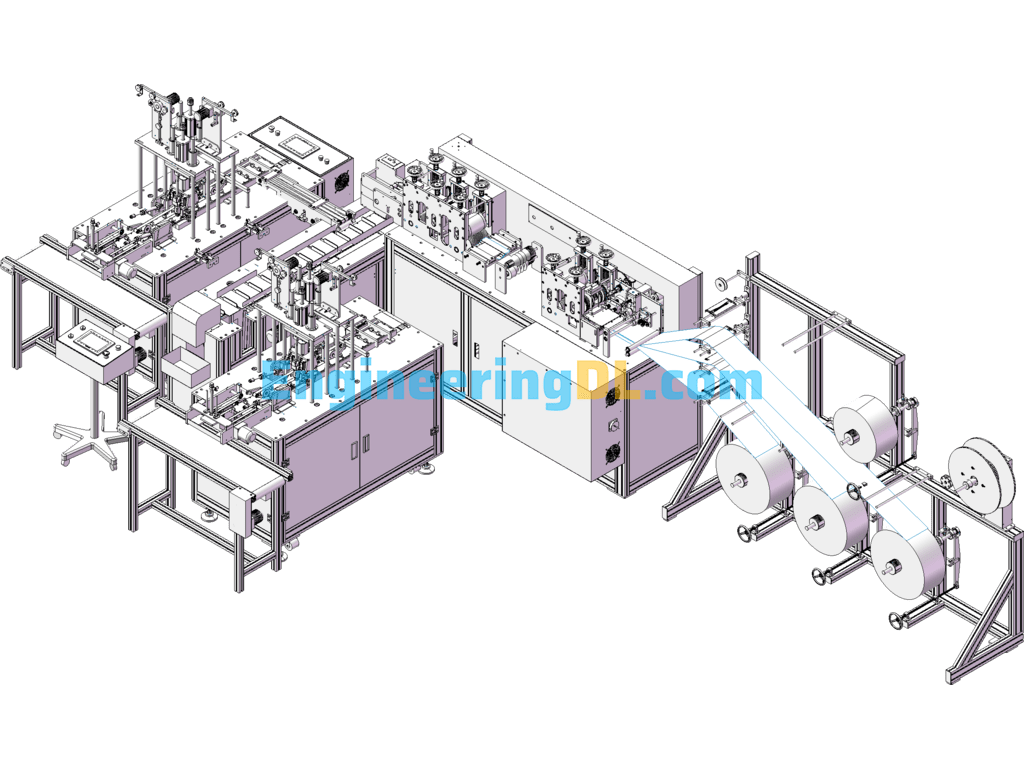

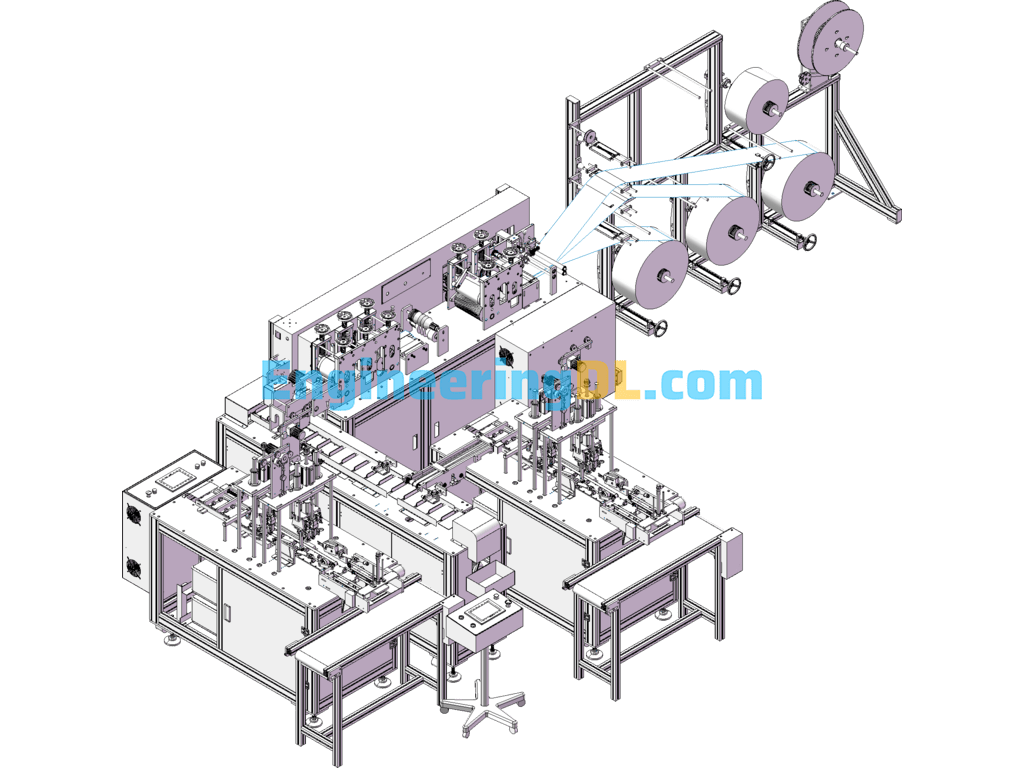

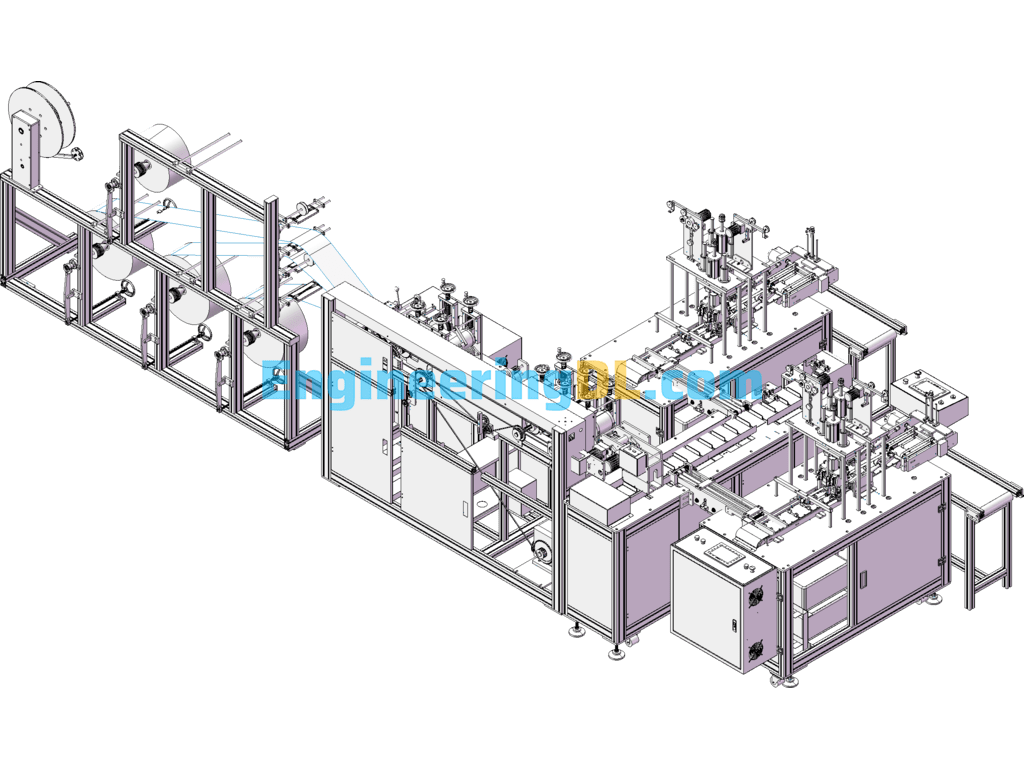

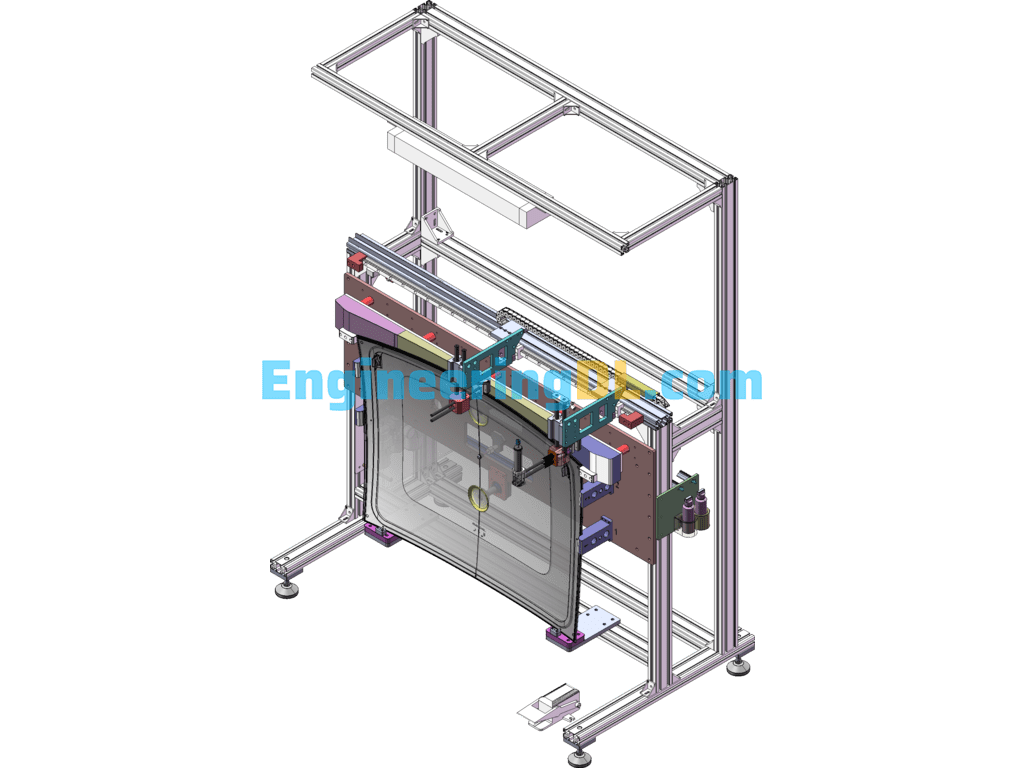

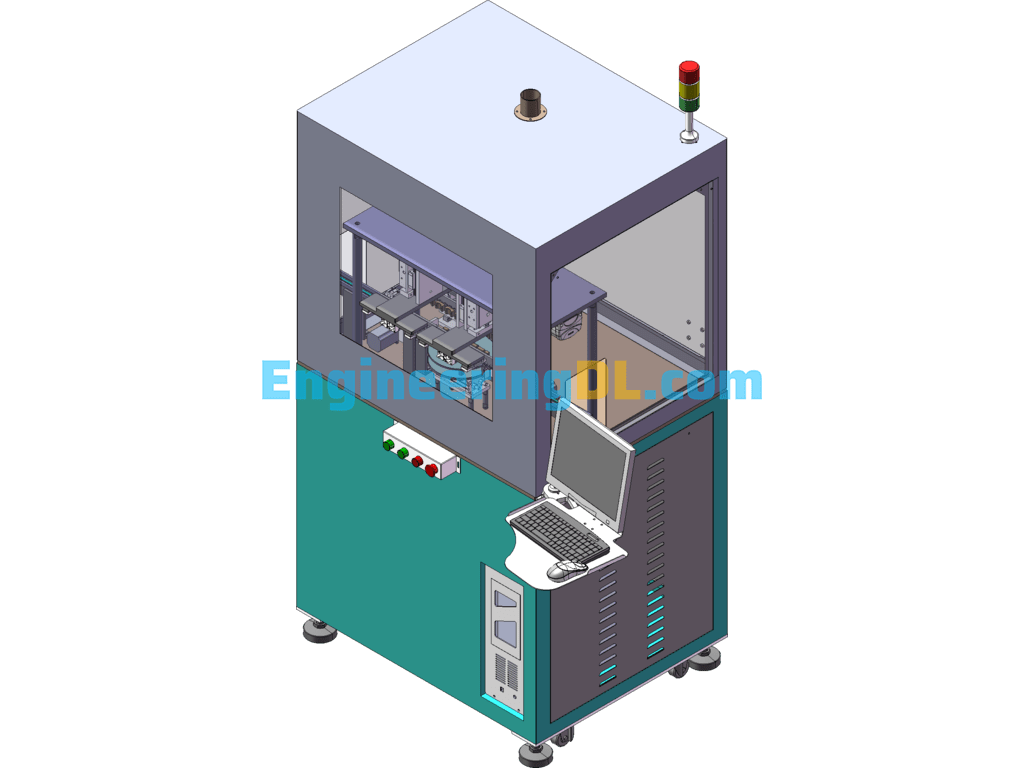

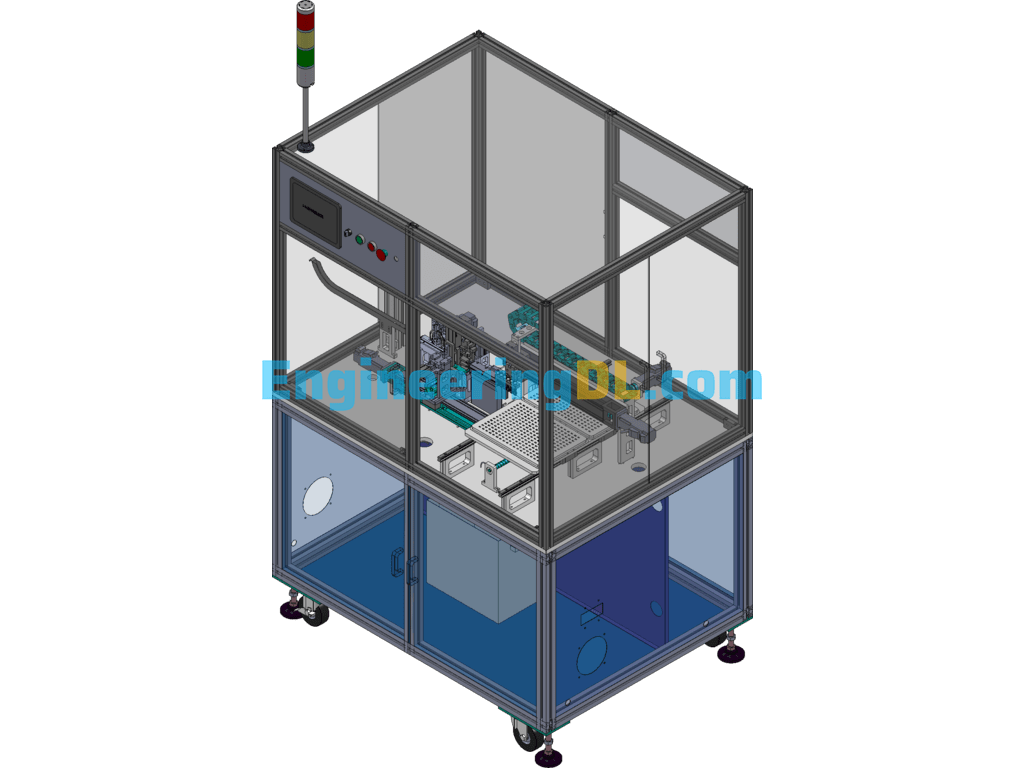

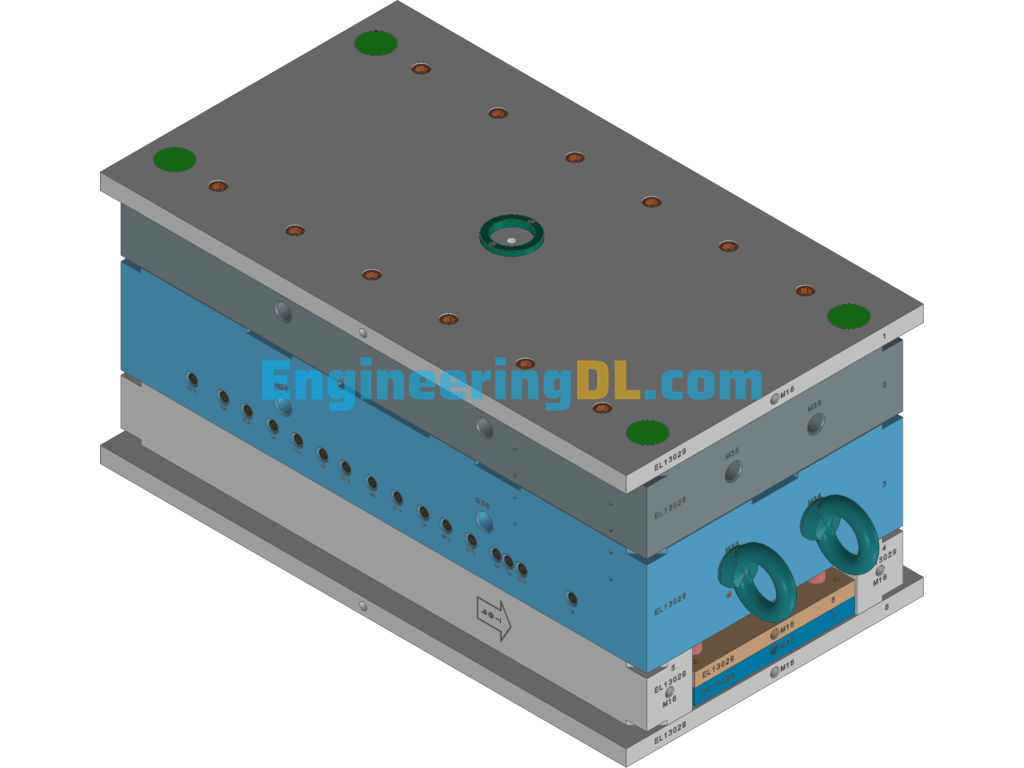

Fully automatic flat mask machine (one tow two), the attachment contains more than 1200 total assembly + parts drawings, you can see all the design structure, contains all the parts, can be edited but no parameters, which contains STP files, 3d software can be opened. Fully automatic flat mask machine, only one operator is needed to load the fabric on the material rack, the rest of the subsequent actions to the finished product are all done by the machine (nose press, layering, pressing together, playing ear band, ultrasound), the finished product finally flows out of the packaging by the finished conveyor belt. Equipment equipment has been mass production: size 6.3 m (L) x 5 m (W) x 2 m (H), efficiency 110-120 per minute, equipment 220VAC, 50HZ, rated power about 9.5KW, air pressure 0.5-0.7Mpa, air consumption about 300L/min. Welcome to download

————

The drawing is from my exchange with others (only stp, I save my own SolidWorks format), and is dedicated to the diamond members of Kepa.com, thank you for your long-term support.

–Kaibab.com group master 3.

———–

Automatic flat mask machine one tow two production line, fully automatic production of flat mask machine, consists of a body plus 2 ear band spot welding machine. From the production of the mask body to the fusion of ear straps, nose wire fusion until the finished product, fully automated, without any manual operation.

