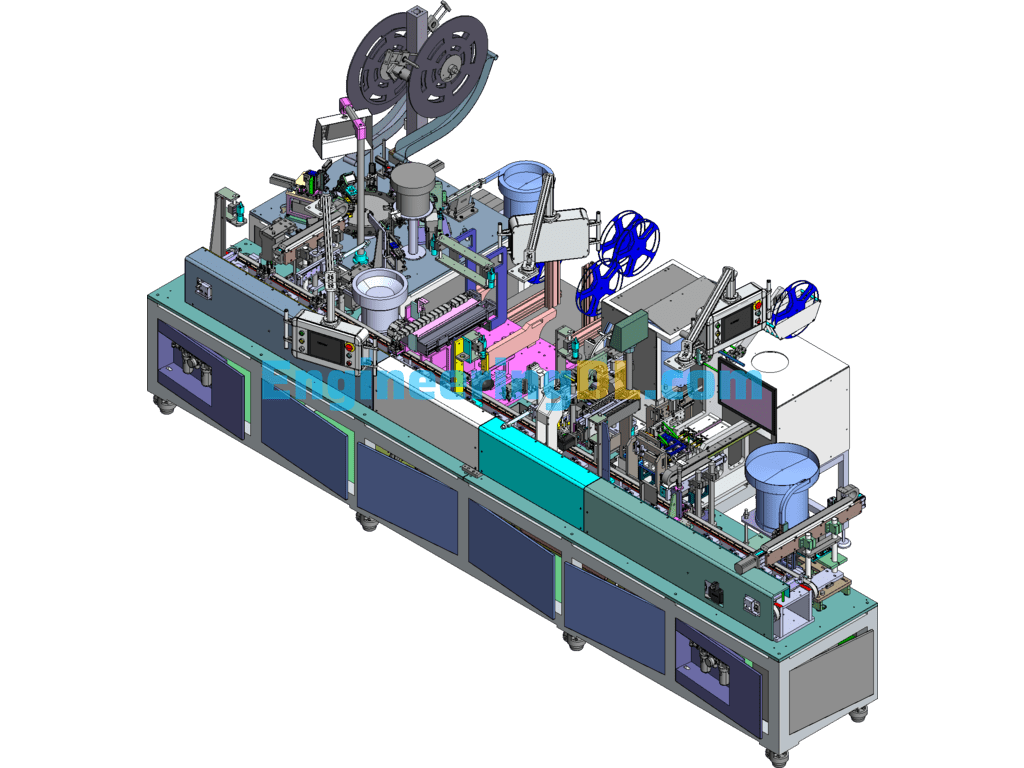

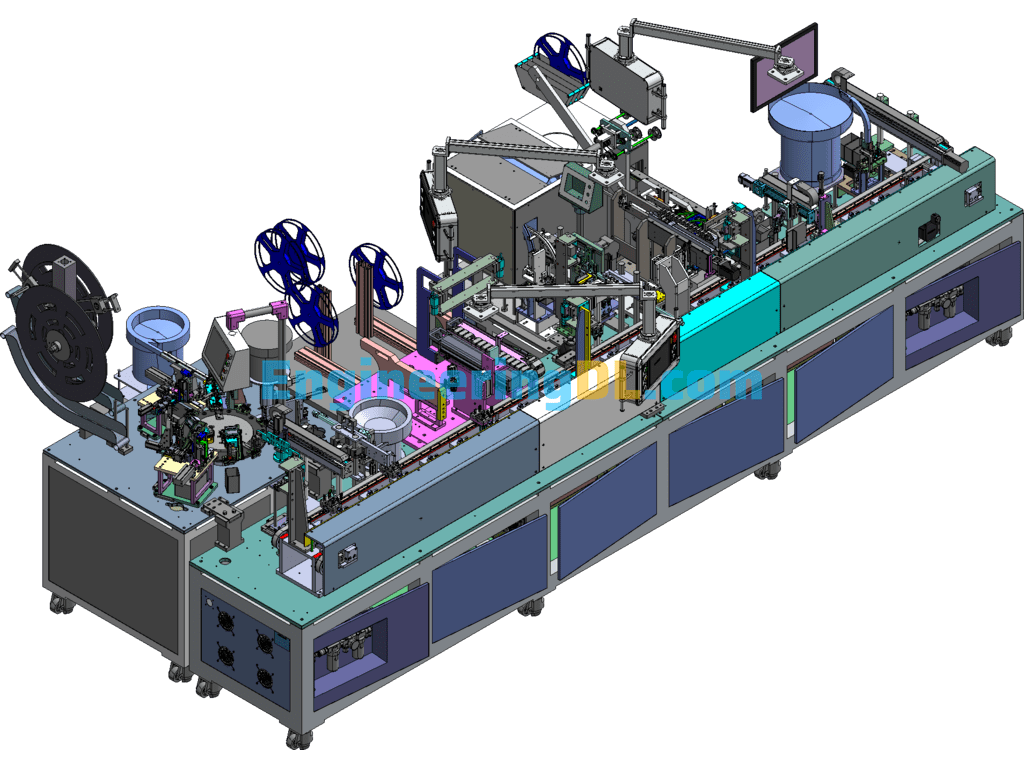

