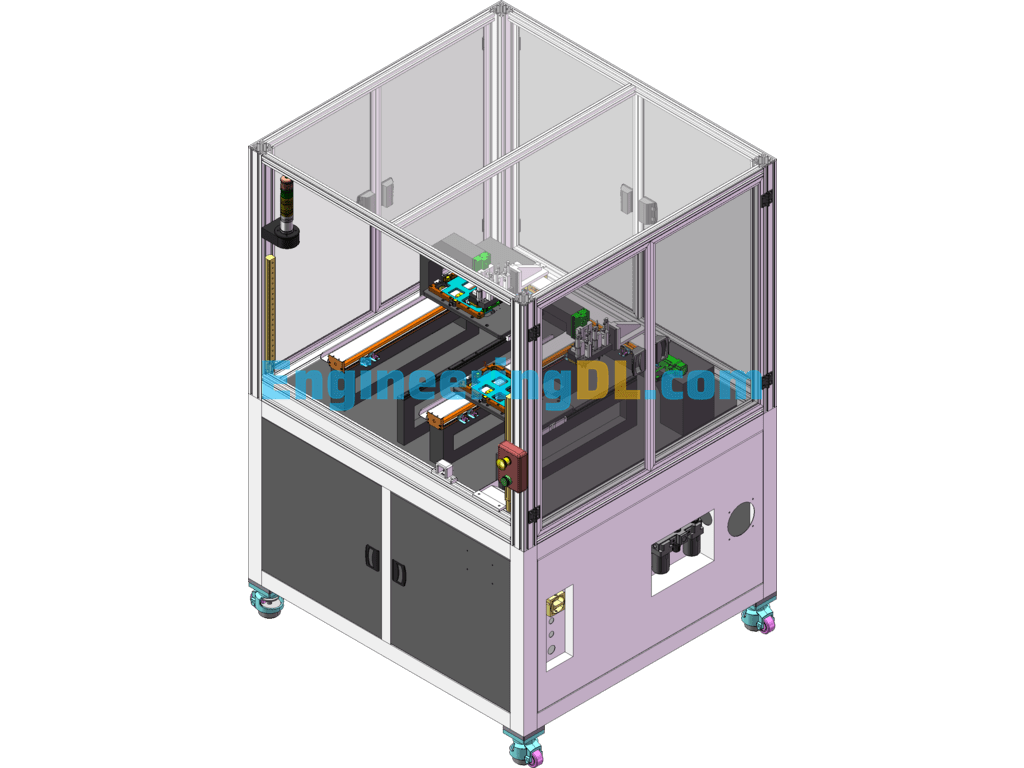

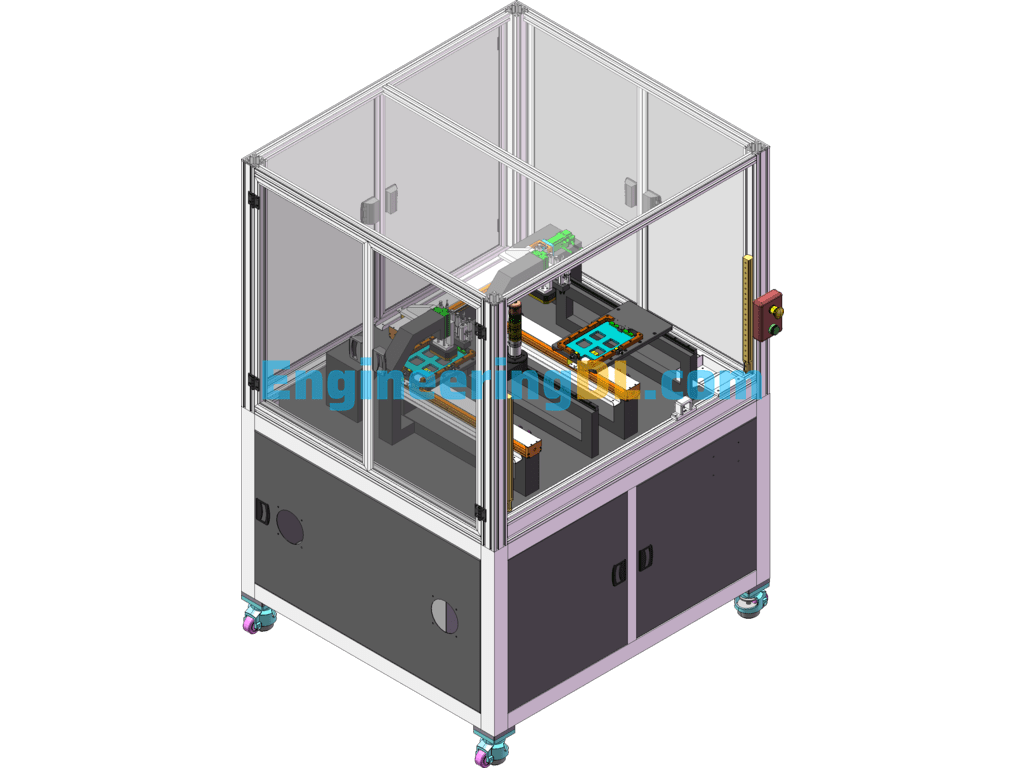

