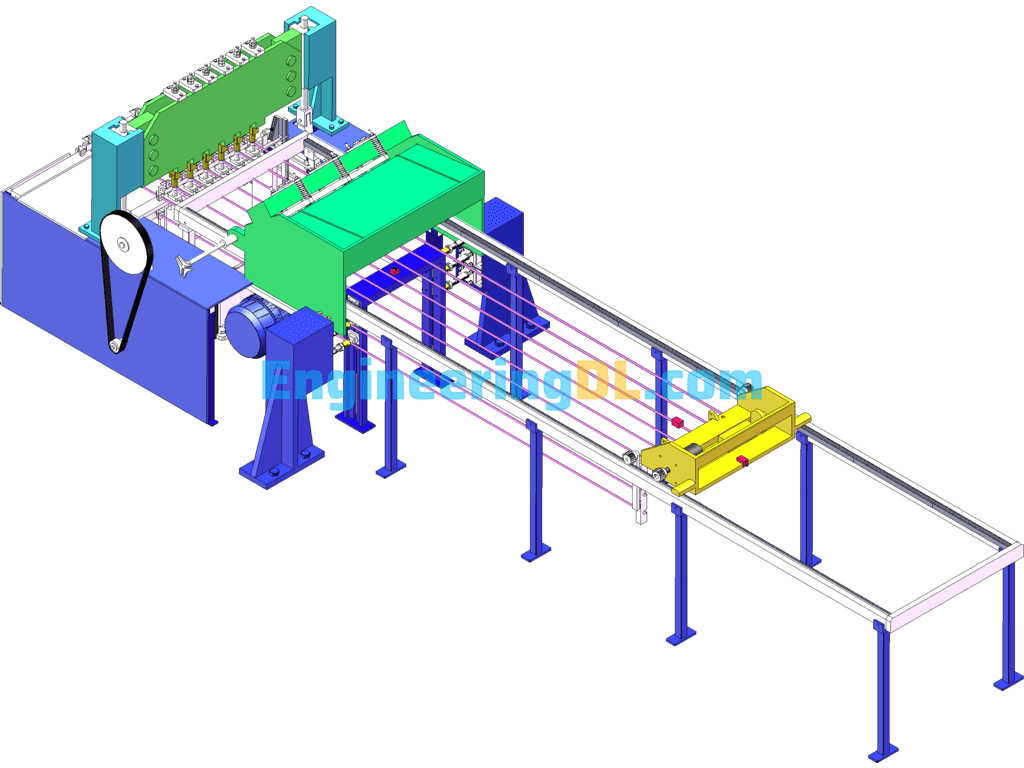

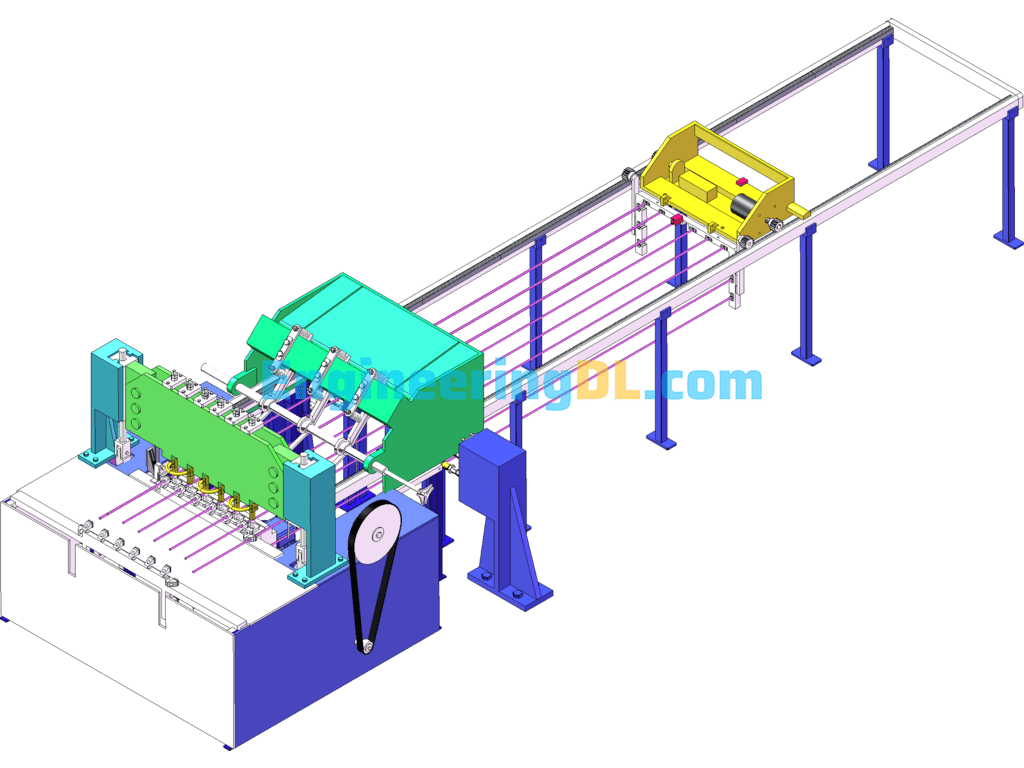

