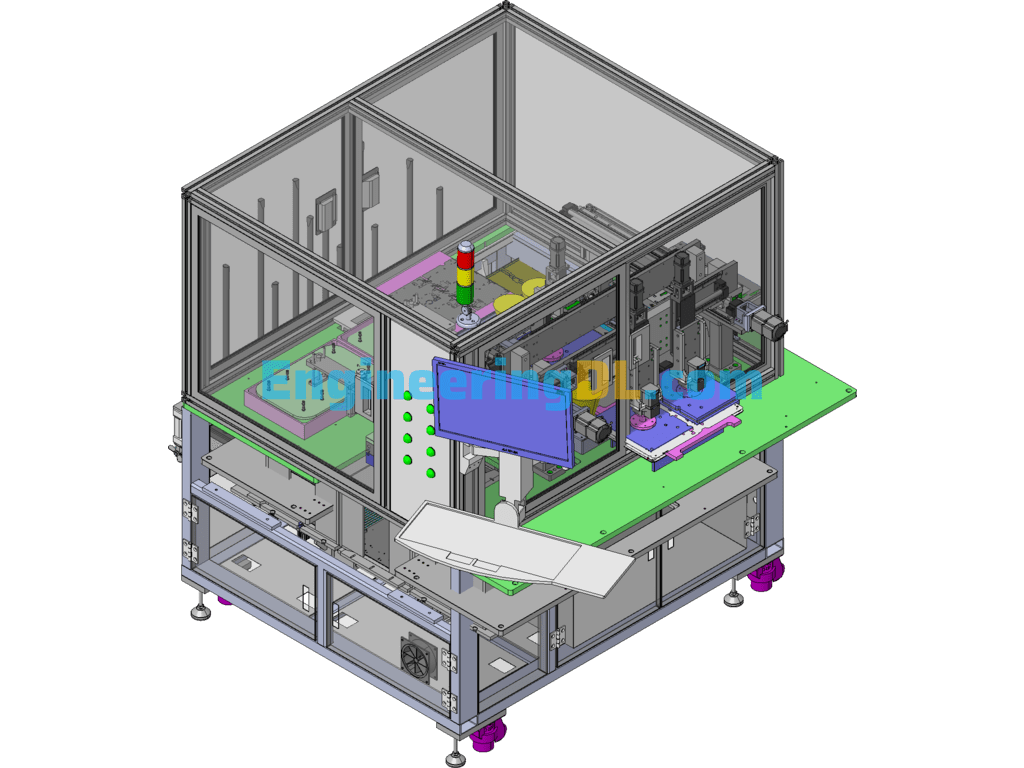

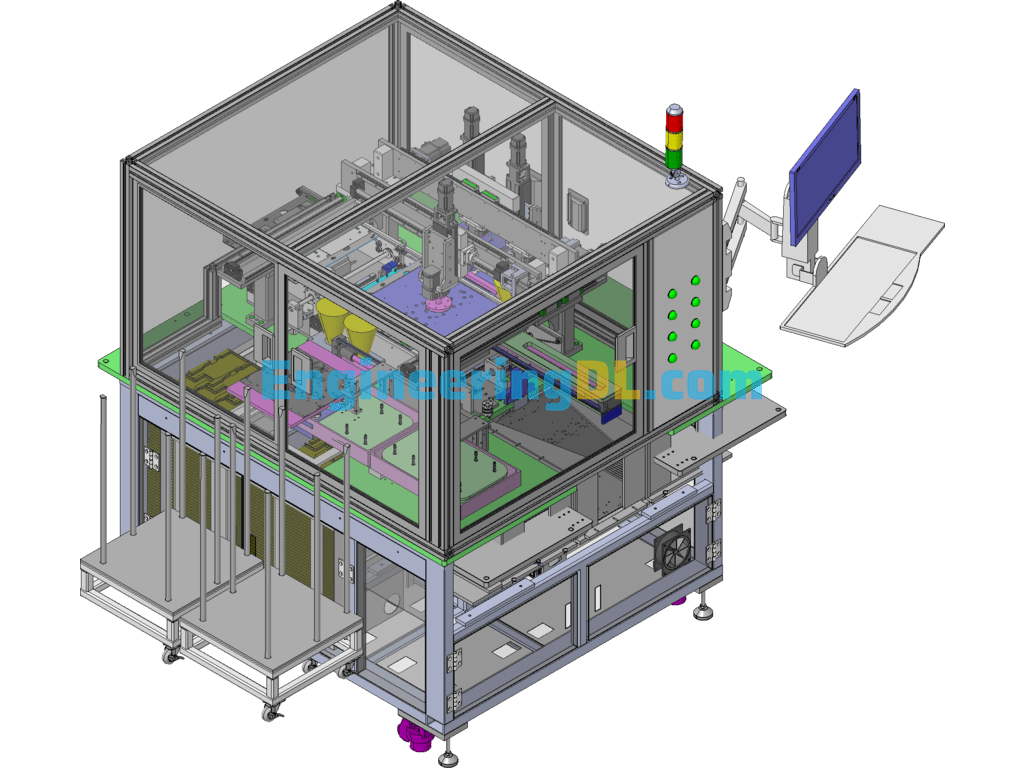

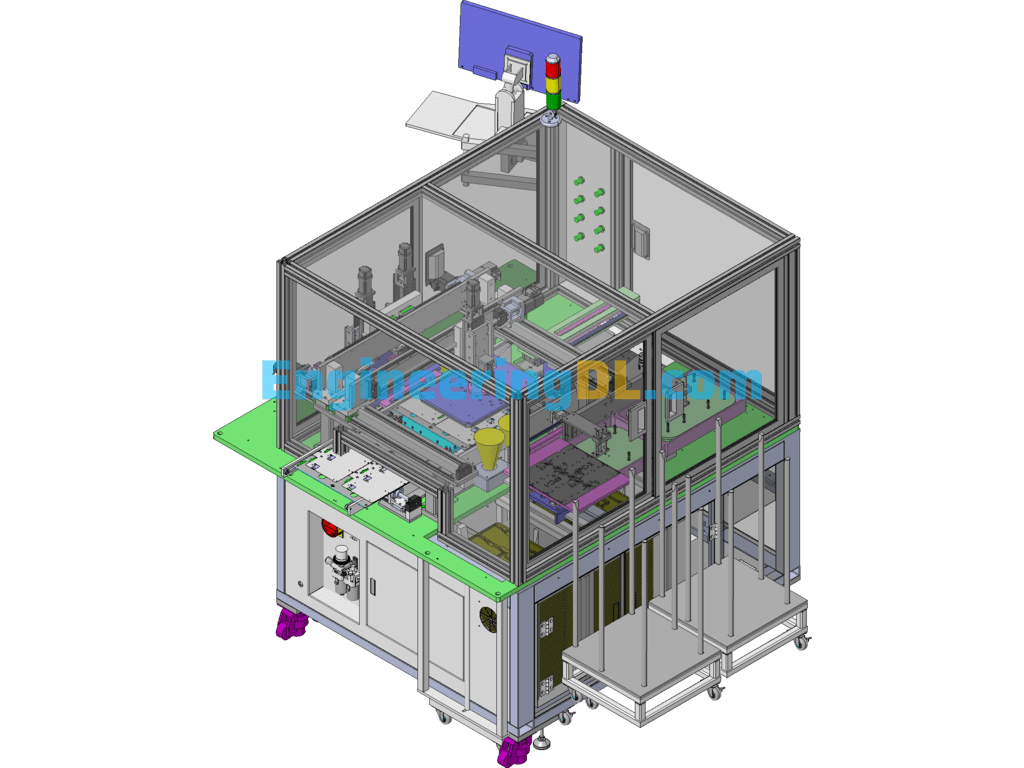

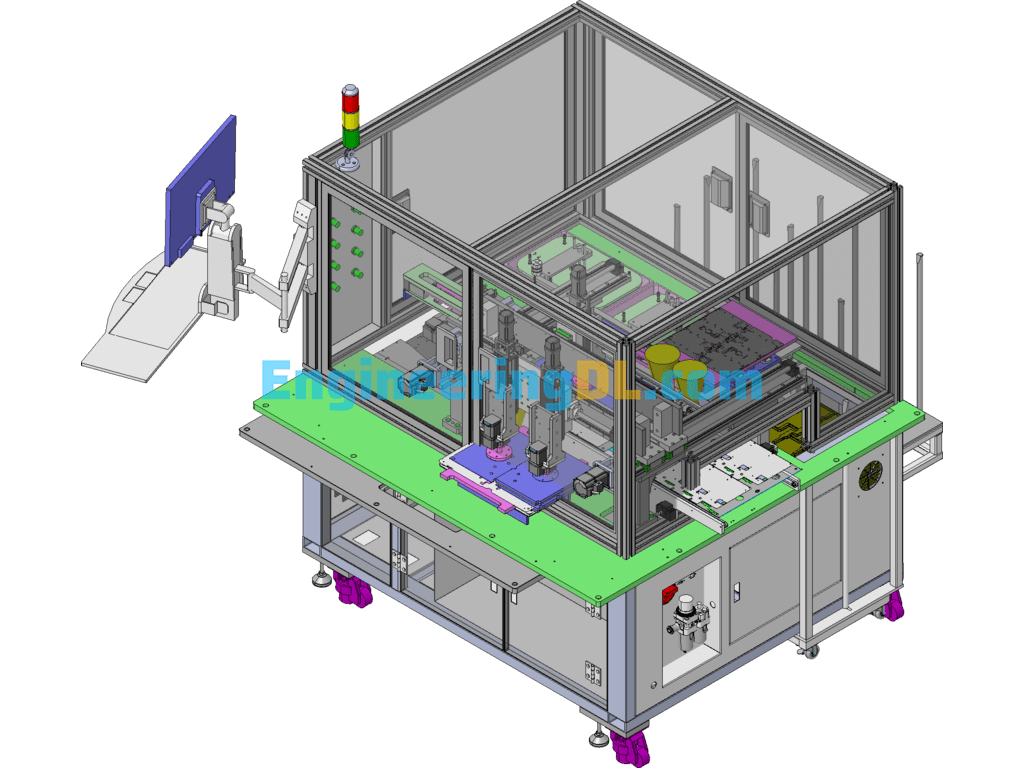

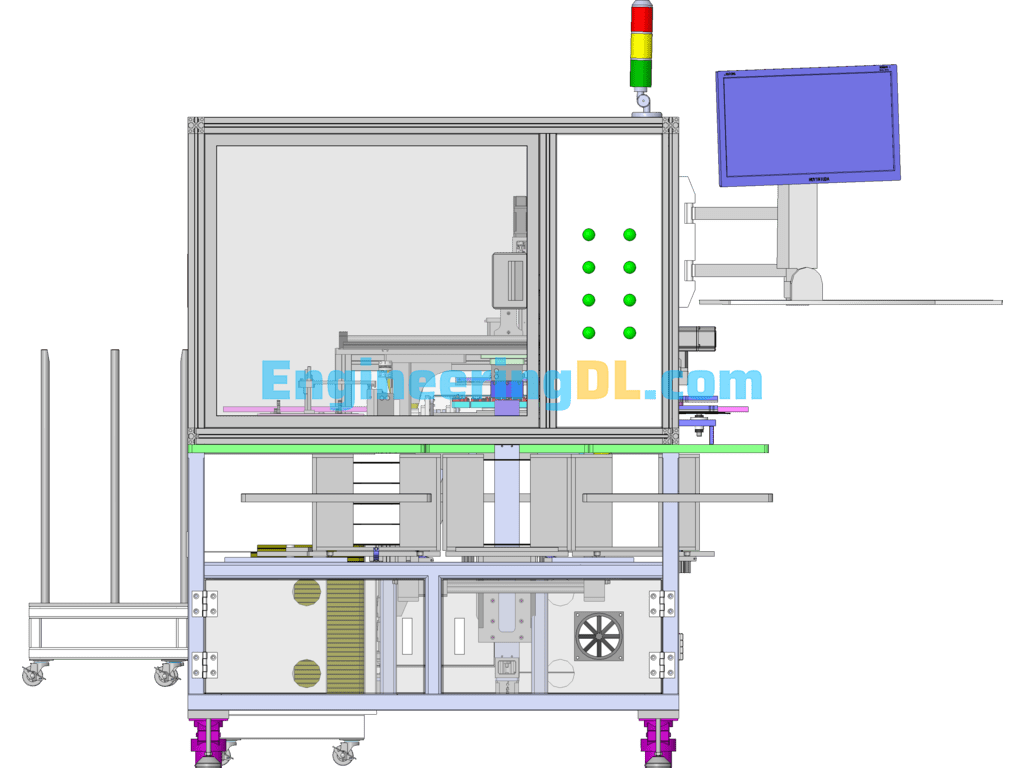

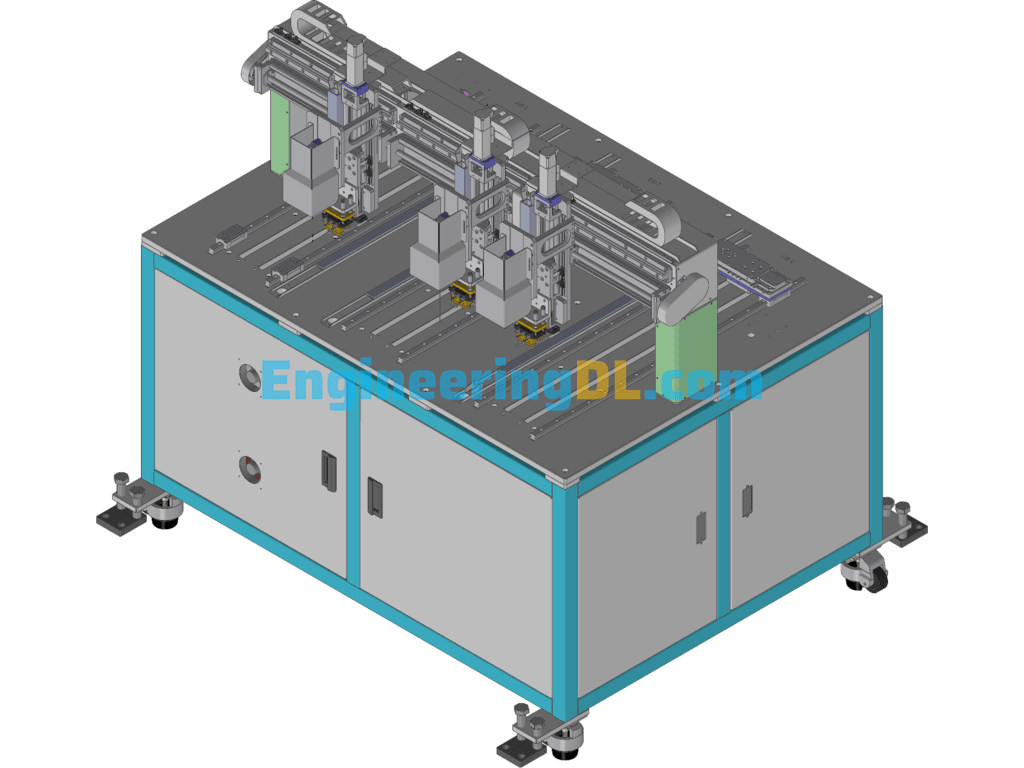

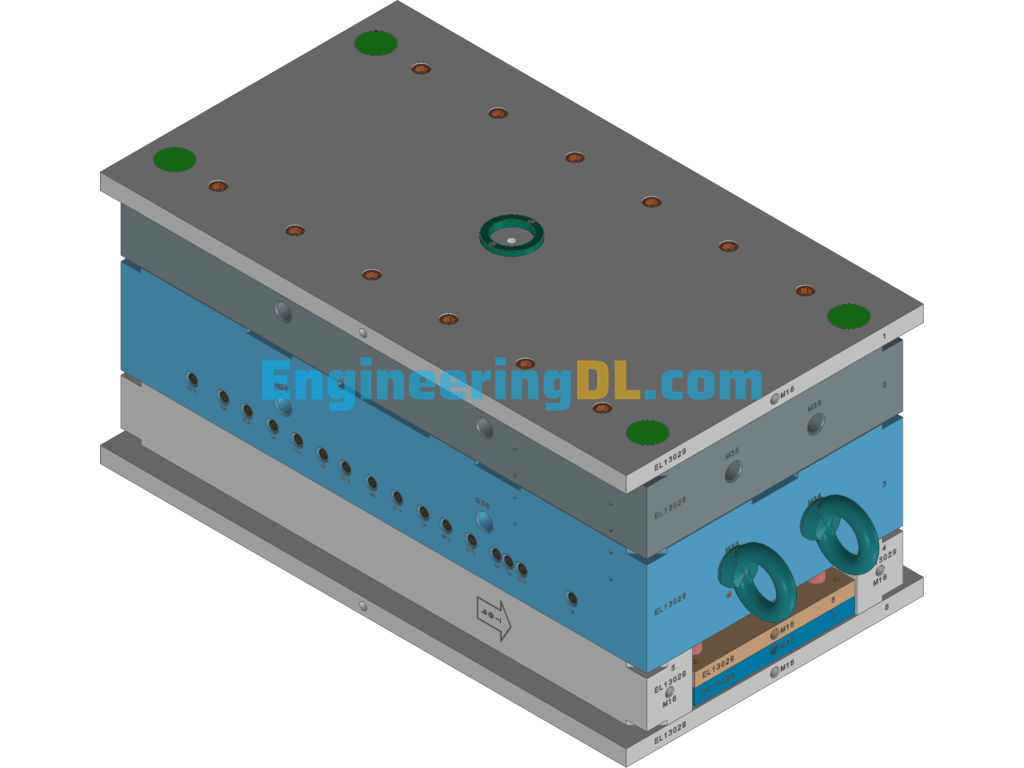

