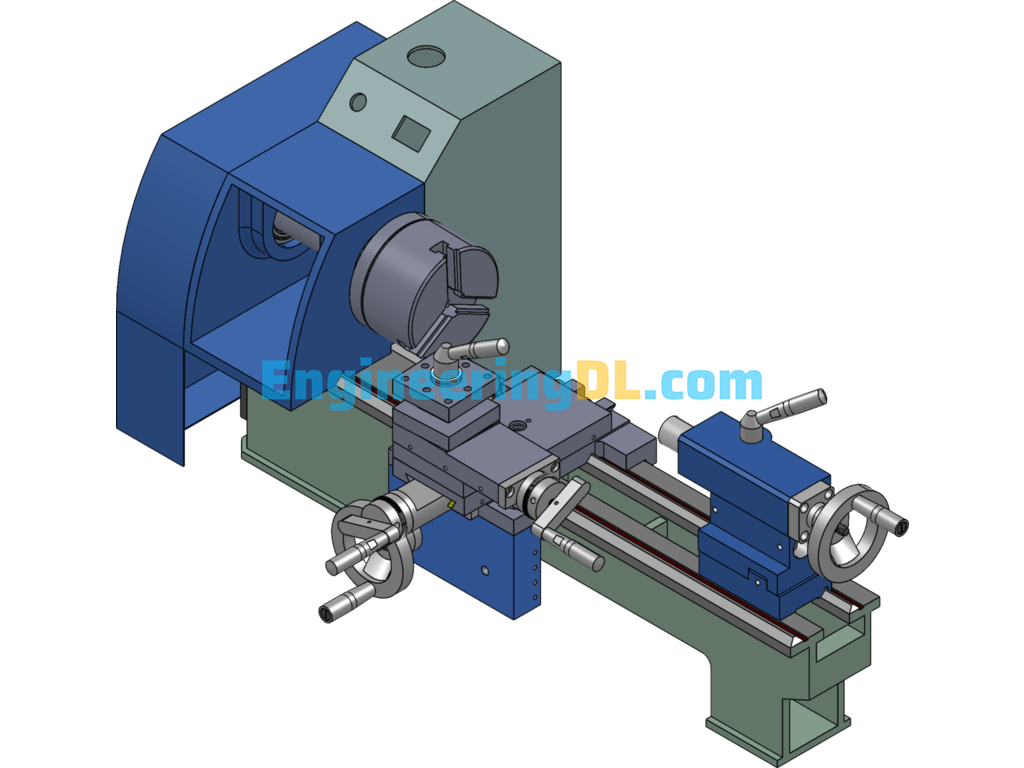

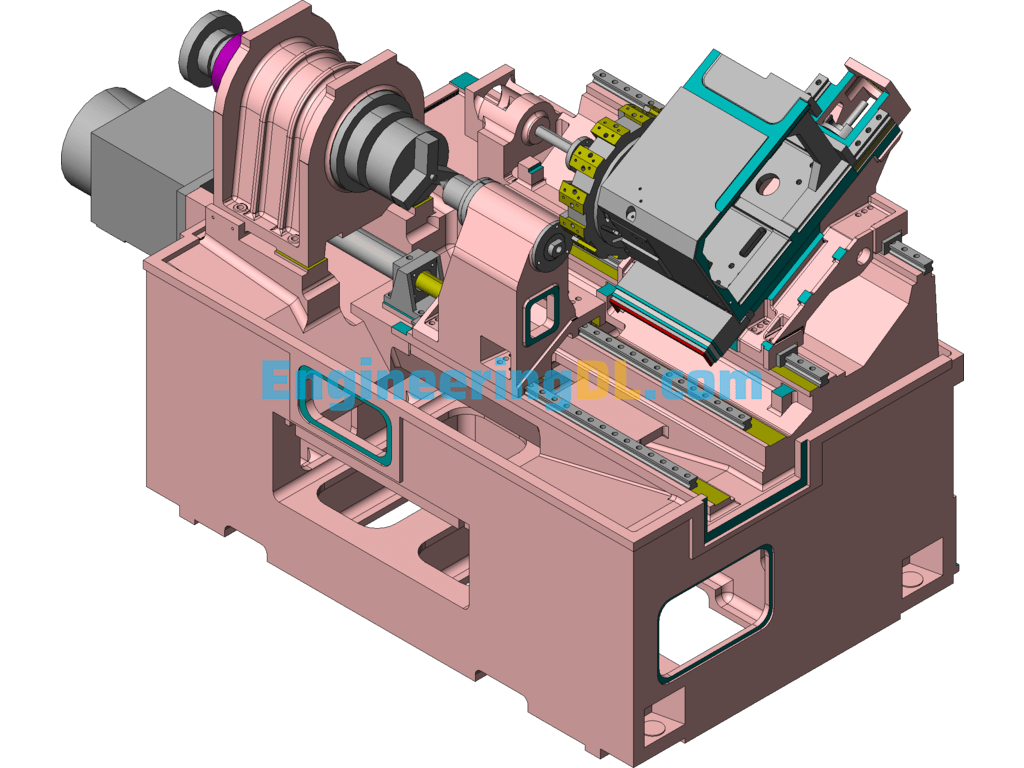

A lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. Drills, reamers, reamers, taps, plates and knurling tools are also available on the lathe for corresponding machining.

Its components include.

