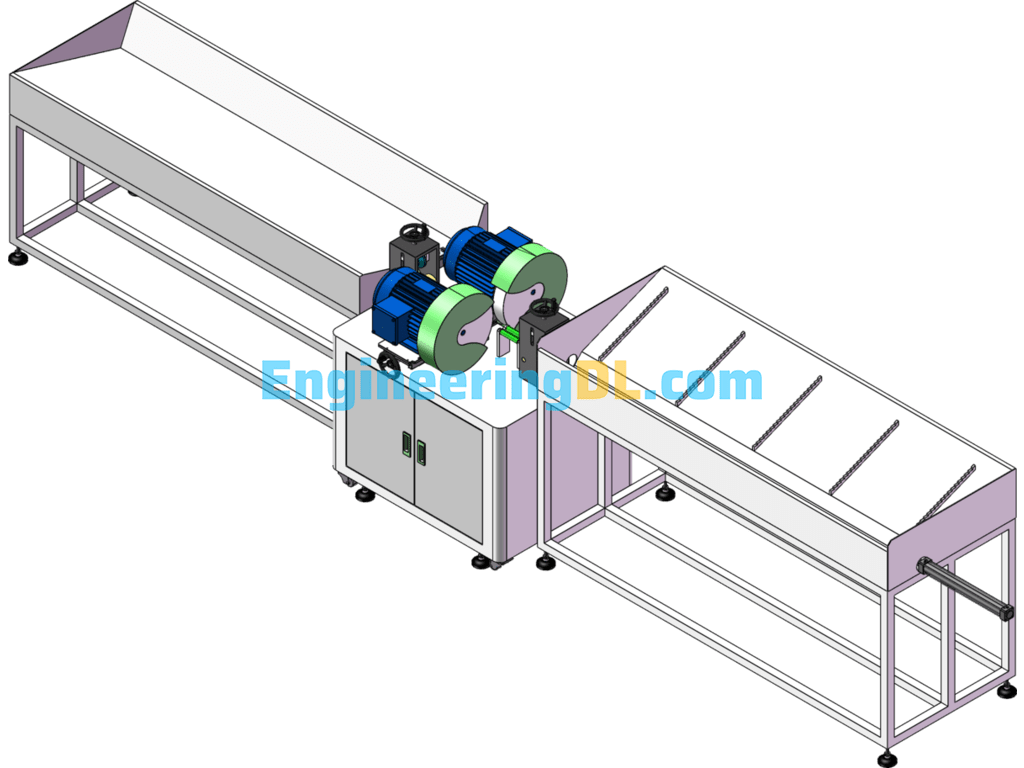

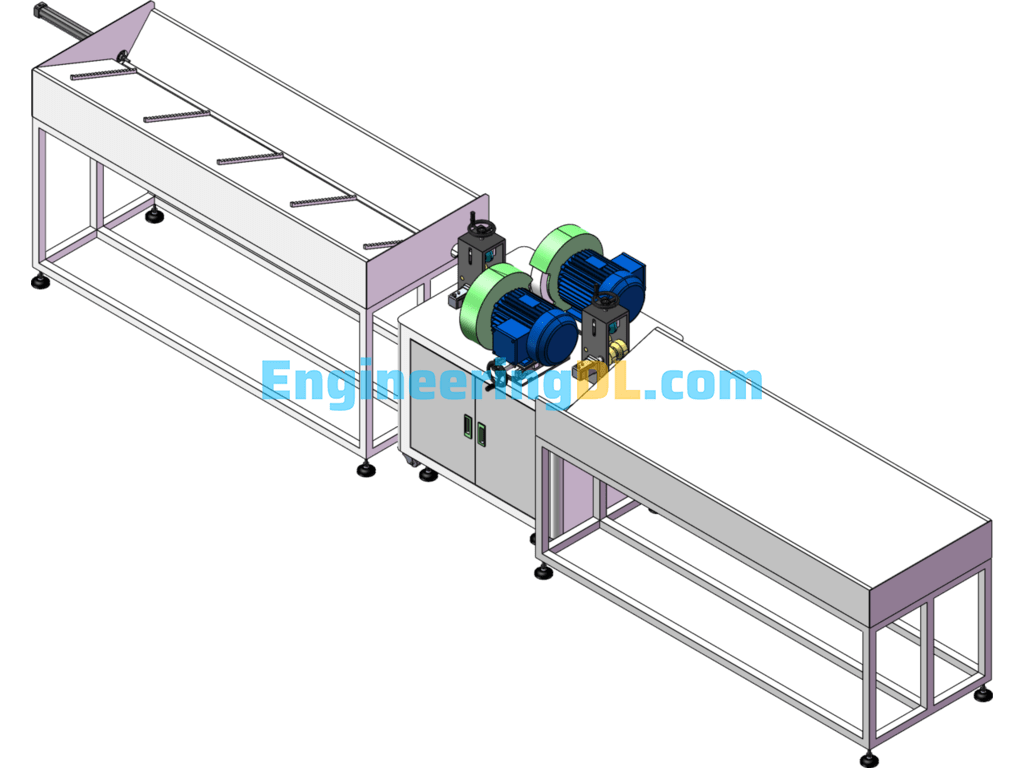

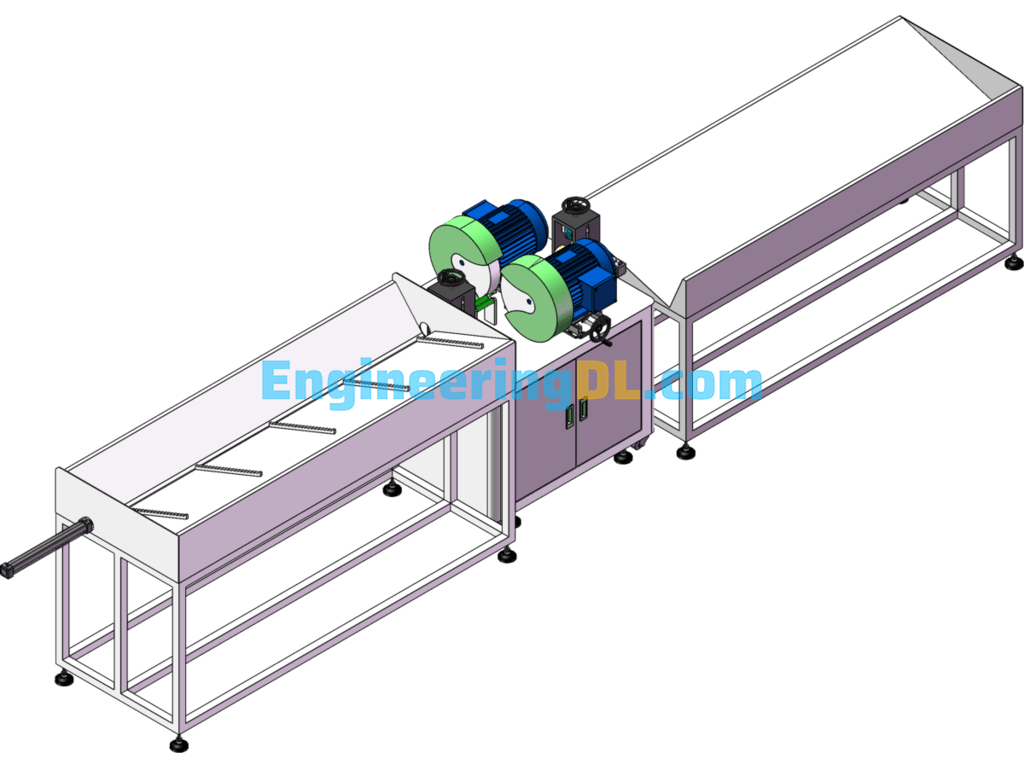

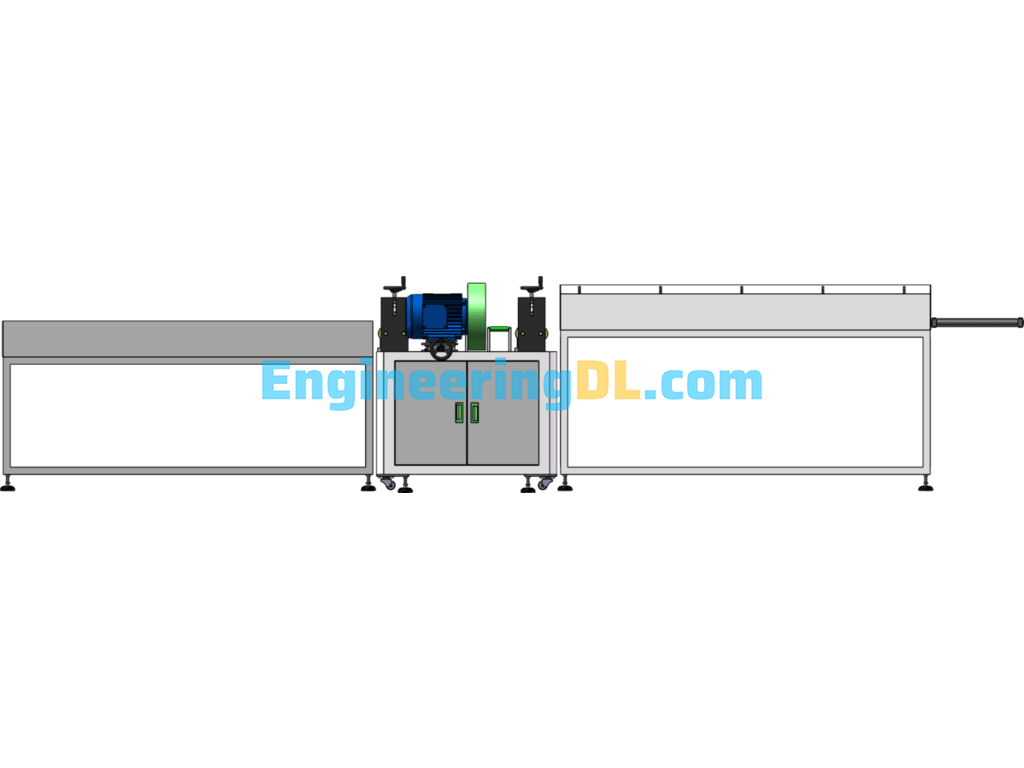

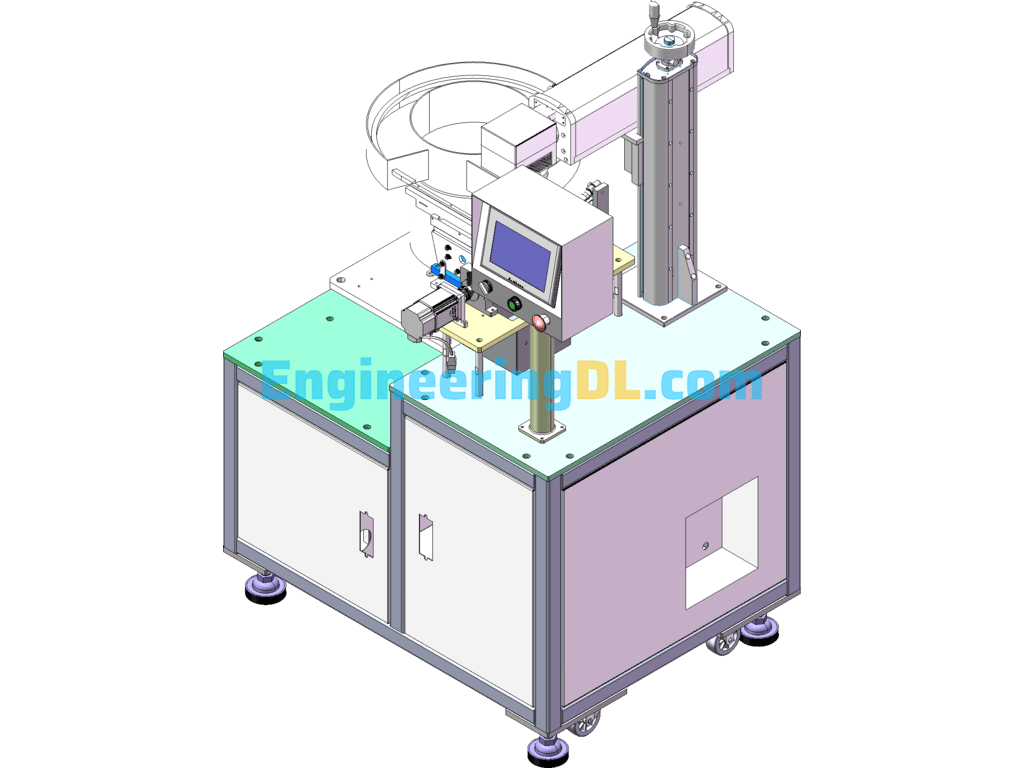

This equipment is a pipe automatic polishing equipment, that is, after the long pipe is cut into short pipe and both ends are sealed and welded, the surface of the pipe is brushed or mirror polished. Use this equipment to complete the product polishing treatment to improve PPH and reduce manpower one of the automated equipment. The automation target is tentatively set at 0.8 degree of finish after treatment, CT is about 60 S/ piece, capacity is more than 60 pieces/H. By being able to adapt to the production of different lengths of pipes. Other specifications according to the general standards of the industry. Main structure

