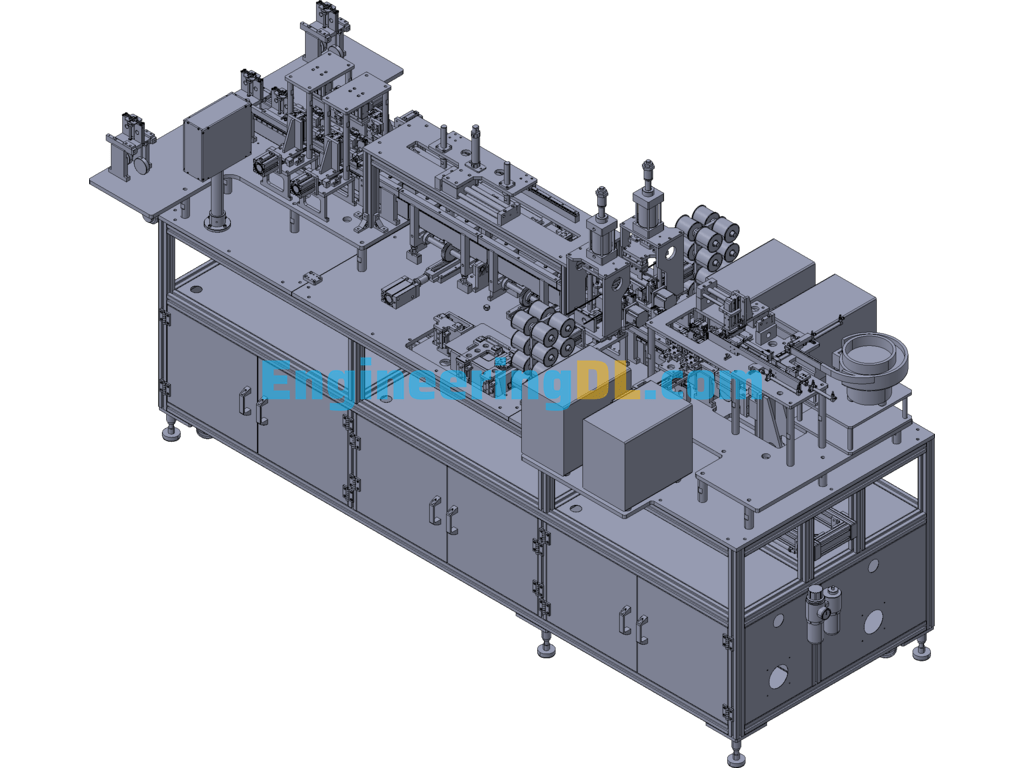

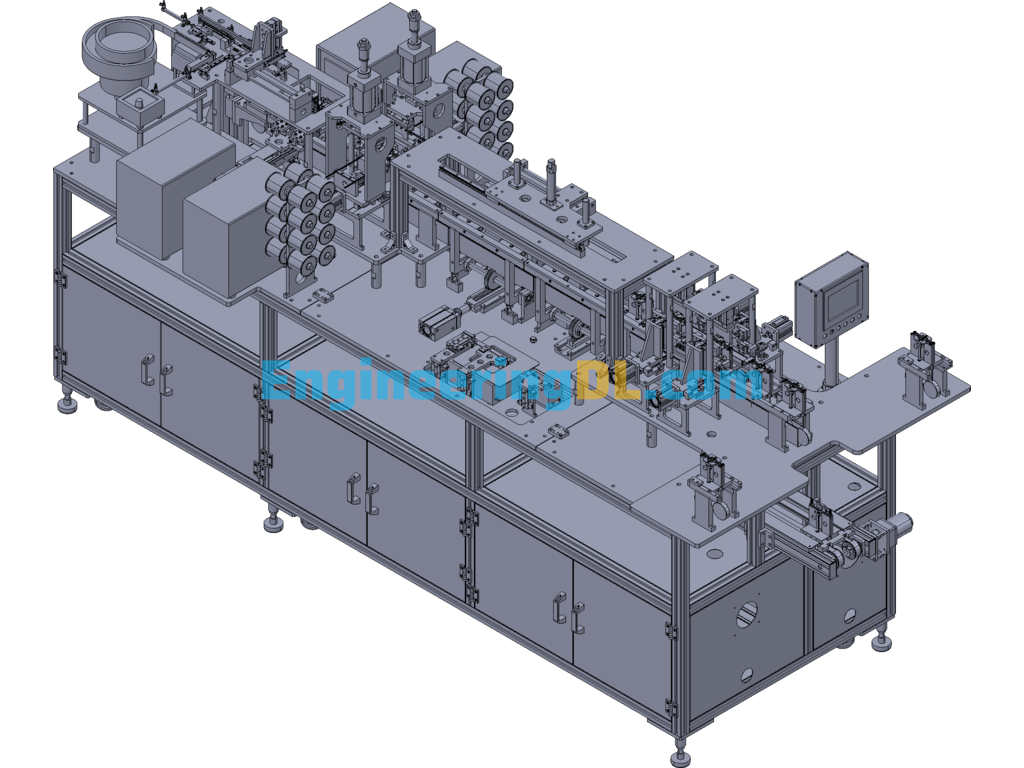

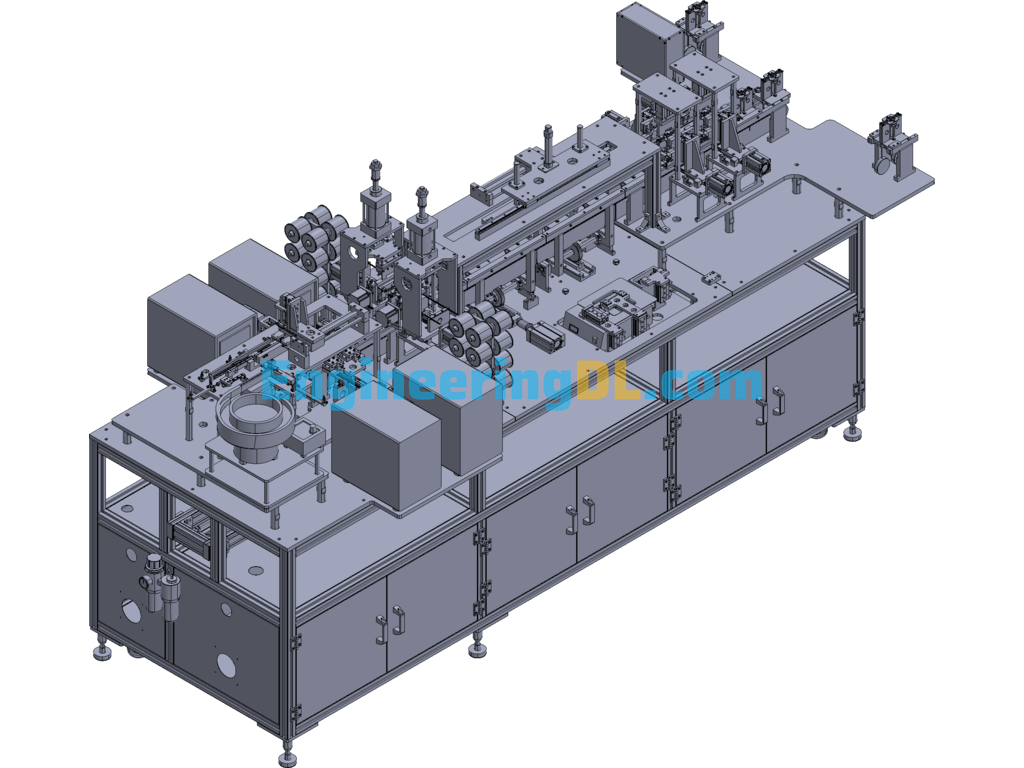

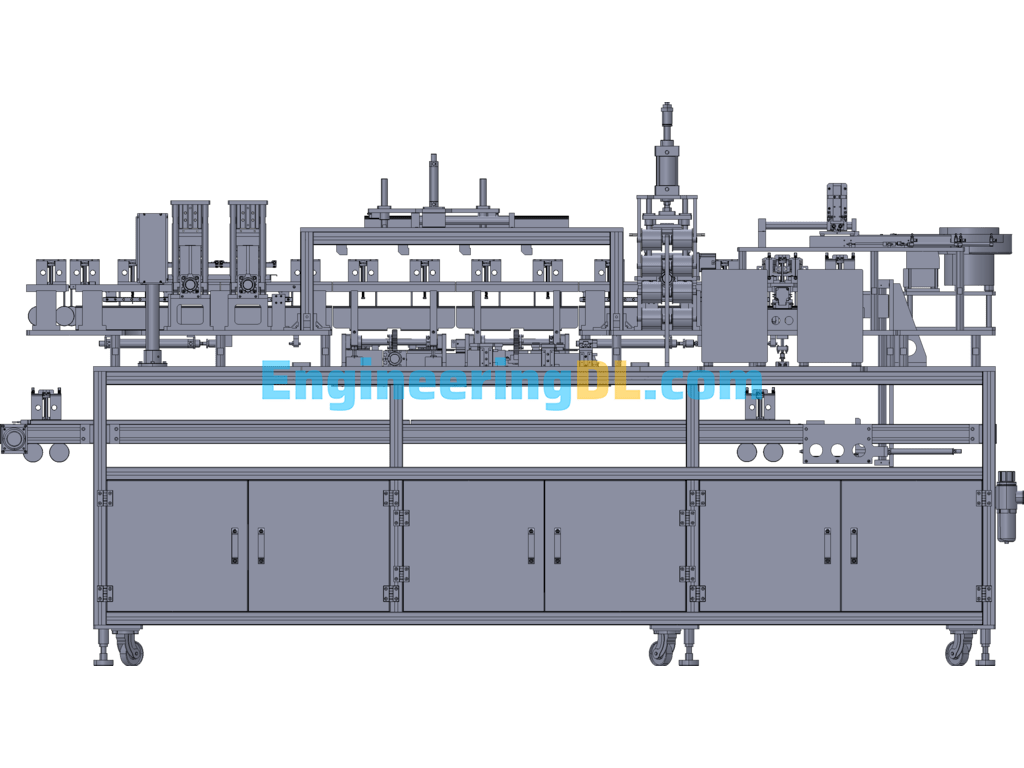

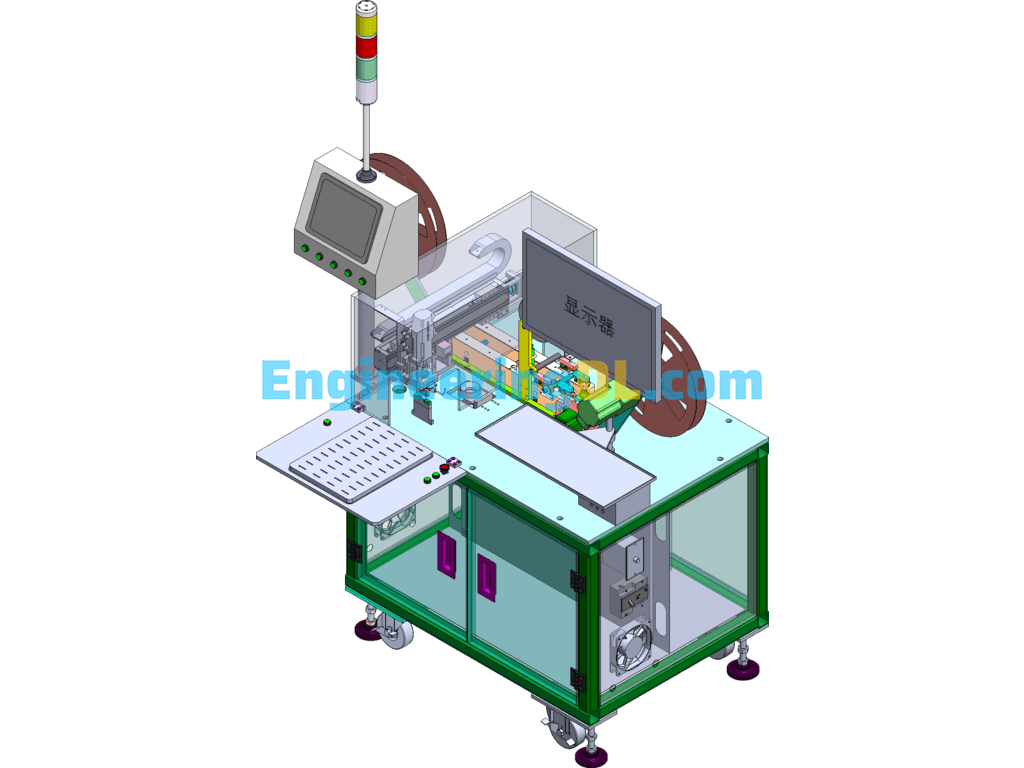

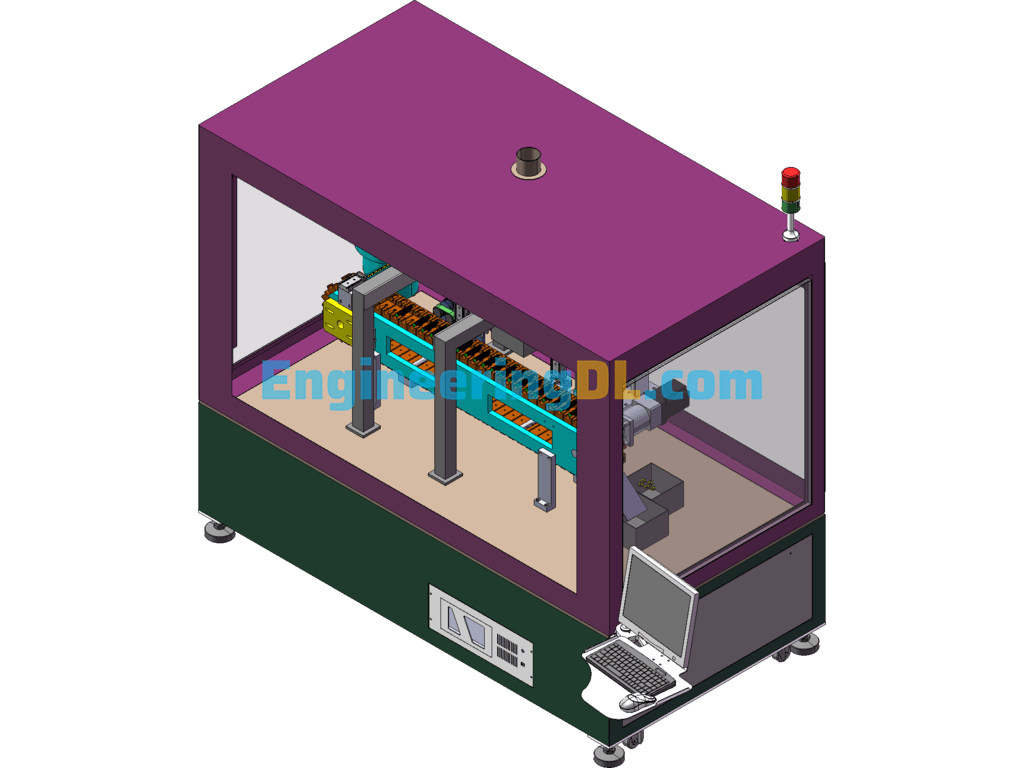

The cable is positioned and pushed into the slots by the clamps, and