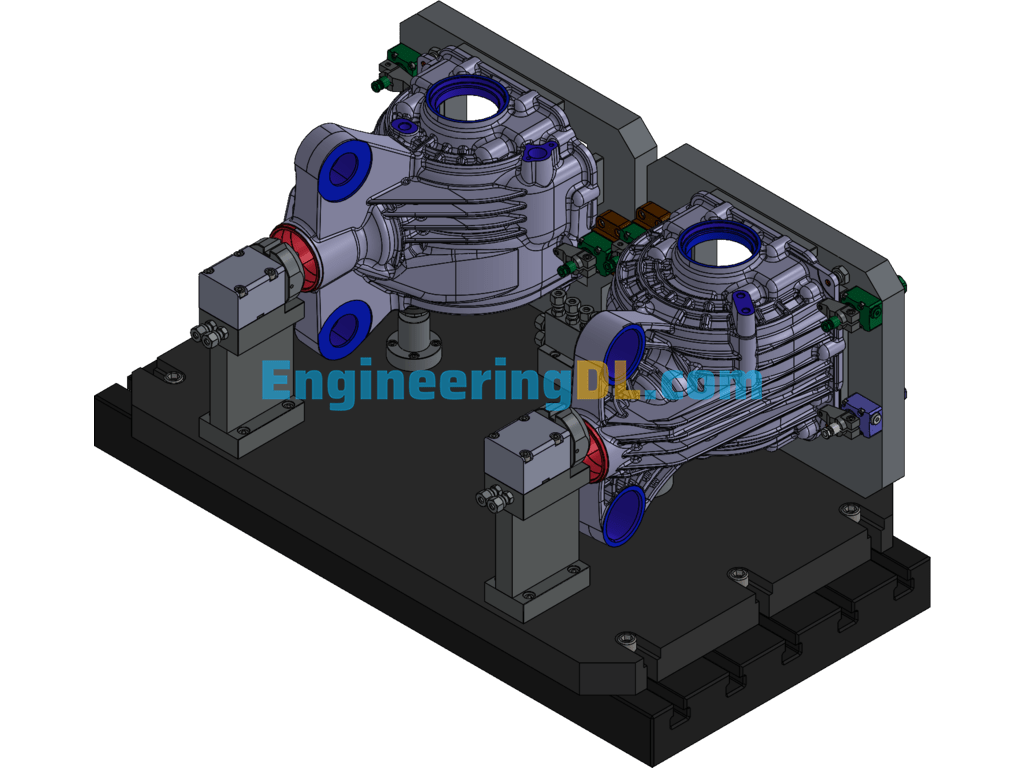

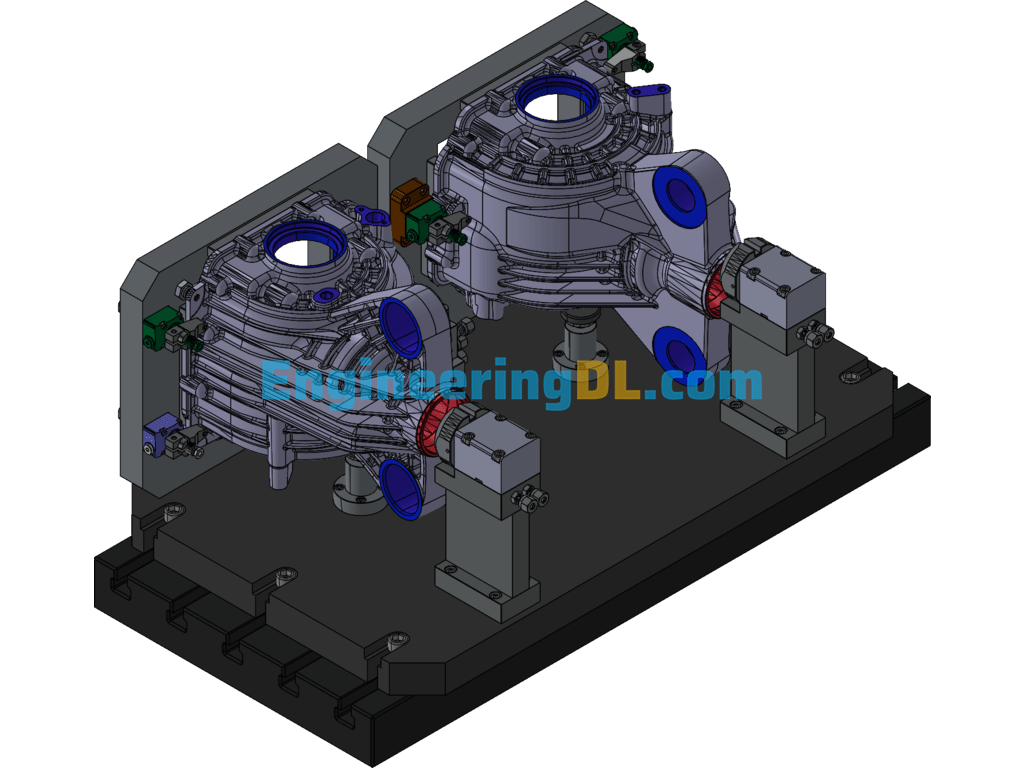

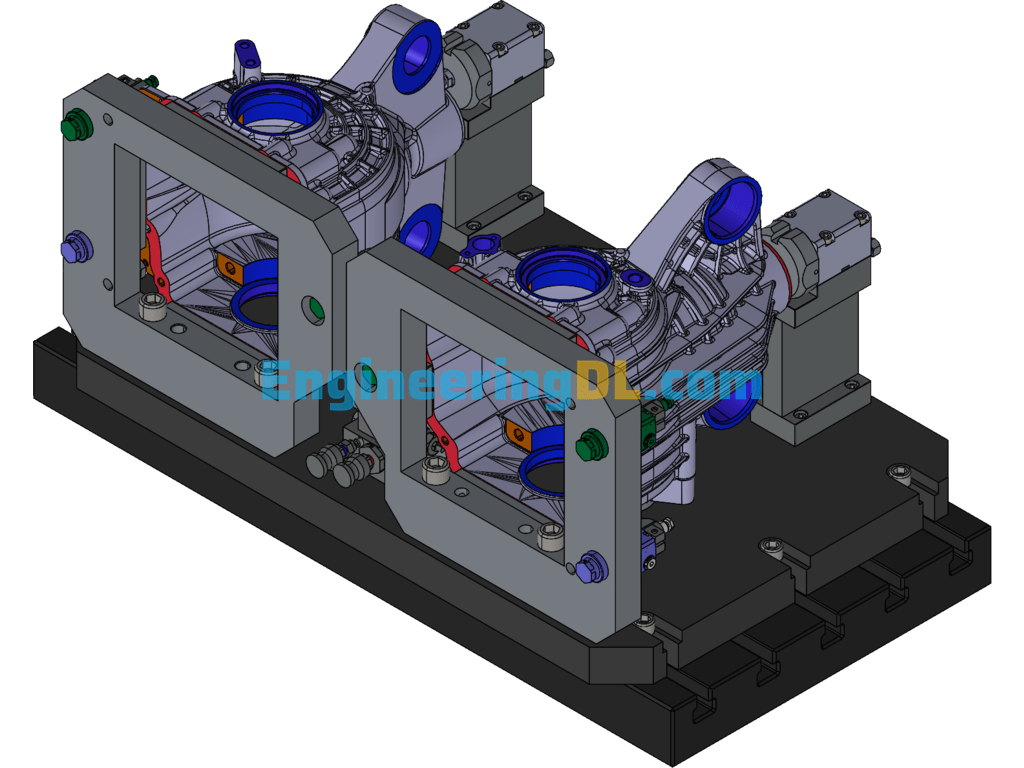

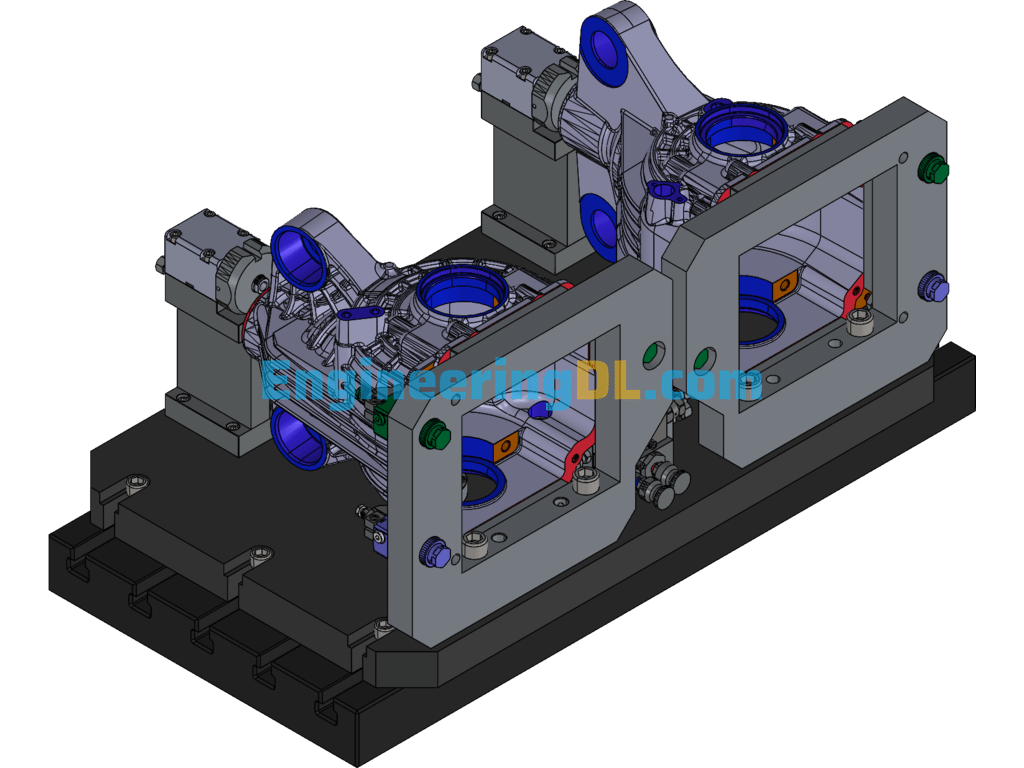

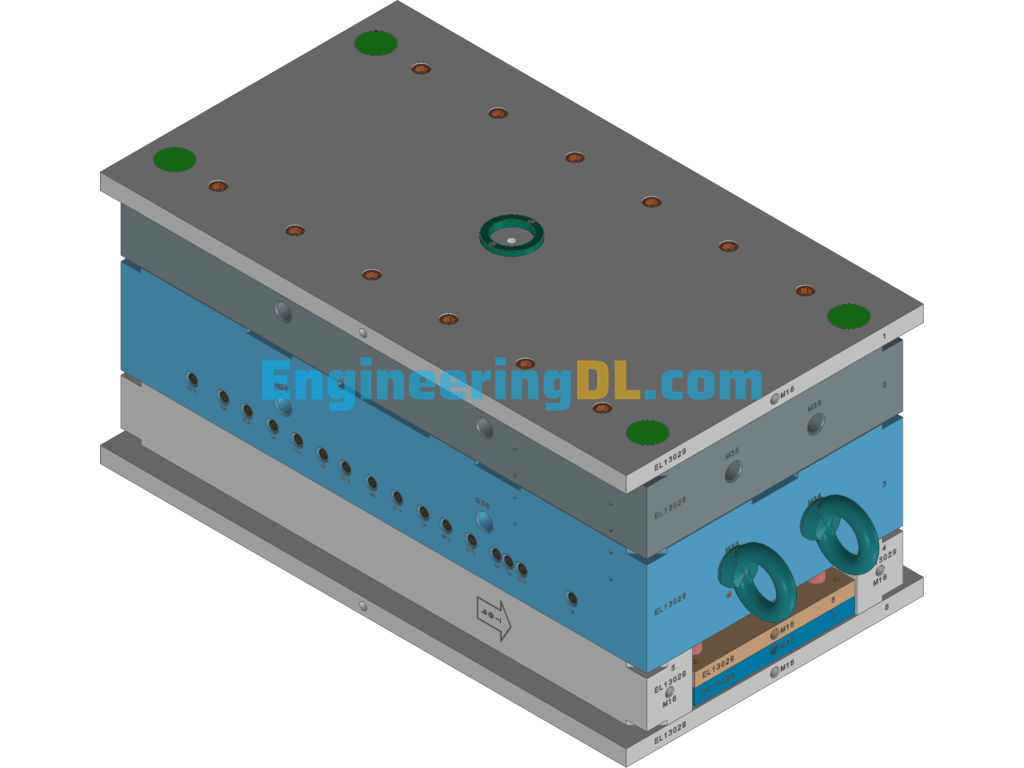