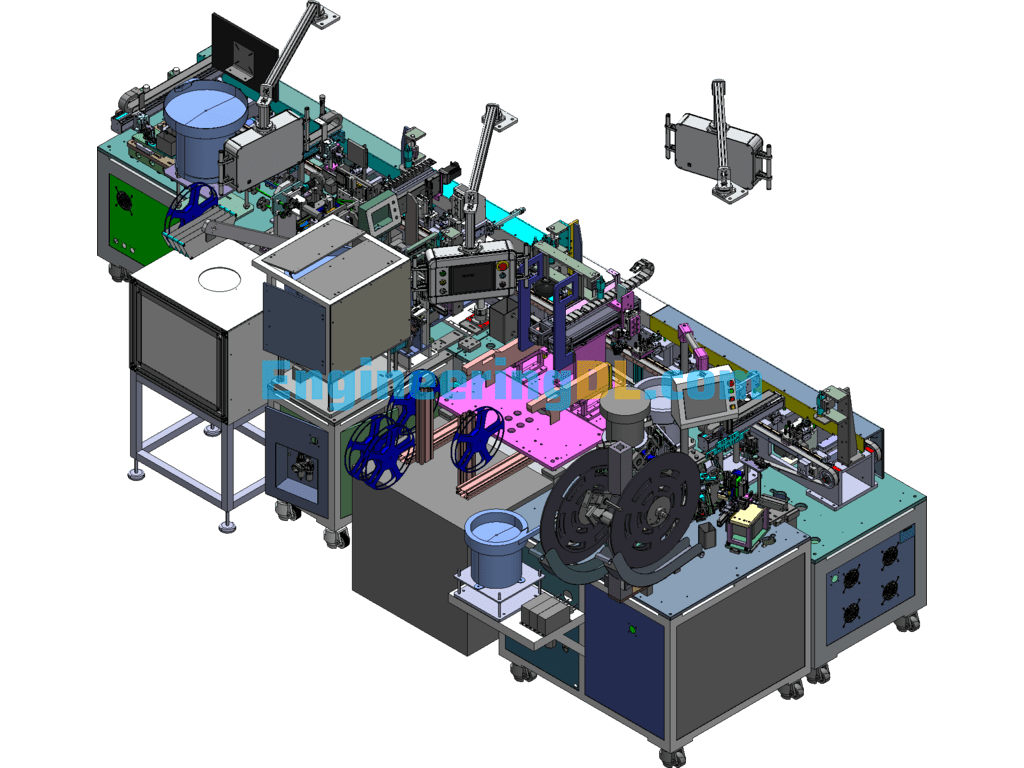

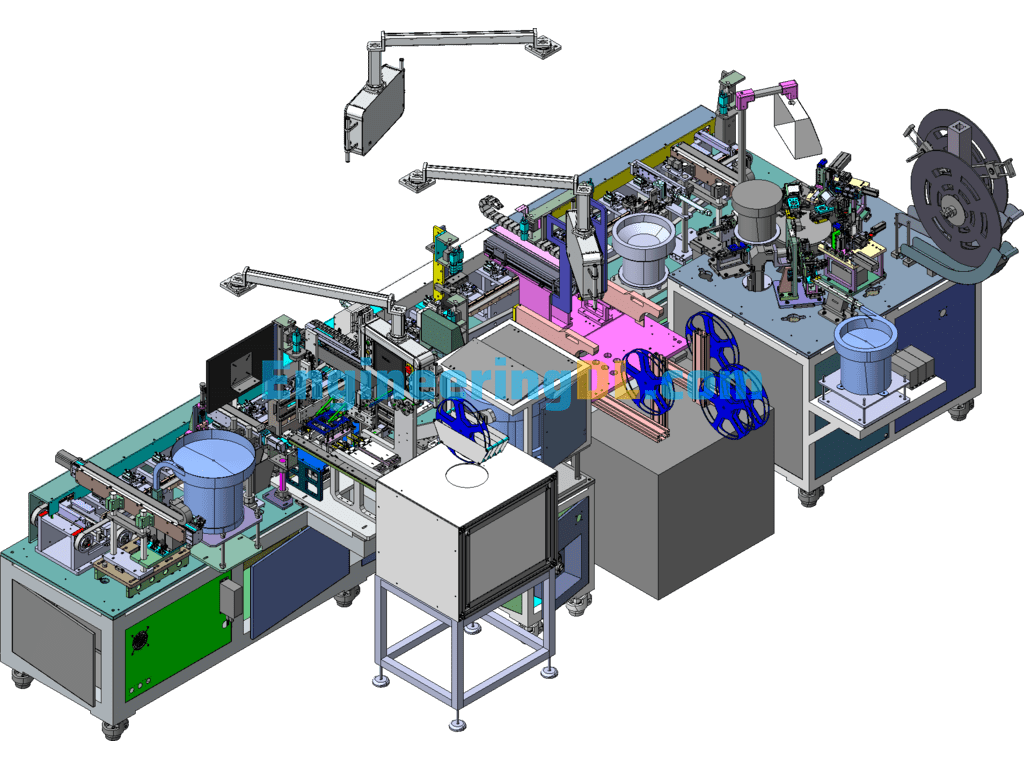