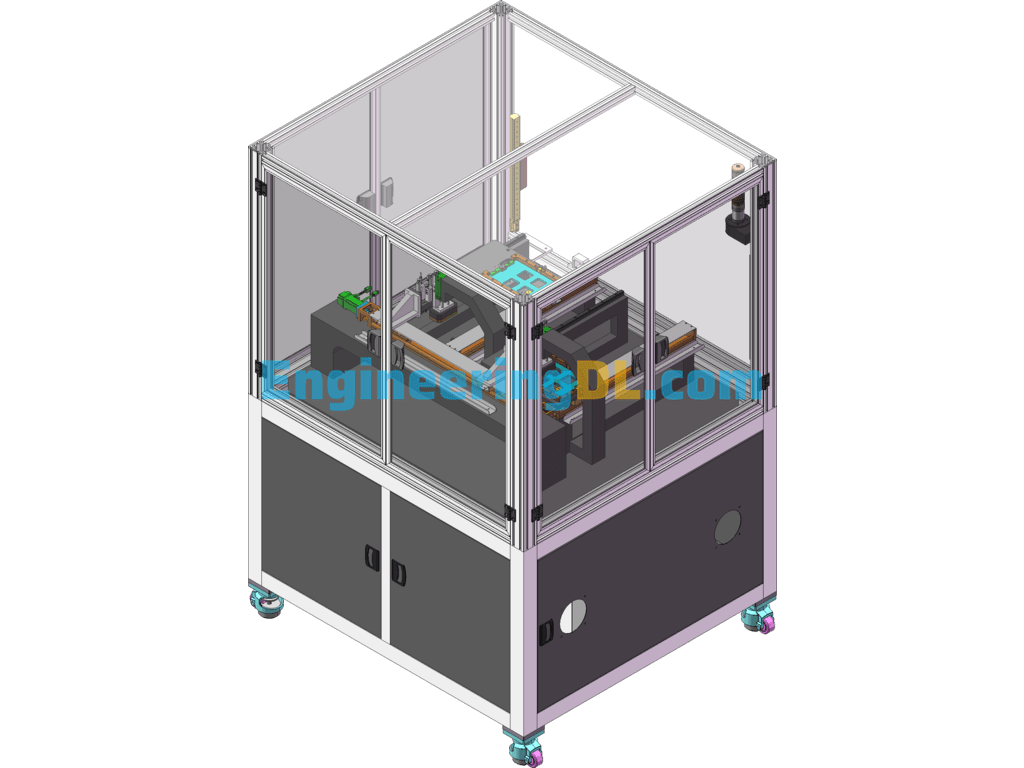

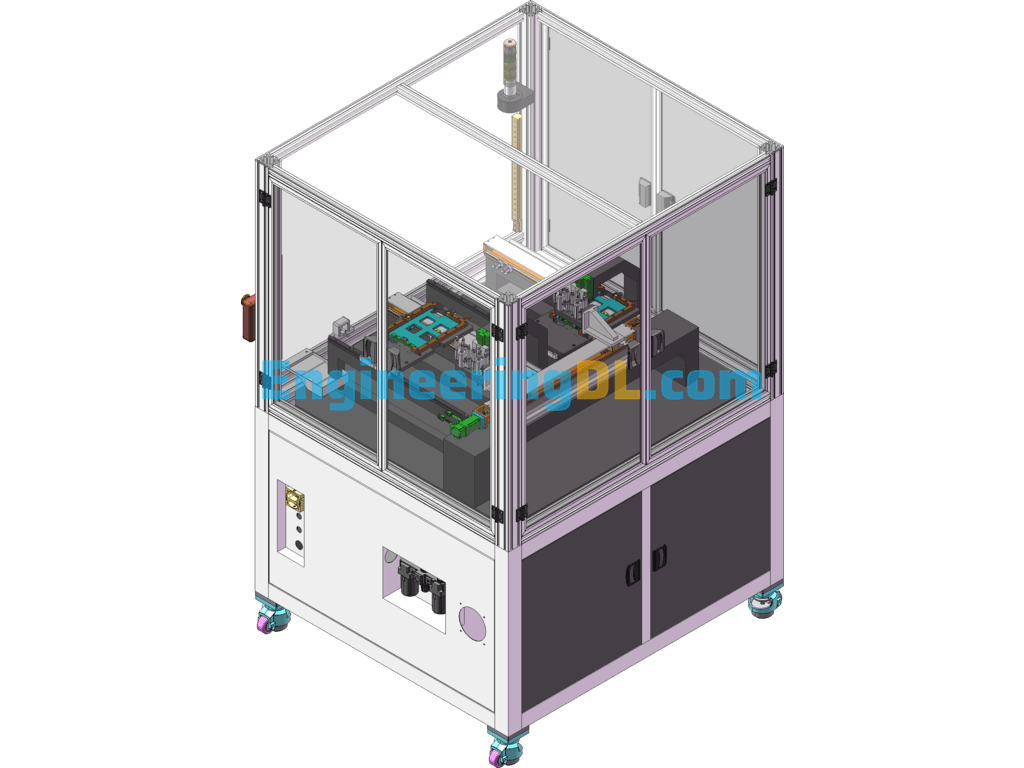

