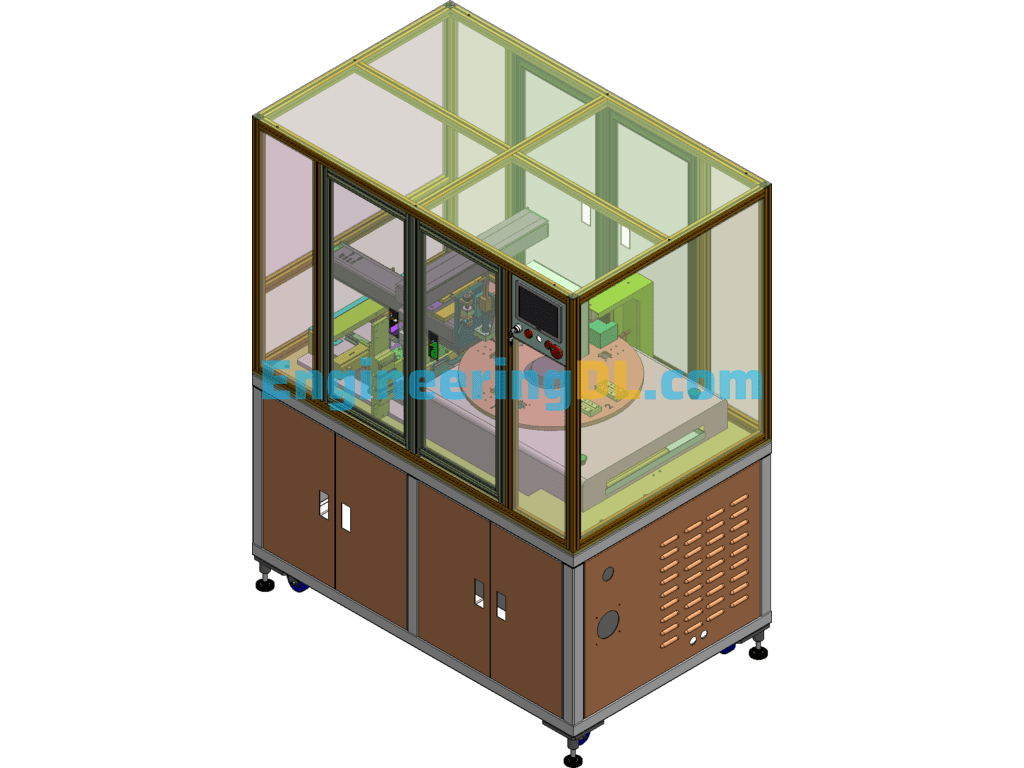

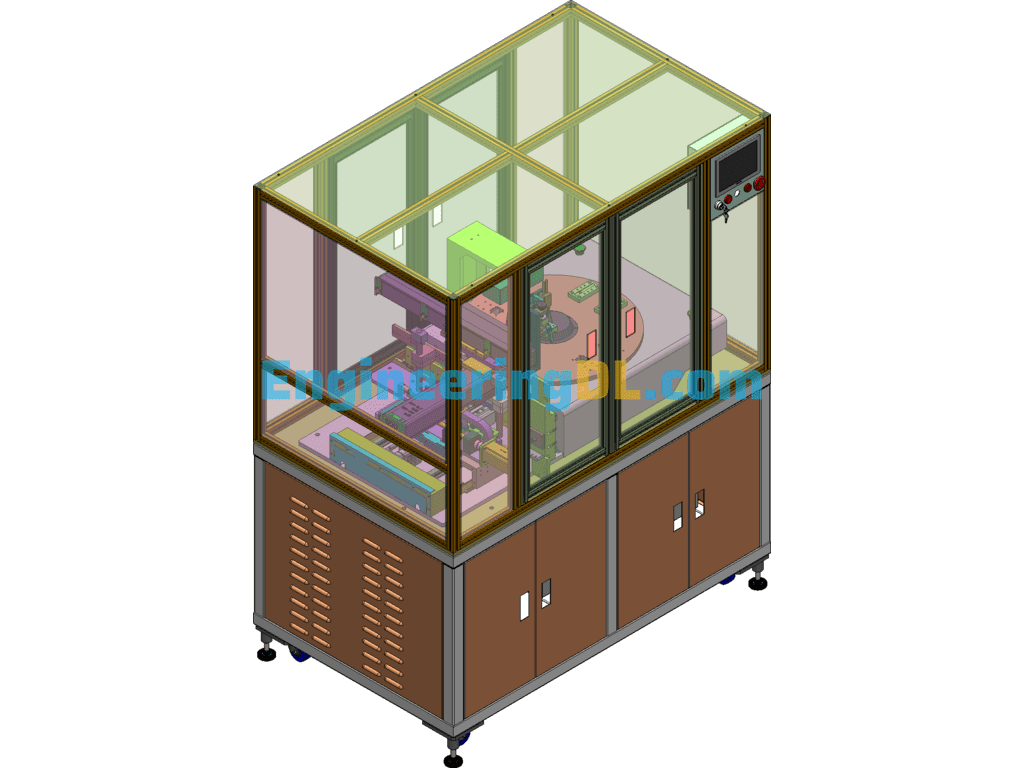

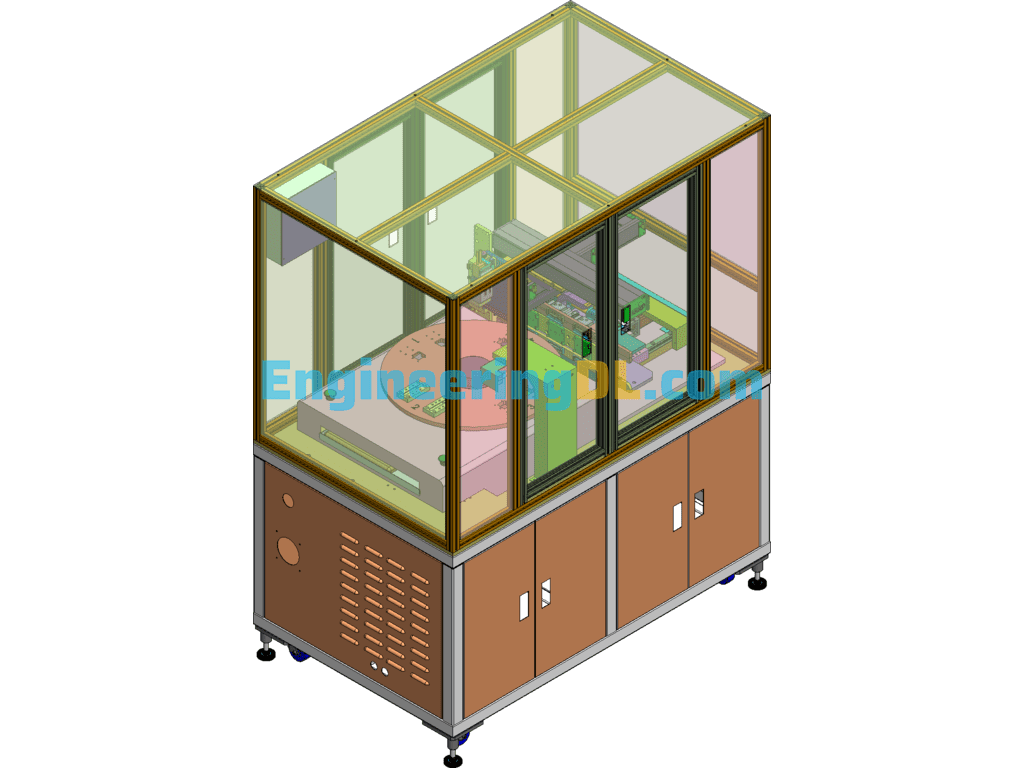

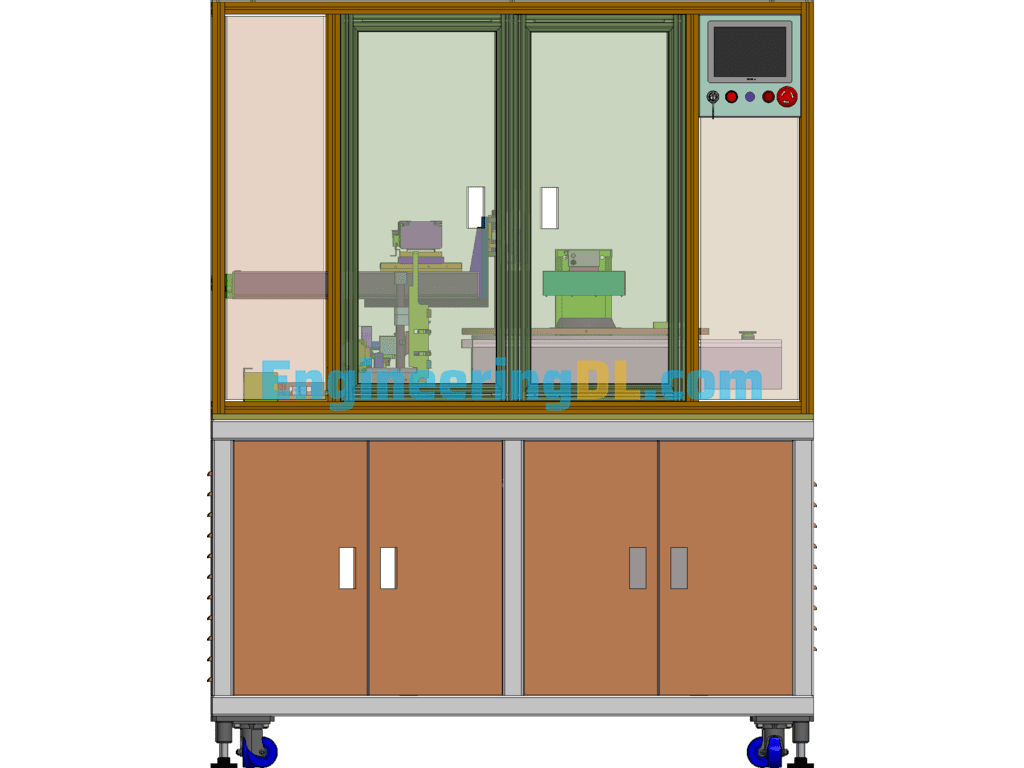

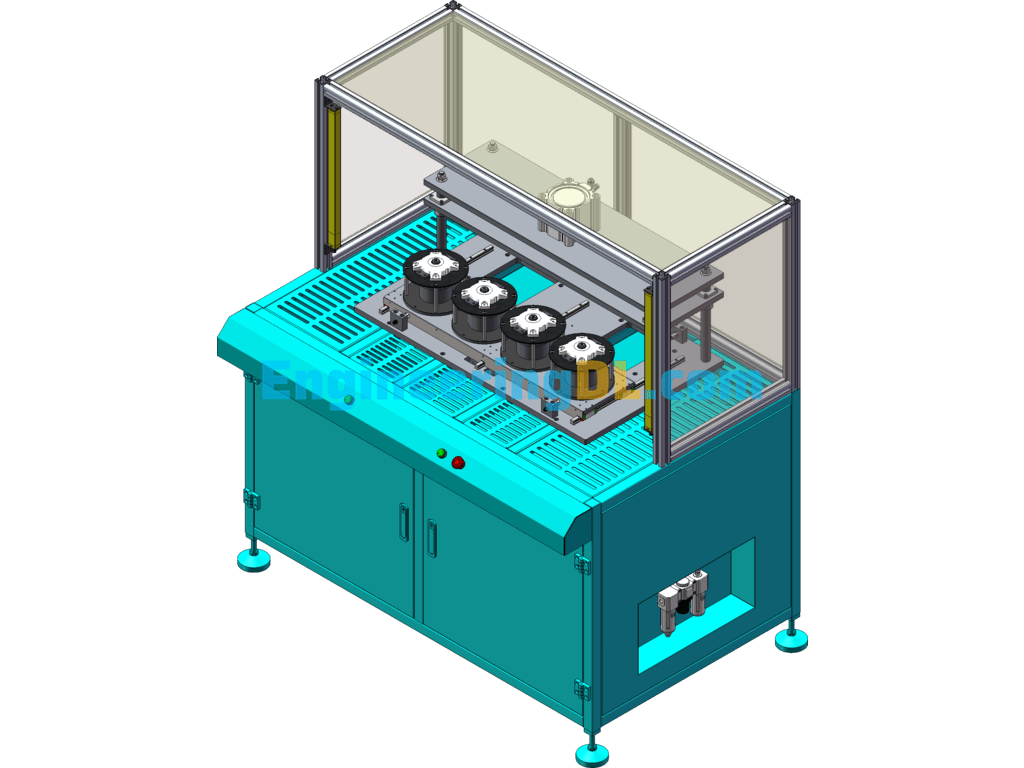

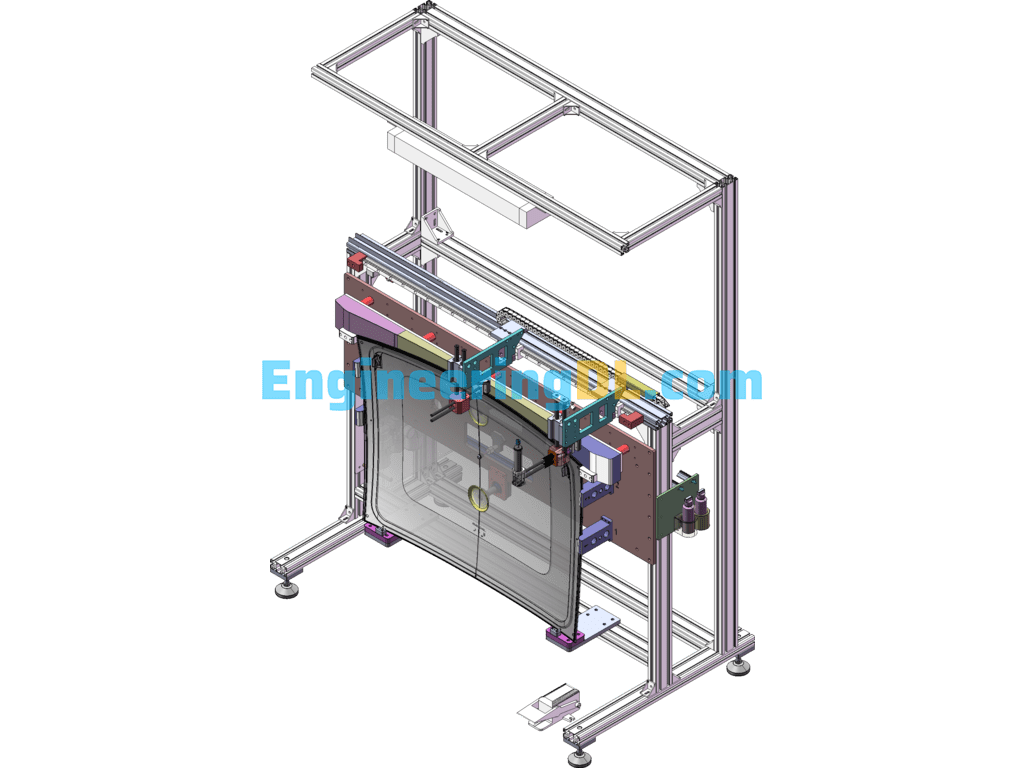

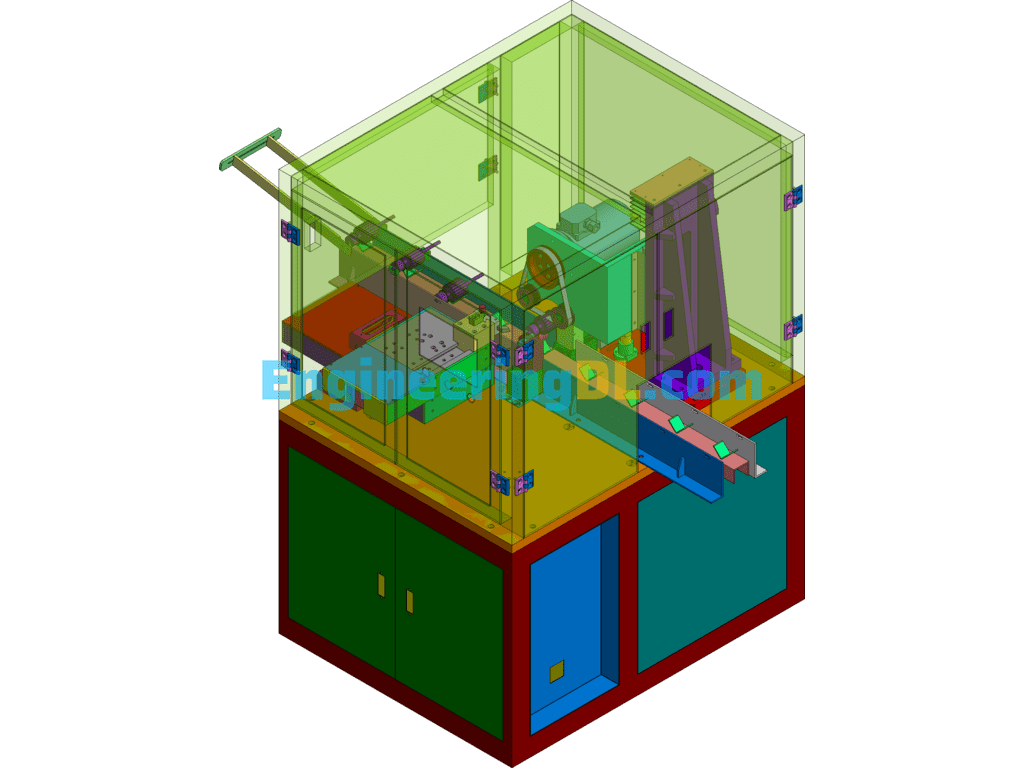

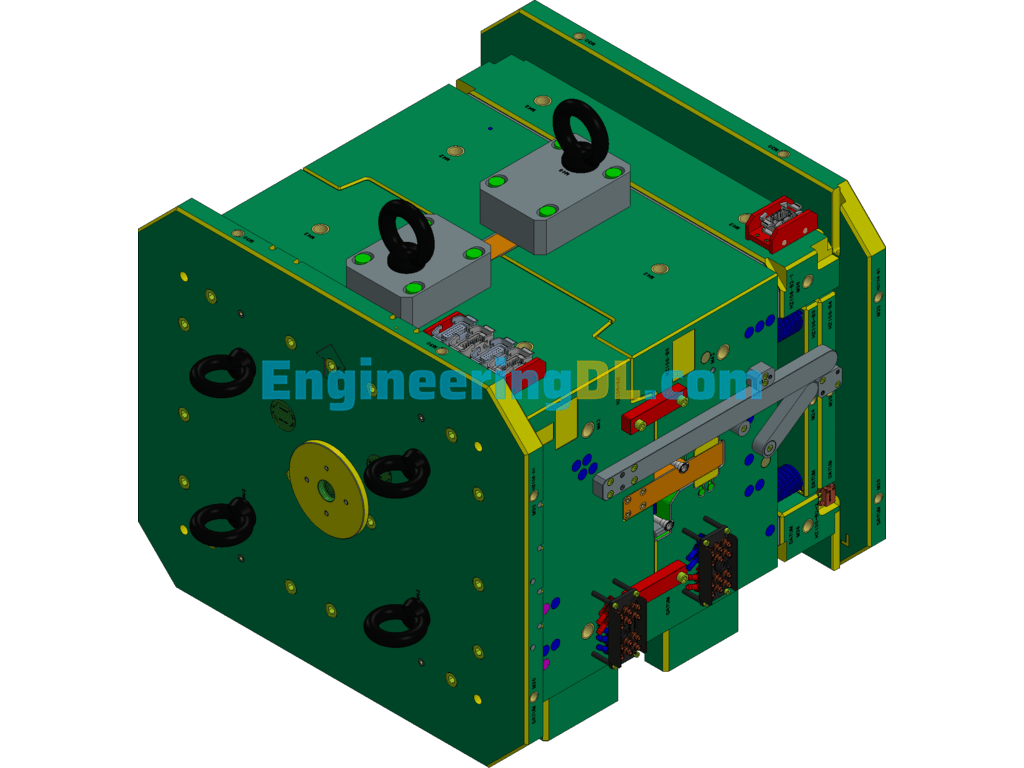

