2021 Mechanical design and manufacturing and its automation graduation design (including thesis)

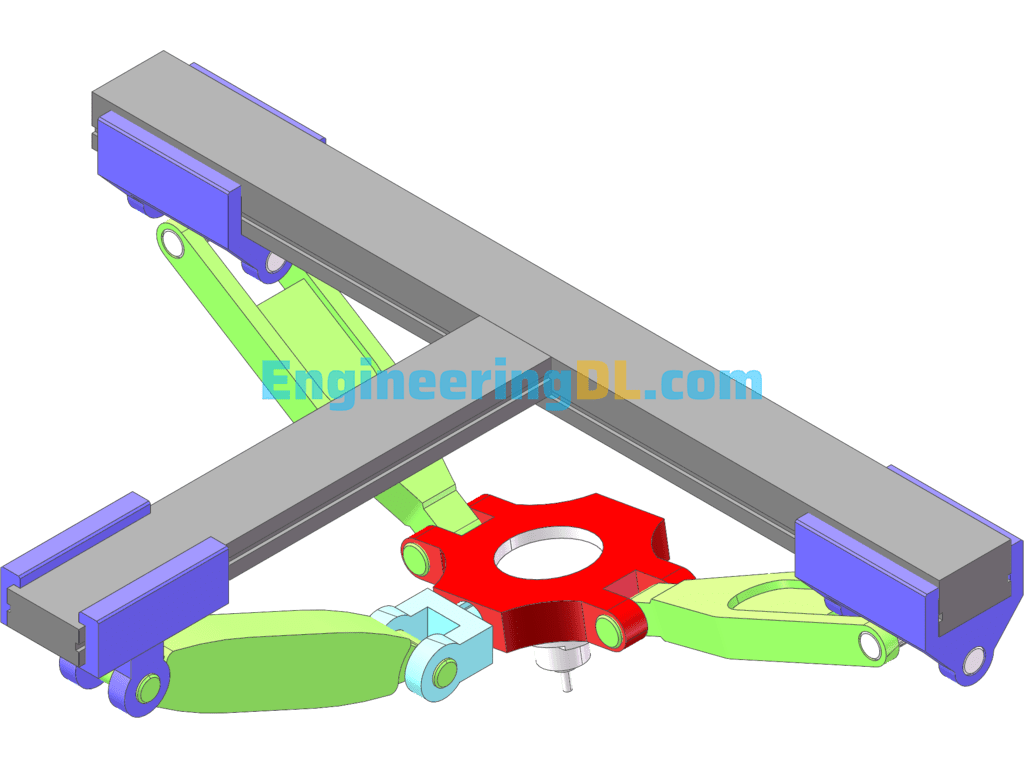

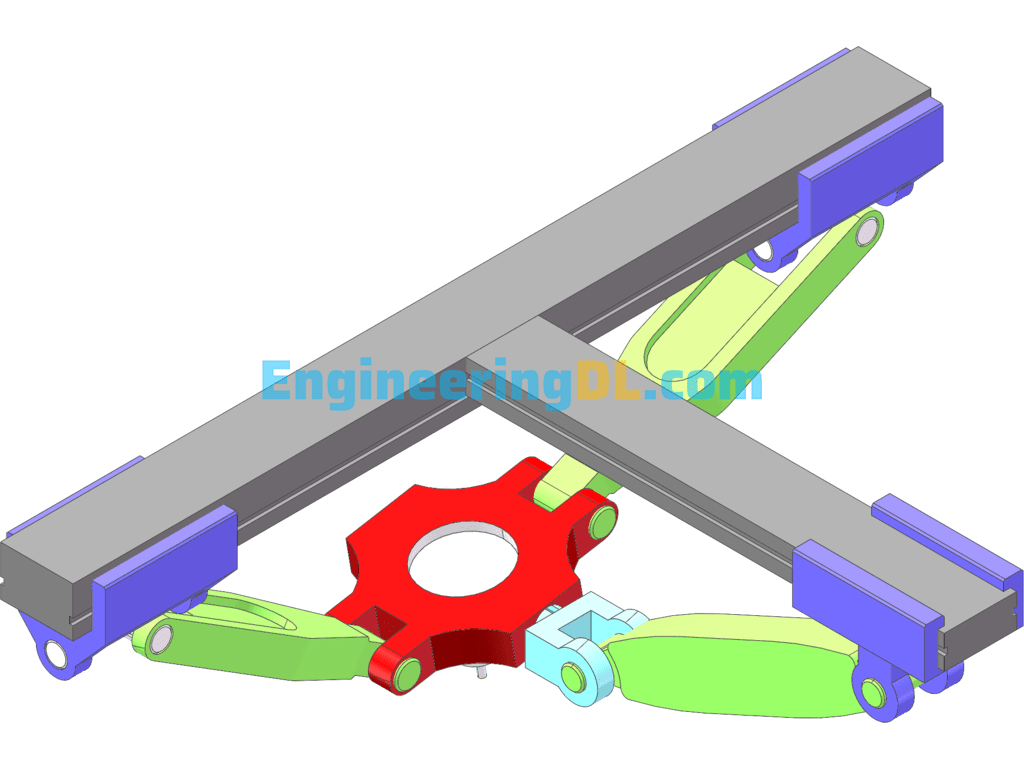

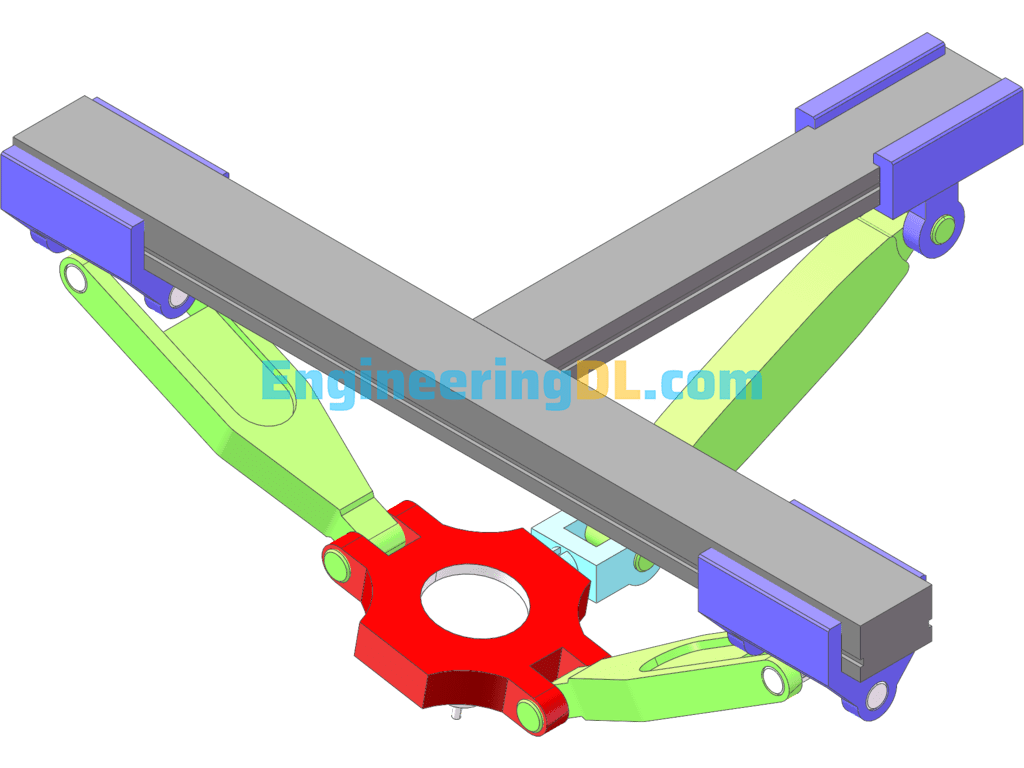

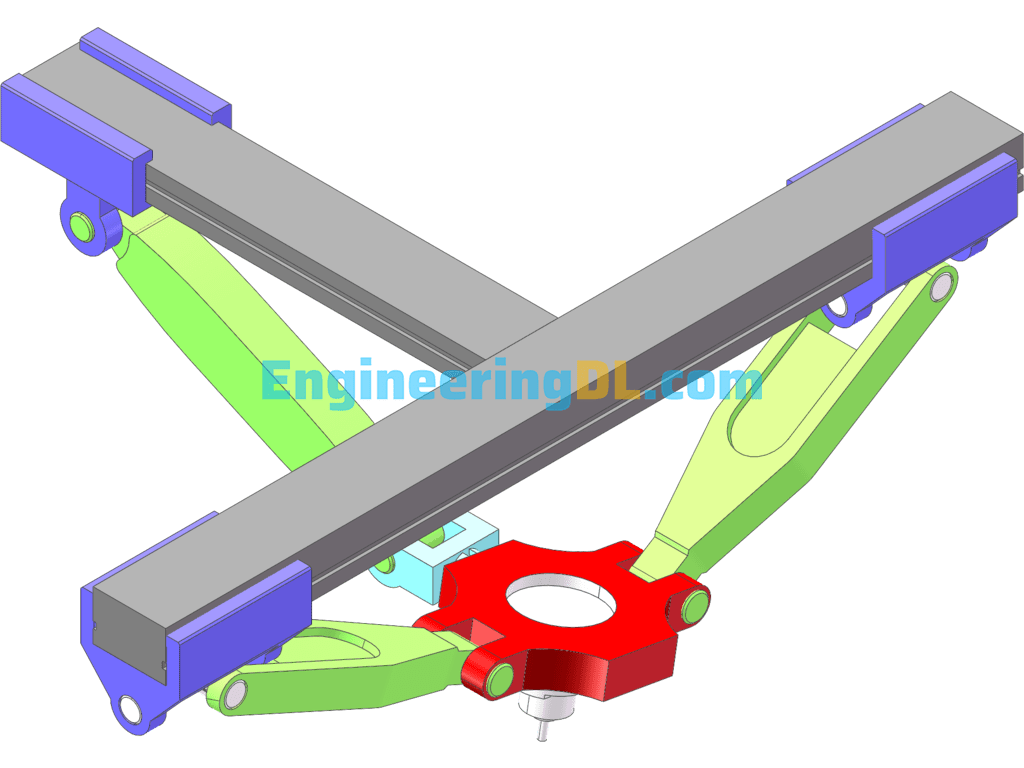

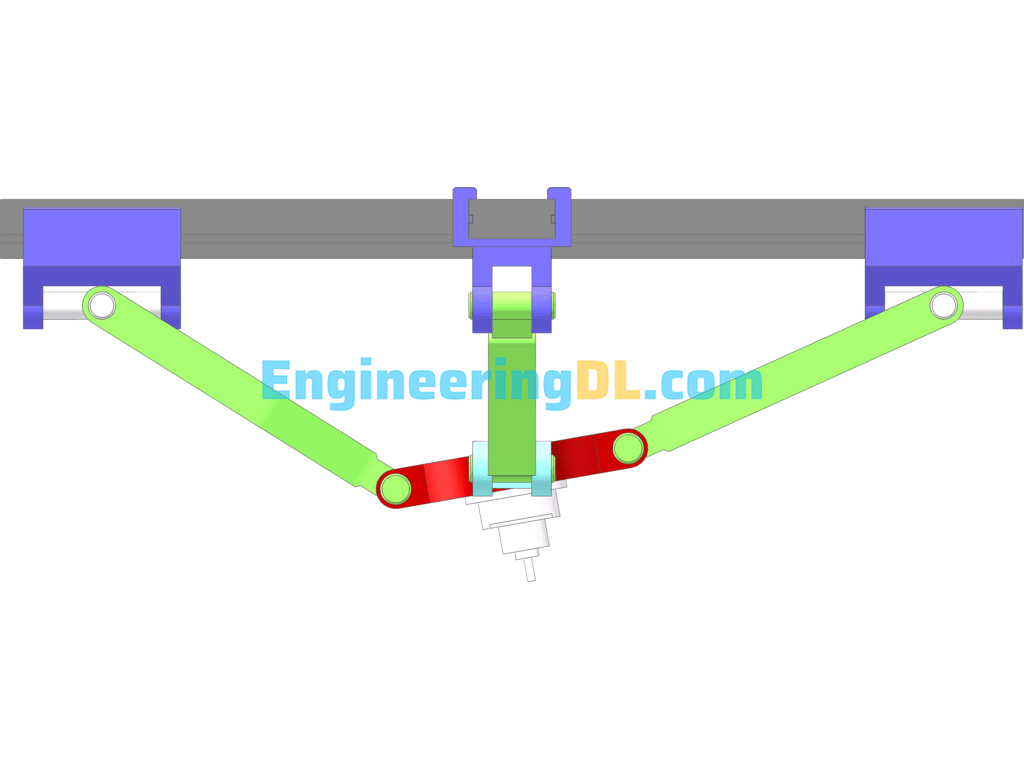

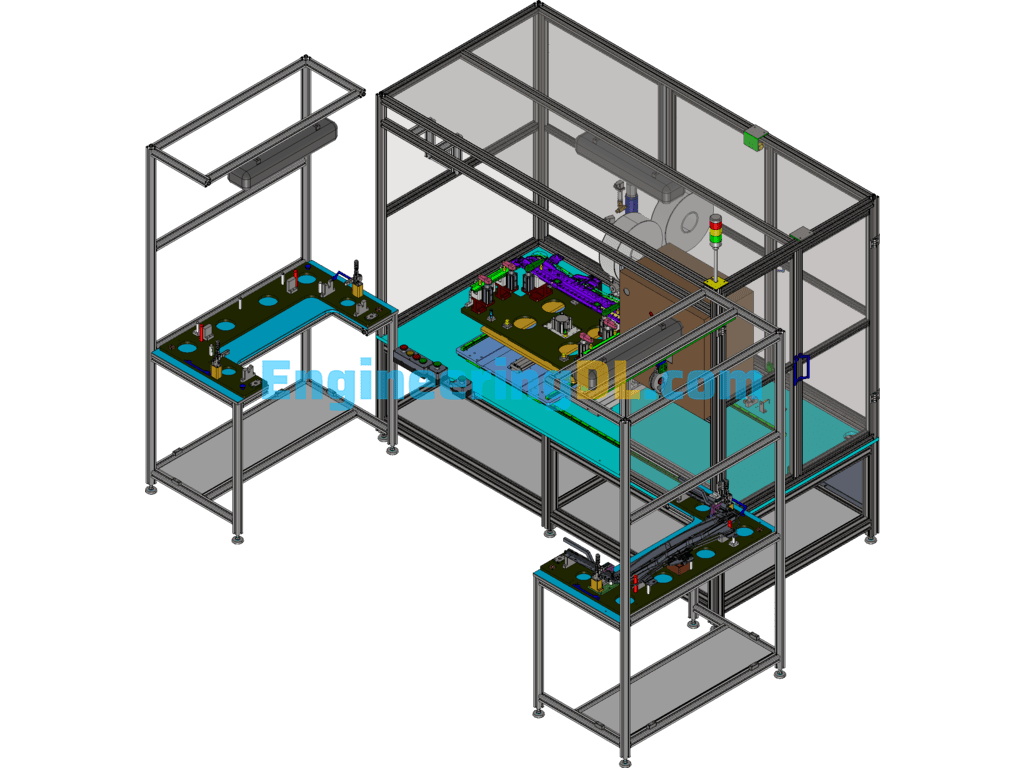

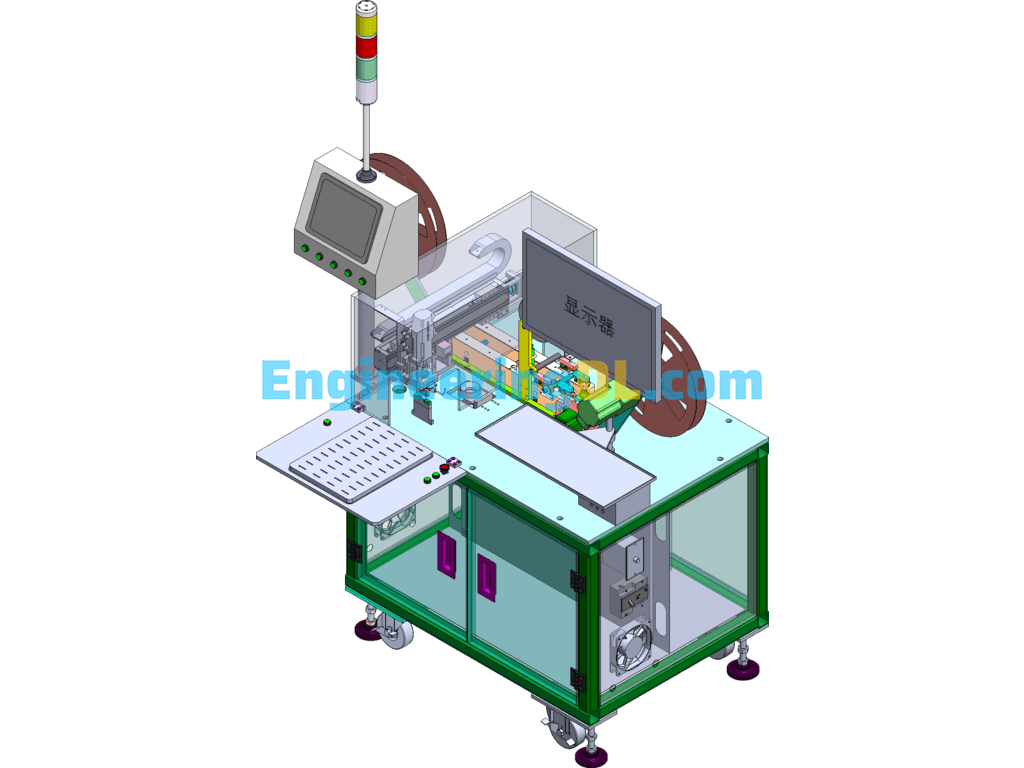

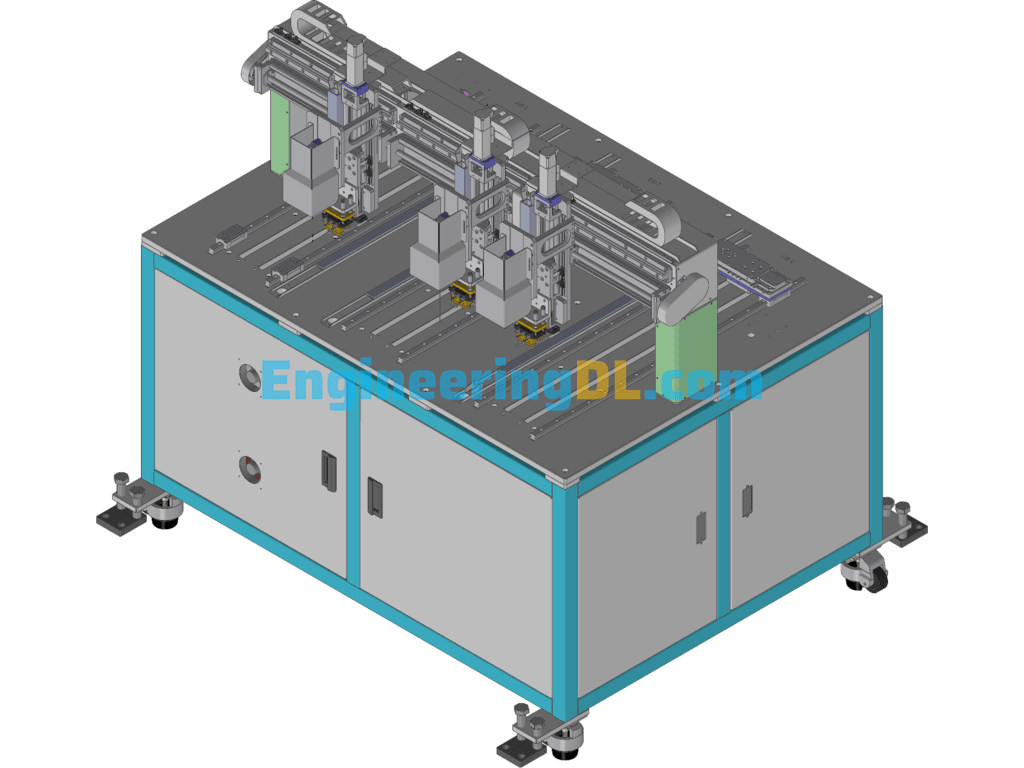

