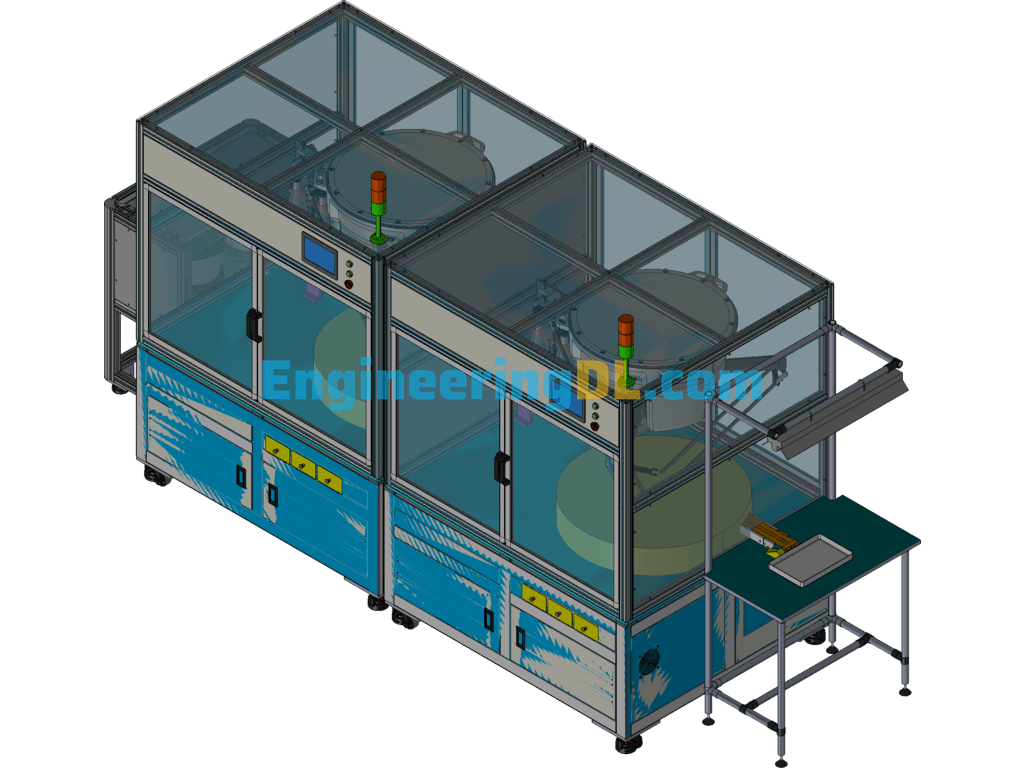

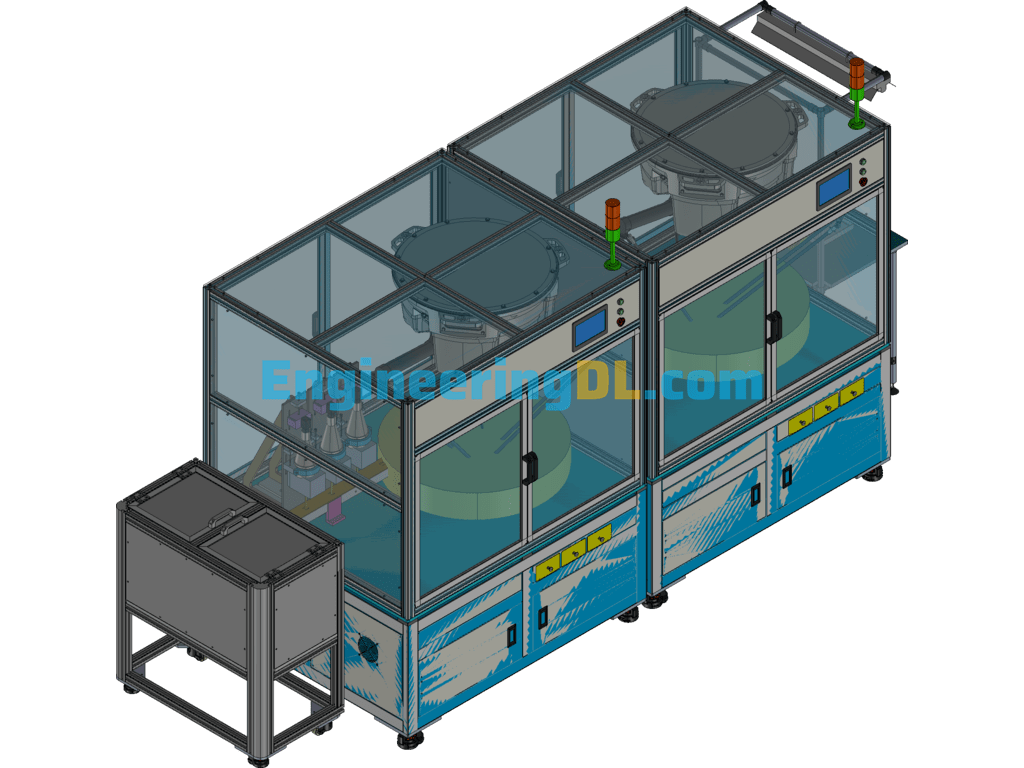

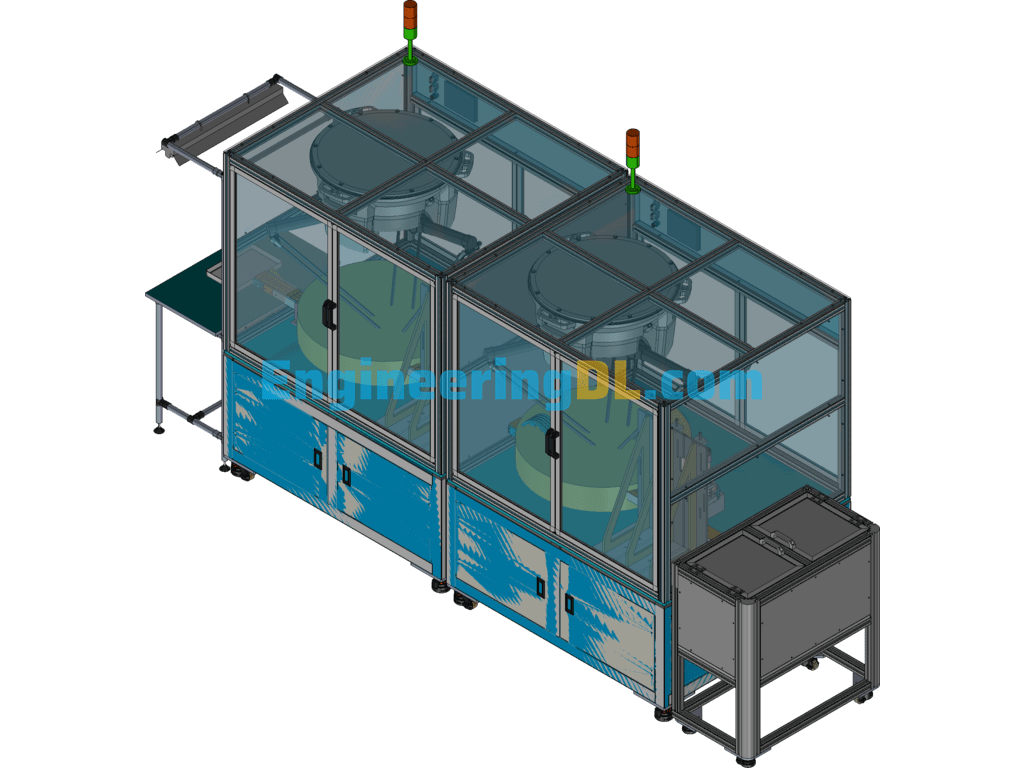

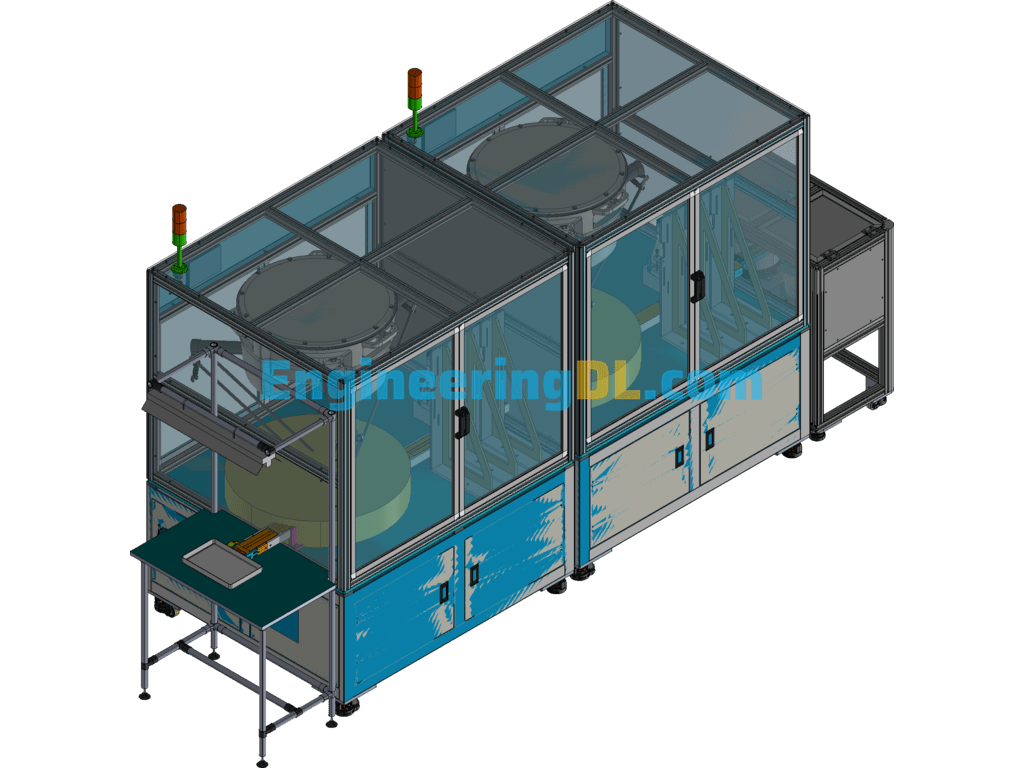