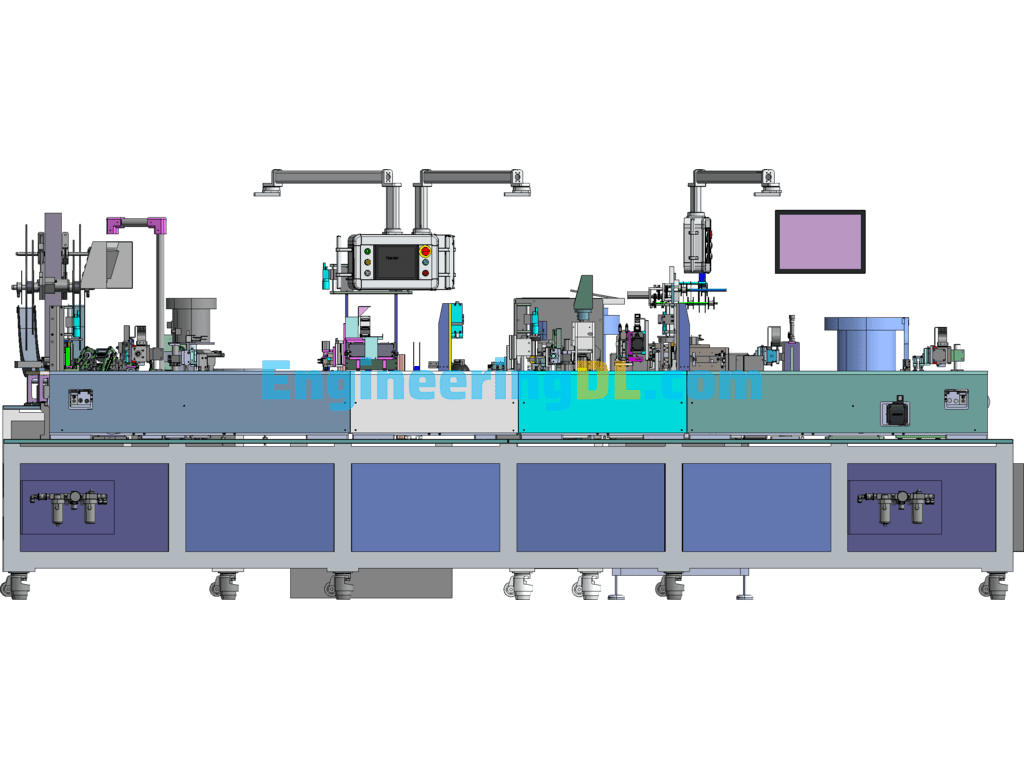

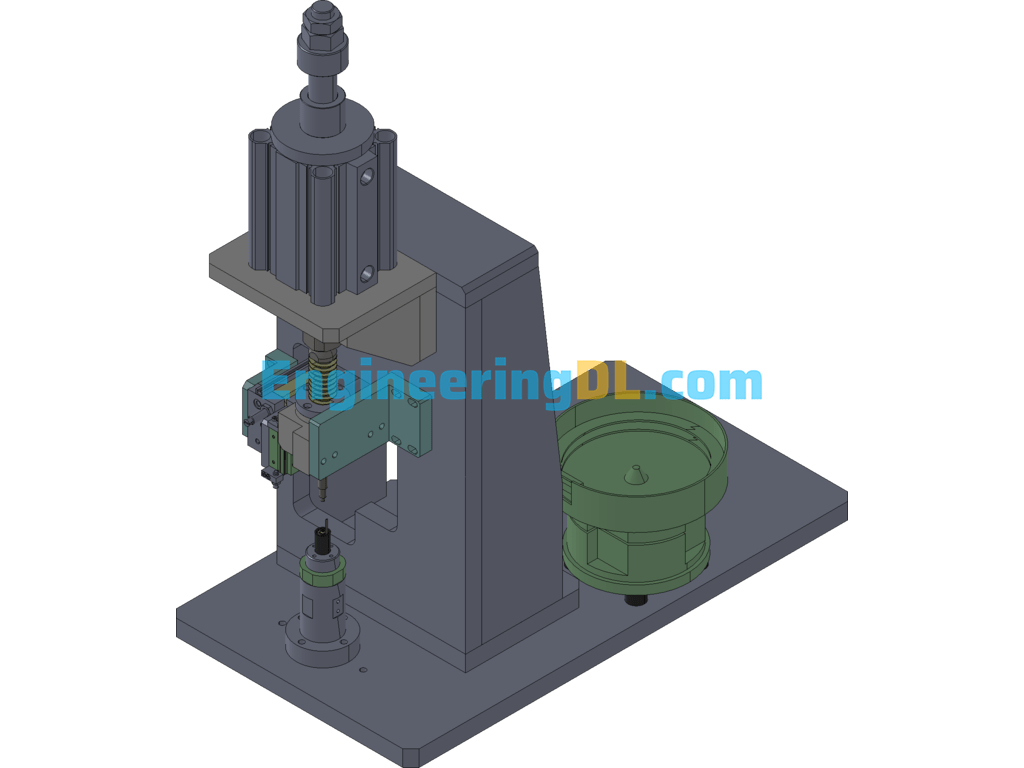

