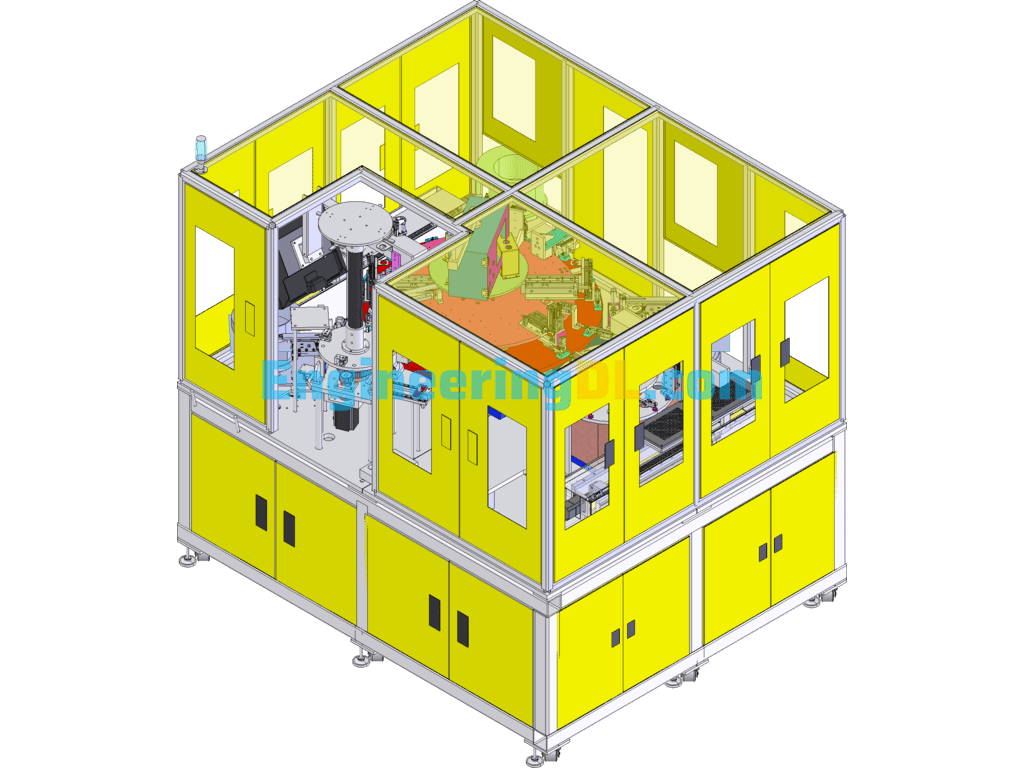

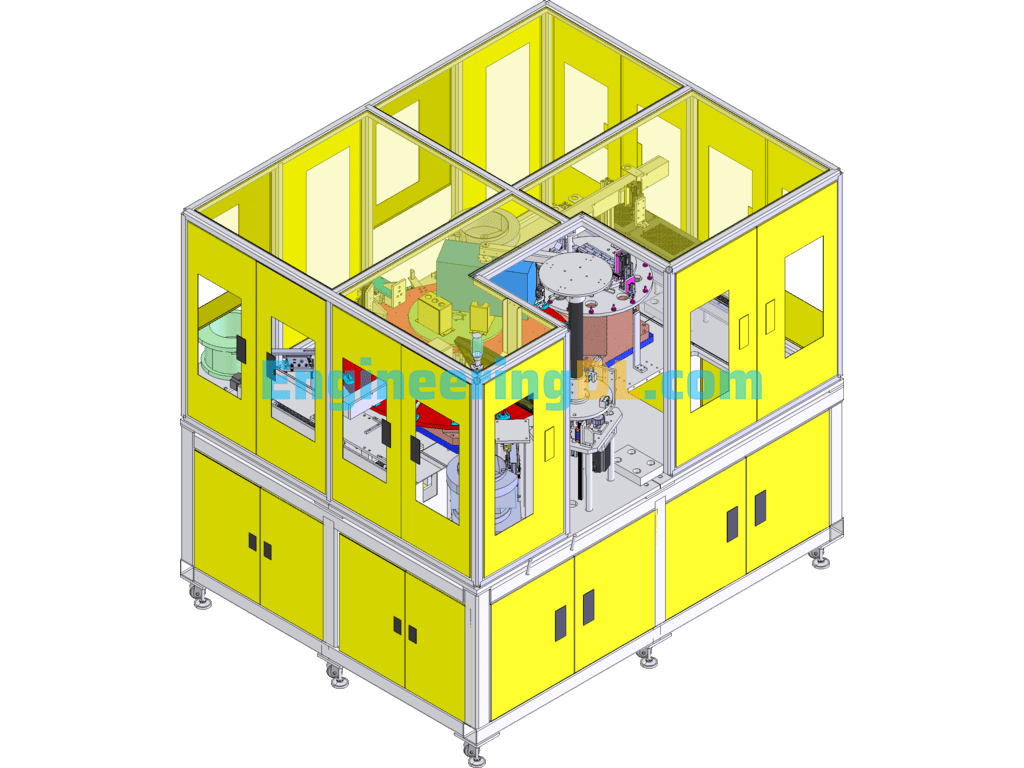

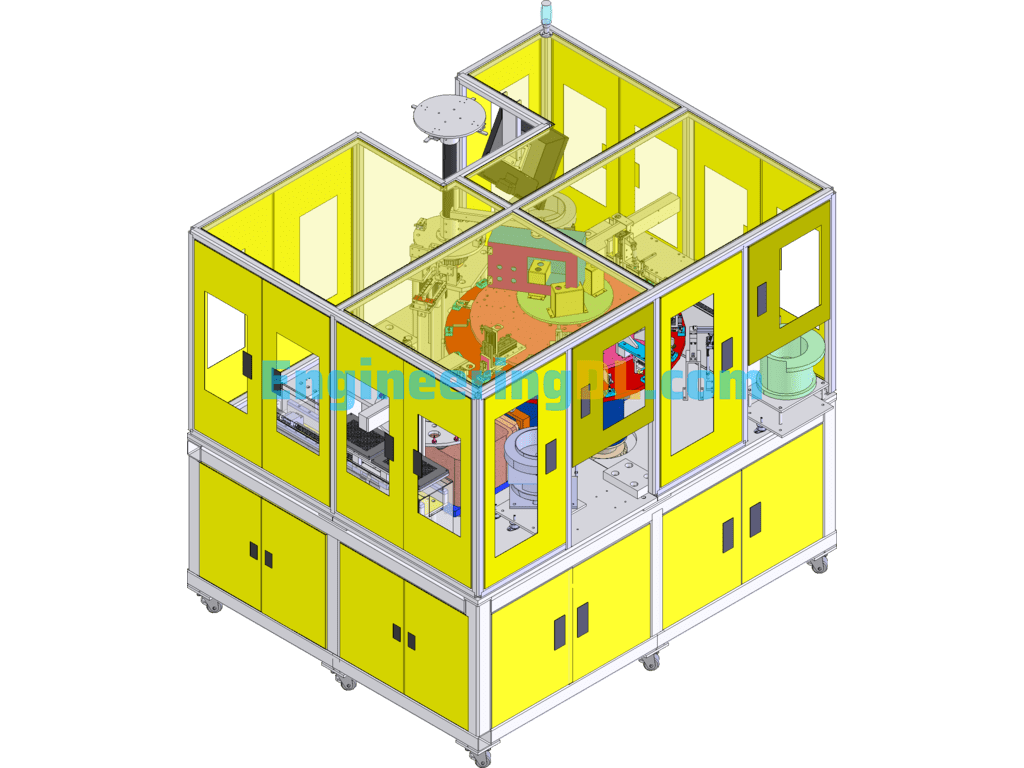

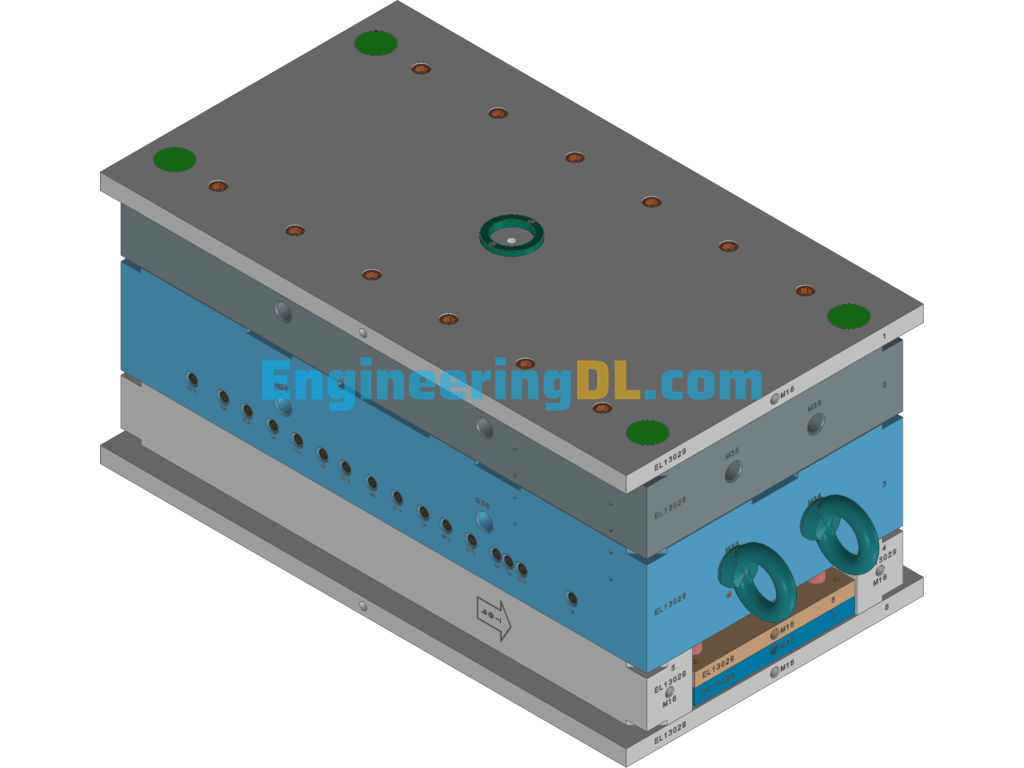

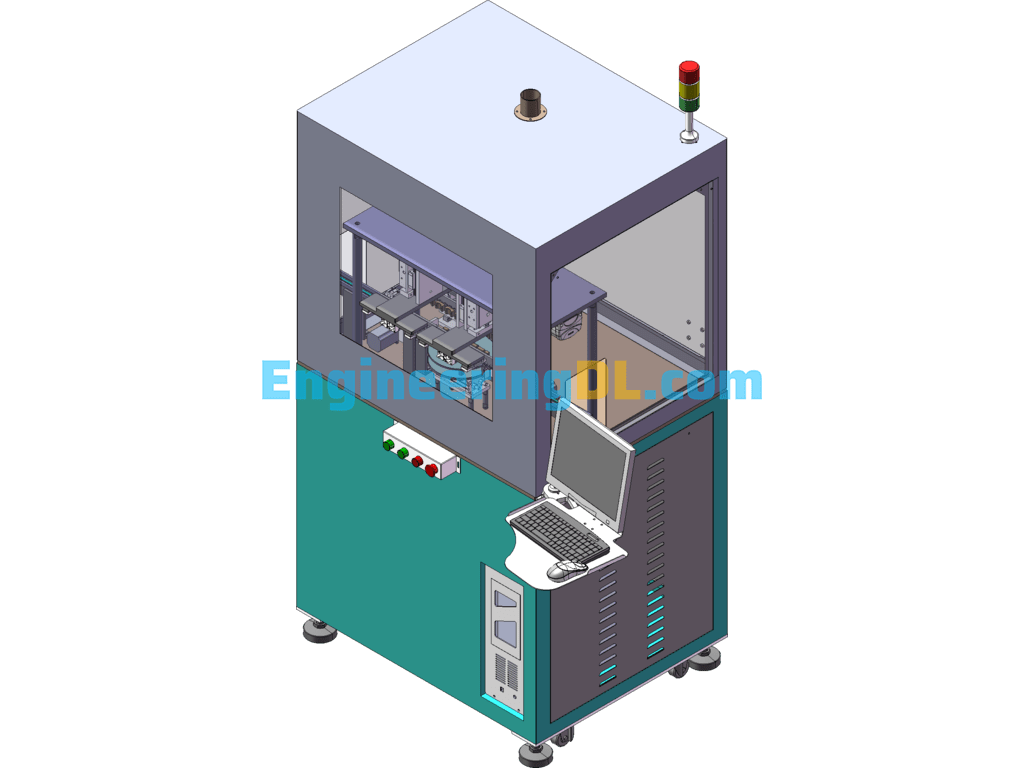

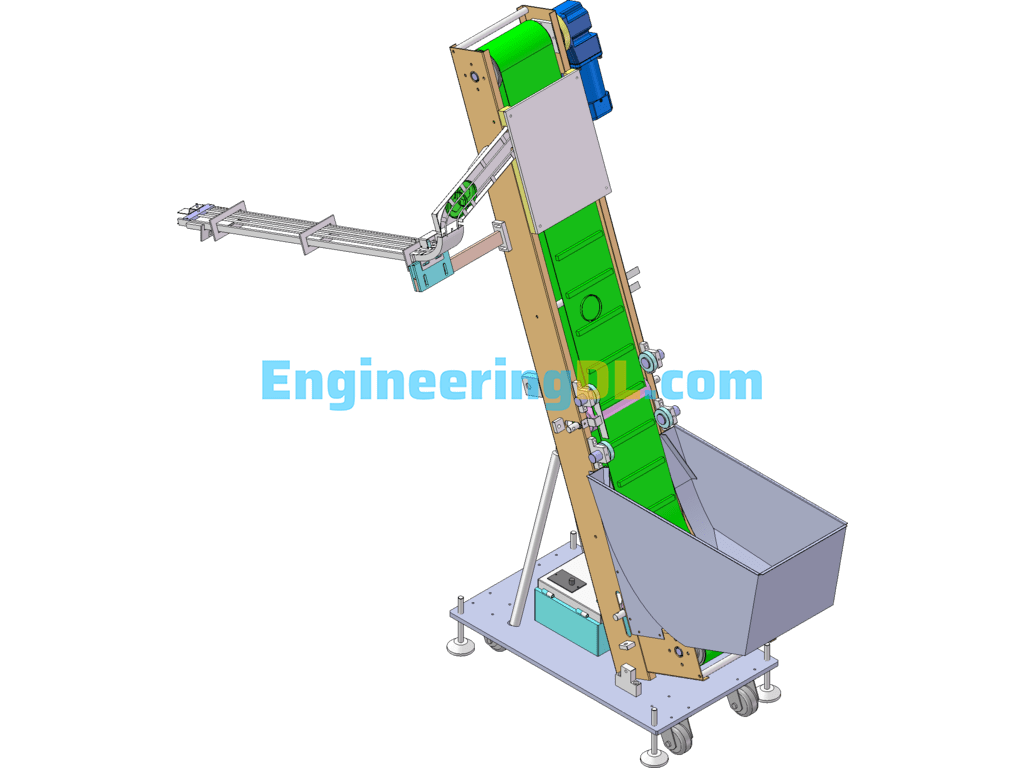

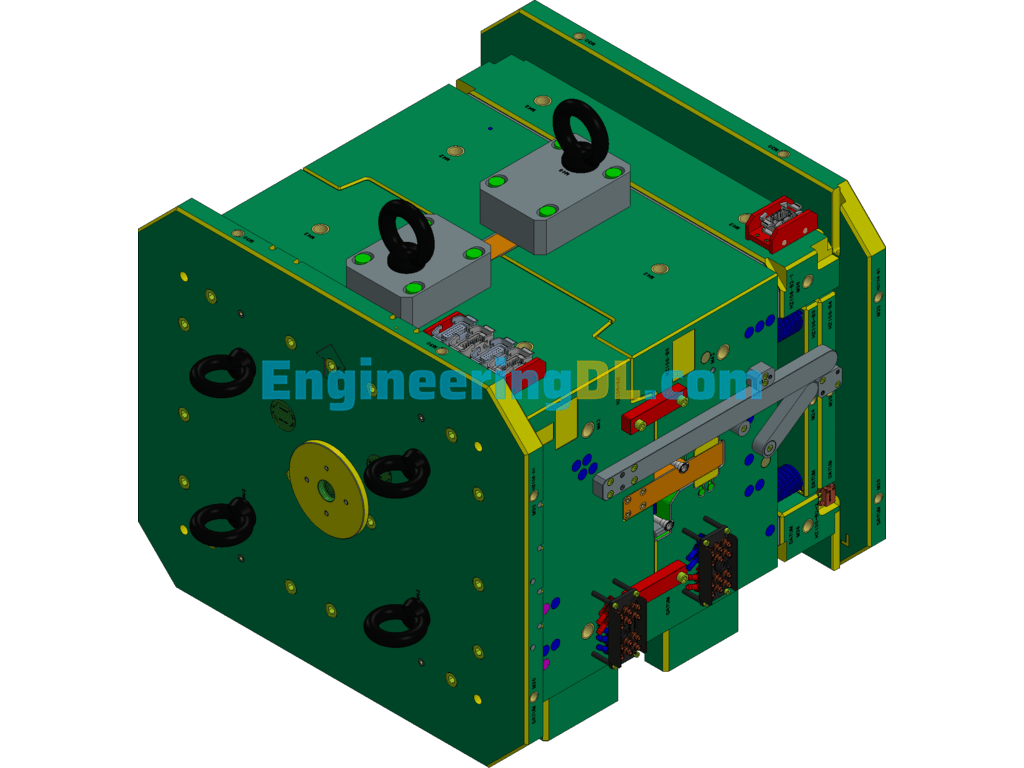

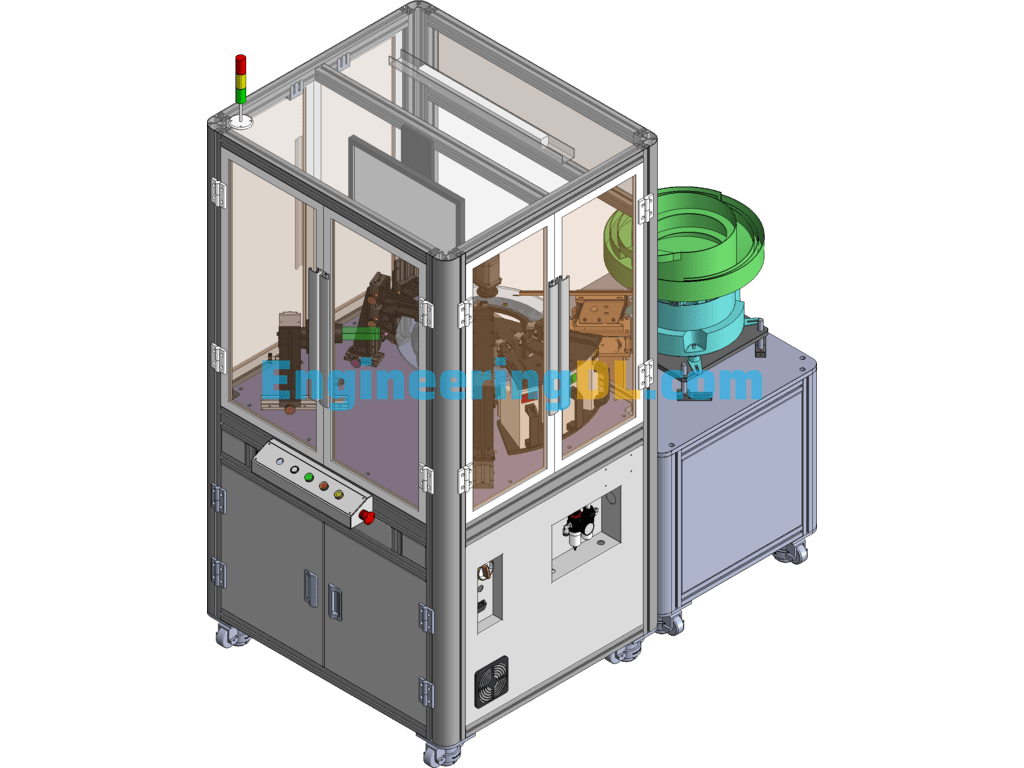

Fiber optic head assembly machine network signal plug non-standard assembly equipment a. Equipment description of the equipment for the products: fiber optic head, signal plugs, communication connectors, assembly of various types of fiber optic connectors. The equipment is a latest fiber optic head automatic assembly machine: the equipment is mainly used for fiber optic network port communication and signal to interface products such as assembly, equipment for turntable operation, feeding position is divided into three vibrating discs and a material