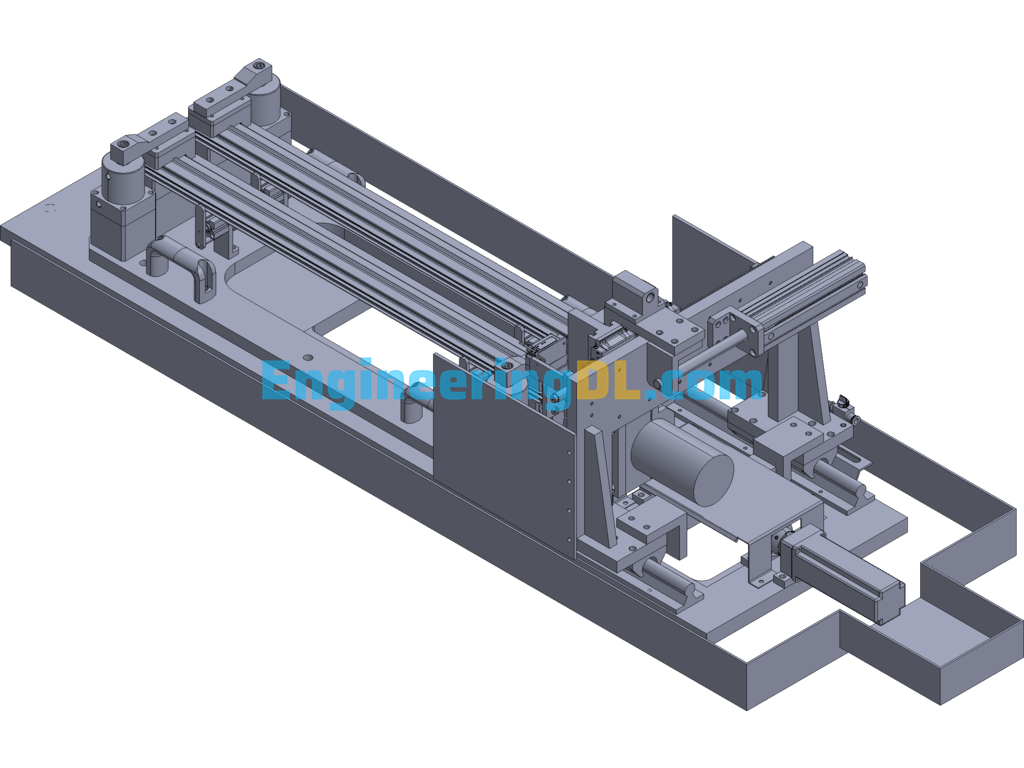

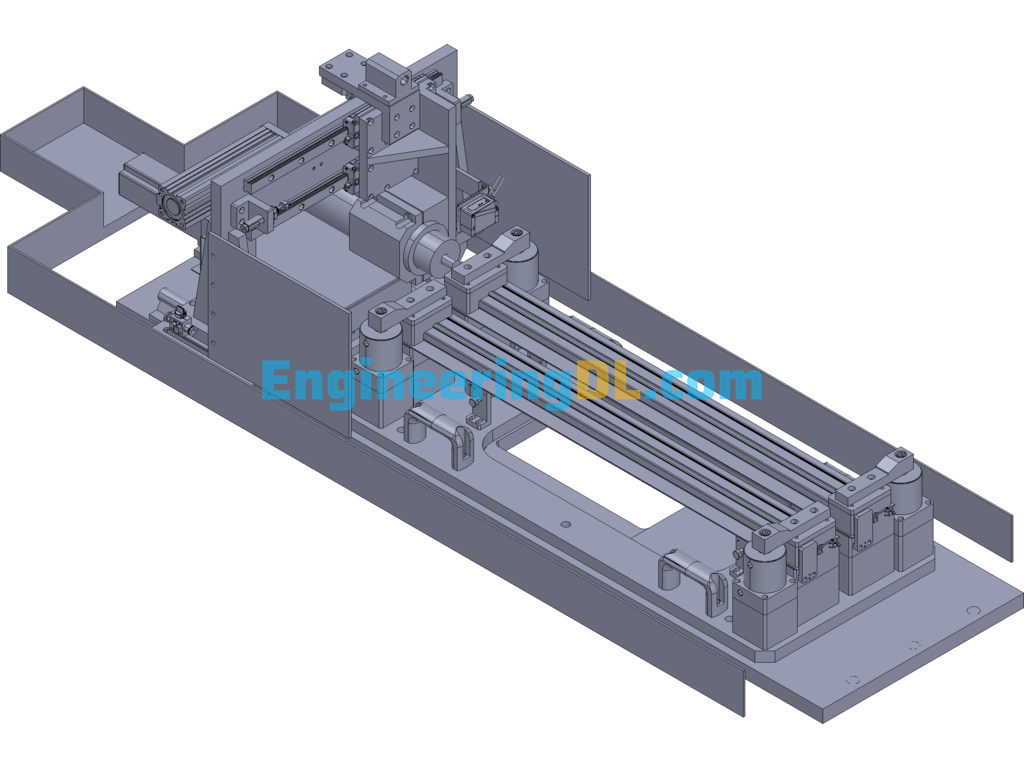

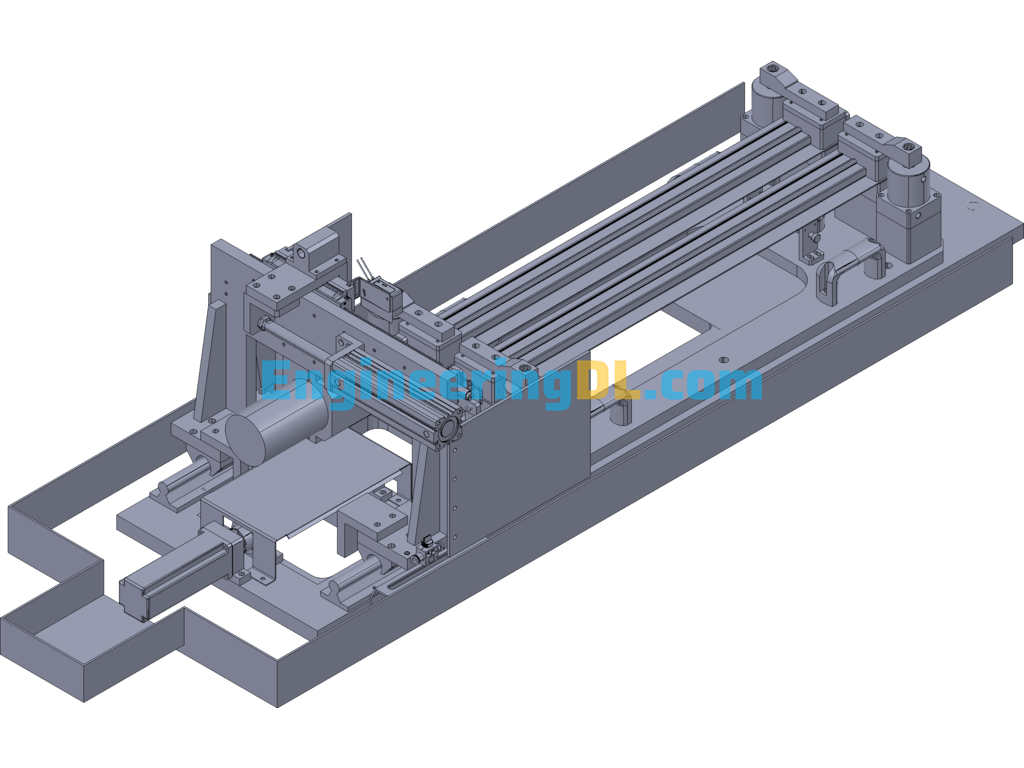

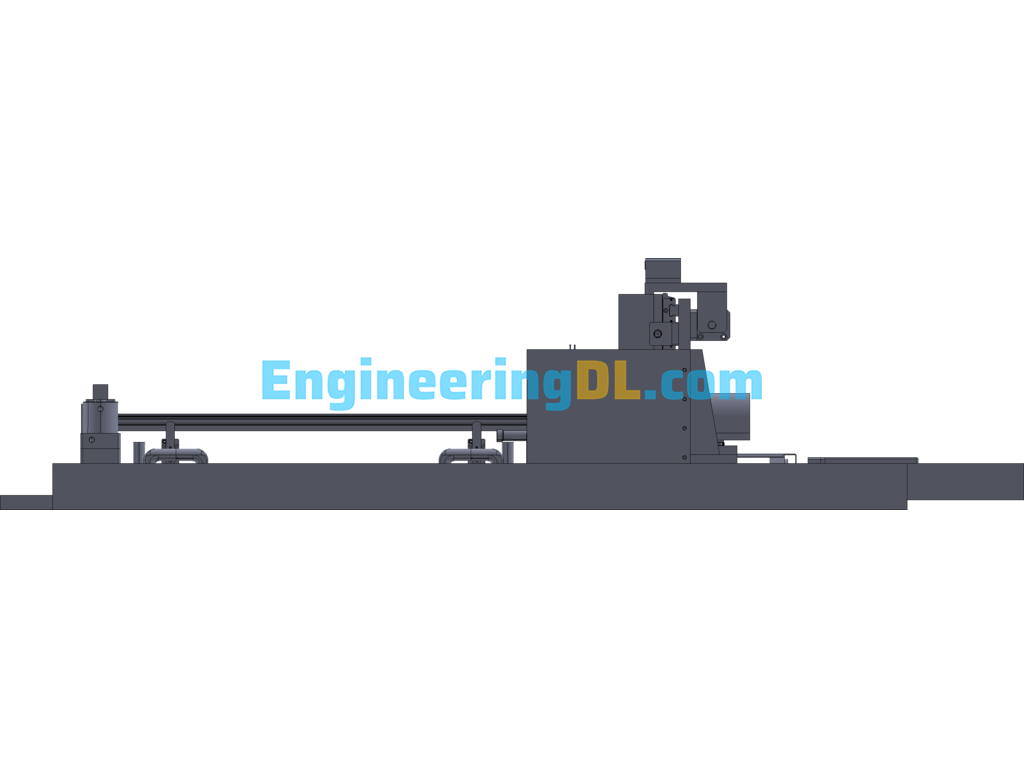

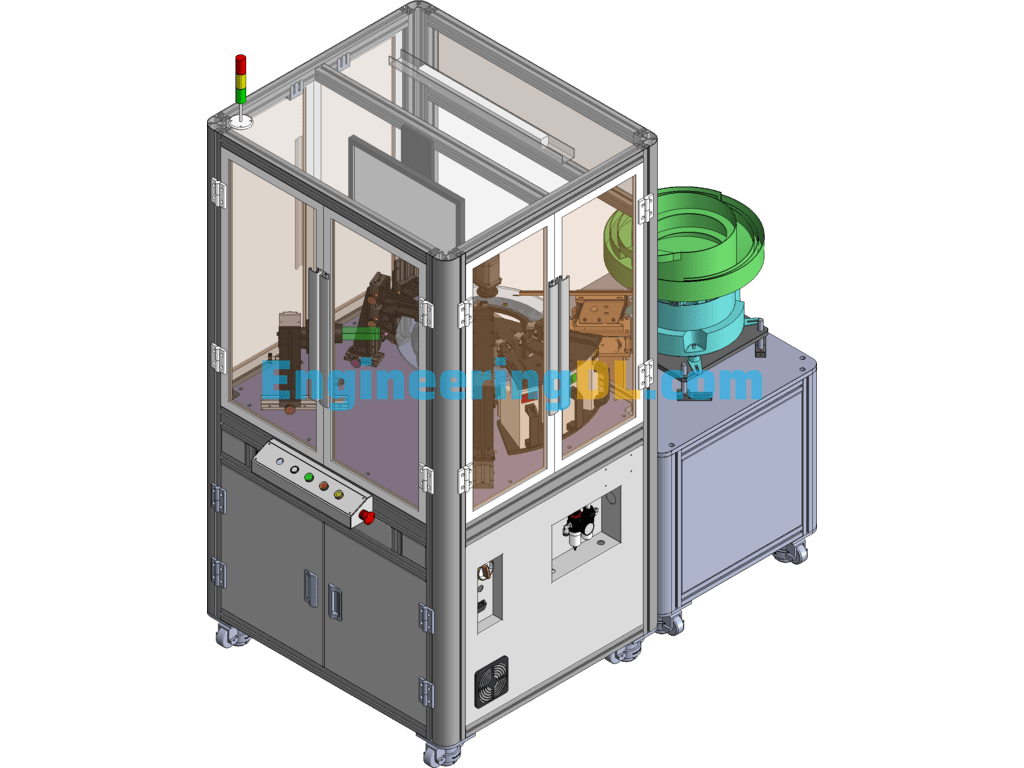

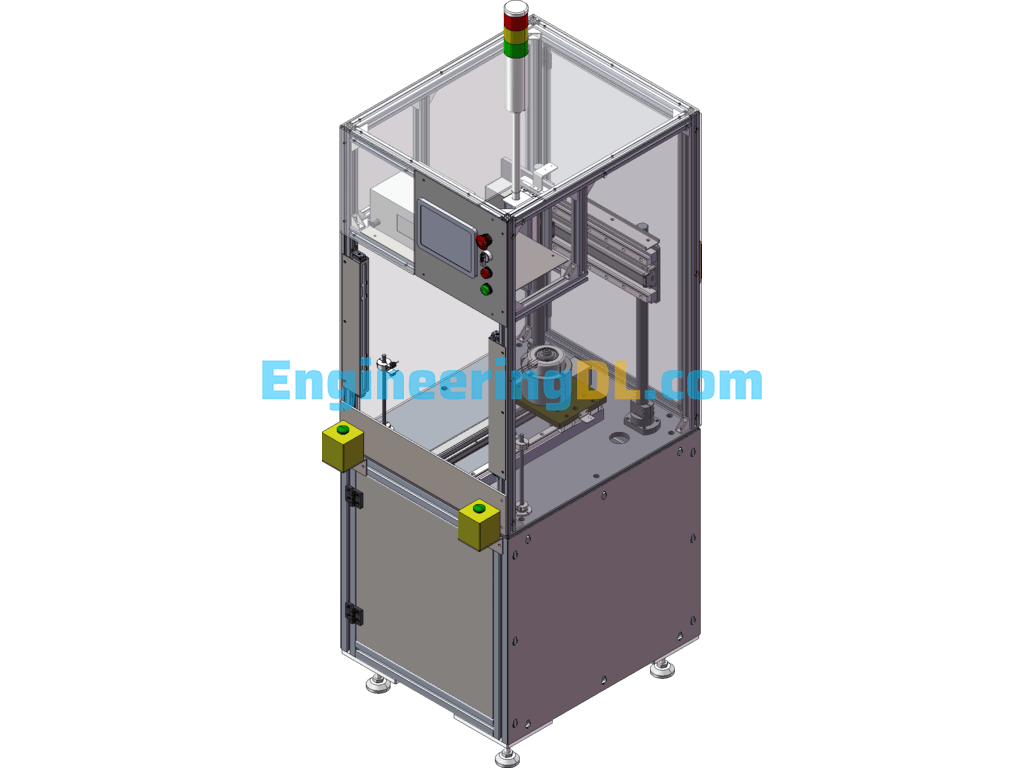

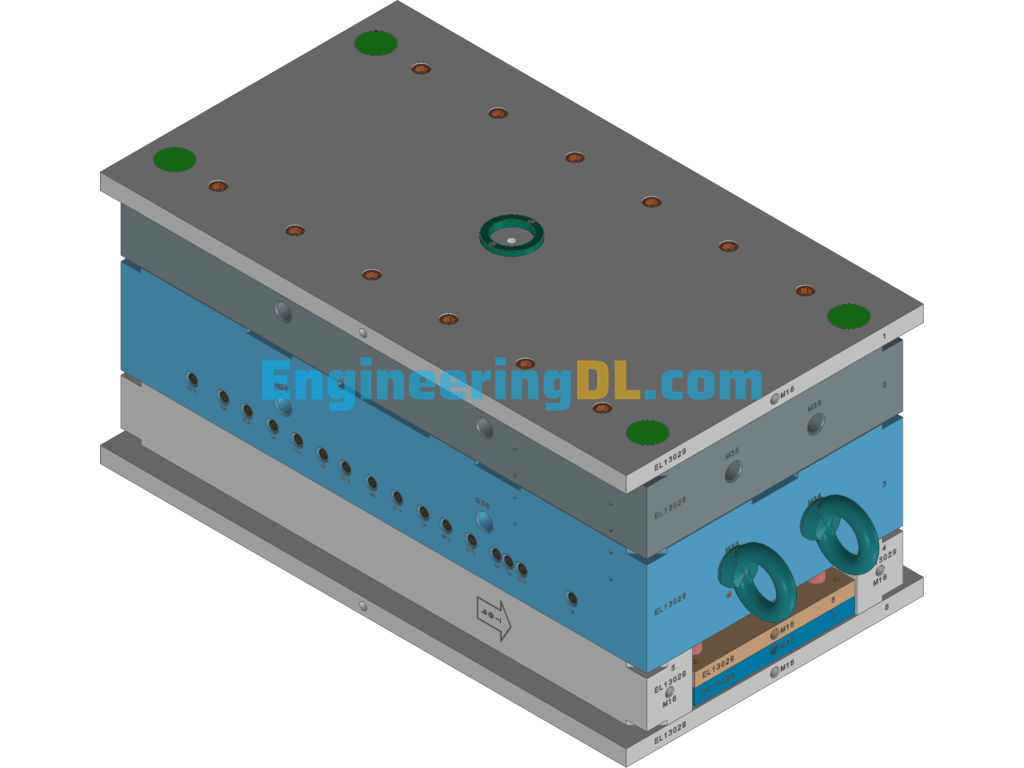