The fourth sequence: using equipment: VMC850 (the same as the first sequence)

Machining part: after installing the other half of the shaft tile on the E datum surface, machining C and D datum holes, end faces and the associated features of the tab surface;

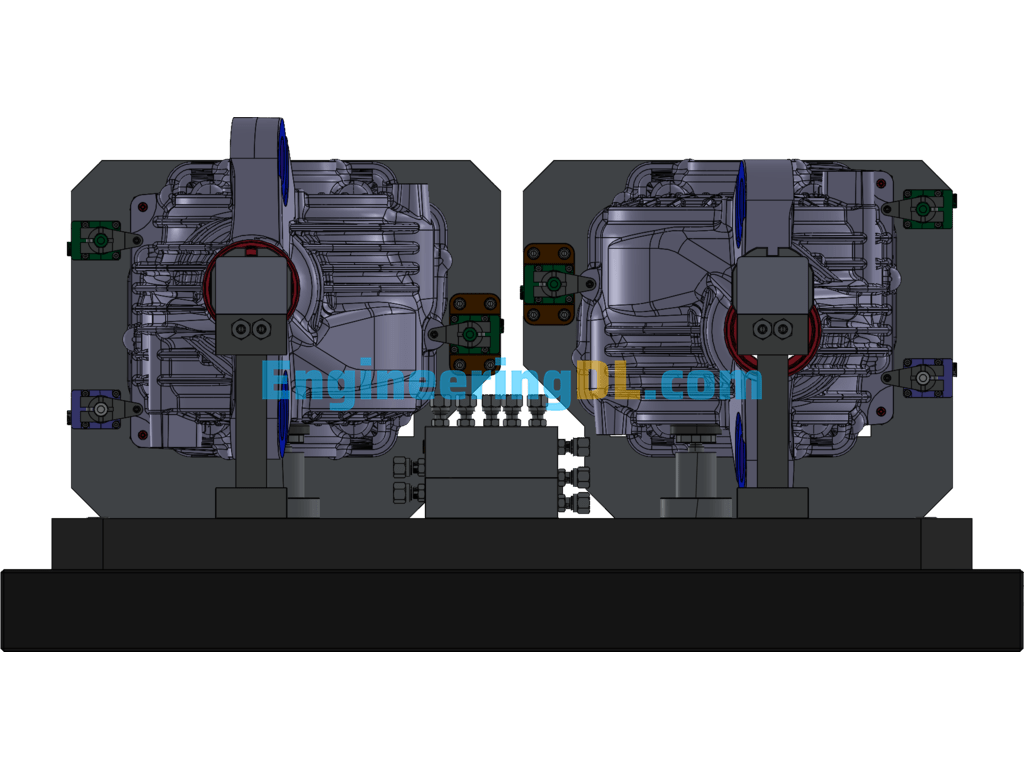

Clamping principle:

Using the installation bond surface machined in the first sequence as the device surface, the F-F view of the Two 2-??8 pin holes for centering, two pins on one side;

Program requirements:

Two pieces in one clamping: the first one (first station) for C datum and related features; the second one (second station) for D datum and related features, one tool for fine boring C and D datum (shank hole), no interference with the tool in the middle cavity

