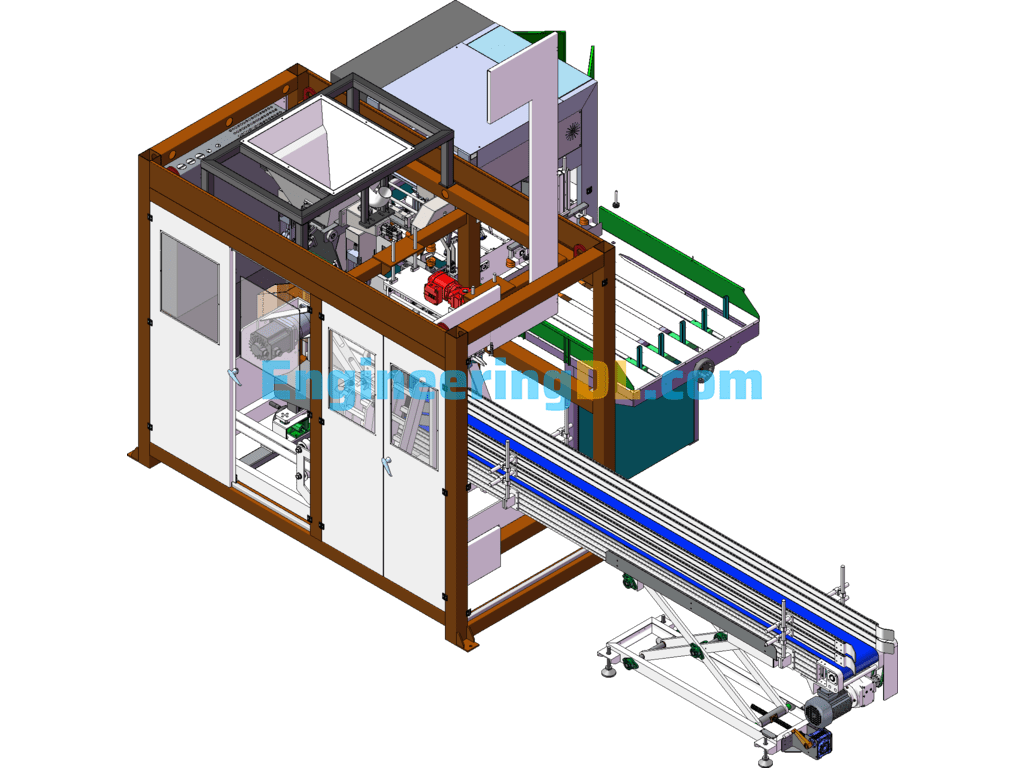

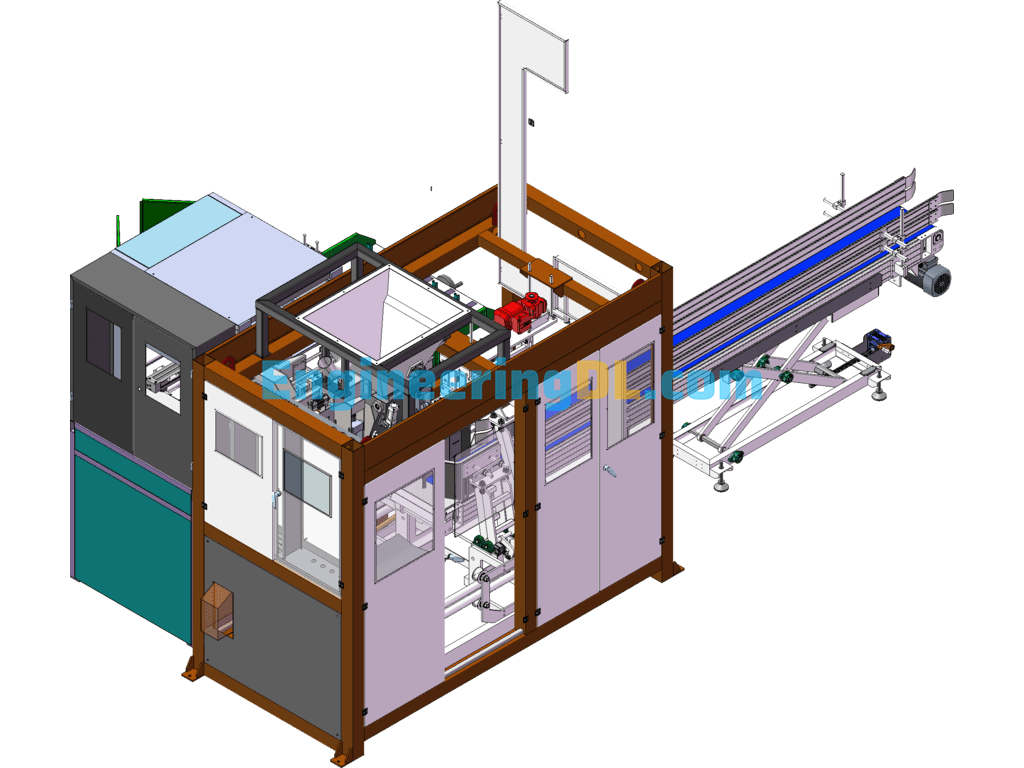

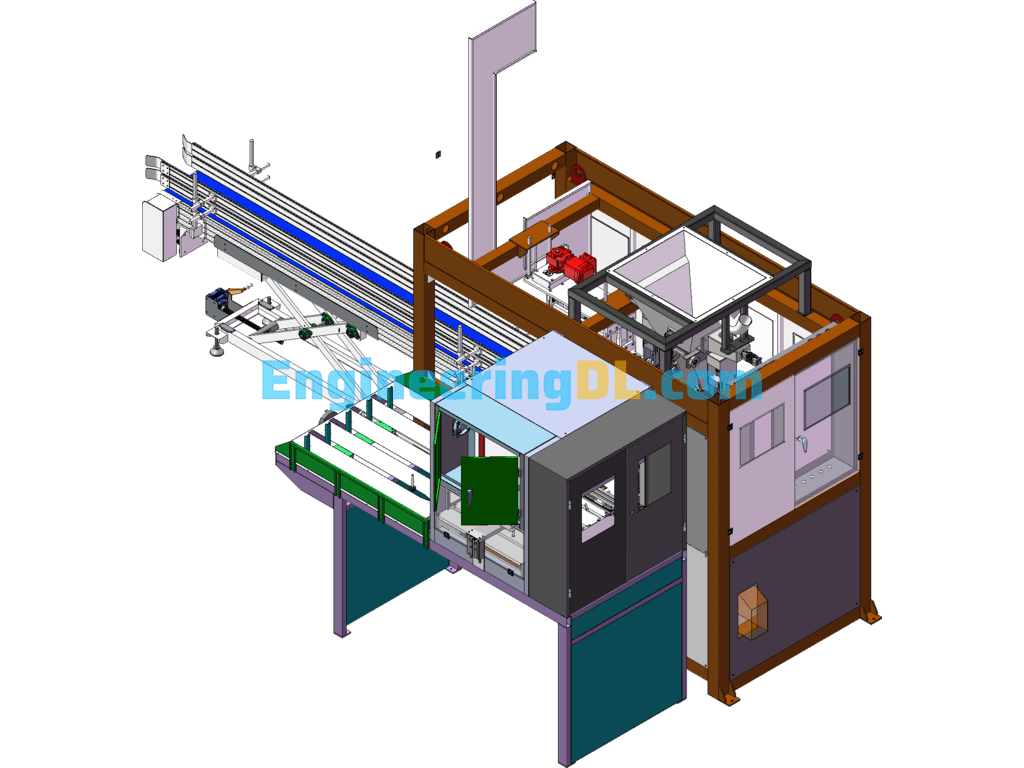

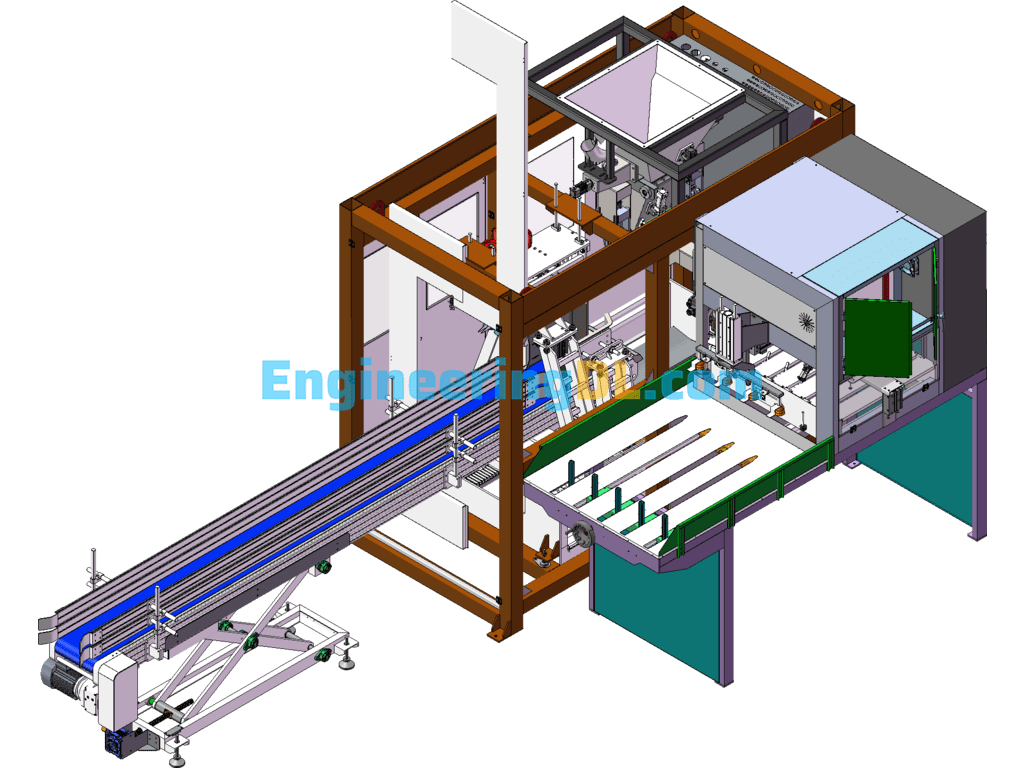

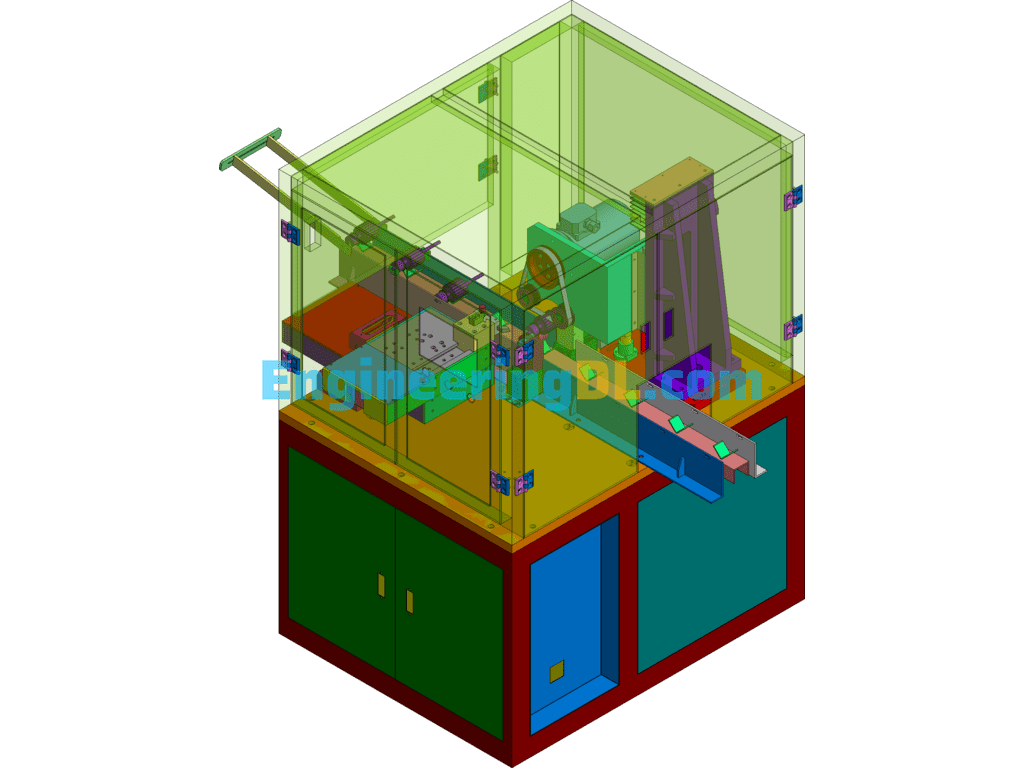

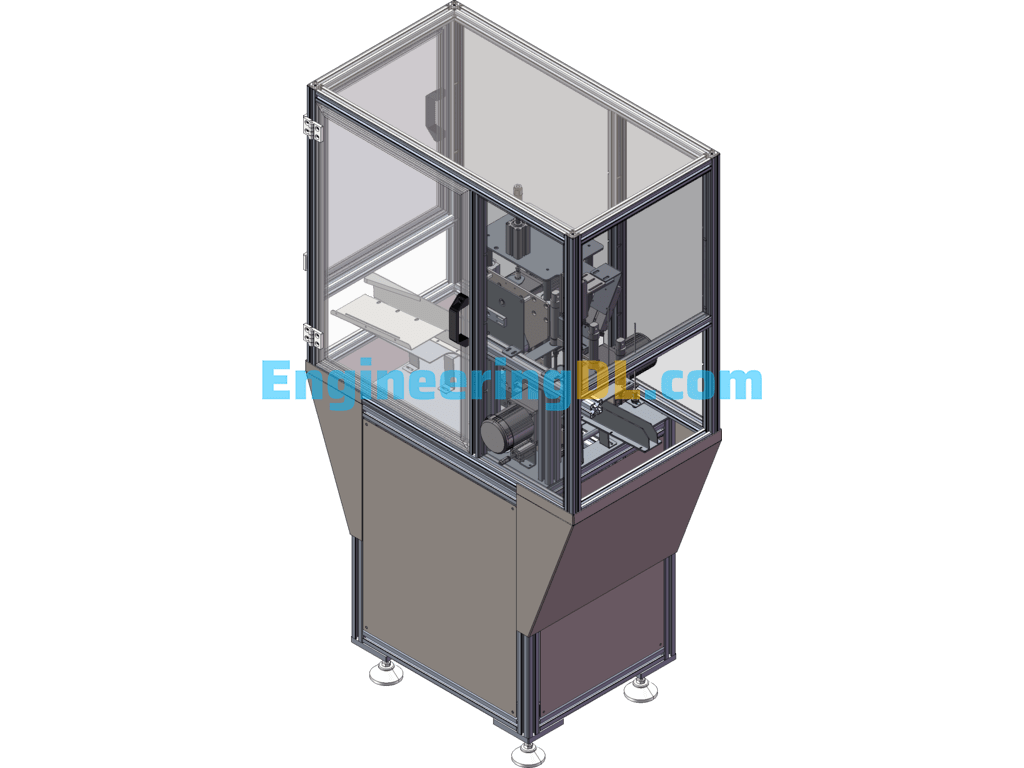

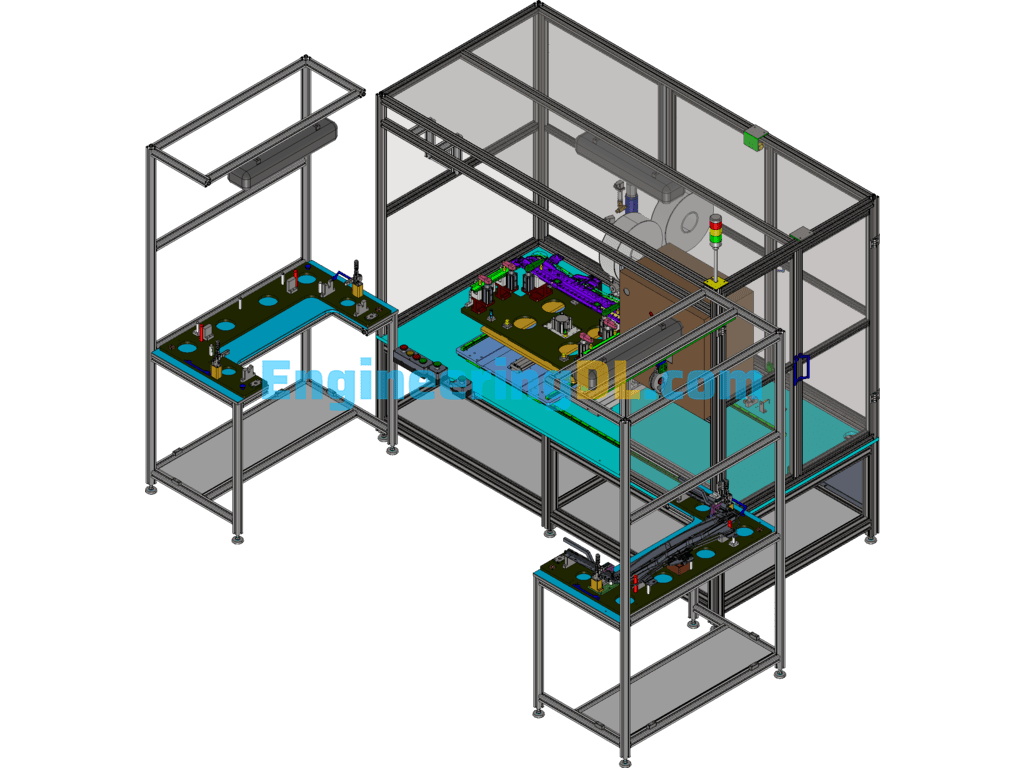

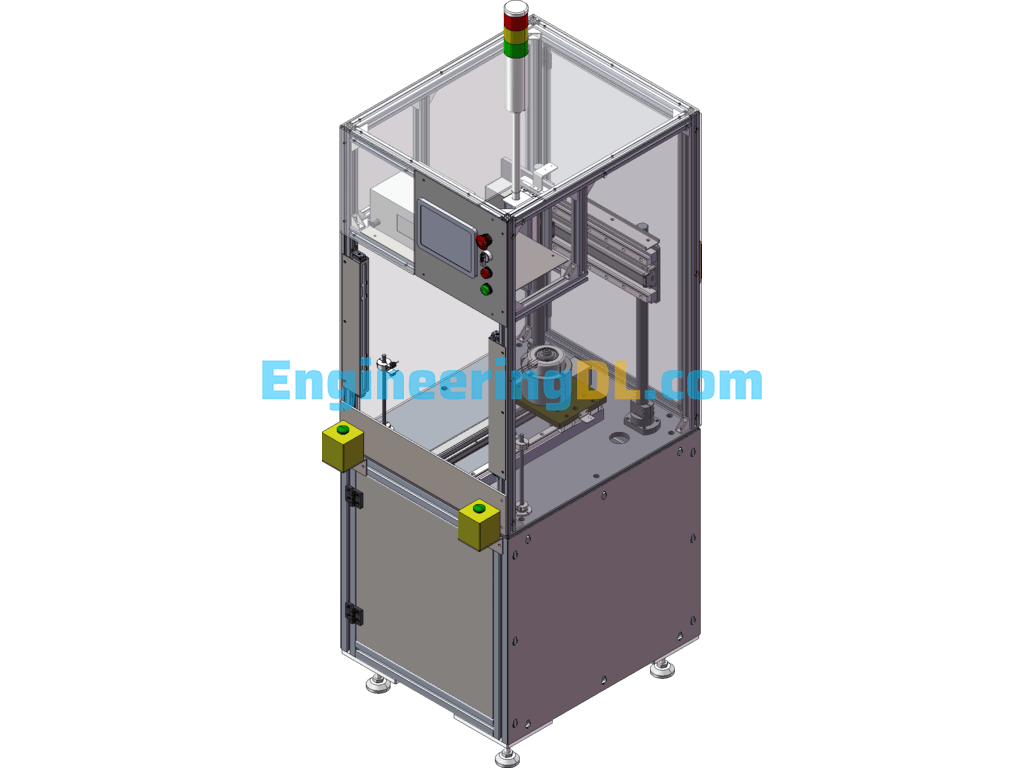

Automatic top bag packaging machine model contains the following structures: bag holder, bag out conveyor, bag mouth limit device, bag pairer, bag feeder, filling mouth assembly, feeder, bag opener, bag picker, bag picker, bag dragger, outer frame assembly, bag presser, guide, bag shaker and other mechanisms. Include list BOM and three-dimensional model The automatic bag packing machine adopts the industry’s leading design ideas, is the ideal equipment for 25KG packaging, strong flexible production, simple and firm structure, easy operation, stable