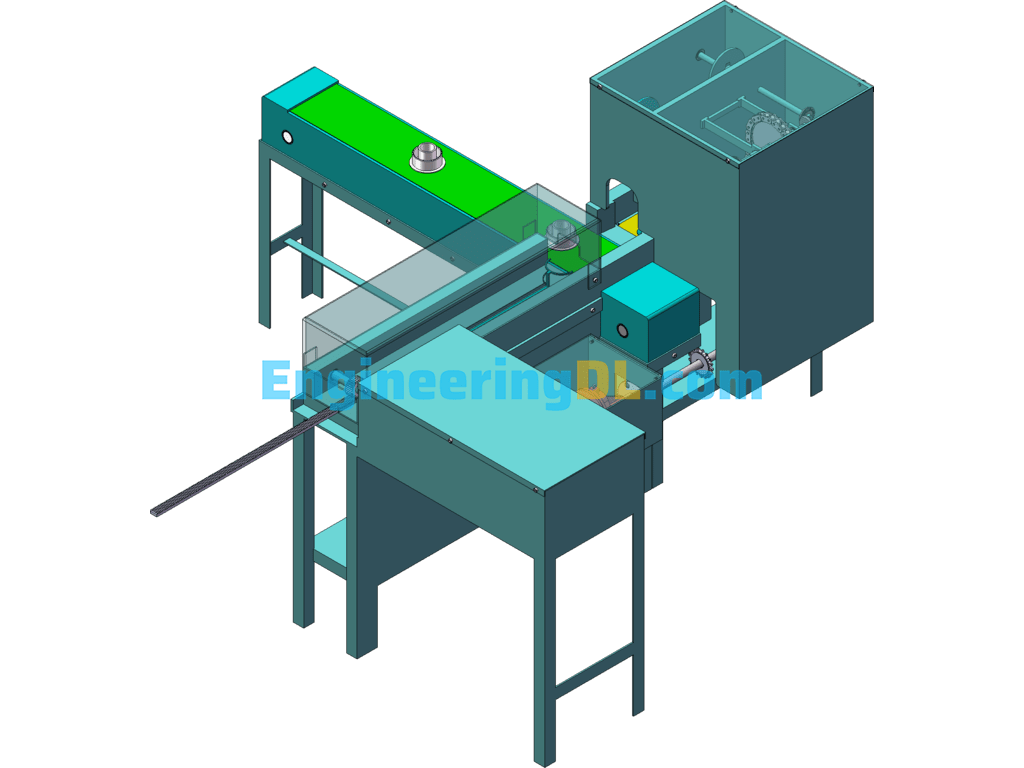

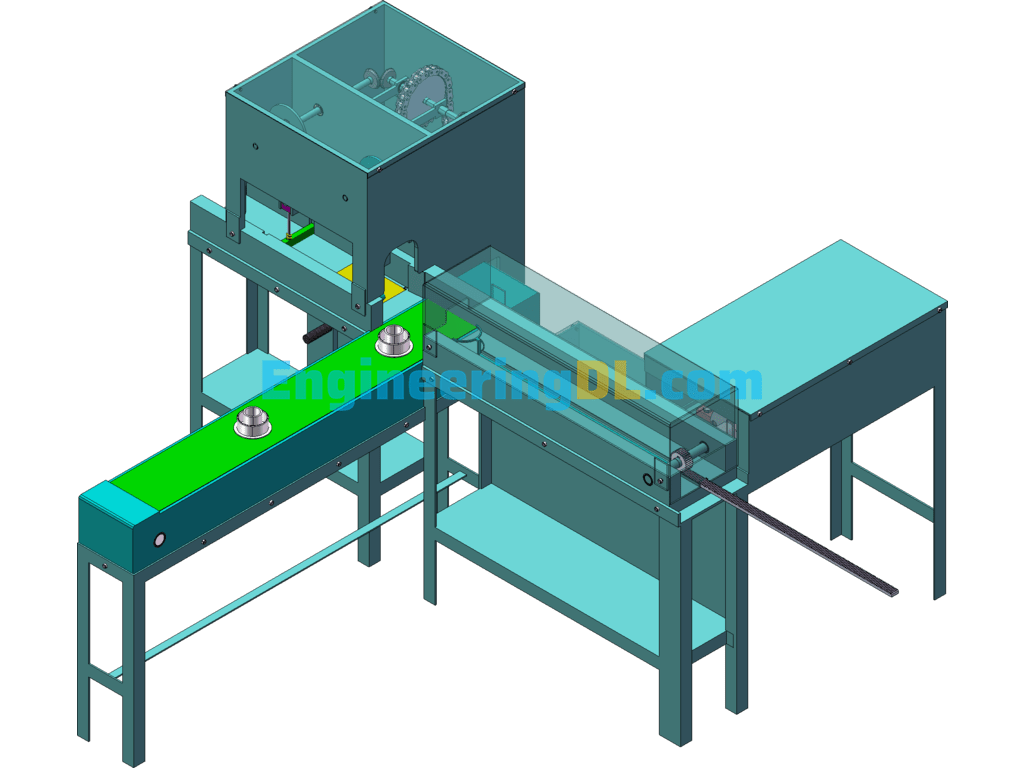