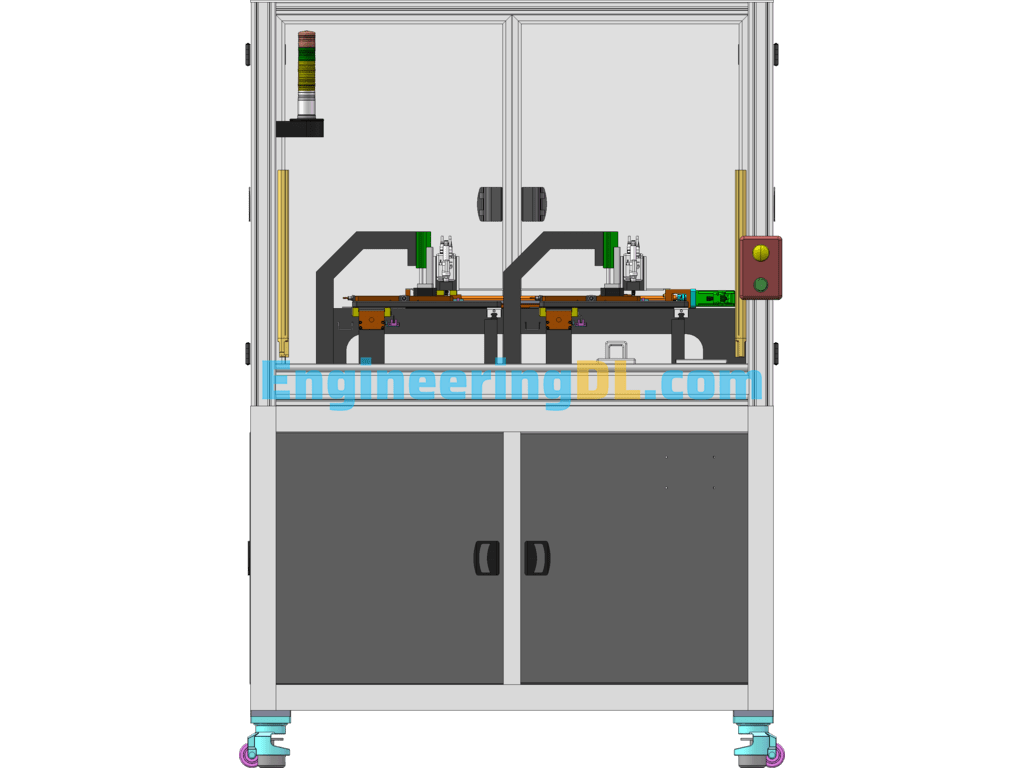

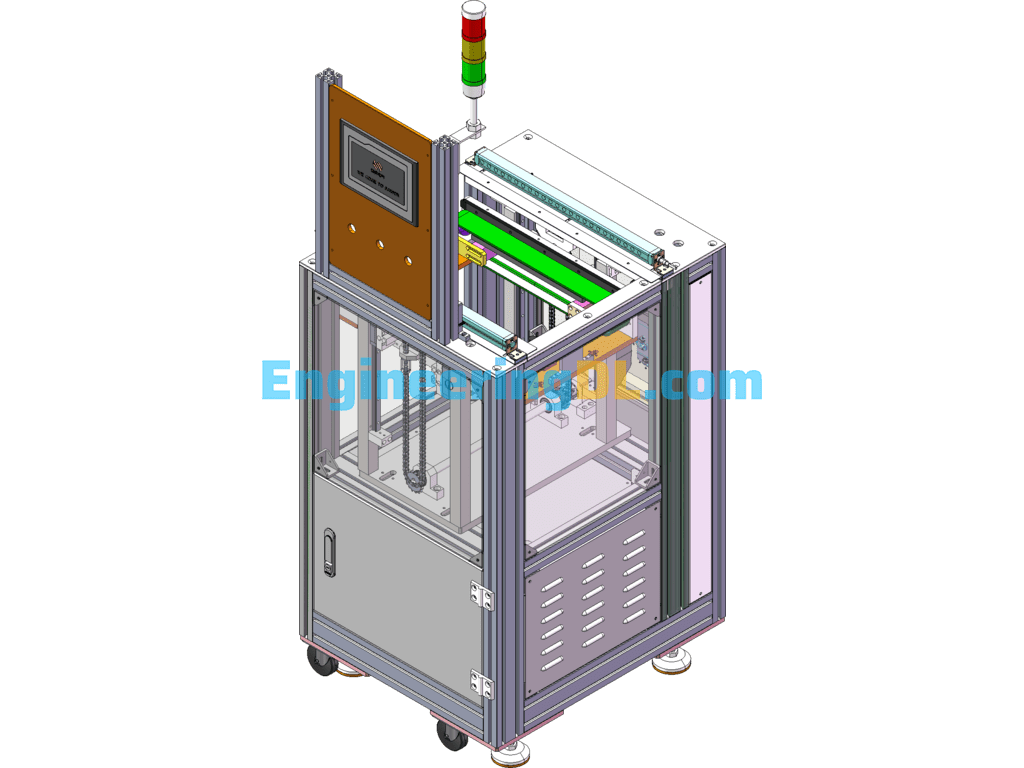