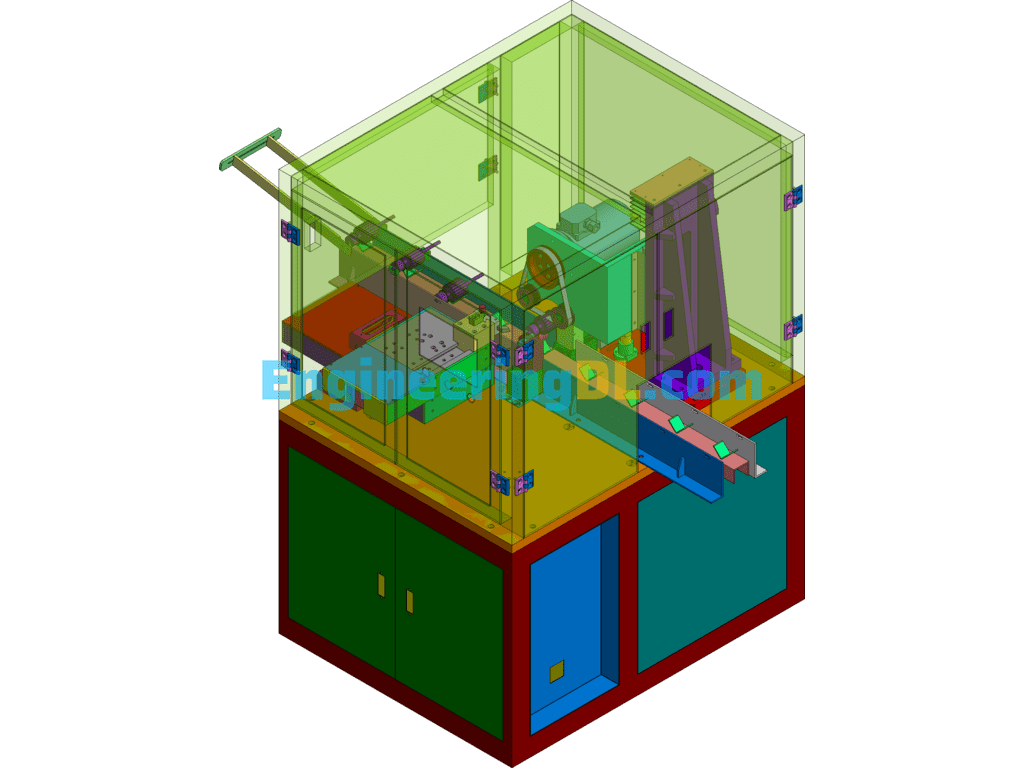

Robot sorting machine equipment functions.

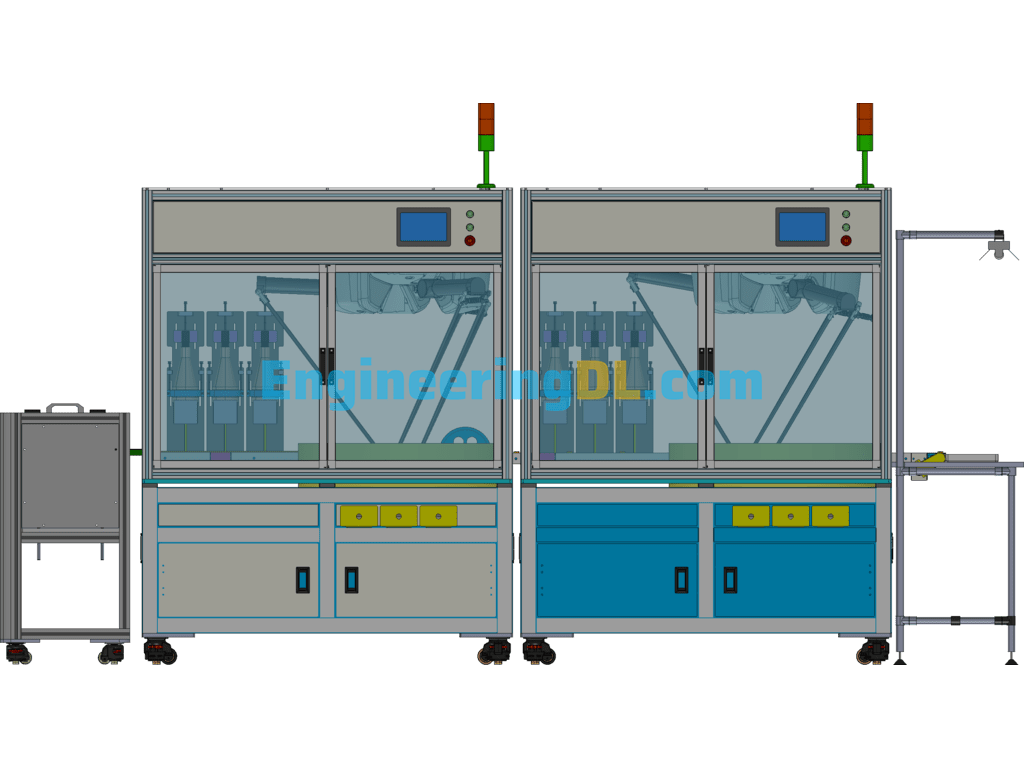

Through two one-out-two vibrating trays loading, conveyor belt conveying materials, three groups of CCD to detect product scratches, missing corners, dirty situation respectively, parallel sorting type robot to quickly sort defective products to different chutes, in the middle by flipping mechanism to flip the other side to repeat the detection of sorting work, and finally leave the process of good products.