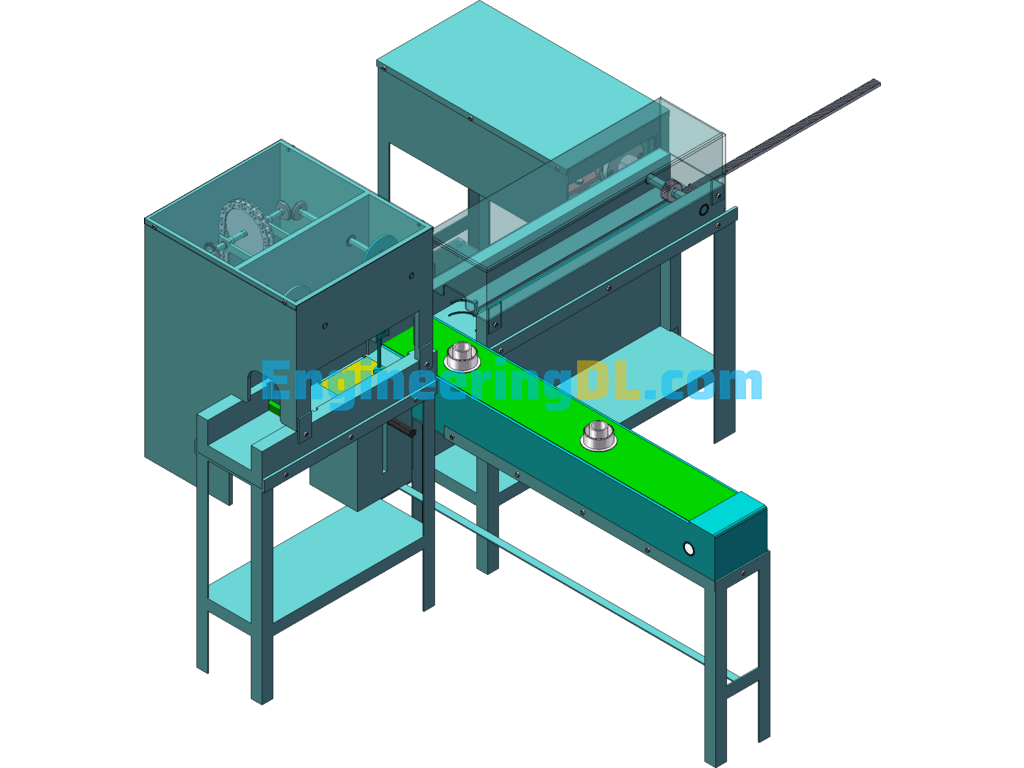

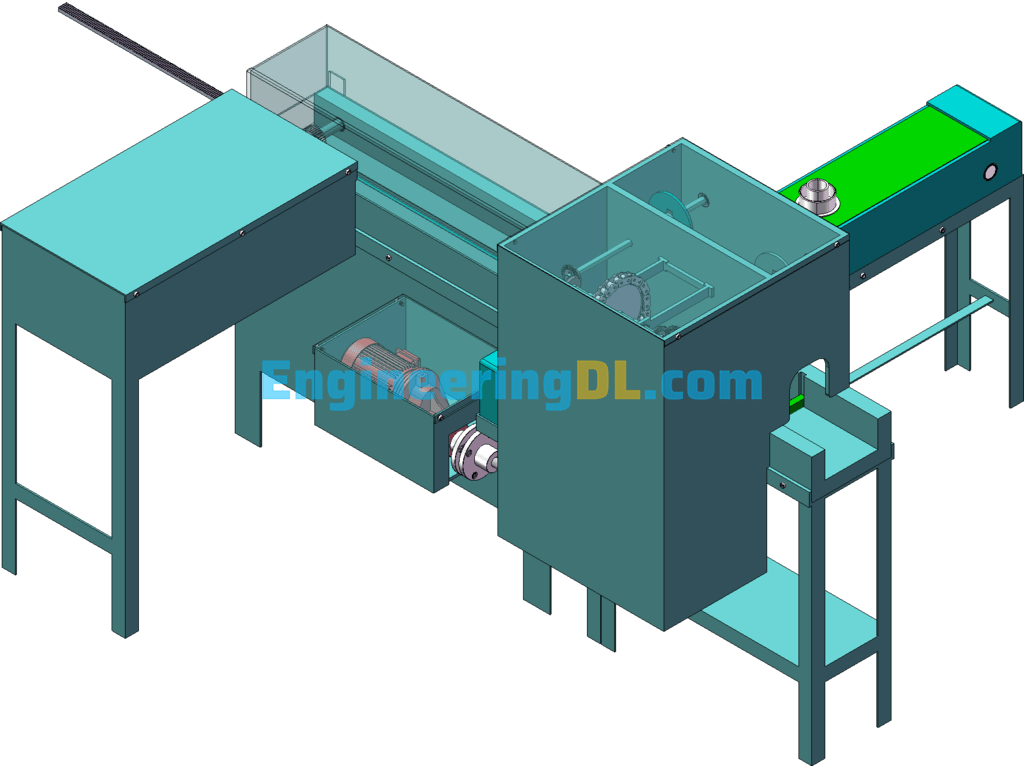

