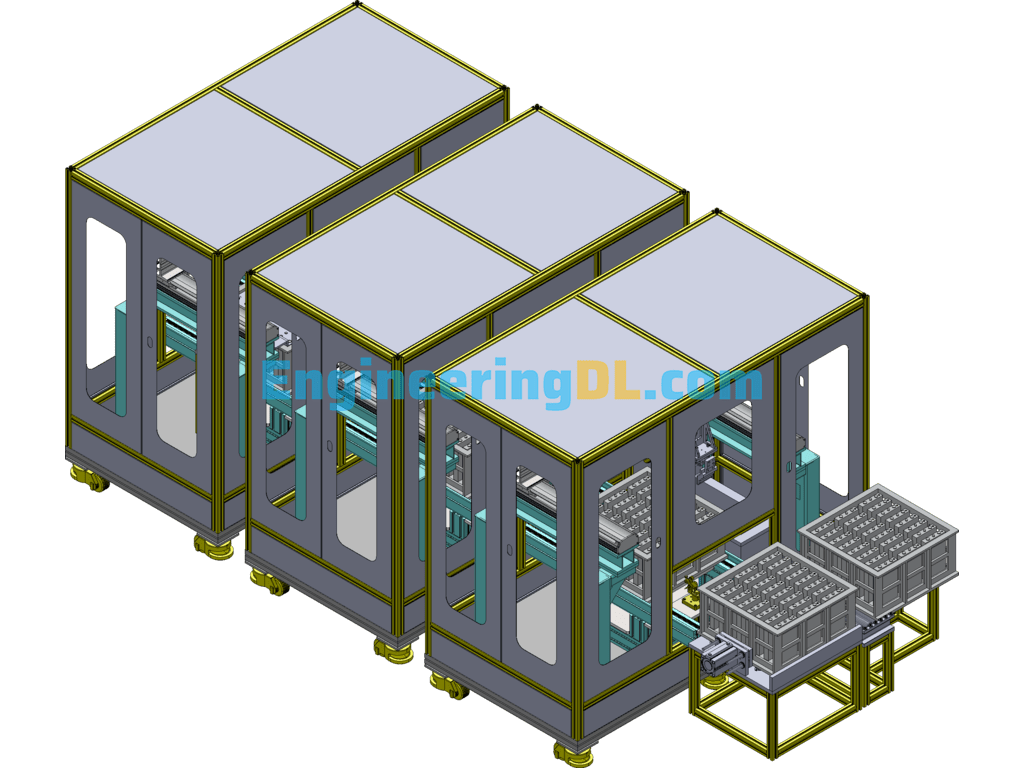

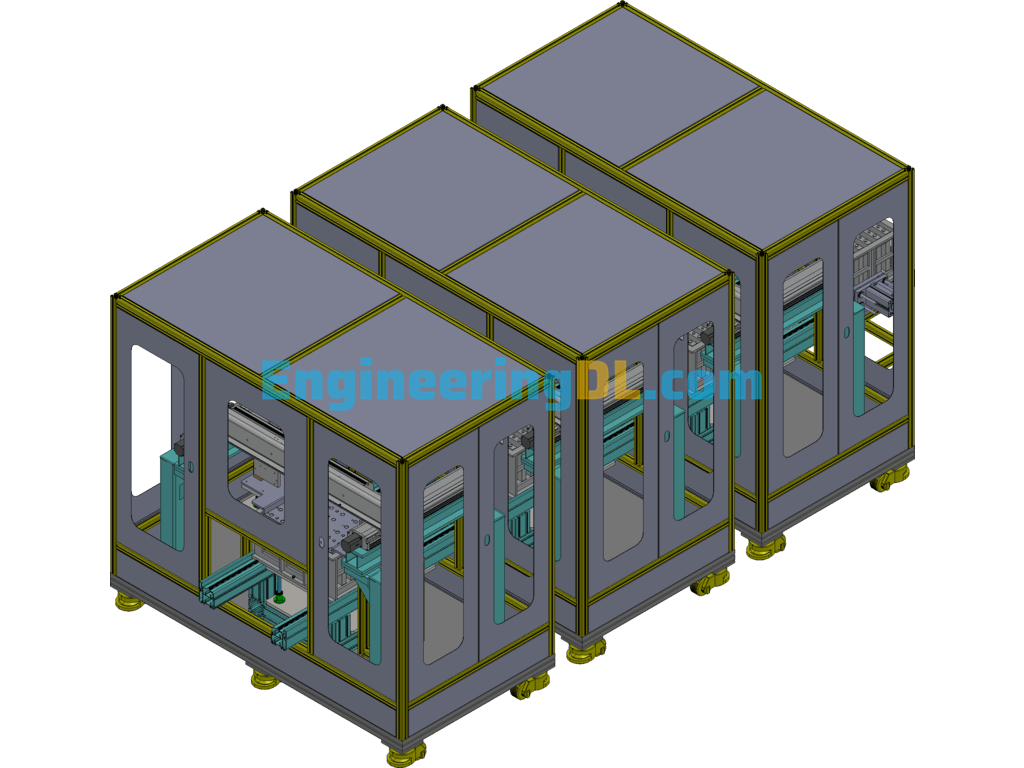

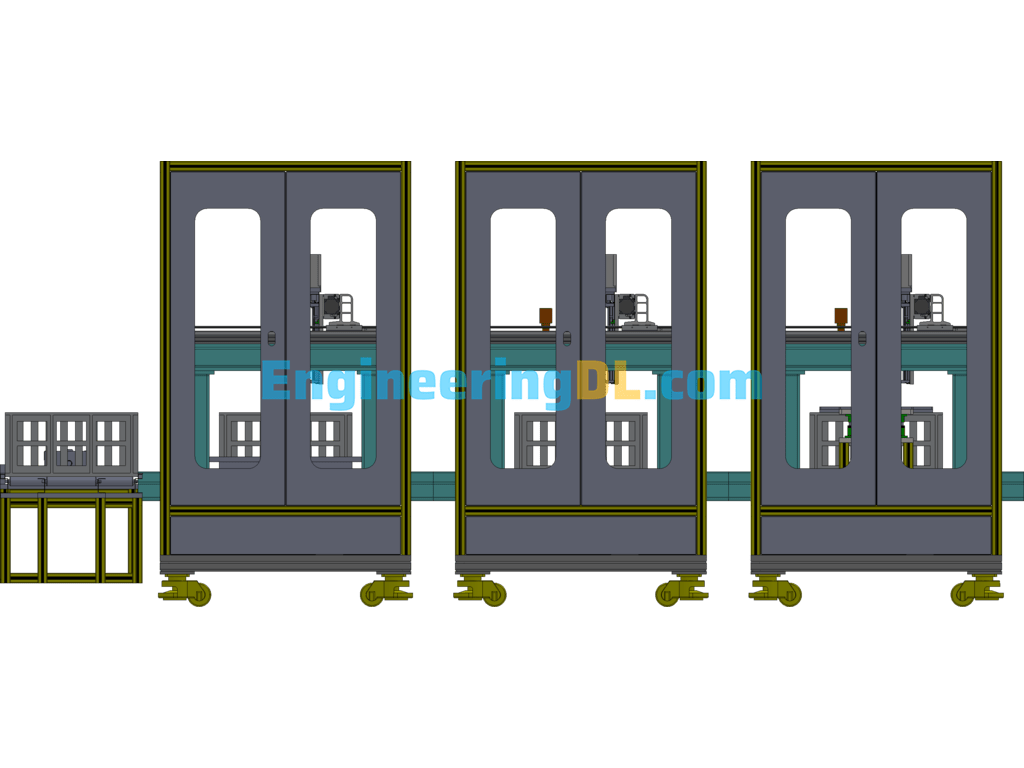

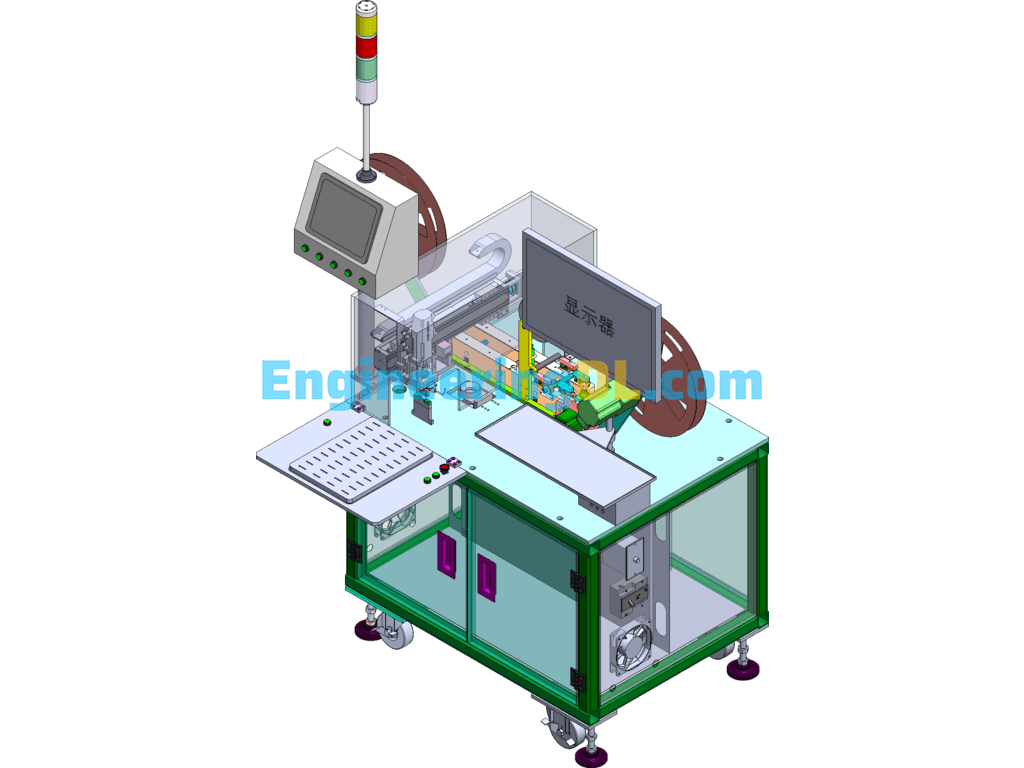

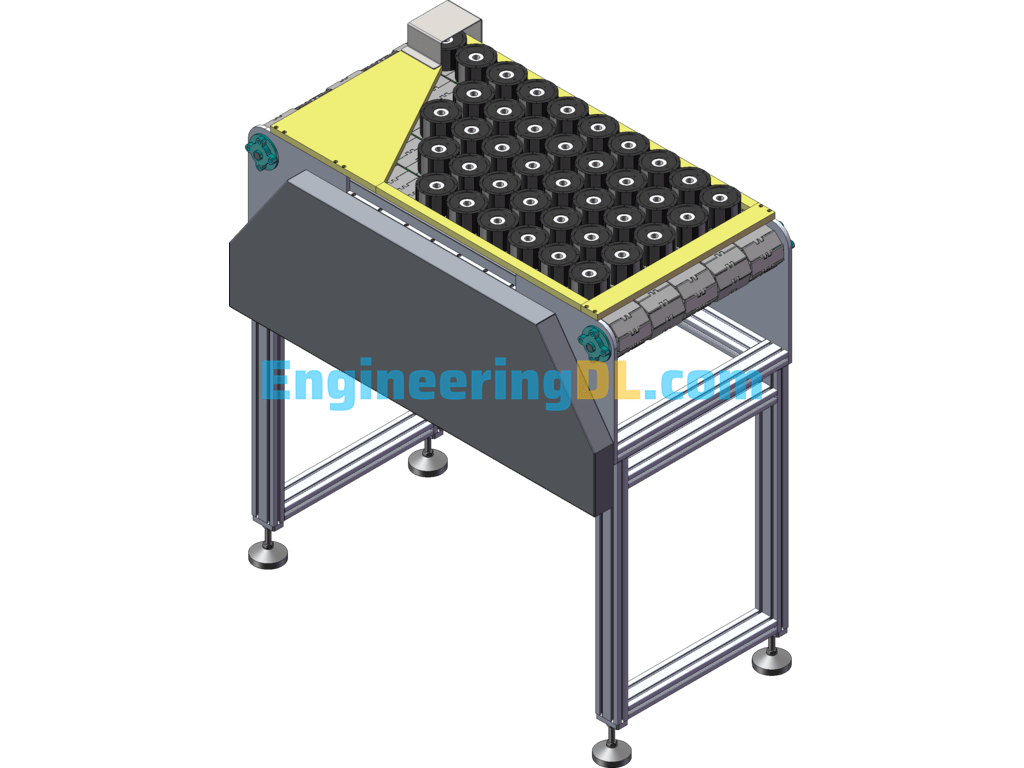

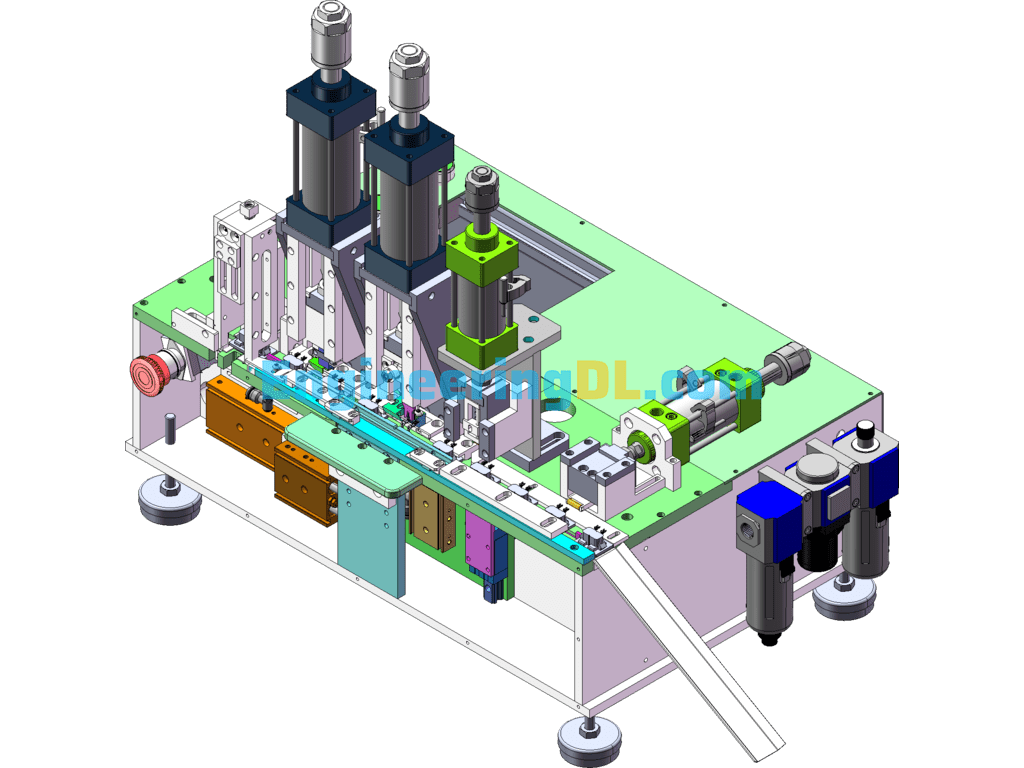

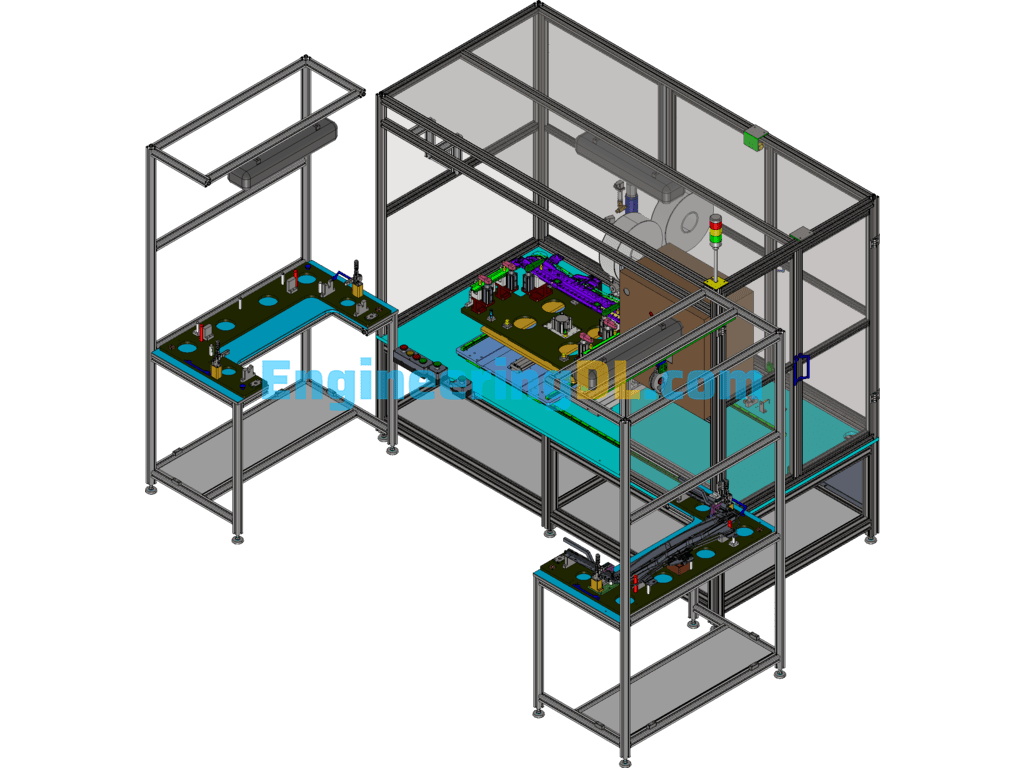

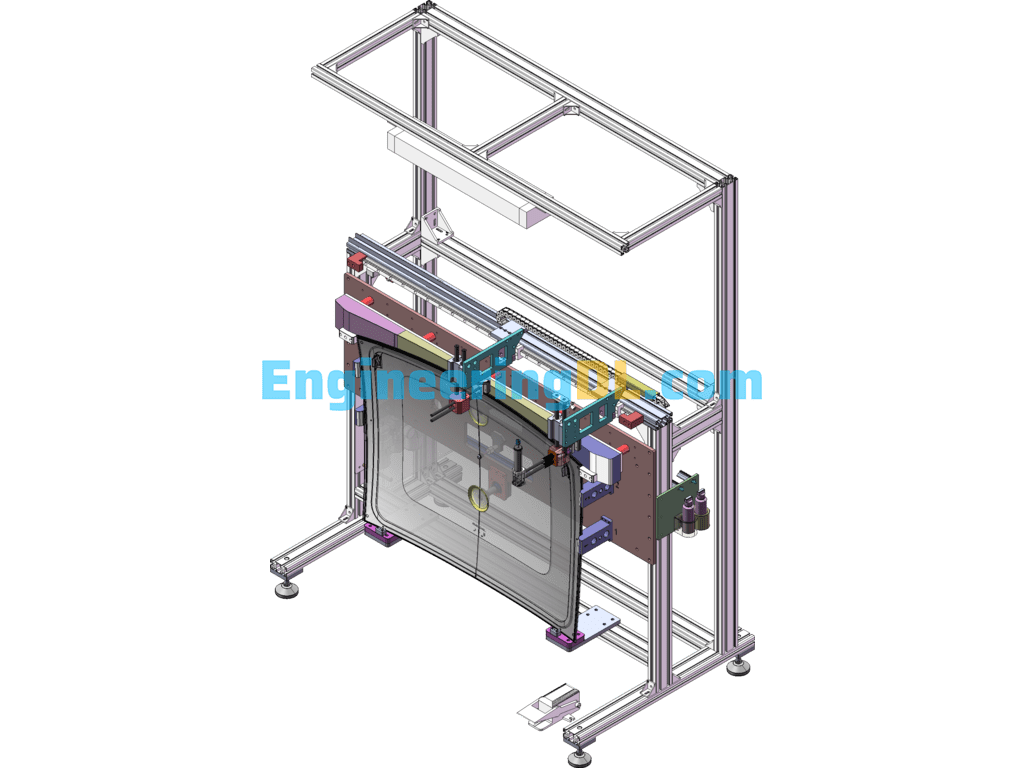

Non-standard automation equipment: 3D drawing of lithium battery hole