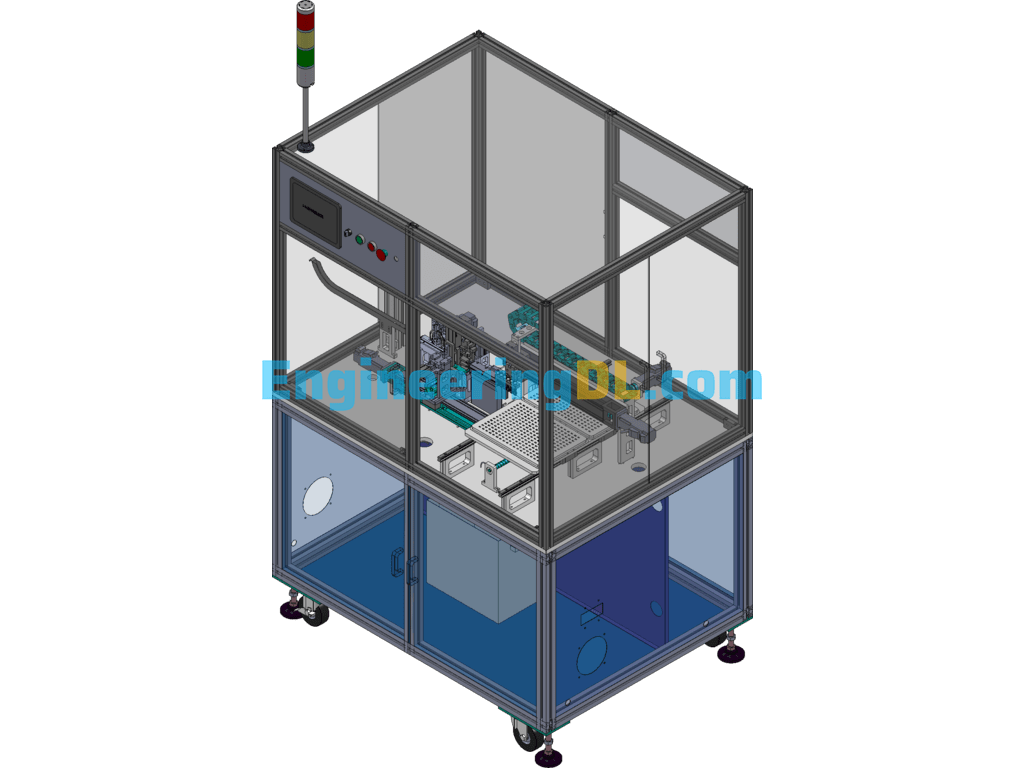

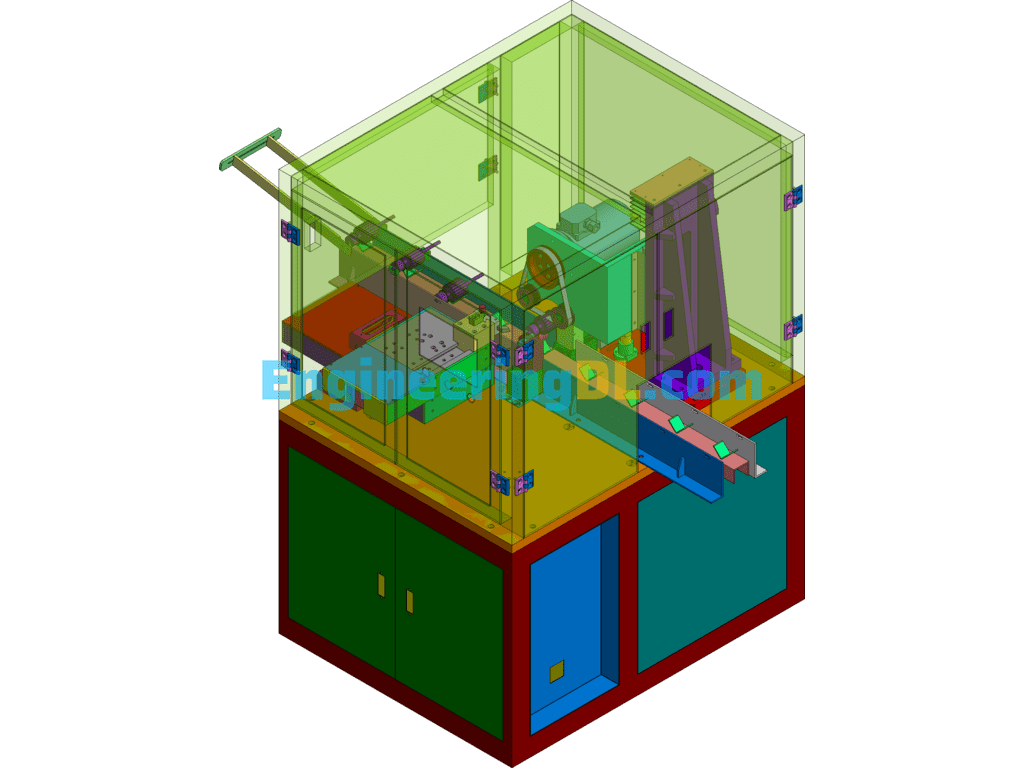

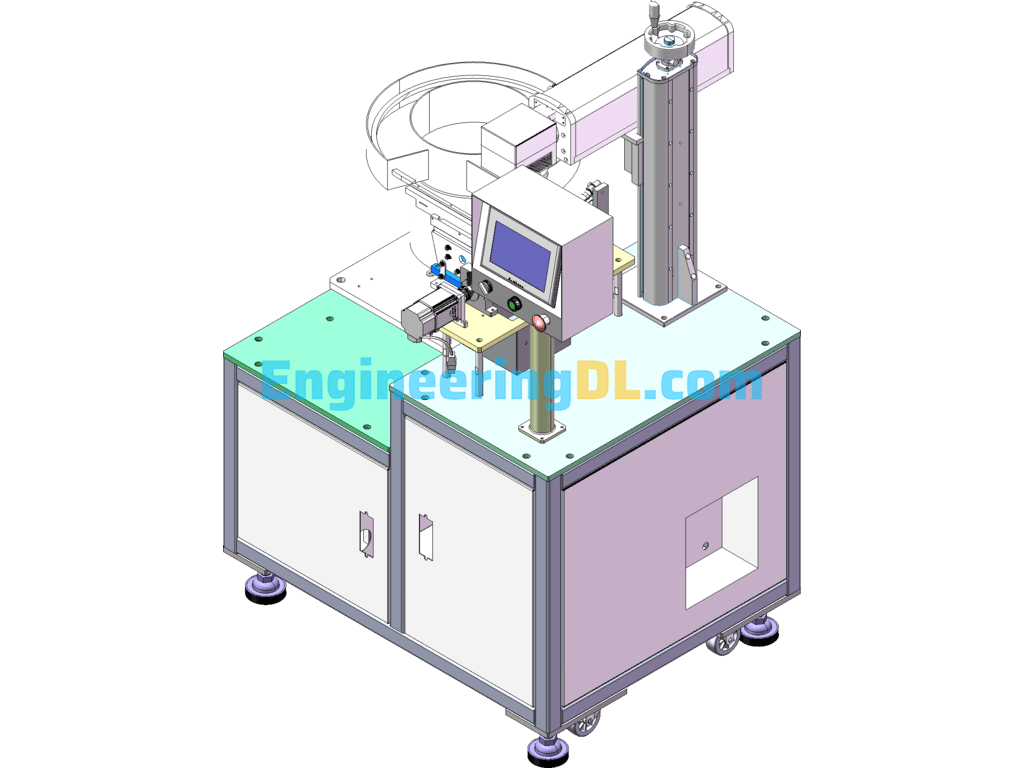

Specification: Dual Power Supply Switchgear Distribution Cabinet SolidWorks

|

User Reviews

Be the first to review “Dual Power Supply Switchgear Distribution Cabinet SolidWorks”

You must be logged in to post a review.

There are no reviews yet.