use, low maintenance and other advantages, not only for the conventional environment, but also for dusty environments, widely used in food, chemical, fertilizer, animal protection, feed and other industries. Applicable packaging materials: fine granular or granular materials. Production capacity: 18 tons/hour (according to packing specification 25kg/bag). Packing materials automatically enter the storage bin of automatic weighing machine through the loading machine. The bag is automatically loaded to the loading station through the robot, and the weighing machine automatically drops the material into the bag. The weighed bags are put into the automatic running to the sewing machine station, and the automatic sewing machine automatically folds and seals. The equipment is compactly arranged, low energy consumption, energy-saving and efficient. Easy operation and maintenance, stable performance, low failure rate and reliable operation. Pneumatic bag clamping device automatically sets bags, pneumatic bag clamping and automatic bag dropping. With fault self detection function, it can automatically detect the status of each action of fast adding, medium adding, slow adding, weighing, stabilizing, bag clamping, discharging and bag dropping. Forced packing function in manual state, in case of failure of automatic control program, it can be operated manually to complete the packing process without interruption of production. Automatic bag-on-bag packaging machine composition is divided into: bag preparation platform, bag pickup and pre-opening, bag-on-bag robot system, bag clamping and opening system, bag tray and bag holding system, bag mouth guide and conveying system, outer frame assembly, control cabinet and electrical control system. Features