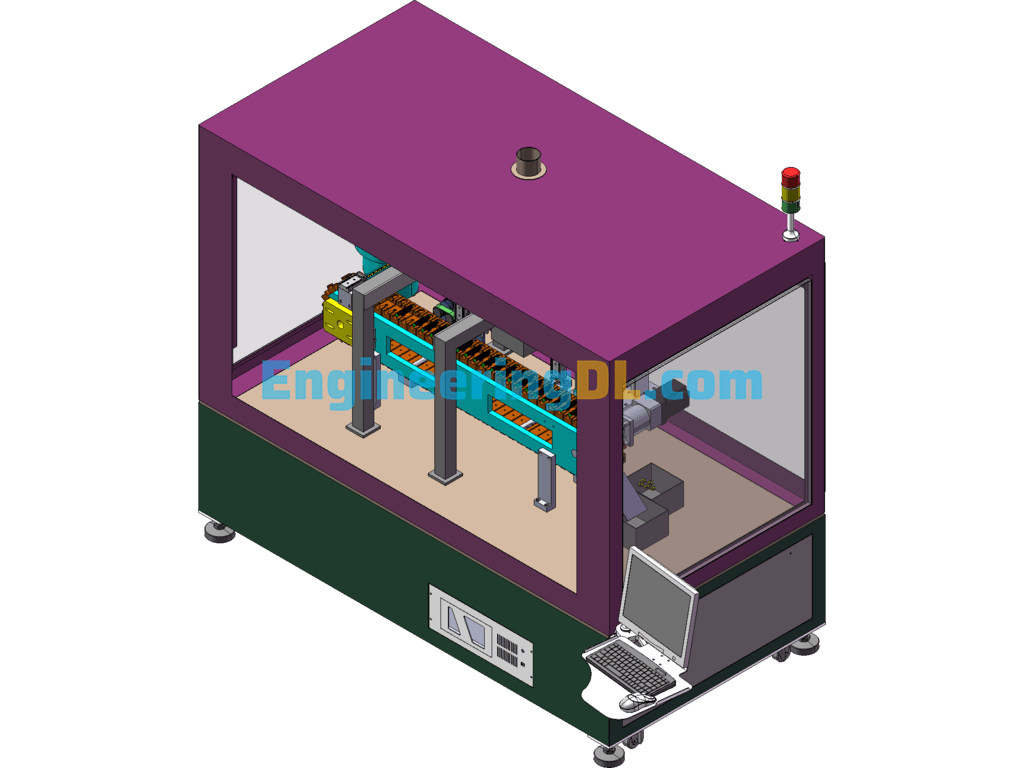

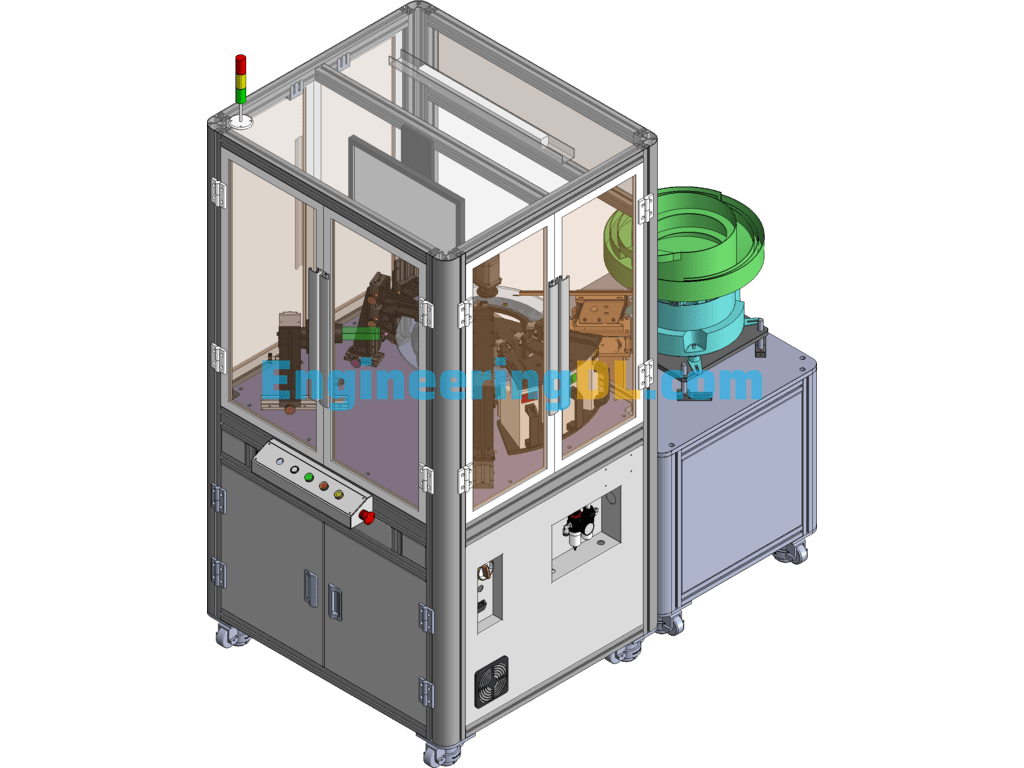

1. High rigidity frame: square tube & white sheet metal baking paint parts, transparent observation window.

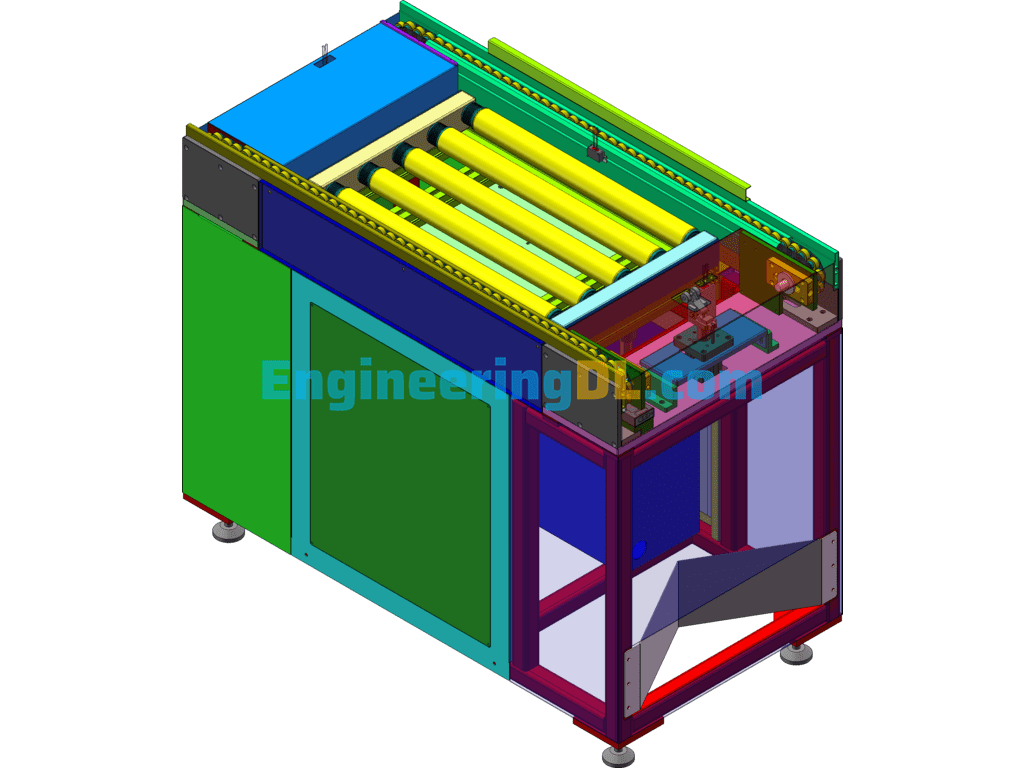

2. pipe division & push feeding machine: cylinder, stepping motor & speed reduction mechanism, can adapt to different diameter feeding roller, pipe jacking and positioning mechanism;