tray for feeding, that is, by the four fiber optic head parts assembled together, assembled finished product is commonly used fiber optic head, assembly parts are: fiber optic shell, fiber optic plastic parts, fiber optic metal parts, fiber optic core is the most in the needle fiber optic head. Fiber optic core is also the most in the needle fiber head, the equipment uses a large turntable and two small turntables to complete the assembly and feeding, the middle of the largest turntable for the 16-station splitter design, the small turntable which on the fiber optic core turntable is also 16-station, the robot from the feeding tray to pick up the fiber optic core and put the turntable in the treatment of good positioning, to assemble to the fiber optic plastic parts, the overall principle of action of the equipment is, feeding robot to take The overall action principle of the equipment is that the feeding robot takes the material to the small turntable, the turntable rotates to the docking station with the large turntable, the cylinder in the large turntable clamps the product to the large turntable fiber head to assemble, when the large turntable rotates to the next station, the stepper motor drives the small turntable to the plastic parts, another vibration plate for the fiber shell feeding vibration plate, the same is the pneumatic robot clamps to the large turntable for assembly, the receiving position is also the robot when assembling the finished fiber head When the finished fiber head is assembled, the robot will pick up the finished product and put it into the receiving tray one by one, and then the device will alarm to prompt the manual receiving after the receiving tray is full. II. The main assembled parts of the equipment are as follows: 