of bag feed packaging machine: A). Suitable for flat plastic bags, paper-plastic composite bags and other packaging bags automatic bagging, bag opening and sacking packaging, using the pick bagging method of bagging. B). With no bag and entrapment detection function, no bag or entrapment is not firm when not filling the material. Avoid emptying of materials, thus ensuring the cleanliness of production environment and the continuity of production line. C) The bag clamping and discharging device adopts fully sealed design, and also adopts the technology of separating the discharging channel and dust removal channel to minimize the spillage of dust. The whole periphery of the machine is completely sealed. D). There is a vibrating device, after the completion of feeding, the bottom of the bag will be placed, the material in the bag will be vibrated and some of the gas will be discharged to ensure that the subsequent sealing is intact. E) Precision components are sealed design, not exposed installation, can be suitable for dust environment, which can ensure a long life of the equipment. F) All the components of the packaging machine are made by famous companies at home and abroad, which can ensure the long-term, stable and reliable operation of the equipment. G) There is a fault self-diagnosis function and sound and light alarm system, timely alarm for the problems that arise. There are open operation safety hazards, set with open door shutdown protection device to protect the safety of the operator. (H) the design of special bag outside the auxiliary exhaust mechanism, before filling to reduce the amplitude of bag opening, to discharge part of the air inside the bag, to achieve the purpose of improving the packaging speed. Spare bag bin: double discs automatically switch working mode, each disc can store more than 200 empty bags (woven bags or paper bags), equipped with vacuum detection system when taking bags. The placement of empty bags is detected by the detection device. Filling station: automatic bagging machine can automatically and continuously pick up bags, open bags, automatically detect and automatically fill bags, etc. The materials released from the electronic quantitative scale are loaded into the bags through the transition hopper and the bags are transferred to the vertical bag conveyor. The machine can realize the functions of pneumatic claw hand bag clamping, vacuum suction cup bag opening, positive and negative pressure detection, automatic bag discarding, etc. Clamping and shaping machine: complete the closing of full bags to ensure that the mouth of the bag enters the folding machine smoothly.