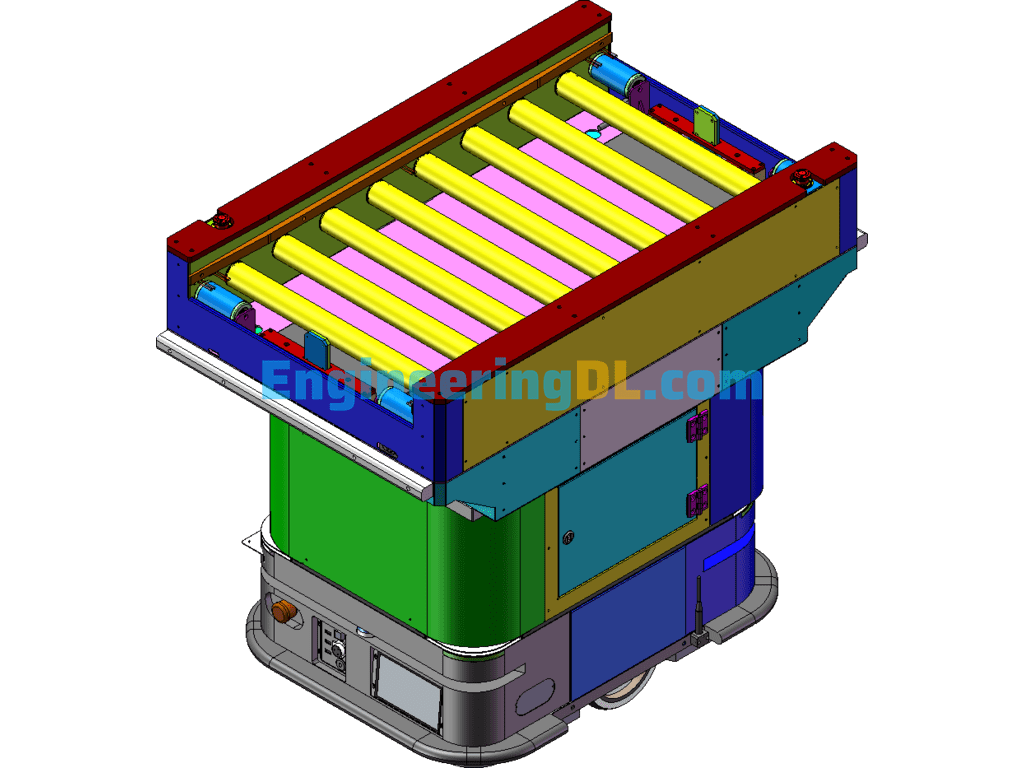

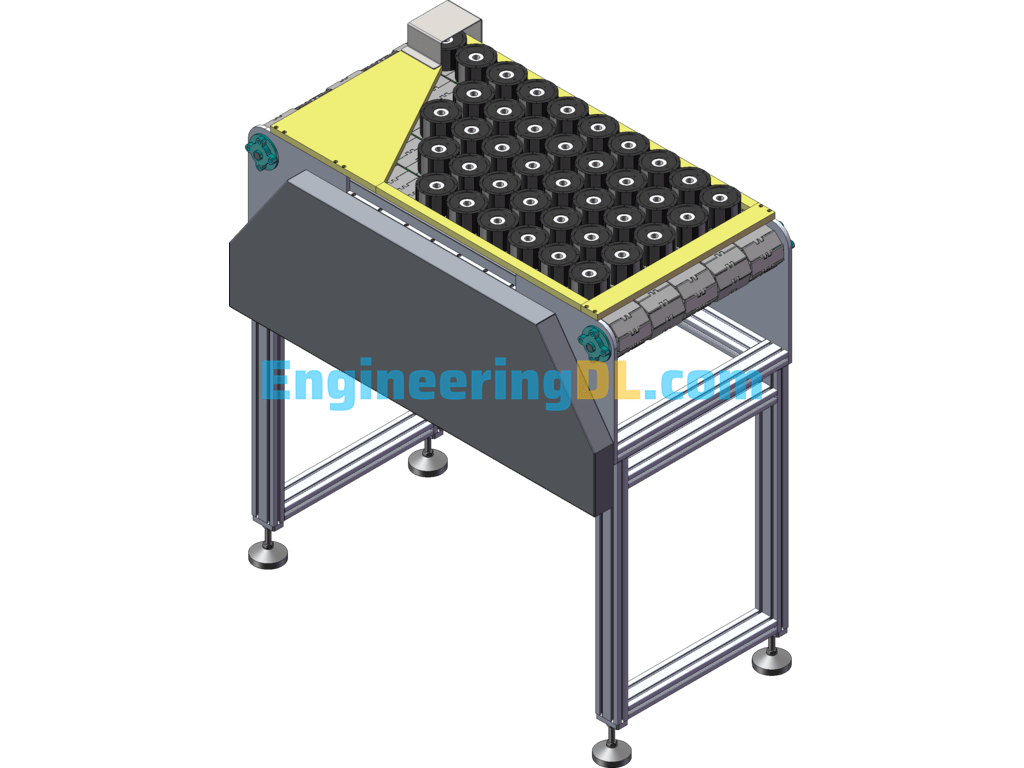

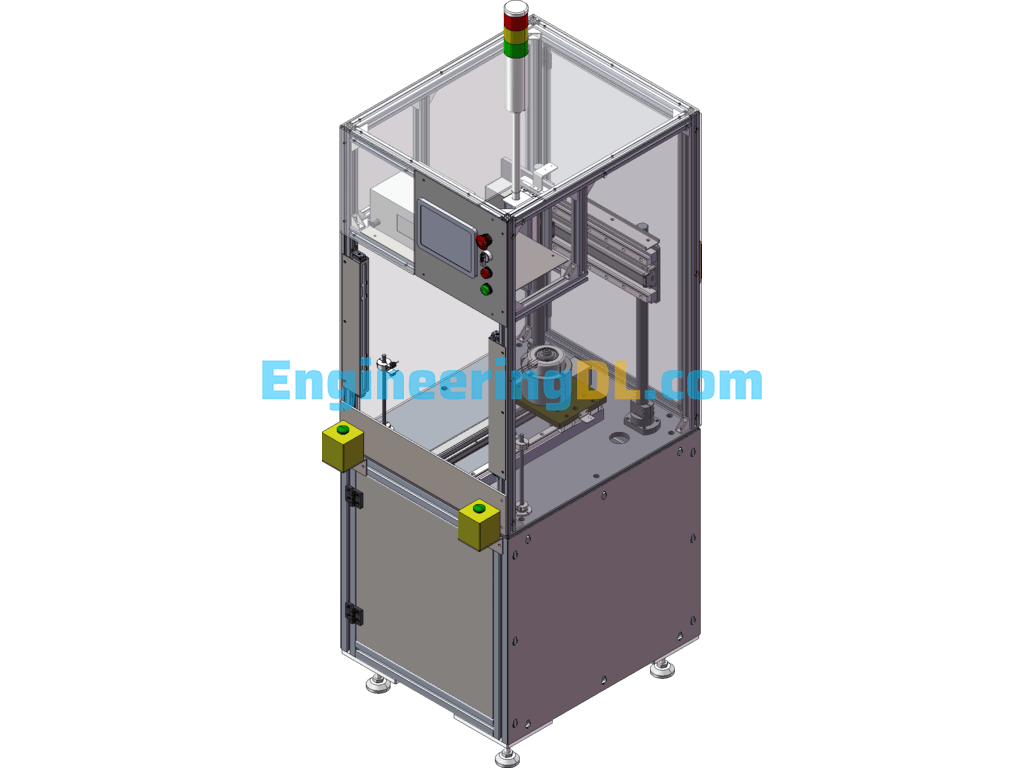

fpc flexible board automated steel press design solution, SolidWorks2014 design, including detailed 3D model, STEP file, keyshot rendering file, does not contain features, can be edited and modified, the mechanism is complex, decompression size close to 0.98 GB, a total of more than 310 parts. fpc flexible board automated steel press design (3D document + keyshot Rendering file) FPC single-layer flexible board structure: this structure of the flexible board is the simplest structure of the flexible board. Usually substrate+transparent adhesive+copper foil is a set of raw materials bought, and protective film+transparent adhesive is another raw material bought. First, the copper foil is etched to get the desired circuit, and the protective film is drilled to expose the corresponding pads. After cleaning, the two are combined by rolling. The exposed pads are then protected by electroplating with gold or tin. In this way, the large board is ready. Generally, we have to press the corresponding shape of the small circuit board. There is no protective film and directly on the copper foil printed solder resist layer, so the cost will be lower, but the mechanical strength of the circuit board will become worse. Unless the strength requirements are not high but the price needs to be as low as possible, it is best to apply the protective film method.

Specification: Automatic Steel Press Design For Fpc Flexible Boards (3D Document + Keyshot Rendering File) SolidWorks, Inventor, 3D Exported

|

User Reviews

Be the first to review “Automatic Steel Press Design For Fpc Flexible Boards (3D Document + Keyshot Rendering File) SolidWorks, Inventor, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.