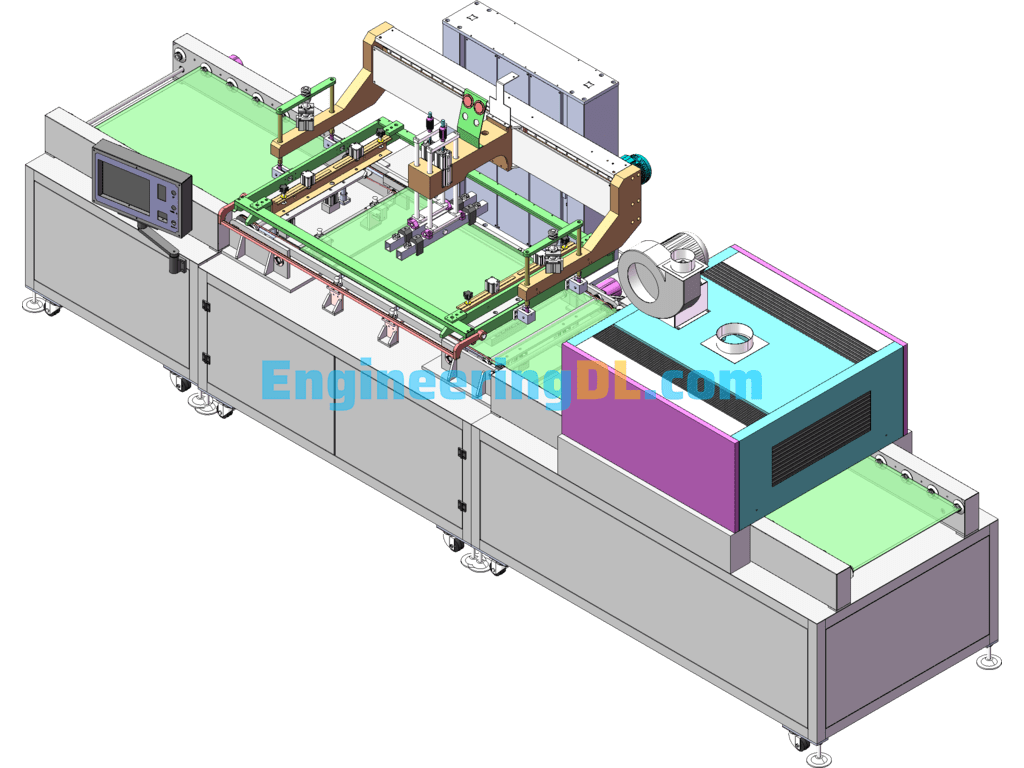

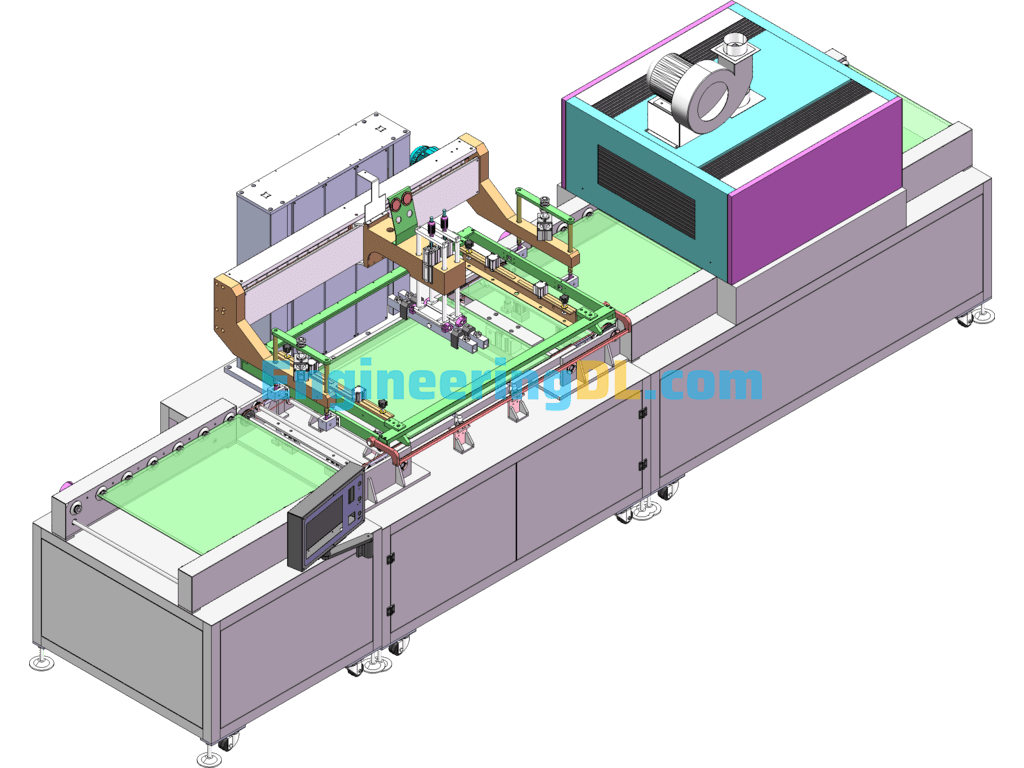

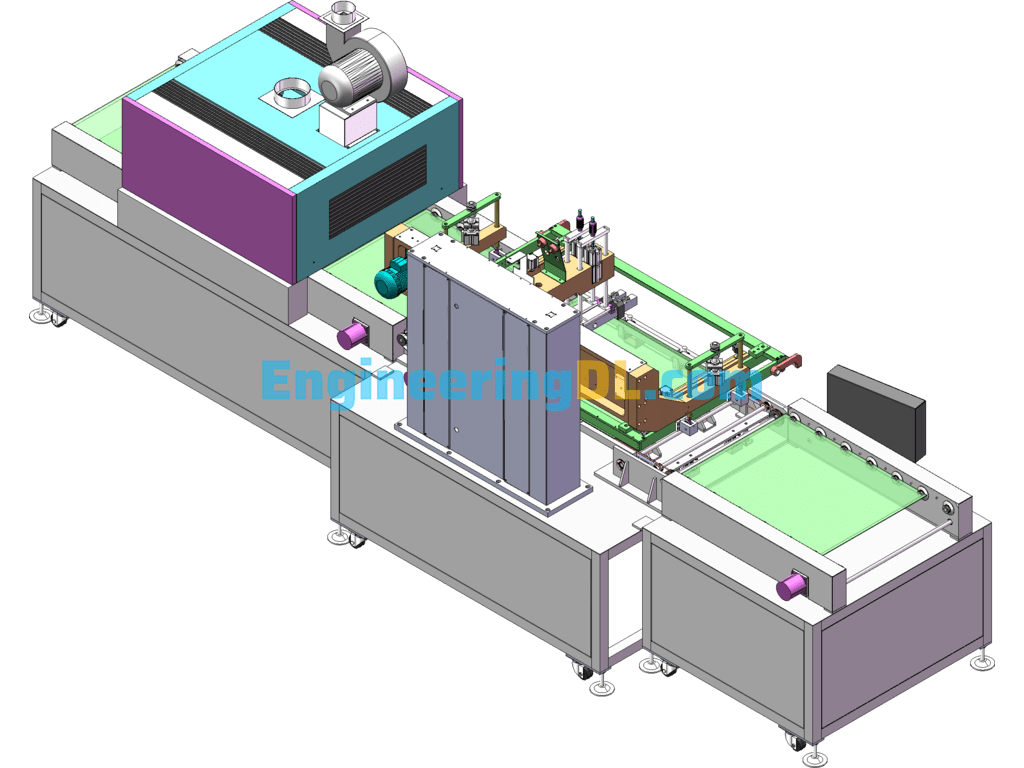

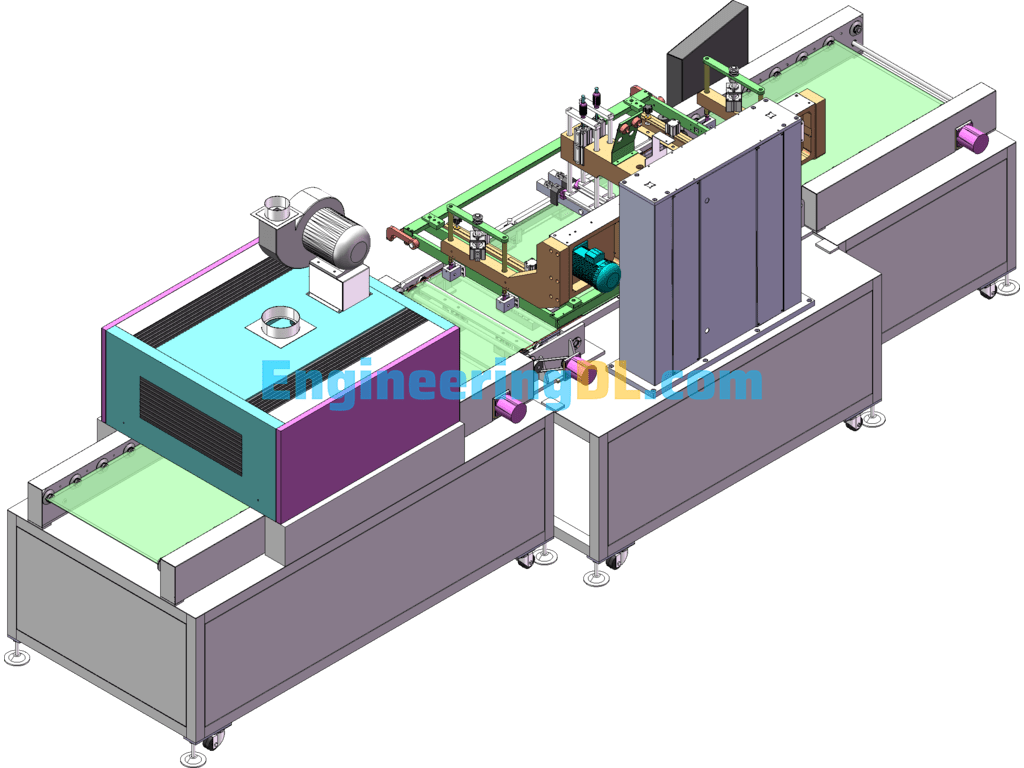

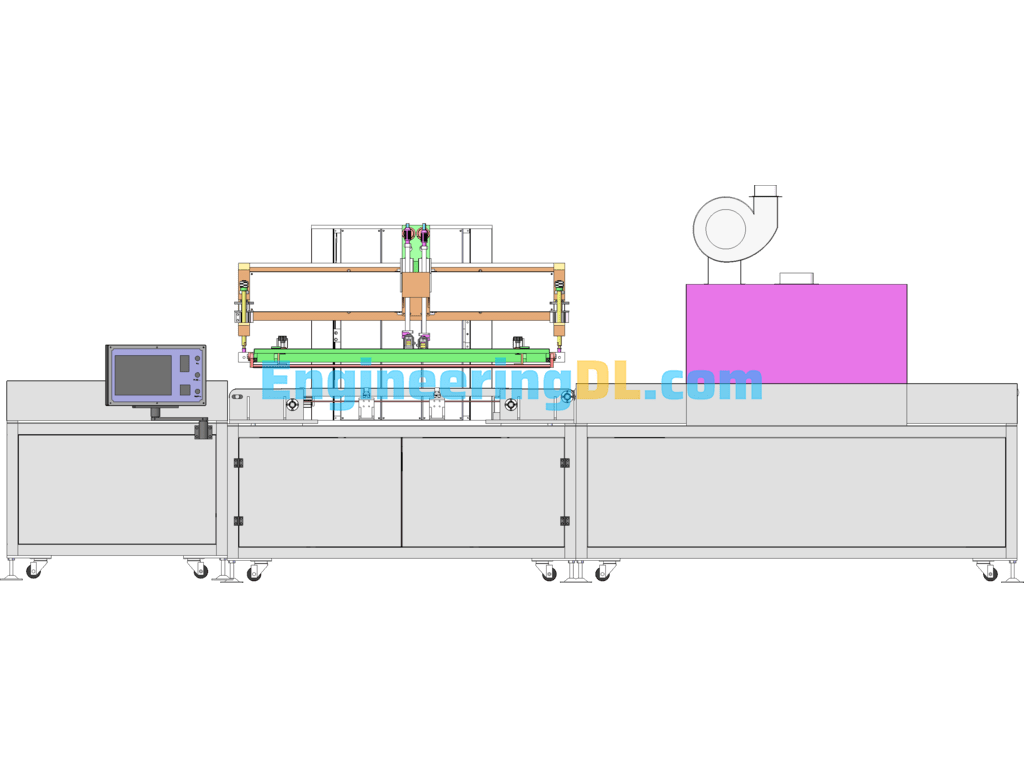

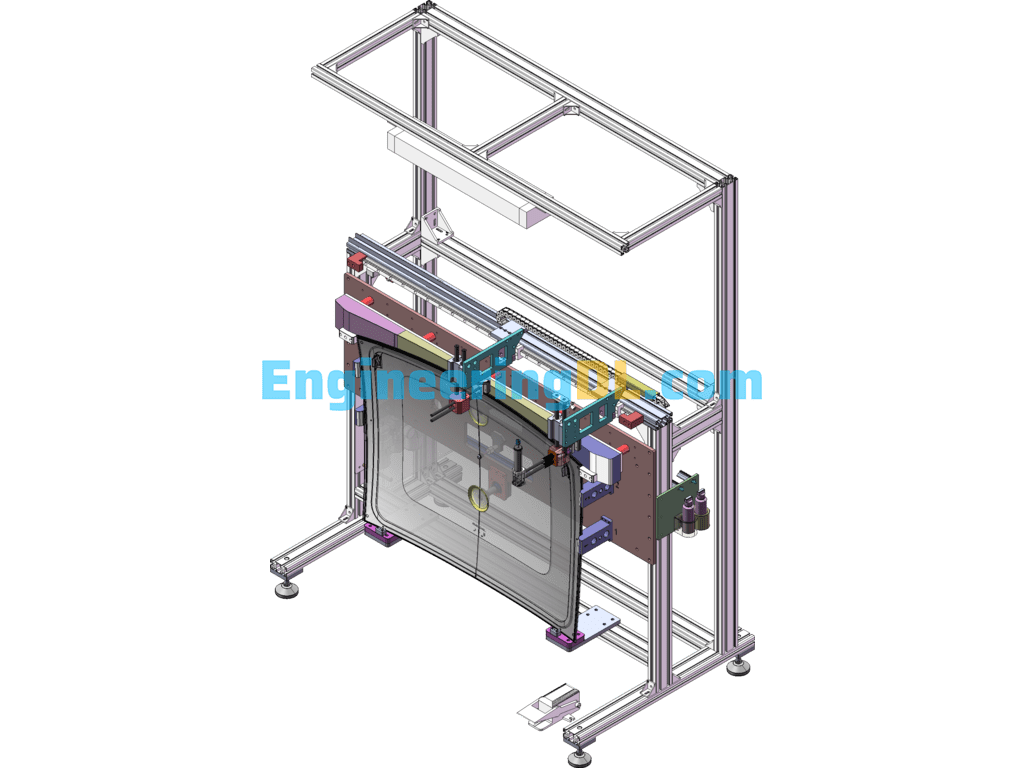

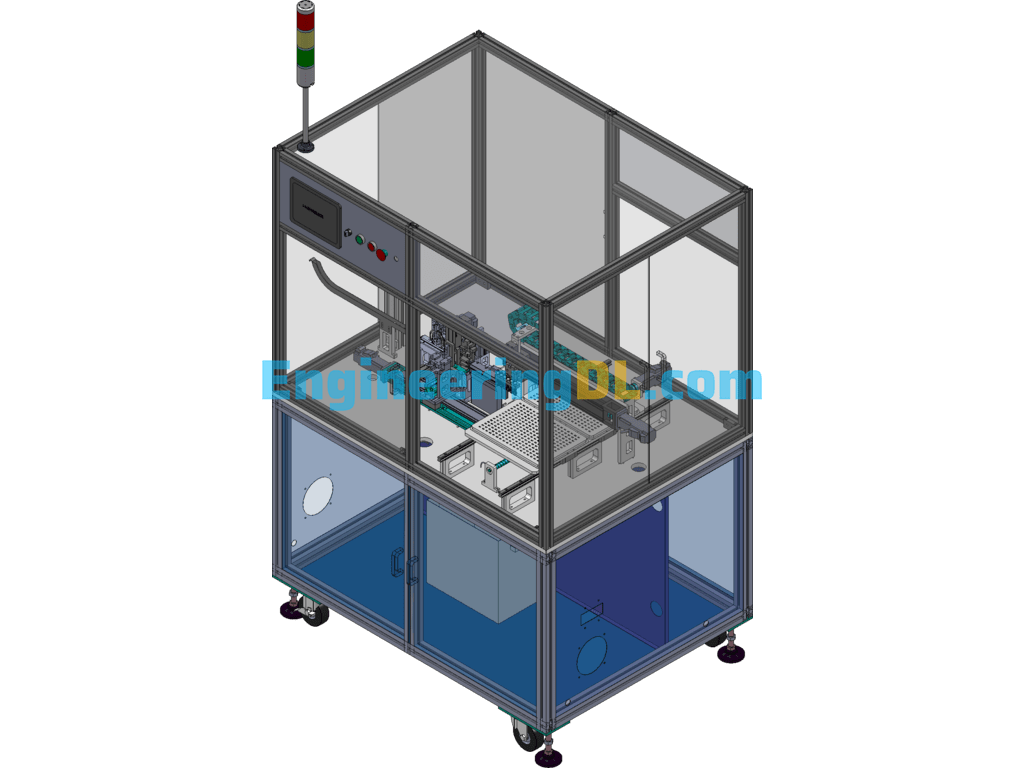