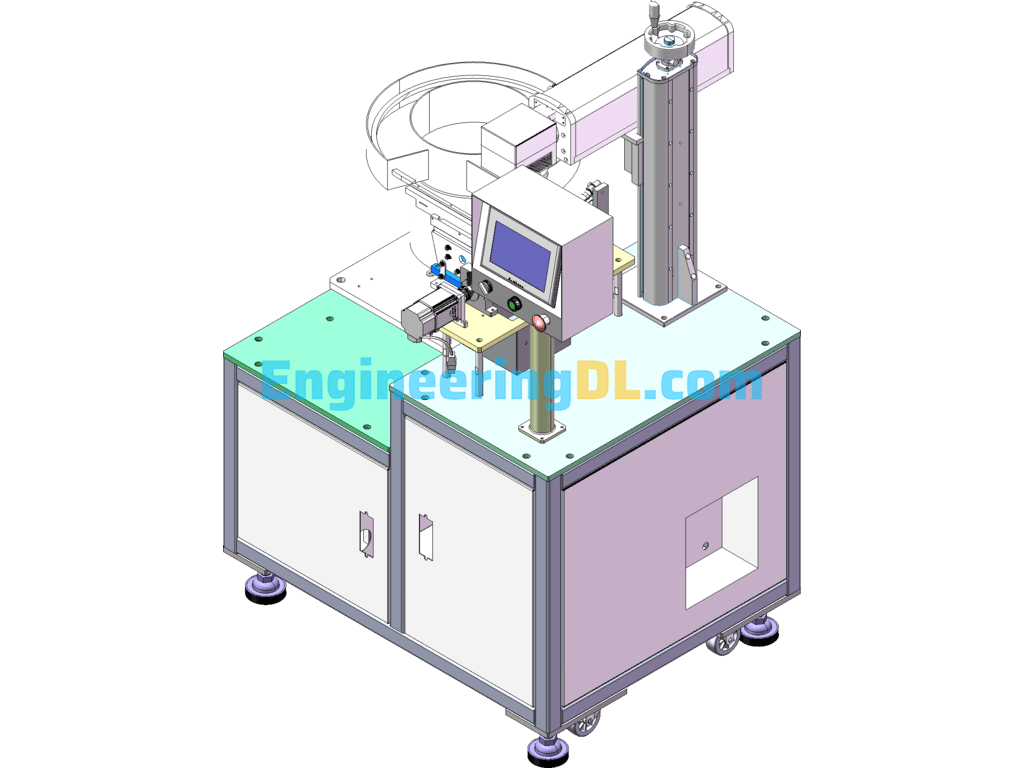

This equipment mechanism is designed by SW2016 contains parts features can be edited, mainly for PETG .TPU.PU and a variety of polyvinyl chloride containing 30% (PVC) based plastic welding. Such as: double blister blister packaging, blister and paper card heat sealing, upper and lower cardboard + blister blister heat sealing, folding boxes, hardware tools, LED energy-saving lamps, toothbrushes, stationery, cosmetics, sandwich blister packaging, etc., and will be different shapes blister or blister plastic material automatic welding at the same time automatic edge cutting. Various kinds of concave and convex shape pattern, PVC cushion, sleeping pad heat sealing, letter and text pressing, etc. Adopt precision indexer as rotating transmission device, automatic rotation of disc table, smooth rotation; high sensitive NL5557 spark protection device, inhibit sparks to effectively prevent damage to the mold. Robotic automatic material release, robotic automatic grasp out finished products, fast speed. Reinforced frame, PLC control, man-machine interface touch screen operation, easy to operate. Equipment has automatic turntable high frequency machine, automatic turntable high frequency machine with double manipulators, fast welding speed to save manpower. Include STP and UG common editable format.

Specification: Automatic Glass Assembly Equipment + Engineering Drawings + BOM SolidWorks

|

User Reviews

Be the first to review “Automatic Glass Assembly Equipment + Engineering Drawings + BOM SolidWorks”

You must be logged in to post a review.

There are no reviews yet.