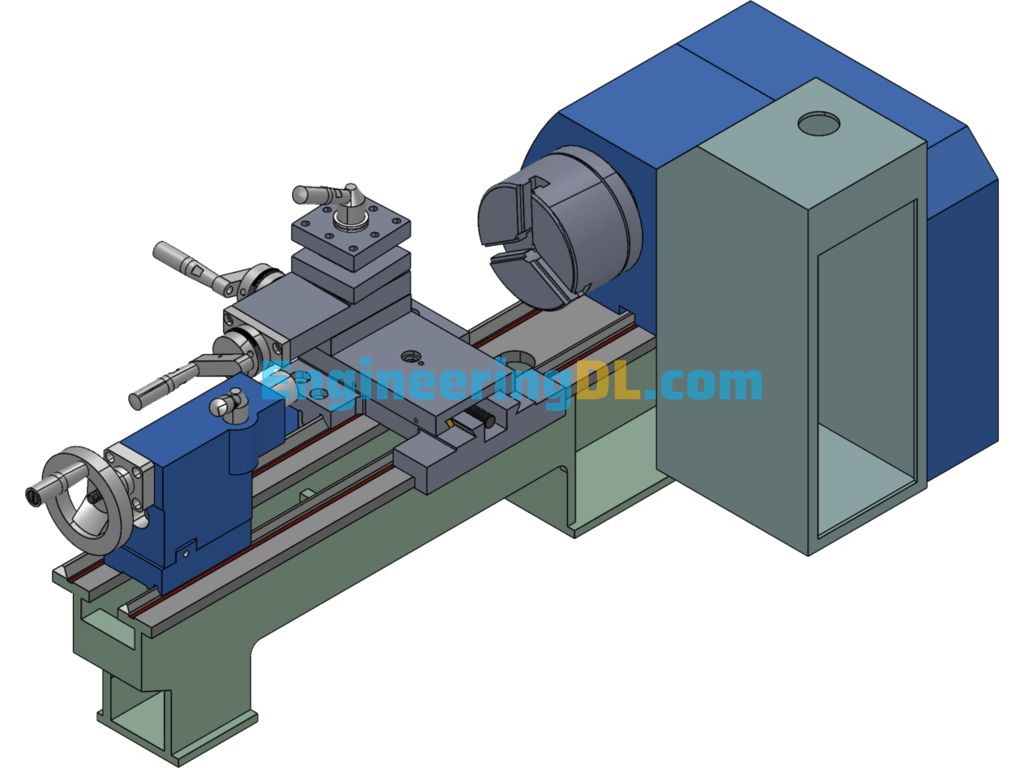

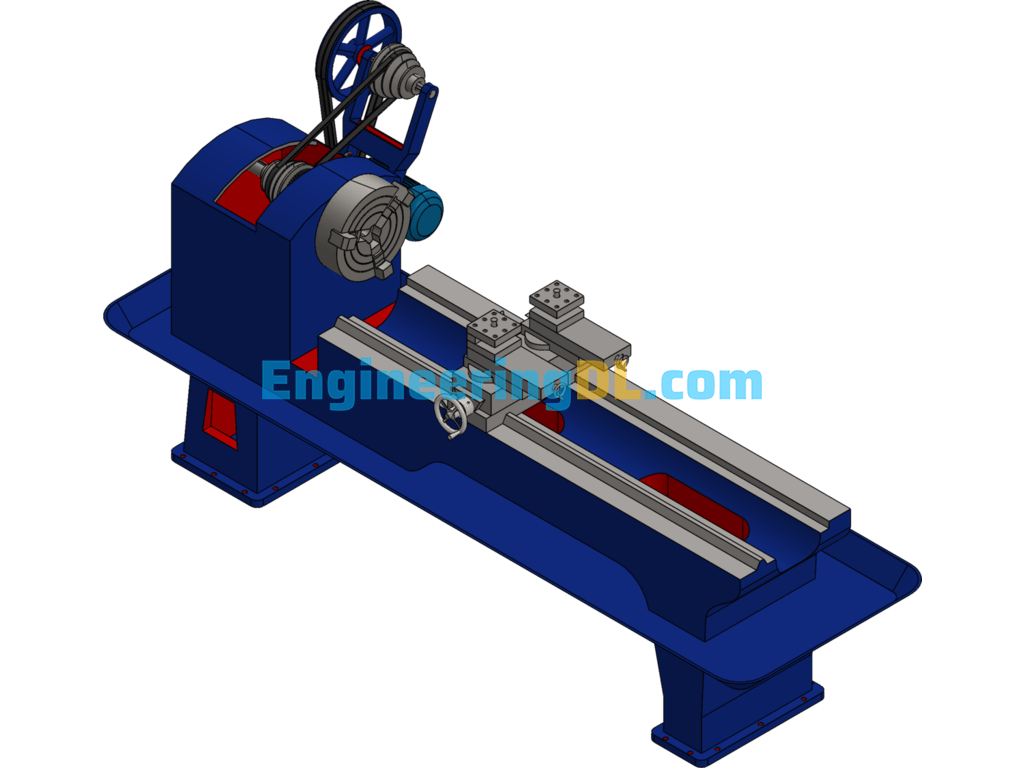

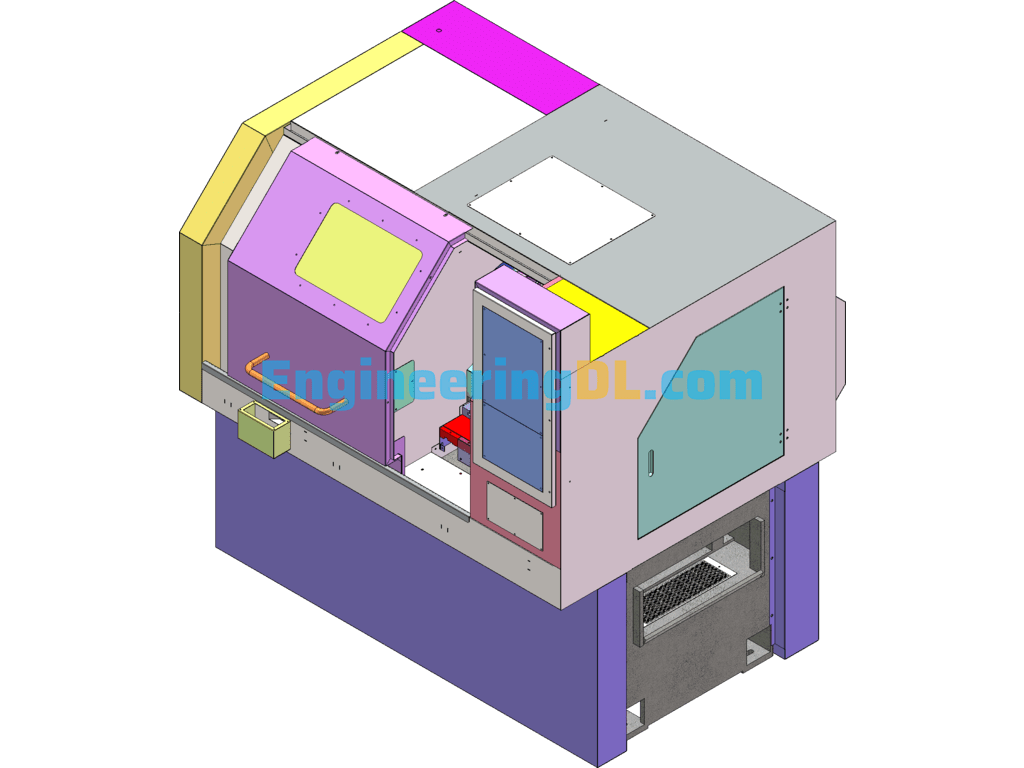

Spindle box: also known as the bed box, its main task is to the main motor from the rotary motion through a series of variable speed mechanism so that the spindle to get the required forward and reverse two different speeds of steering, while the spindle box to divide part of the power will be transmitted to the movement of the feed box.