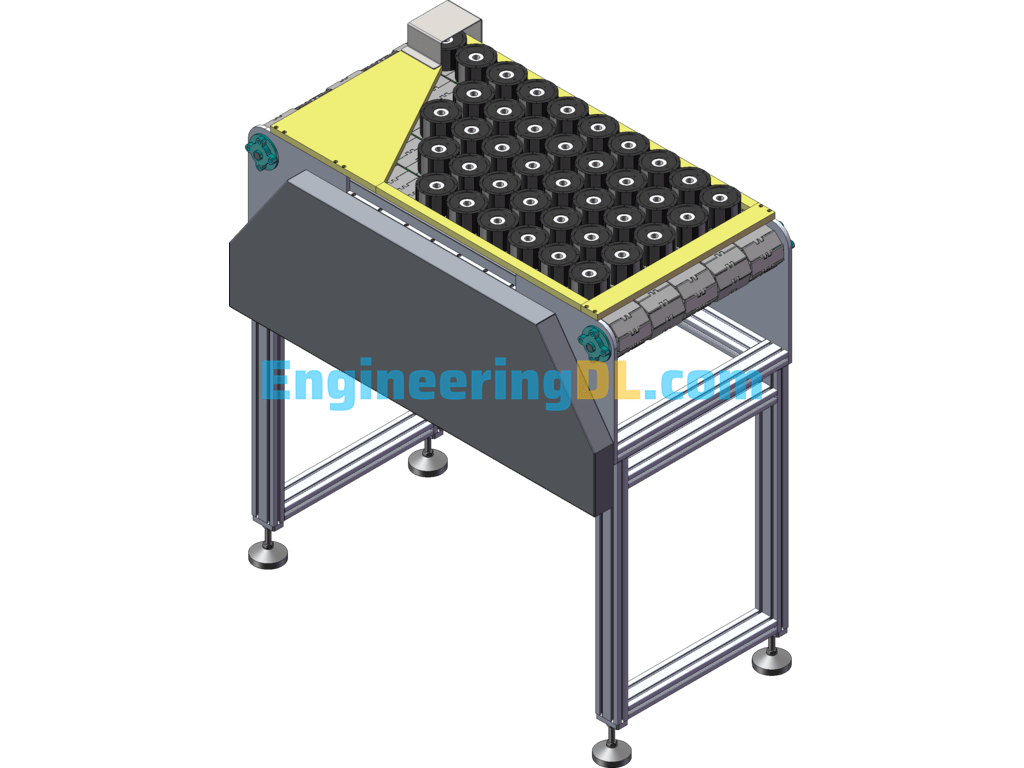

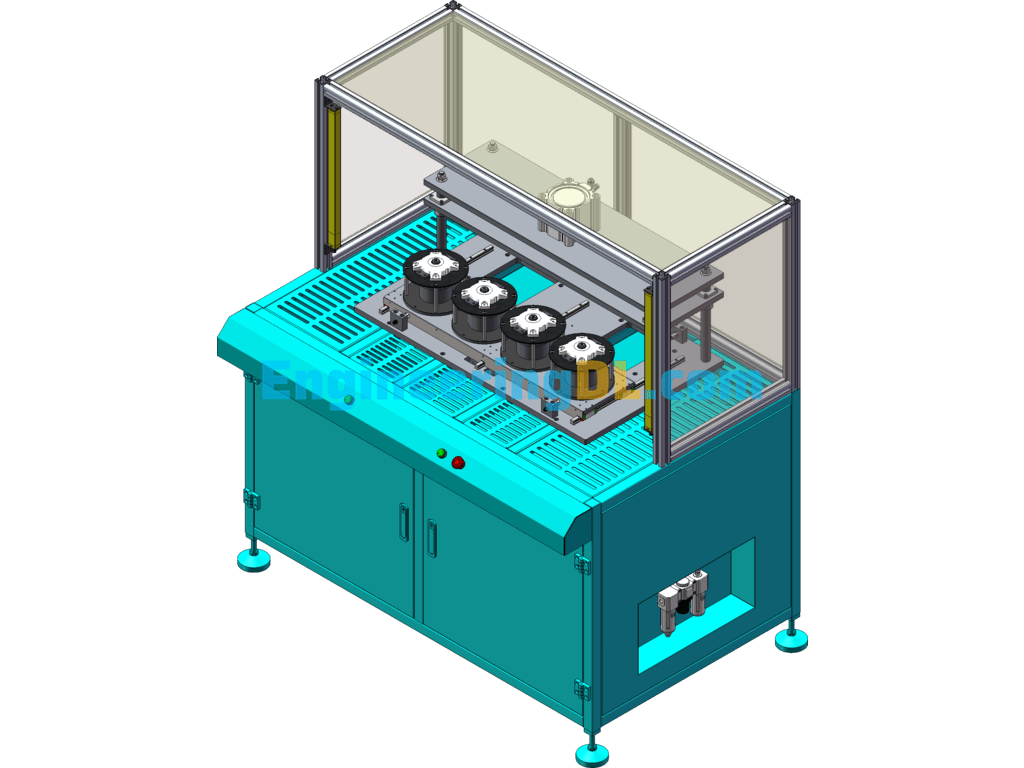

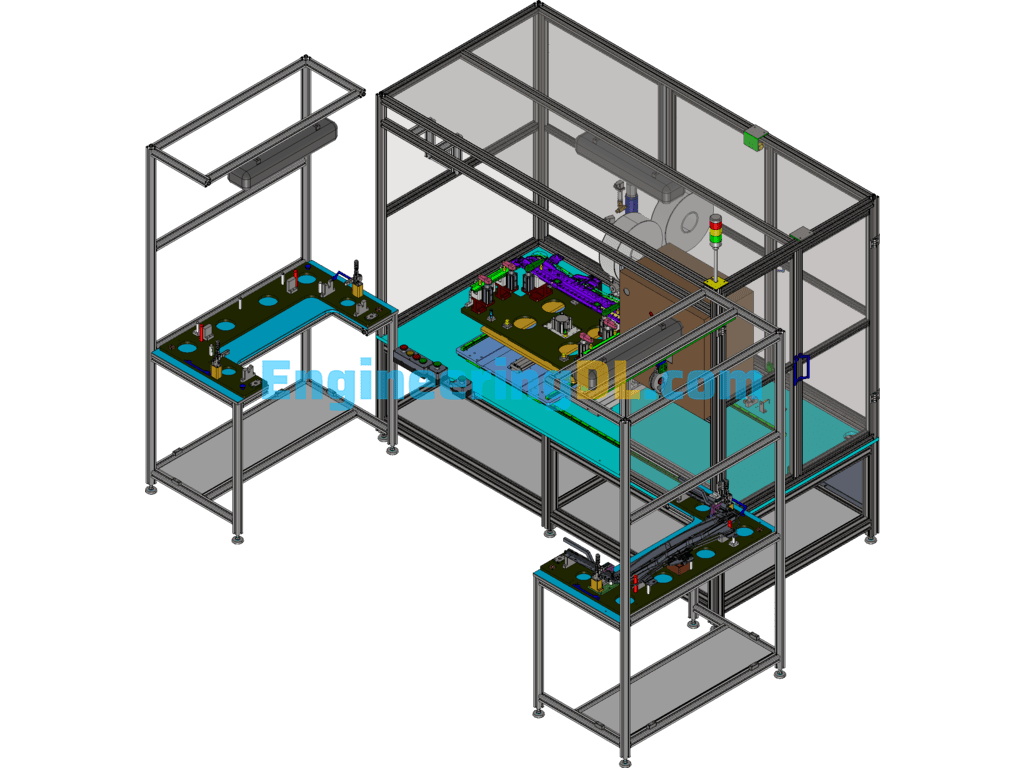

Automatic screen printing machine 3D model, automatic screen printing machine, the maximum printing area of 800 * 600, the main features of the equipment is 360 ?? stop rotary cylinder, ultra-high printing accuracy; LCD human-machine interface; 4-9mm adjustable mesh (screen and cylinder mesh distance); pull-out screen frame, easier to transport the state of the inspection and cleaning of the screen; PLC control centralized lubrication oiler, to ensure that the transfer part lubrication, reduce the key parts of the easy to damage and extend the service life; optical full monitoring of the printing process empty sheet and crooked sheet state, effectively reduce scrap. PLC-controlled centralized lubricator ensures the lubrication of the transmission part, reducing the damage of key parts and prolonging the service life; optical monitoring of the entire printing process of the empty sheet and distorted sheet state, effectively reducing the scrap rate. Process flow: raw materials — automatic feeding (double-sided dust removal, tearing protective film, electrostatic removal) — automatic printing (punching positioning holes, quality inspection lights) — automatic baking and winding (automatic varnishing, film protection, laminating tape, release paper, etc.) — subsequent processes can achieve automatic punching and cutting — finished products. Fully automatic only needs 1-2 people to operate, and a set of fully automatic only needs 15-20 square meters. With a proposal book of fully automatic screen printing machine design.

User Reviews

Be the first to review “Automatic Screen Printing Machine SolidWorks”

You must be logged in to post a review.

There are no reviews yet.