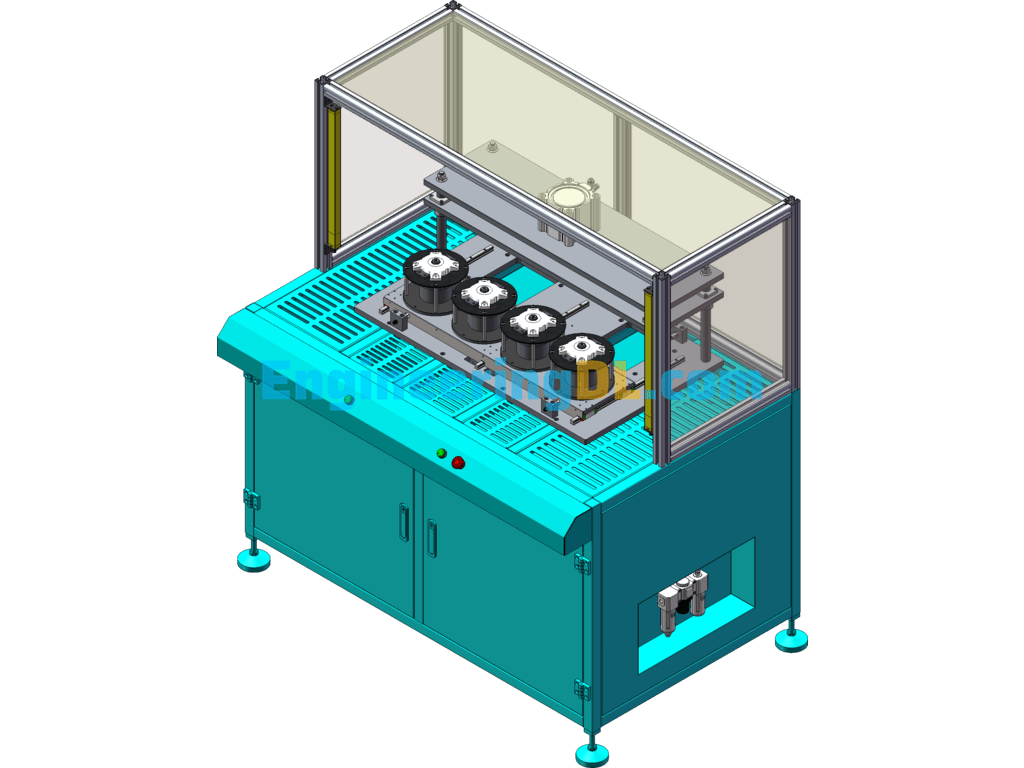

3. inclined duplex polishing mechanism: polishing wheel position & angle adjustment mechanism, slide rail, screw & front and rear adjustment mechanism;

4. adjustable jig: precision adjustment jig cavity size, anti-static;

5. control system. Contains PLC, HMI, electrical box and other main control units and detection, safety alarm, counting and other hardware and software systems.

(The diagram is for reference, the actual plan is subject to the final review and confirmation of the drawings)

User Reviews

Be the first to review “Automatic Polishing Machine For Pipes (Steel Pipes) SolidWorks”

You must be logged in to post a review.

There are no reviews yet.