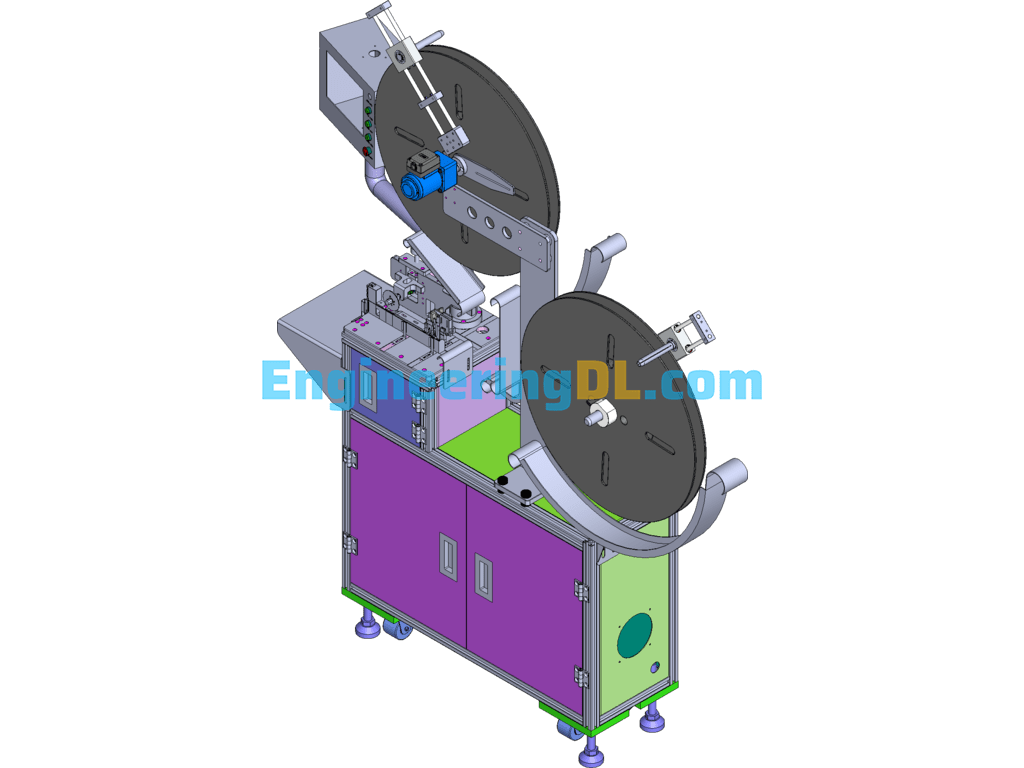

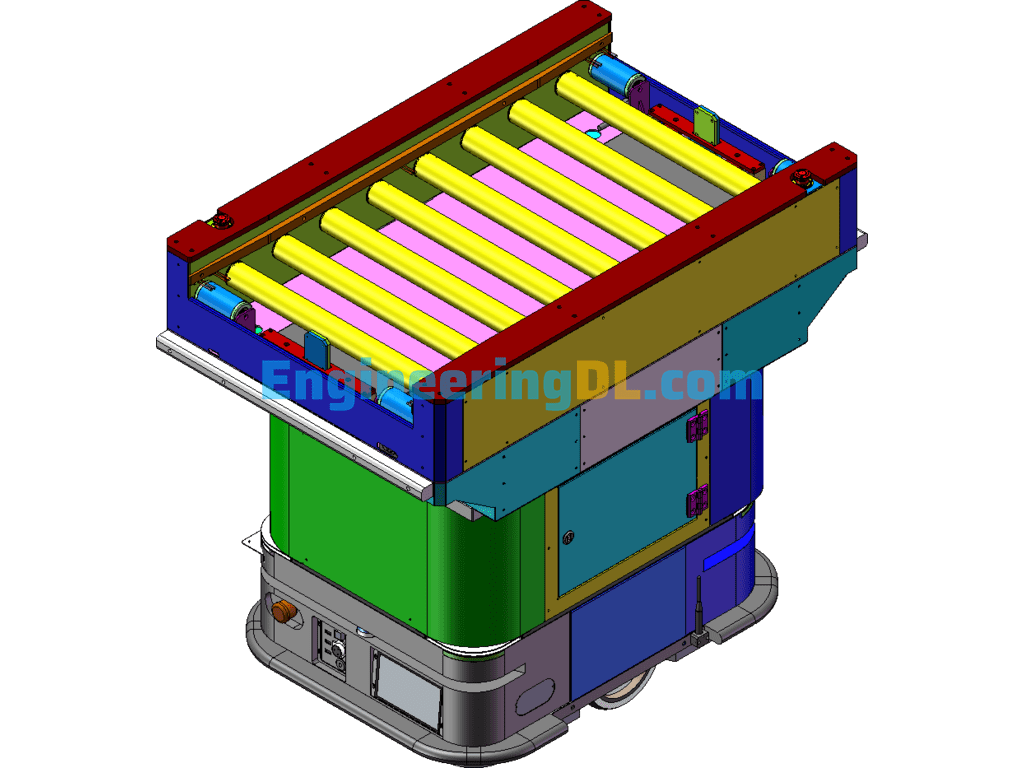

Design of paper bag packaging machine for tableware packaging [including SW 3D modeling and 9 CAD drawings