The use of hybrid power as the power source of machine tools is now gradually entering the market, it belongs to a new type of machine tools, has been favored by various countries. The hybrid mechanism has the advantages of high overall rigidity, low overall inertia, high load bearing capacity and good dynamic performance, but the existing hybrid and parallel machine tools have the disadvantages of small range of workpiece processing and low flexibility. To address the above problems, this paper proposes a new five-axis hybrid machine tool and conducts the following research: (1) The structure of the five-axis hybrid machine tool is introduced, and after the structure is introduced, the kinematic analysis of the five-axis machine tool is carried out, mainly including the five-axis machine position analysis, speed analysis and the end motion analysis of the hybrid mechanism. This is the basis for the subsequent modeling simulation and machining path simulation of the five-axis hybrid machine. (2) 3D modeling of the five-axis hybrid machine tool and simulation analysis of the tool end trajectory of the five-axis hybrid machine tool, before the simulation analysis, all the drive subs of the five-axis machine need to initialize the design, that is, the drive subs return to the initial position and set the corresponding parameters. After the initialization of the drive subs, the motion simulation of the five-axis hybrid machine will be analyzed, and the simulation results show that the tool trajectory at the end of the tool is spiral. This is a good foundation for the subsequent surface simulation of the machine. (3) To simulate the surface machining of the five-axis hybrid machine, we first analyzed the tool attitude and swing center position of the hybrid machine, then converted the surface to be machined into NC code by UG post-processing and inverse solved the displacement of the drive by MATLAB, and then used SolidWorks to simulate the surface machining. The surface machining simulation further proves the rationality of the five-axis hybrid machine designed in this paper.

———- Reviewers have their say ————

The latest version of the current graduation design, including 3D + design notes, is therefore rated Diamond!