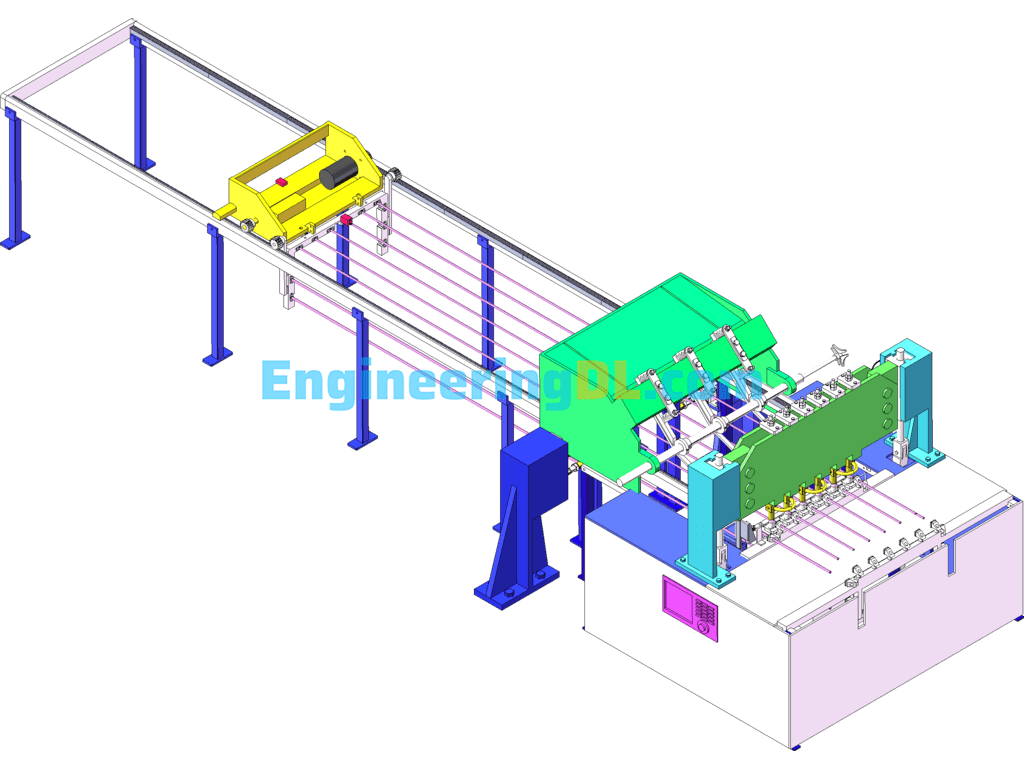

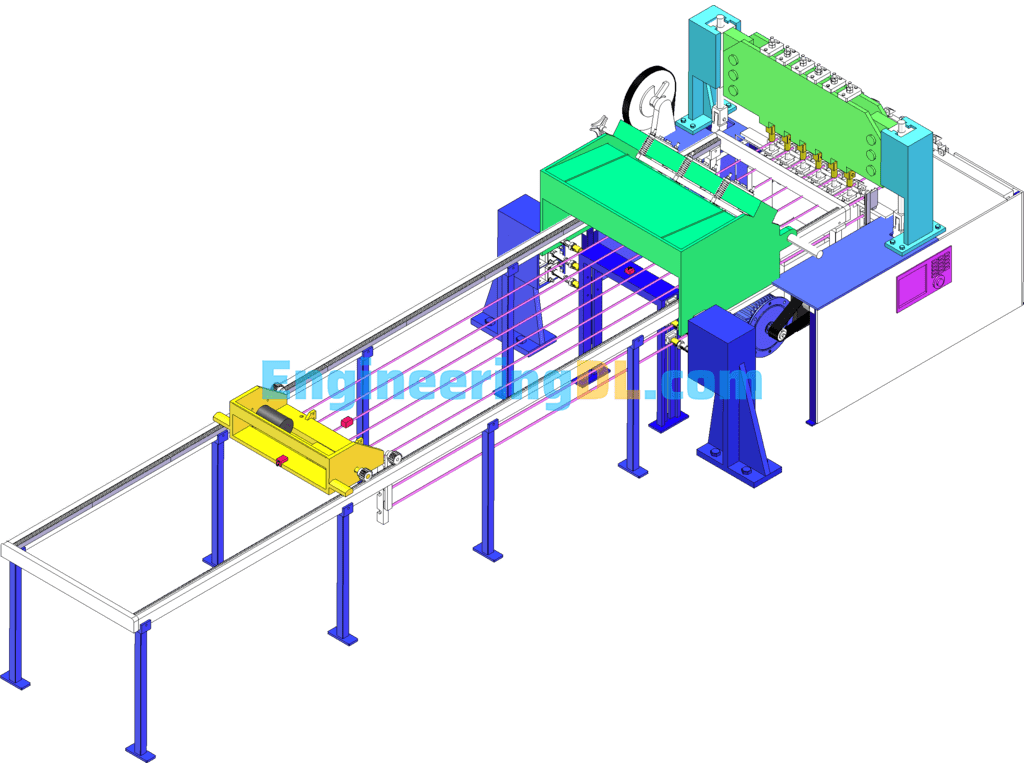