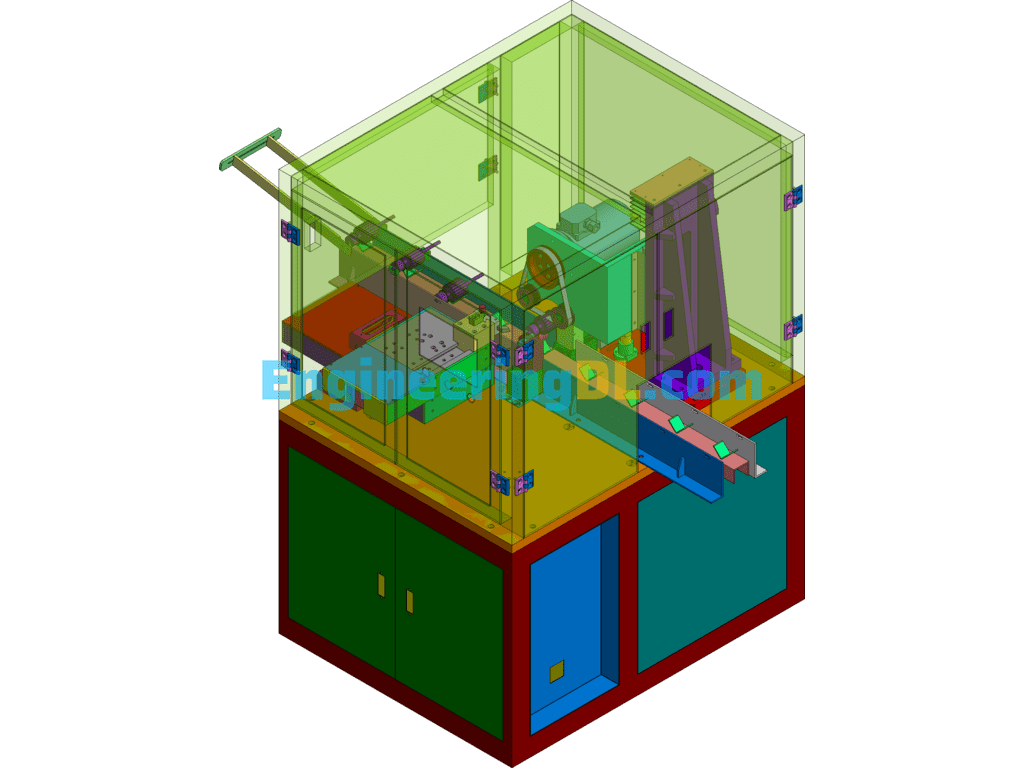

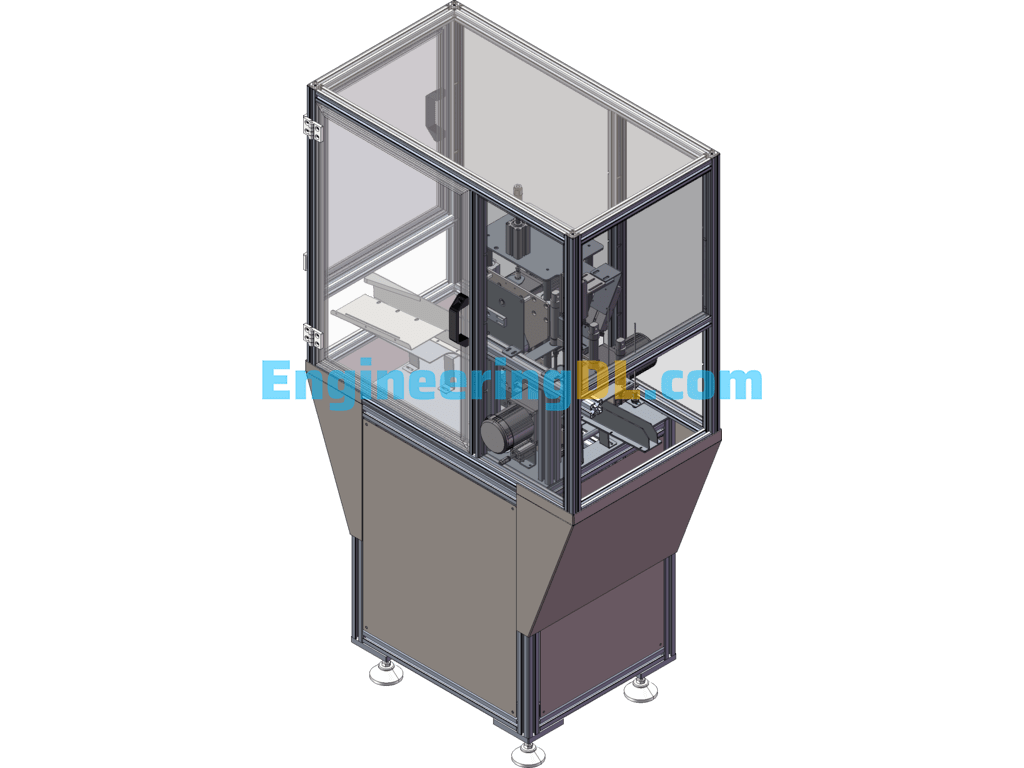

This is an engraving machine technical reform to add a head in order to achieve the chamfering of the skylight guide and inverted lasso hole at the same time, the original two processes to shorten a process, in order to meet the original machine mobile slide bearing and strength, the entire structure of the load-bearing plate using 704A super stone hard aluminum material processing, and do the force deformation analysis, the results show the effect to meet the requirements

The whole structure is designed and analyzed by CREO, and now it is converted to STP format, which can be opened directly. 2.2KW electric spindle is used for the drilling host, and ER16 CNC chuck is used for the collet, which can clamp 6-10mm diameter tool shank, with fiber optic sensor to achieve effective compensation for the deviation of the guide length. The workholding part adopts Airtac rotatable cylinder with delicate and compact structure.

Now we share it for learning and communication.

Specification: Engraving Machine Technical Modification Retrofitting Machine Head 3D Exported

|

User Reviews

Be the first to review “Engraving Machine Technical Modification Retrofitting Machine Head 3D Exported”

You must be logged in to post a review.

There are no reviews yet.