1, fiber core feeding: the product is placed in the plastic box, the feeding robot takes the product from the plastic box and put it into the rotating tray, which can minimize the time for material change and has the alarm function for lack of material. 2, Fiber optic plastic parts feeding: plastic parts are vibrating disc and straight vibrating transmitter with automatic feeding, and there is a shortage of material alarm function. 3, Fiber optic metal parts feeding: metal parts for vibration disc and straight vibrator with automatic feeding, and shortage of material alarm function. 4, Fiber optic shell parts feeding: fiber optic shell parts are also vibrating disc and straight vibration transmitter with automatic feeding, and there is a lack of material alarm function. 5, Splitter turntable: 16-station rotating disk, the big turntable is divided into three layers, the bottom layer is for rotating disk and fixed jig and other operations, the middle layer is for each cylinder clamping mechanism fixed, the uppermost layer is for loading junction box air tube alignment, etc. 6, Loading and discharging robot: absorbing products from the indexing disk, and according to the attributes indicated by the software, the function settings of loading and discharging robot automatically switch materials, etc. The above is the function and principle of this equipment there are many more, more details part here is not much introduced have like direct download research can be, other more clever design structure you download can have time to slowly study research, this is a very good set of fiber optic head automatic assembly equipment drawings, welcome you to study research thanks. Three main technical parameters: Category specifications parameters machine size: 2100 * 1700 * 2000MM (L * W * H) input voltage: AC-220V50Hz or AC-380V 50Hz optional machine maximum power: 2.2K W (220V) input gas source pressure: 0.4- 0.6 Mpa air consumption 0.6 Mpa air consumption: 1.5 L/min production efficiency (C/T): ??? 4.0 S / a equipment loading rate: ??? 95% processing mode: automatic pick-up, loading, automatic assembly, automatic receiving robot movement resolution: 0.005 mm robot repeat positioning accuracy: ??? ?? 0.02 mm control communication mode: manual release tray programming mode: touch screen parameter modification

Specification: Fiber Optic Head Assembly Machine Network Signal Plug Assembly Machine Non-Standard Assembly Equipment SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Fiber Optic Head Assembly Machine Network Signal Plug Assembly Machine Non-Standard Assembly Equipment SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.