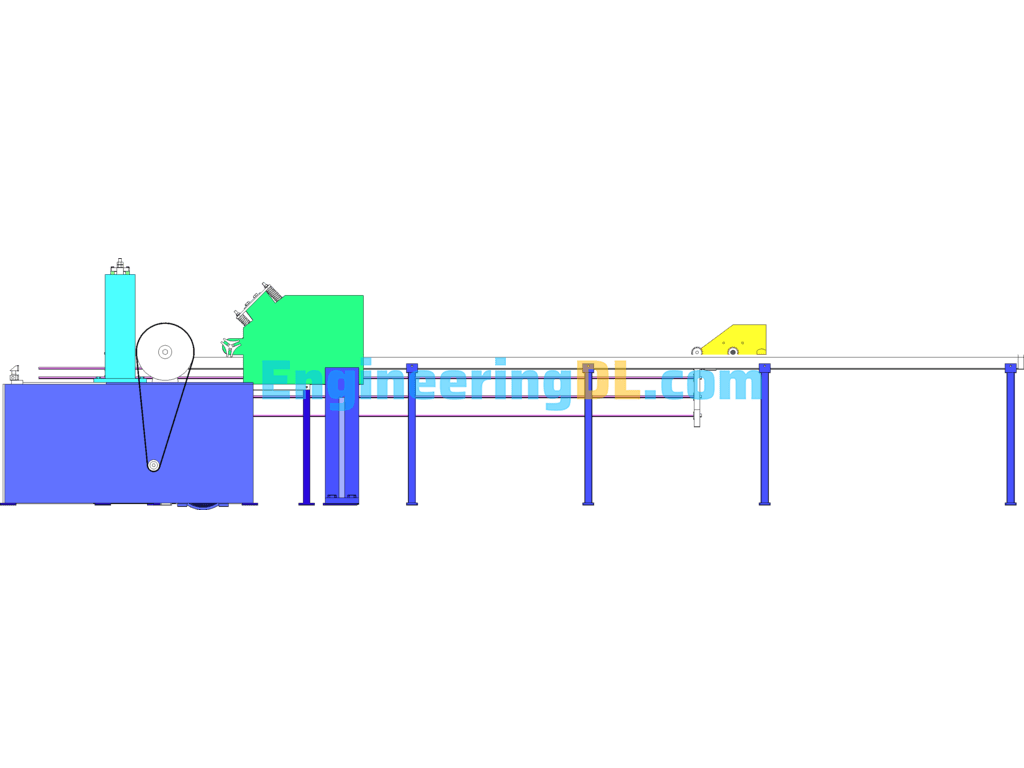