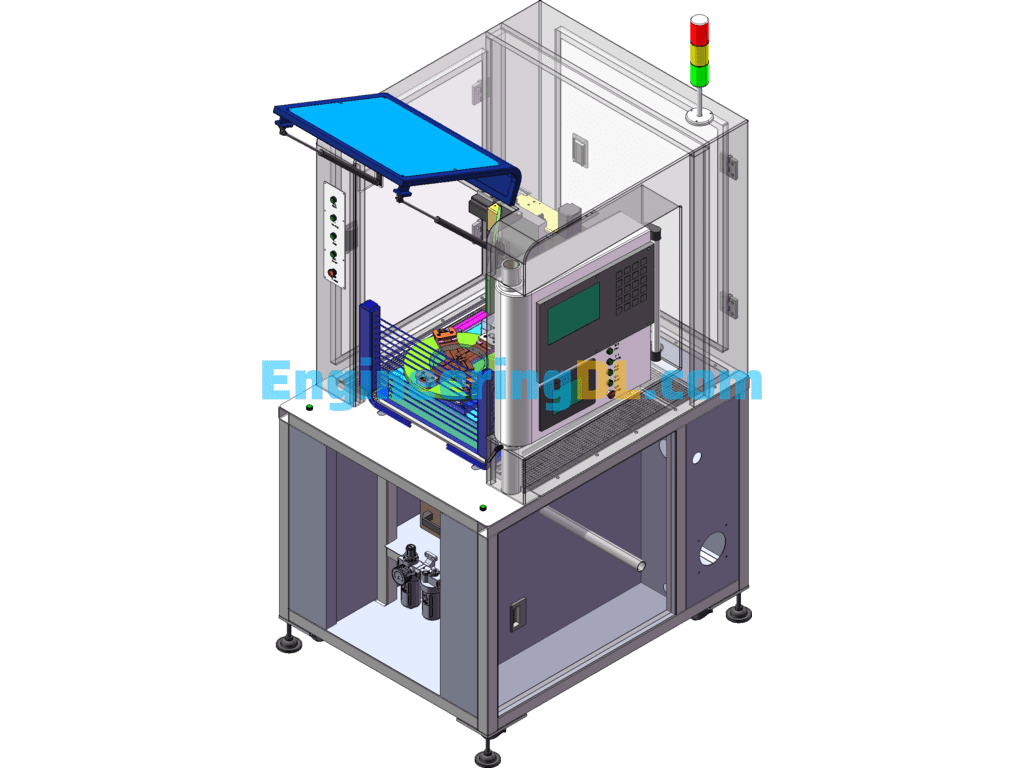

This equipment is a mask body production machine and two mask ear band fusion machine connected when the mask body made by the conveyor belt sent to the mouth ear band fusion machine for the ear band part of the fusion. It can complete a complete ear mask, only one operator can operate the whole production, the production line can realize the fully automatic production of flat mask, mainly including coil material feeding, folding and pressing, nose band feeding, mask forming, mask cutting, ear band and welding, finished product discharging and other processes, complete the whole production process from raw materials to finished mask.

The masks produced are comfortable to wear, no pressure, good filtering effect of masks, and can be applied to medical and health, electronics, mining, construction and other industries.

Product features:

1. small size of the machine, occupies a small area, the whole machine adopts aluminum alloy structure, beautiful and sturdy without rusting;

2. extremely high output, can produce 1-5 layers of mask body according to customer requirements;

3. the folding position of mask body can be adjusted, the size can also be adjusted;

4. the direction of mask ear band is outward;

5. compared with segmented mask production equipment, this set of equipment is more efficient, more labor-saving;

6. plc program control, photoelectric detection, high reliability and low failure rate.

Specification: Sub-3 Generation Flat Mask Machine One Tow Two, Automatic Mask Machine Machine Equipment SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Sub-3 Generation Flat Mask Machine One Tow Two, Automatic Mask Machine Machine Equipment SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.