sealing welding machine Fiber transmission laser: 600W Gas used: compressed air Rated pressure: 0.6MPa Electrical requirements: rated output voltage: 380VAC This equipment is specially used to achieve automatic laser spot welding, laser automatic continuous welding, automatic detection of welding quality, and automatic rejection of NG products by robots, The equipment is mainly composed of conveying tank, XYZ three-axis CNC axis, welding laser, laser welding head, CCD vision positioning system, height detection sensor, fixed positioning mechanism, smoking dust removal mechanism, etc. The equipment is divided into automatic spot welding part, automatic continuous welding part, automatic rejecting part for NG products after welding inspection and discharging area after welding inspection. Voltage frequency: 50Hz three-phase voltage stability +5% Output voltage adjustment rate: <2% Machine size: 4.16mm long, 1.95m wide, 1.8m high Maximum power consumption: 43KW (including two lasers) Machine weight: 400Kg/m2 Lithium battery injection hole laser automatic hole sealing machine 3D drawings G976 mechanical design reference material design material works for mature products, only for learning and exchange, not for commercial use, thank you for your cooperation, solidworks design, with assembly drawings and parts drawings.

Specification: Non-Standard Automation Equipment: Lithium Battery Sealing Hole Welding Machine SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Non-Standard Automation Equipment: Lithium Battery Sealing Hole Welding Machine SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.