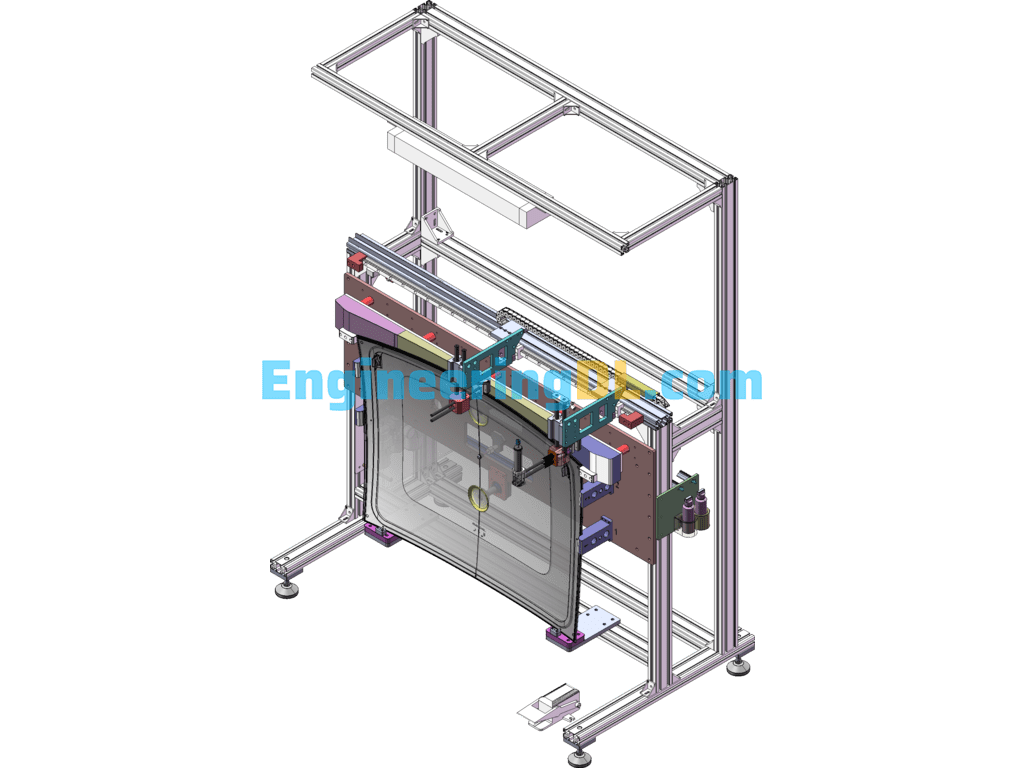

Specification: Automatic Sleeve Packaging Machine 3D Drawing + Bom List SolidWorks, AutoCAD, 3D Exported

|

User Reviews

Be the first to review “Automatic Sleeve Packaging Machine 3D Drawing + Bom List SolidWorks, AutoCAD, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.