The equipment can be used for sorting a variety of regular shaped products, such as cubes, cylinders, etc. This equipment is based on 6*4*1.5 magnets as an example.

The structure contains four kinds of institutions:

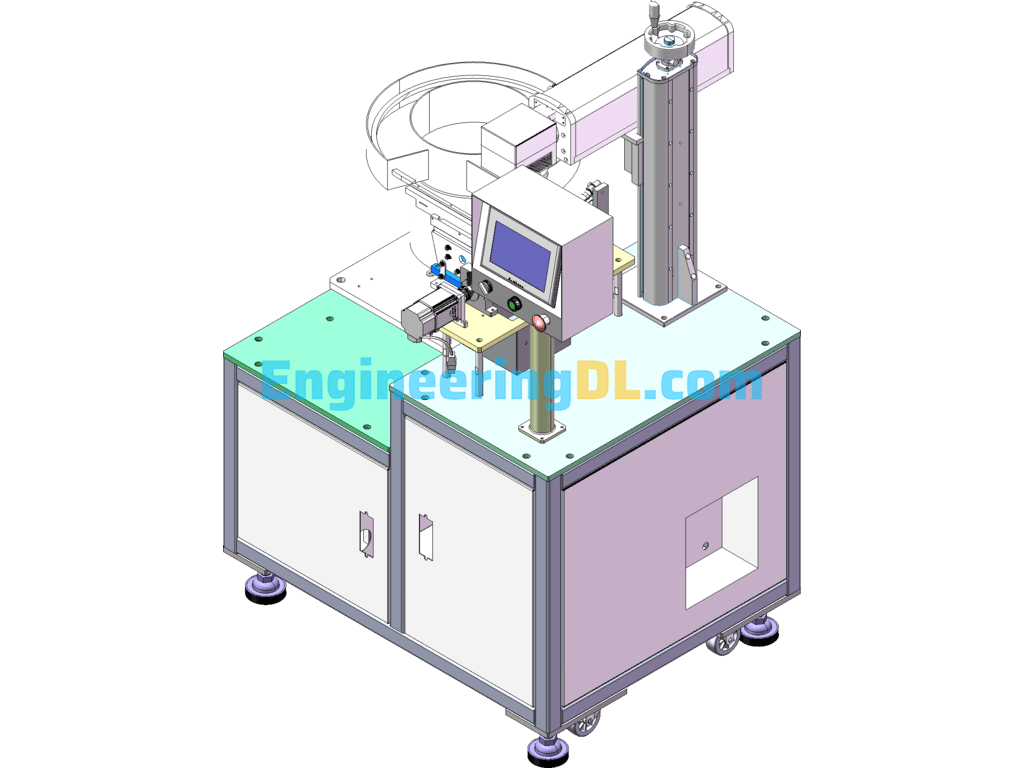

1. feeding vibration plate: using two one-out 2 type vibration plate, to achieve simultaneous on four rows of materials.