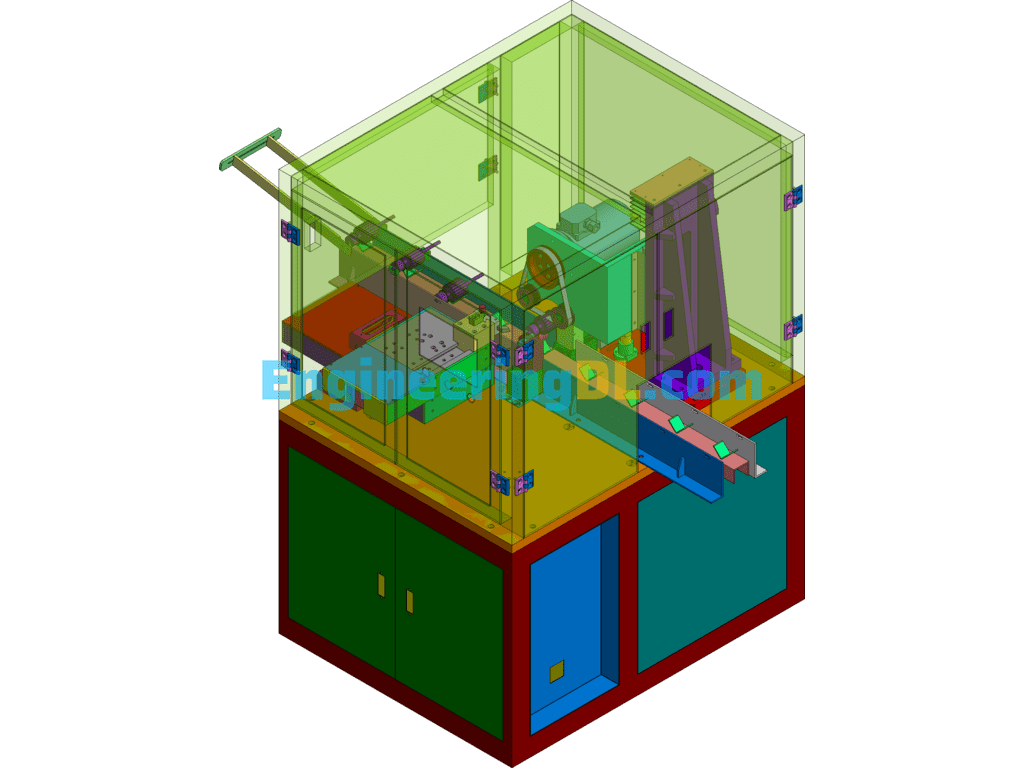

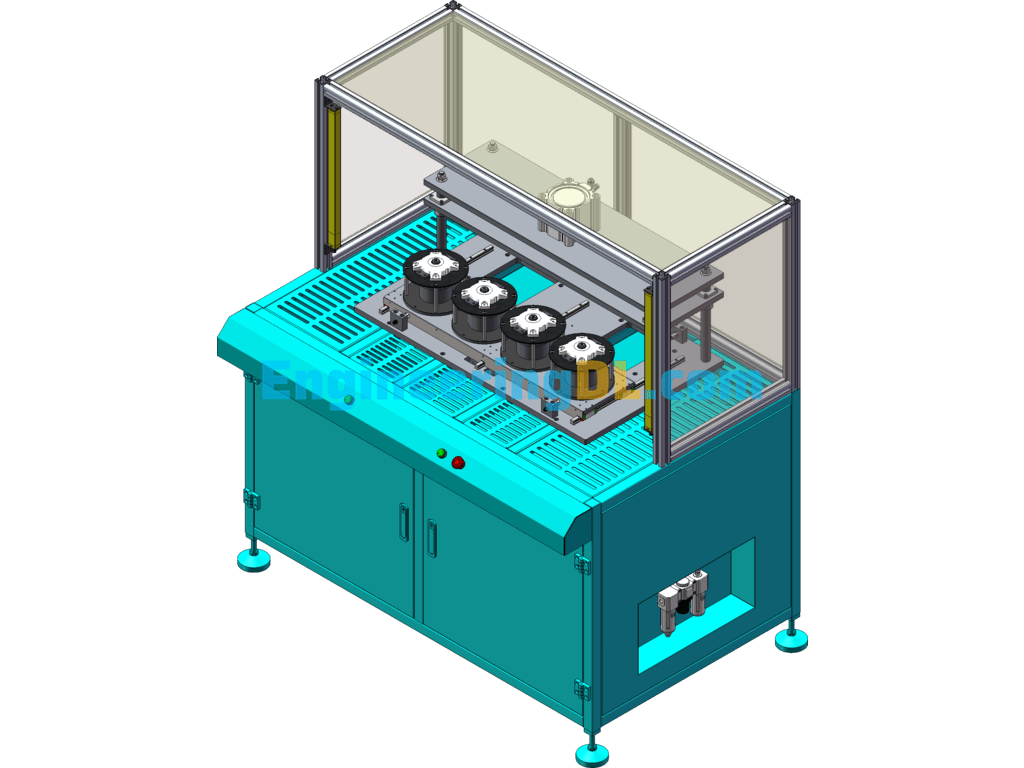

Flat plate segment difference testing equipment action process:

