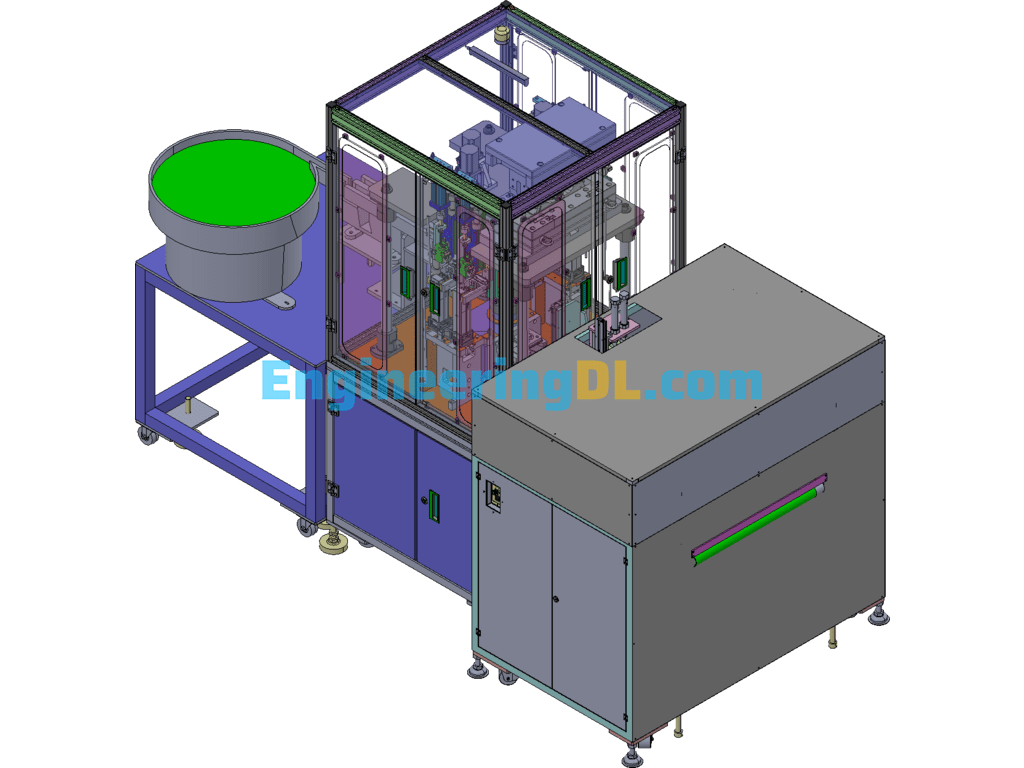

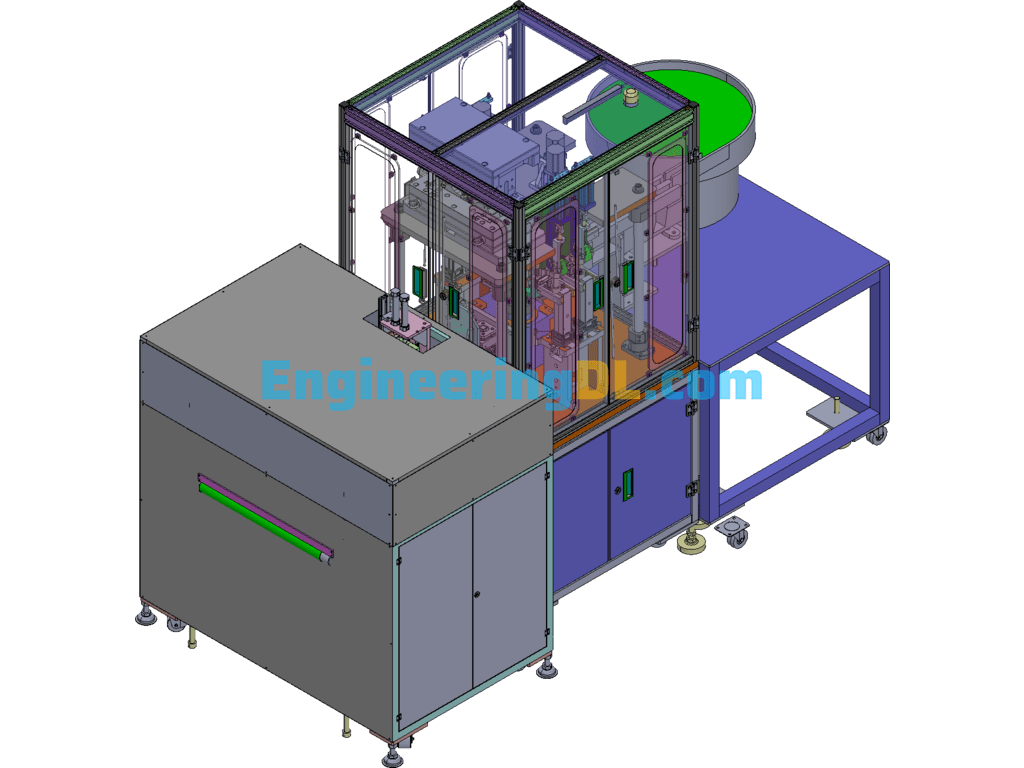

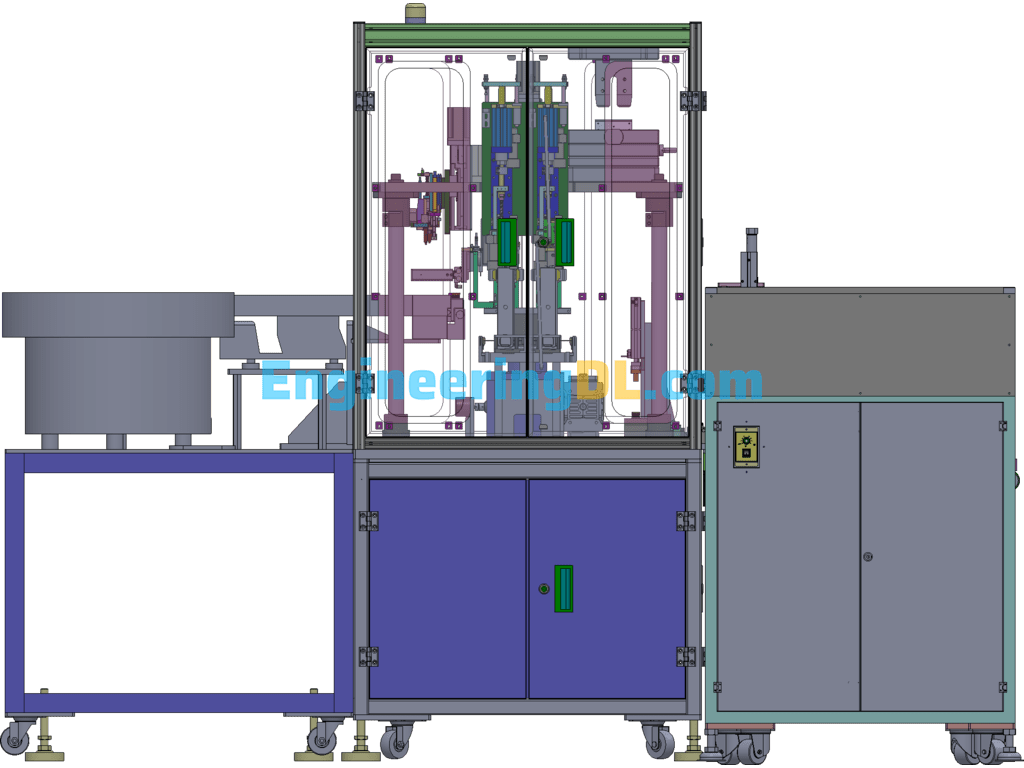

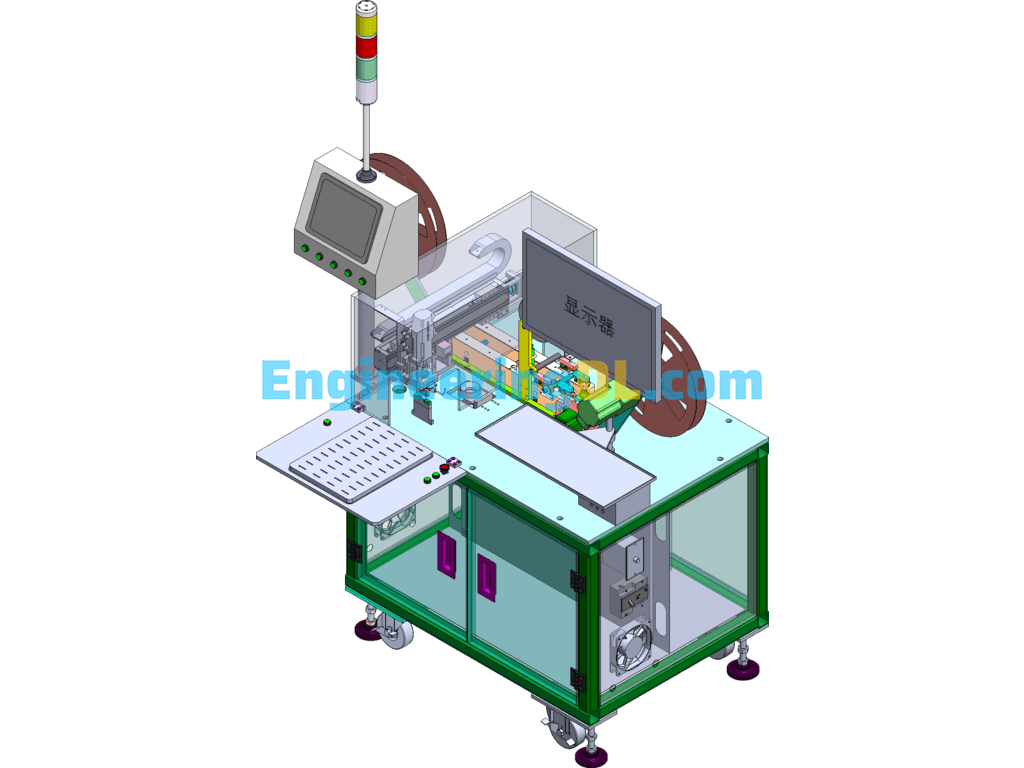

This equipment mechanism is designed by SW2016 contains parts characteristics can be edited, this equipment to chip placement angle and position accuracy requirements are high, the efficiency requirements of the equipment is not high, the whole machine has more than three cameras, compared with the traditional machine, in addition to the linear movement characteristics of the Bang head, more