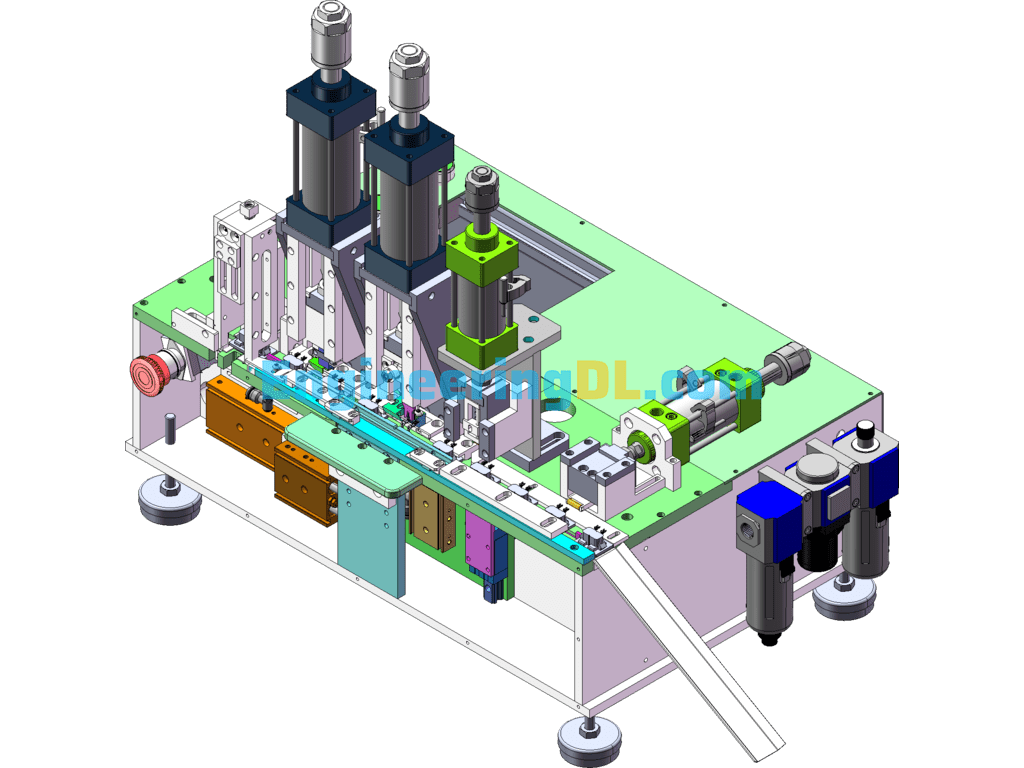

2. defective products discharge mechanism: acrylic slide material channel with drawer type hopper, both beautiful and convenient to take defective materials.