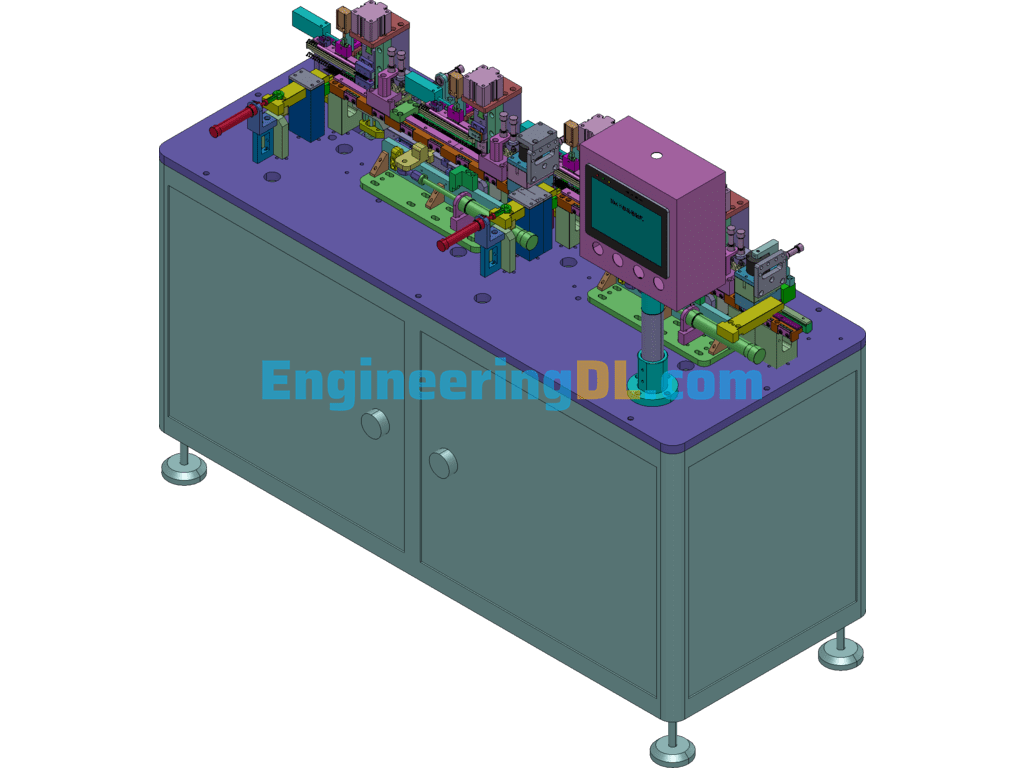

This equipment is the assembly line automatic assembly machine for electronic cigarette products