than one can be secondary positioning of the chip camera, to avoid the angle and position changes caused by the suction nozzle picking up the chip according to the chip size, the The precision of chip placement can be kept within plus or minus 12~20um to meet the requirements of TO package for product quality. Weight and power supply: about 800kg, 220 VAC; power: 2000W; air pressure and dispensing method: 4 bar ???P???6 bar, air extrusion type and adhesive type optional; chip: 0.2mm x0.2mm ~1mm x 1mm; chip loading: 6 inch WAFER disk with crystal expansion ring or TRAY disk; vision system: WAFER disk 3 vision positioning system, TRAY disk 2 vision positioning system. TRAY disk 2 visual positioning system; control mode: industrial control machine; UPH: 1000 ~ 2000 PCS; placement accuracy: ?? 20 um, ?? 0.5 ?? or less. Includes STP and UG universal editable format.

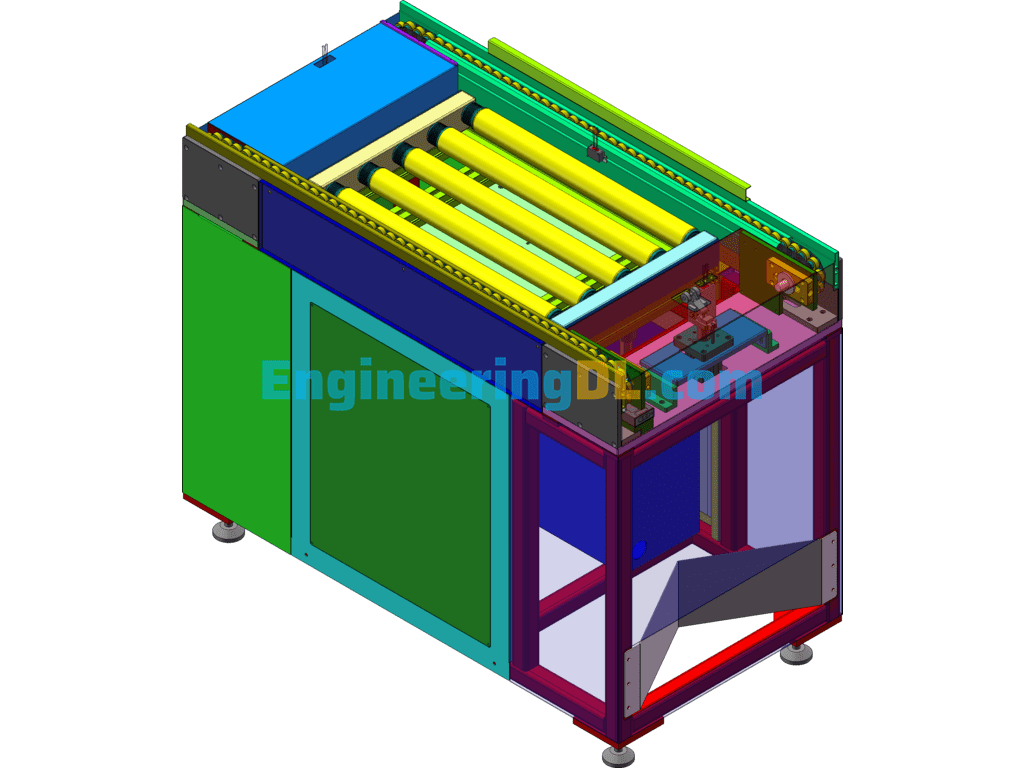

Specification: Lifting Door Spray Oven SolidWorks

|

User Reviews

Be the first to review “Lifting Door Spray Oven SolidWorks”

You must be logged in to post a review.

There are no reviews yet.