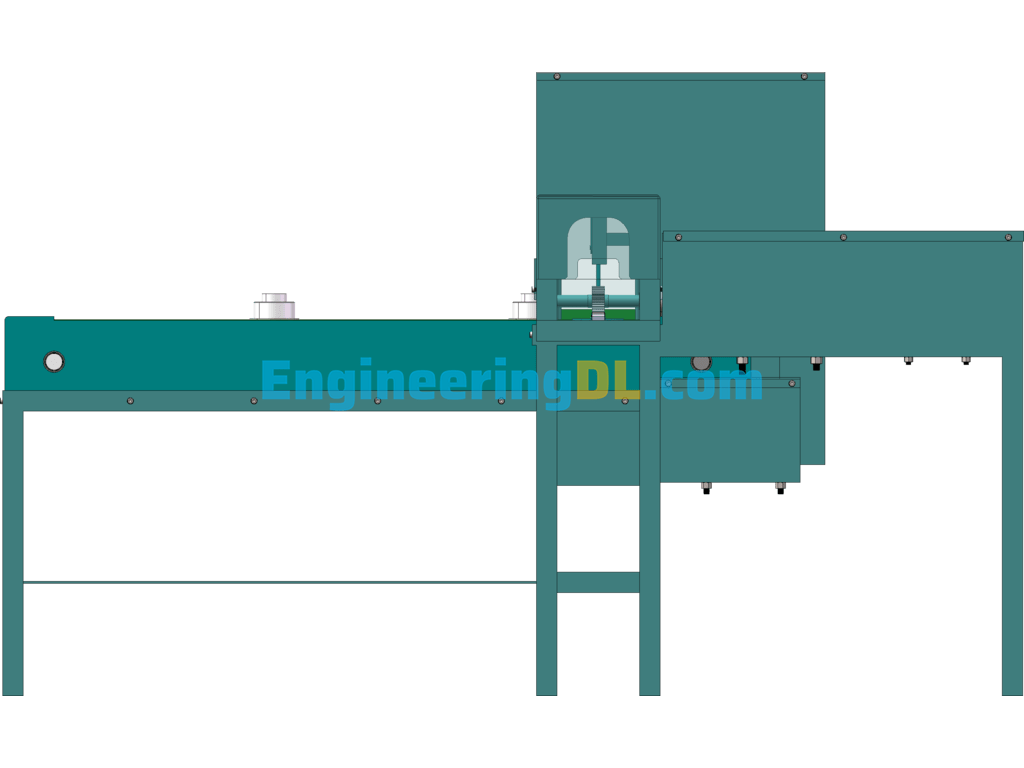

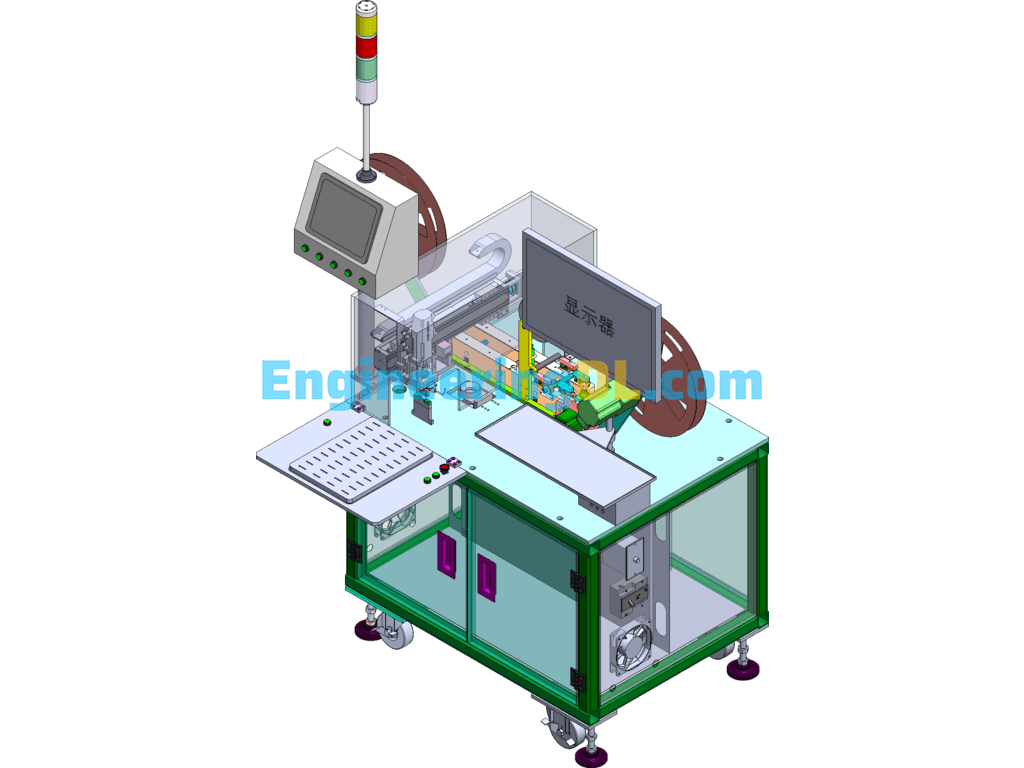

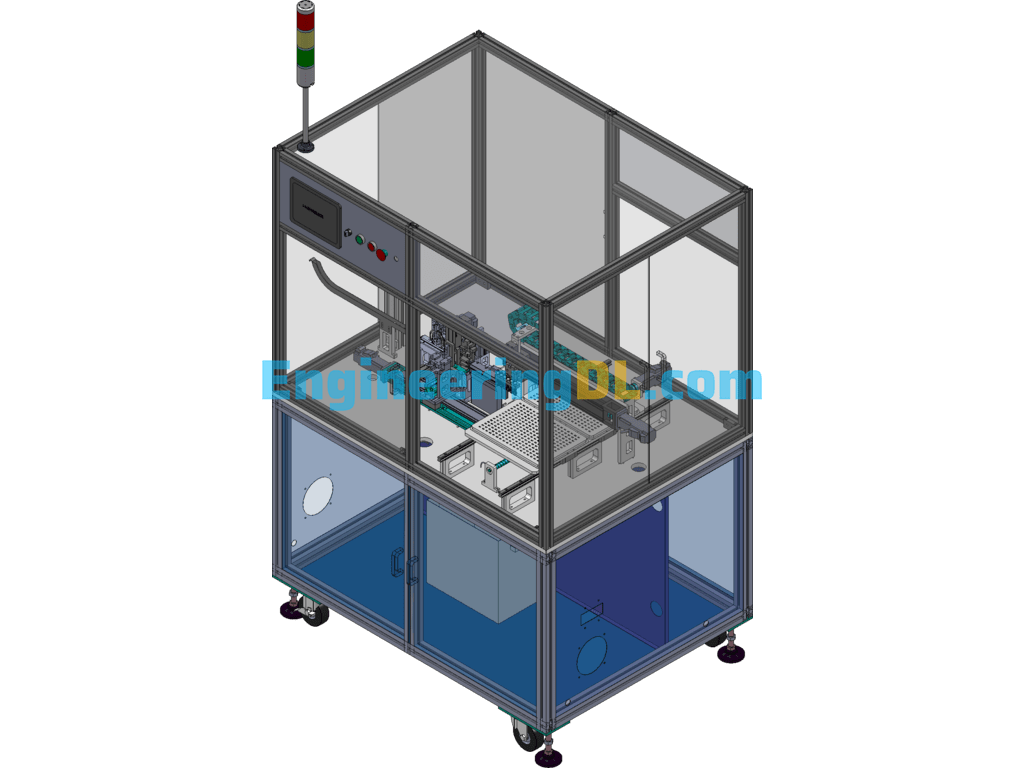

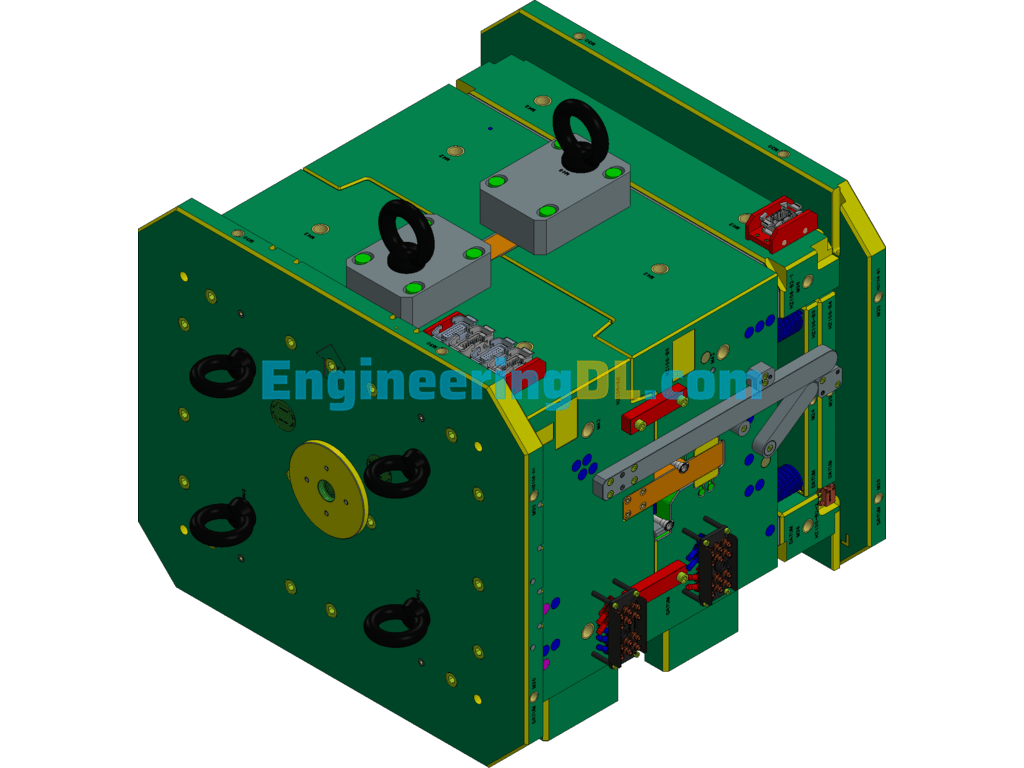

This a continuous paper bag tableware packaging machine. The machine consists of several parts such as conveyor belt mechanism feeding part, rack and pinion pushing part, paper bag pushing part, paper bag opening part, paper bag heat sealing part and power source – secondary reducer and motor. The whole packaging process is automated. Compared with modern machinery, this machine achieves high speed and continuity, and has the advantages of high productivity, low power consumption, simple use, easy and reliable maintenance, etc. Keywords: tableware; special paper bag; packaging machine; heat sealing mechanism

This paper paper paper bag tableware packaging machine, solve the traditional plastic film packaging resource pollution problem, effectively alleviate the problem of white pollution, and packaging speed, precision is also very good, practical, packaging out of good quality, good efficiency. This paper mainly accomplishes the following aspects.