Feed box: also known as tool box, the feed box is equipped with a variable speed mechanism for the feed motion, adjust its variable speed mechanism to get the required feed or pitch, and transmit the motion to the tool holder for cutting through the light bar or screw.

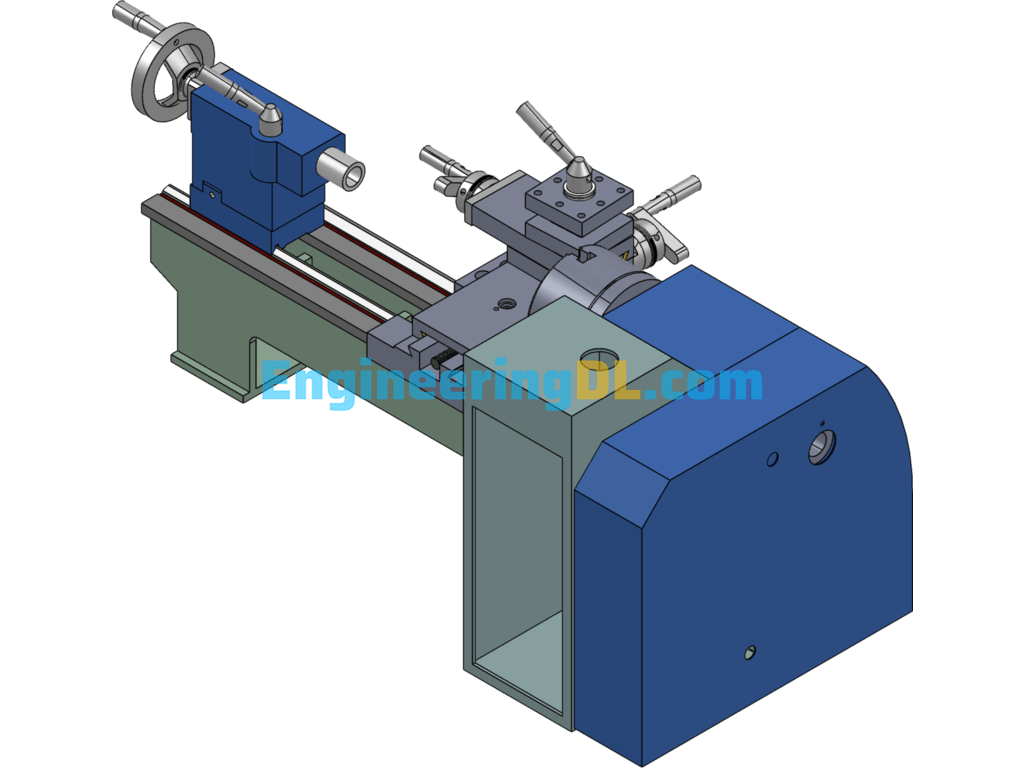

Screw and light bar: used to connect the feed box and the slide box, and transmit the motion and power of the feed box to the slide box, so that the slide box can get longitudinal linear motion. The screw is specially set up for turning various threads. When turning other surfaces of the workpiece, only the light bar is used, not the screw.

Sliding plate box: It is the manipulation box for lathe feeding motion, and is equipped with a mechanism to turn the rotating motion of the light bar and the screw into the linear motion of the tool holder. The longitudinal feeding motion, transverse feeding motion and rapid movement of the tool holder are realized through the light bar drive, and the longitudinal linear motion of the tool holder is driven by the screw in order to turn the thread.

Tool holder: There are two sliding plates (middle and small sliding plates), bed saddle and tool holder body together. It is used to install the turning tool and drive the turning tool for longitudinal, transverse or oblique movement.

Tailstock: mounted on the bed guide and moved longitudinally along this guide to adjust its working position. The tailstock is mainly used to install the rear center to support longer workpieces, and also to install drills and reamers for hole processing.

Bed: It is a large basic part of lathe with high precision requirement guide rail (mountain guide and flat guide rail). It is used to support and connect the various parts of the lathe and ensure the accurate relative position of each part when working.

Cooling device: The cooling device is mainly used to lower the cutting temperature, flush away the chips and lubricate the machining surface by spraying the cutting fluid in the water tank under pressure to the cutting area through the cooling water pump to improve the tool life and the surface machining quality of the workpiece.

The drawing contains source files and step format

Specification: D180x300V Lathe SolidWorks, 3D Exported

|

User Reviews

Be the first to review “D180x300V Lathe SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.