1 Equipment performance: 1. Equipment size about L*W*H=8000mm*2450mm*2000mm. 2.

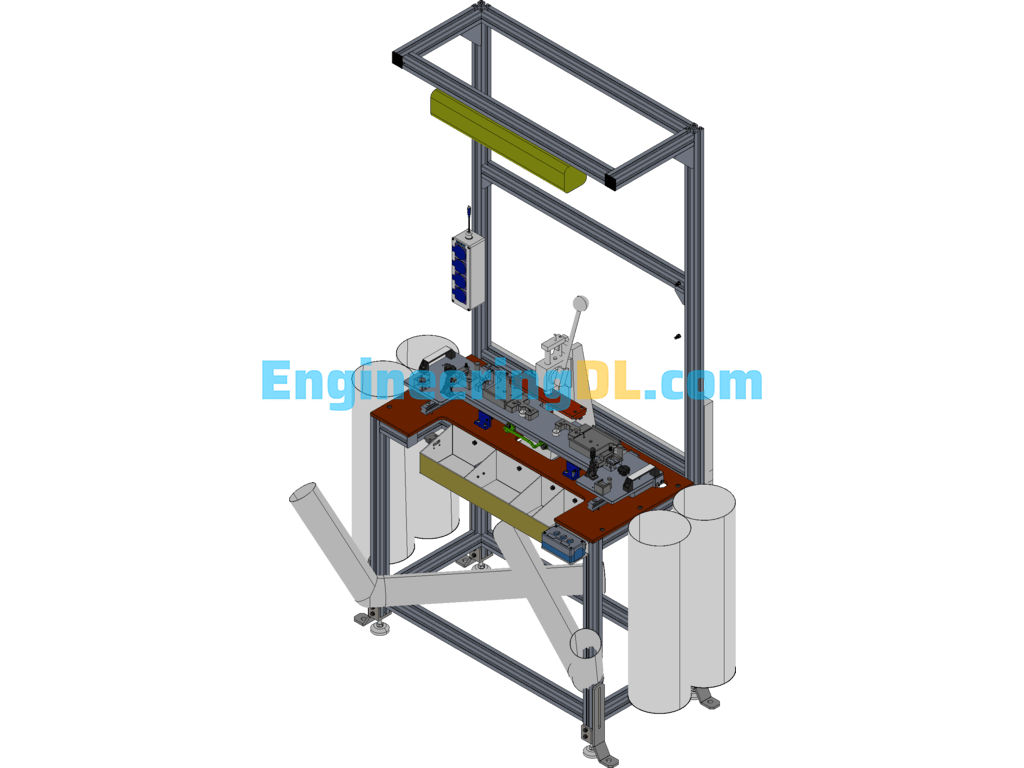

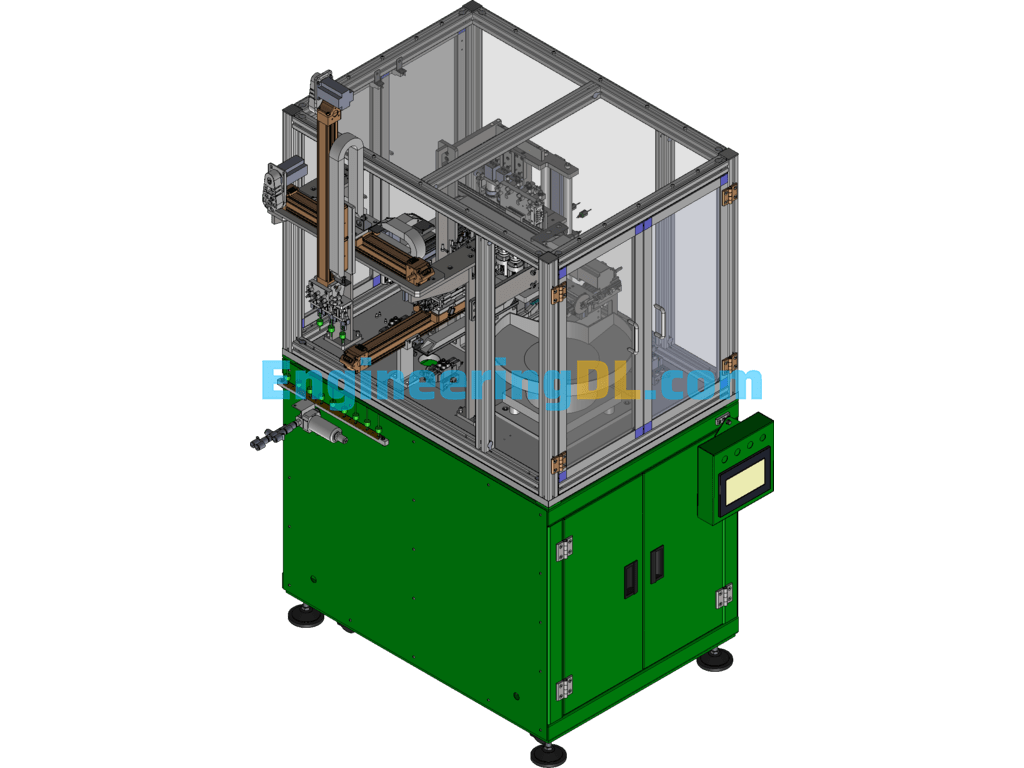

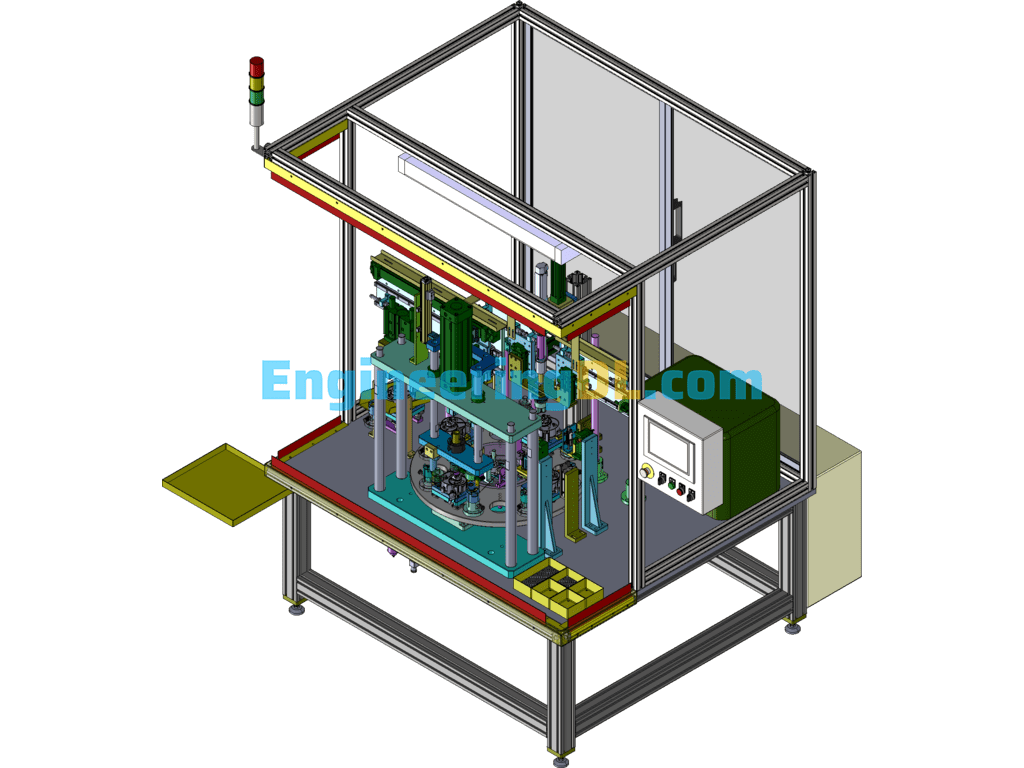

2. The equipment is safe to operate, each part has light brazing induction and safety grating, and there is an emergency stop button.

3. The product scrap rate of this equipment is not more than 5% (except for bad incoming materials and human factors).

4. machine output UPH = 1440pcs. designed machine output 1800pcs/per hour, based on the bottleneck 2s/pcs, 1 day 22 hours

5. OEE ??? 80% (except incoming defective materials and human factors).

6. Noise less than 60db

Equipment control: LCD touch screen human-machine interface, equipment institutions can display the alarm and failure to remind the lifting measures, the text is Chinese. The main control has emergency stop, stop, start, inching and other buttons.

Standard brand: motor: Panasonic; PLC: Omron; pneumatic components: SMC; line rail: HIWIN camera: Germany BASLER (residual material detection 1 5 million camera heating wire riveting 4 11 million camera absorbing cotton detection 1 5 million camera height detection 1 11 million camera rubber pad assembly in place detection 1 11 million camera)

Power requirements: input power: AC 220V 50/60HZ; 5-6kg/cm2 of clean pressure air.

Specification: Electronic Cigarette Assembly Line SolidWorks

|

User Reviews

Be the first to review “Electronic Cigarette Assembly Line SolidWorks”

You must be logged in to post a review.

There are no reviews yet.