(1) Determine the material and basic size of the paper bag.

(2) determine the technical parameters of the paper bag tableware packaging machine, analyze the main components of the mechanism and the principle of movement.

(3) Determine the transmission scheme of the paper bag cutlery packaging machine, i.e. crank slider bag opening, heat sealing mechanism, rack and pinion mechanism, etc.

(4) Determined the fit time of the three mechanisms

(5) The actuator of the paper bag tableware packaging machine was reasonably selected and designed to enable the packaging to be completed smoothly.

The key parts of the packaging machine system were drawn using Auto CAD design software, the key dimensions of the components and assemblies were accurately described, and the design was checked and modified. Determining whether the movements of the various related parts were coordinated solved many problems that would have needed to be solved after the prototype was built.

This design is for a machine applied to a specific packaging production situation for tableware, and further research is needed in the future. For example, how to achieve packaging for different objects and different packaging requirements without replacing the functional components and only with proper adjustment. Another example: how to further improve the reliability and coordination of system operation, so that the system has a certain degree of strain on the failure. With the expansion and efficiency of production, how to make the packaging machine more scale and productivity, which requires more integration with advanced mechanical components. This is the trend of the future.

———- reviewer has something to say ————

Very detailed graduation design, including 3D + CAD drawings + design instructions, so rated diamond!

Specification: Design Of Paper Bag Packaging Machine For Tableware Packaging (3D+CAD+Instructions) SolidWorks, AutoCAD, 3D Exported

|

User Reviews

Be the first to review “Design Of Paper Bag Packaging Machine For Tableware Packaging (3D+CAD+Instructions) SolidWorks, AutoCAD, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.