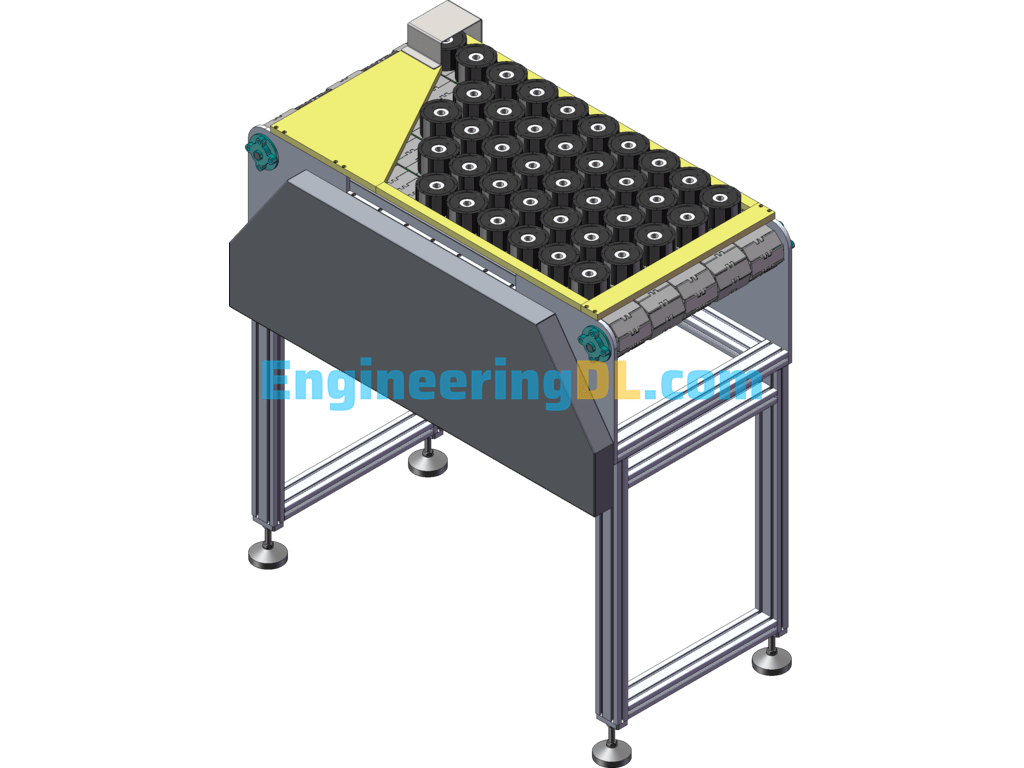

1. test the internal height of flat plate products, divided into two groups of left and right jigs to switch the material supply, saving equipment CT to provide capacity;

2. manually put the product into the jig positioning side clamps fixed.

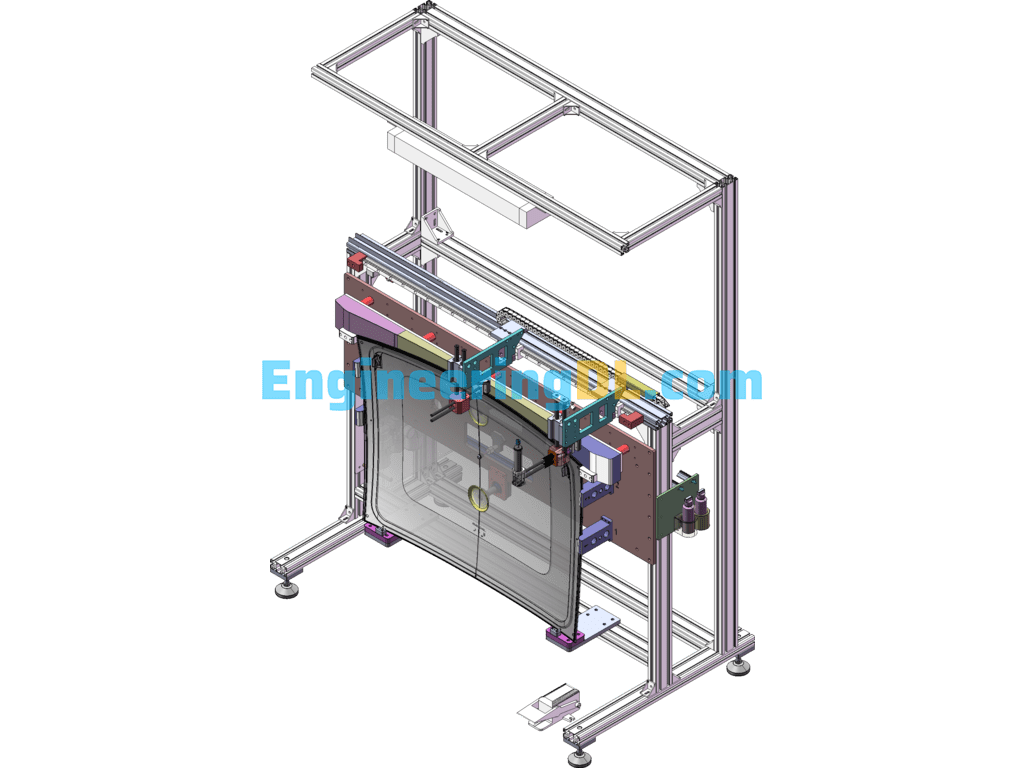

3. Y-axis into the test area, Z-axis cylinder down to fix the product placement movement.

4. GT test cylinder drive GT test head to test the product height.

Specification: Flat Segment Differential Inspection Equipment (Including DFM, BOM) SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Flat Segment Differential Inspection Equipment (Including DFM, BOM) SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.