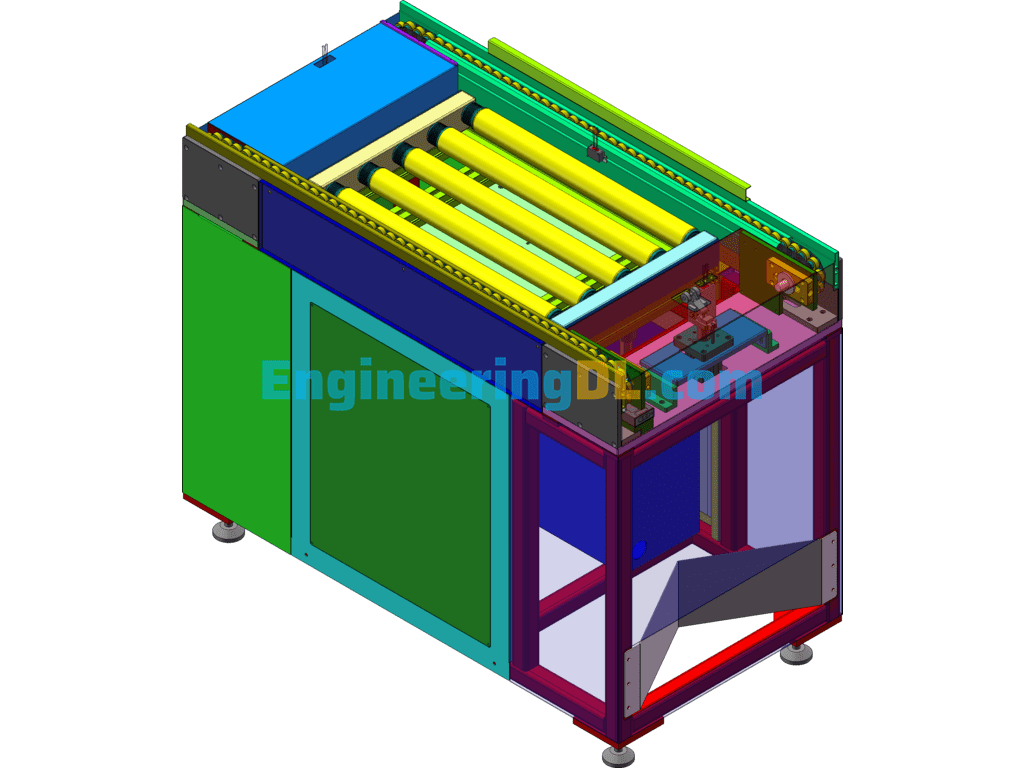

3. detection mechanism: product handling process three groups of CCD lens, detection of product scratches, missing corners, dirty situation.

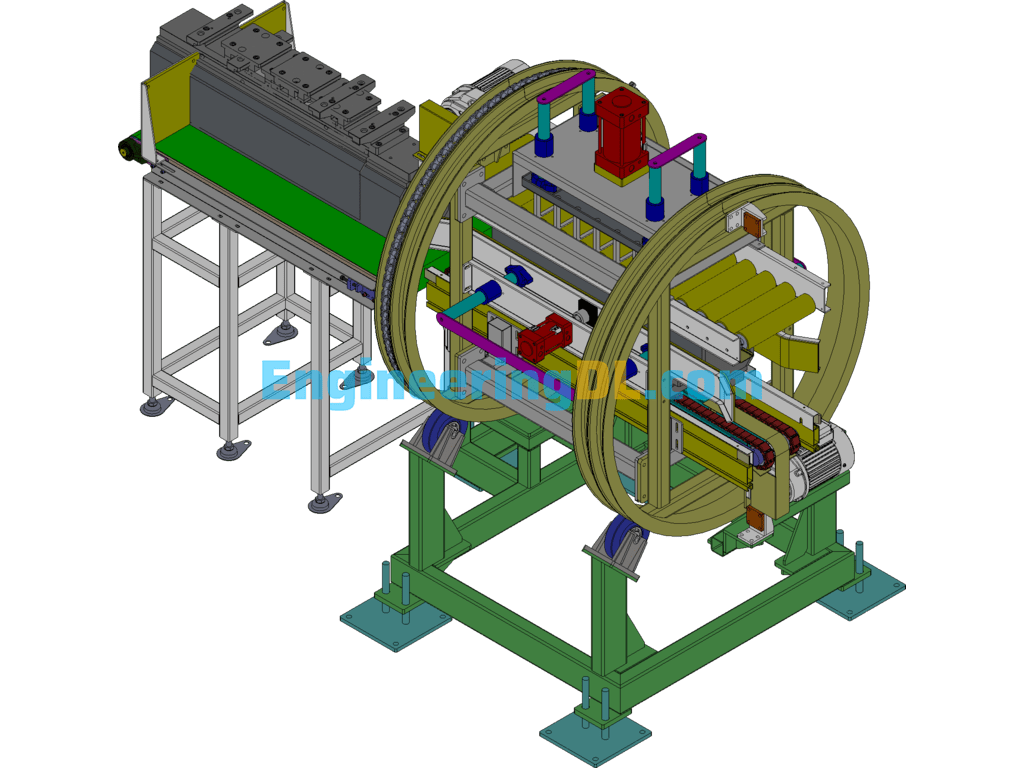

4. material flip mechanism: driven by servo motor. Material flip mechanism: driven by servo motor, the outer diameter is equipped with a material slot, the lower material end using a blowing device to blow out the material.

5. sorting robot: using 4 degrees of freedom, parallel type robot, far beyond the speed of the tandem robot to pick and place defective materials.

6. lower material end conveying mechanism: using open material slot to facilitate CCD detection and robot to take the material.

Specification: Robotic Sorting Equipment For Defective Products (CreoProE), 3D Exported

|

User Reviews

Be the first to review “Robotic Sorting Equipment For Defective Products (CreoProE), 3D Exported”

You must be logged in to post a review.

There are no reviews yet.