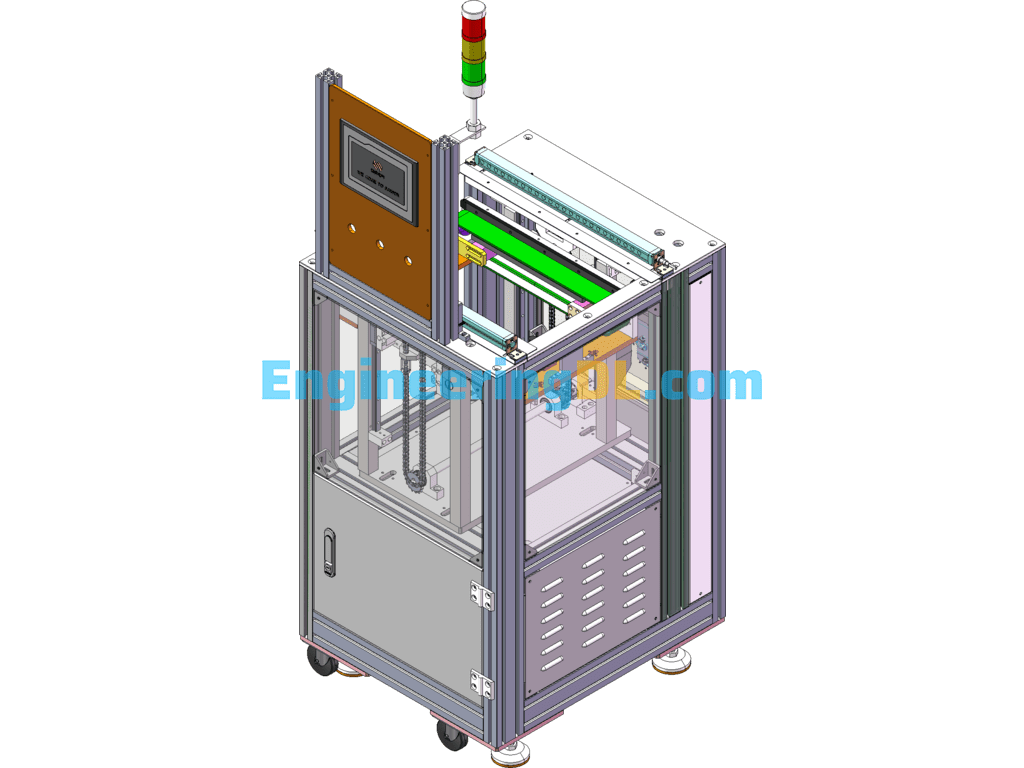

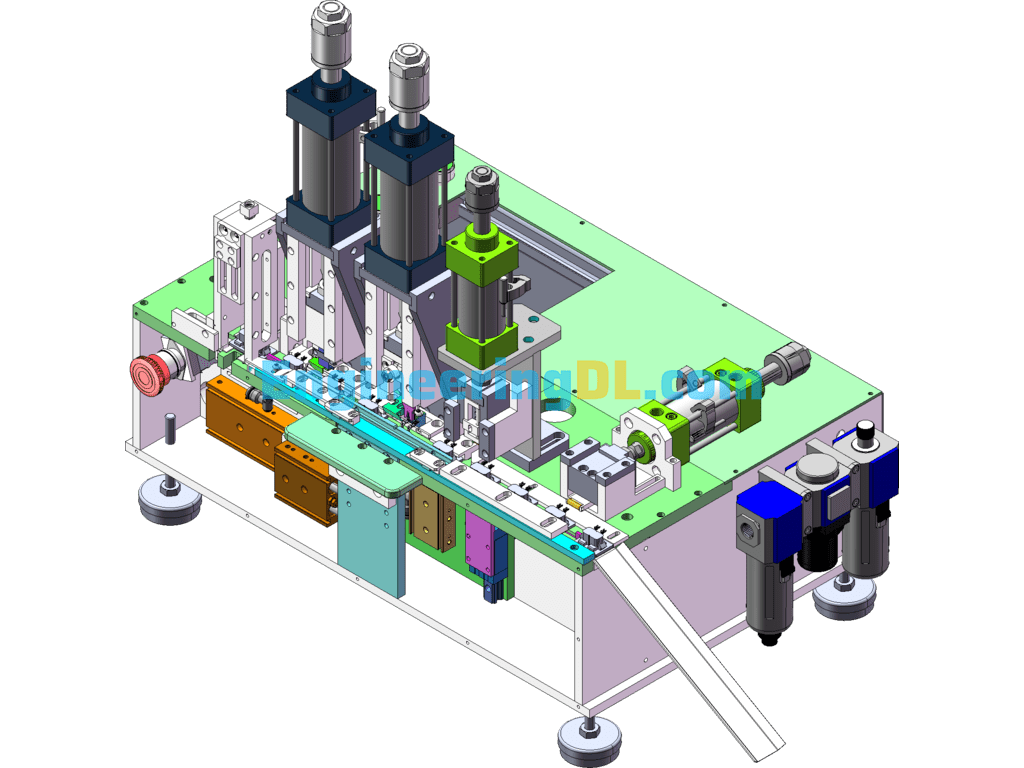

Specification: A Hybrid 5-Axis Machine With AB Structure Design And Motion Simulation SolidWorks, 3D Exported

|

User Reviews

Be the first to review “A Hybrid 5-Axis Machine With AB Structure Design And Motion Simulation SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.