then transported to the cutting, stripping, flux & tin dipping, tin pressing and soldering stations by the pushing jaws, and finally the USB-3.0 connector is soldered to the cable as required, and the finished product is transported to the position of the positioner through the recycling mechanism. Efficiency evaluation: It takes about 10 seconds to complete the action of (core wire cutting, stripping outer cover, flux & tin dip, core wire tinning, connector sorting and positioning, connector soldering, etc.) as a cycle to produce 2 wires, and the production capacity is estimated to be 720pcs/h.

USB-3.0 wire processing line staffing: (1 person) spare 1 person, depending on the proficiency of wire positioning.

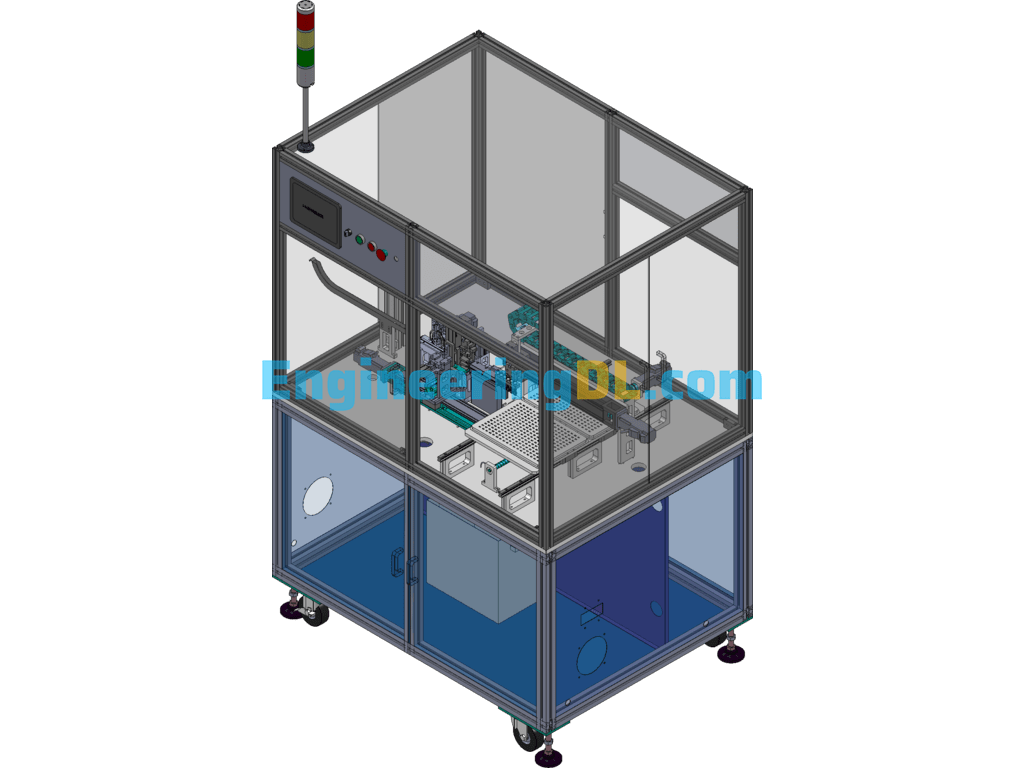

Specification: USB-3.0 Wire Processing Line 3D Exported

|

User Reviews

Be the first to review “USB-3.0 Wire Processing Line 3D Exported”

You must be logged in to post a review.

There are no reviews yet.