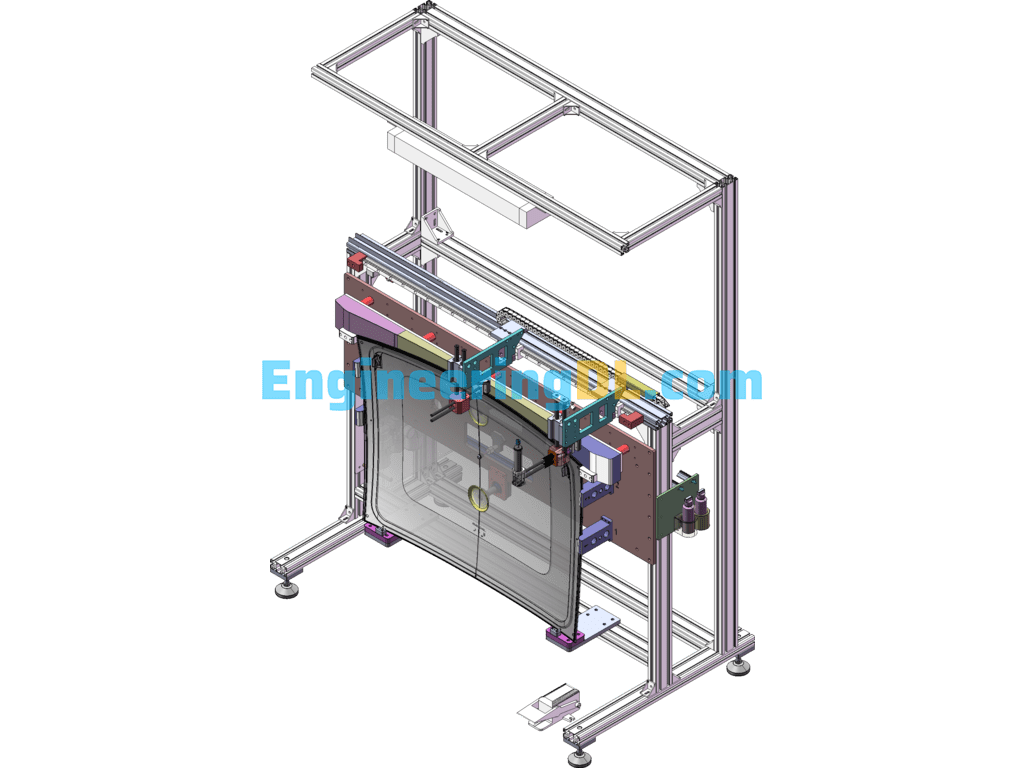

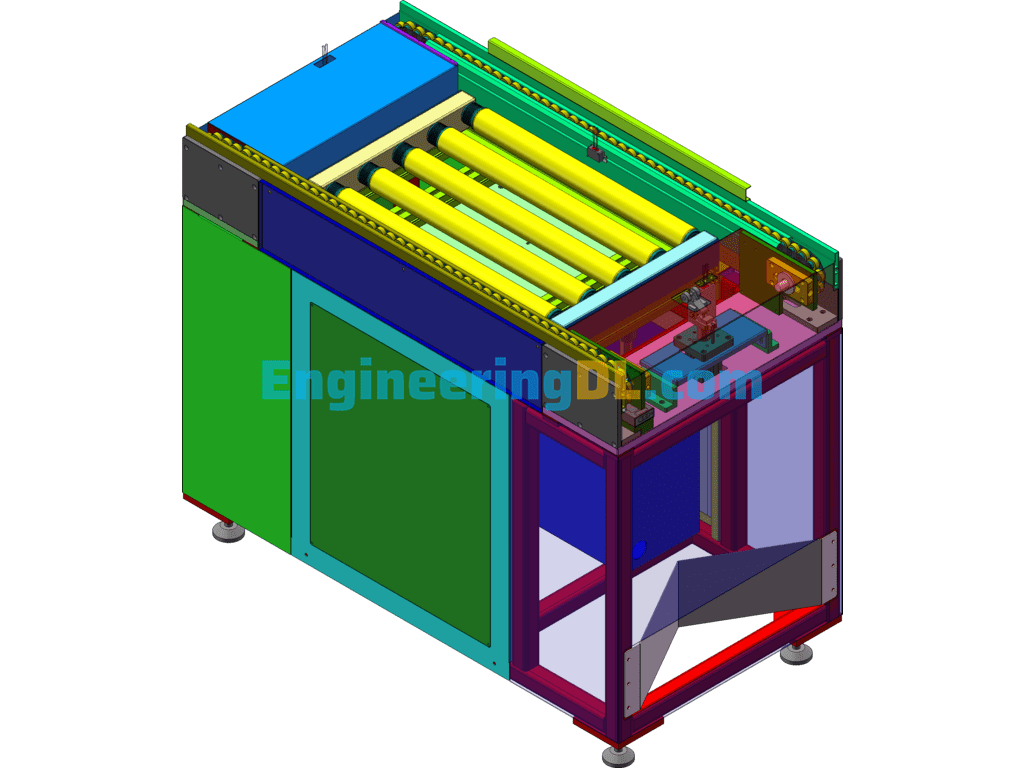

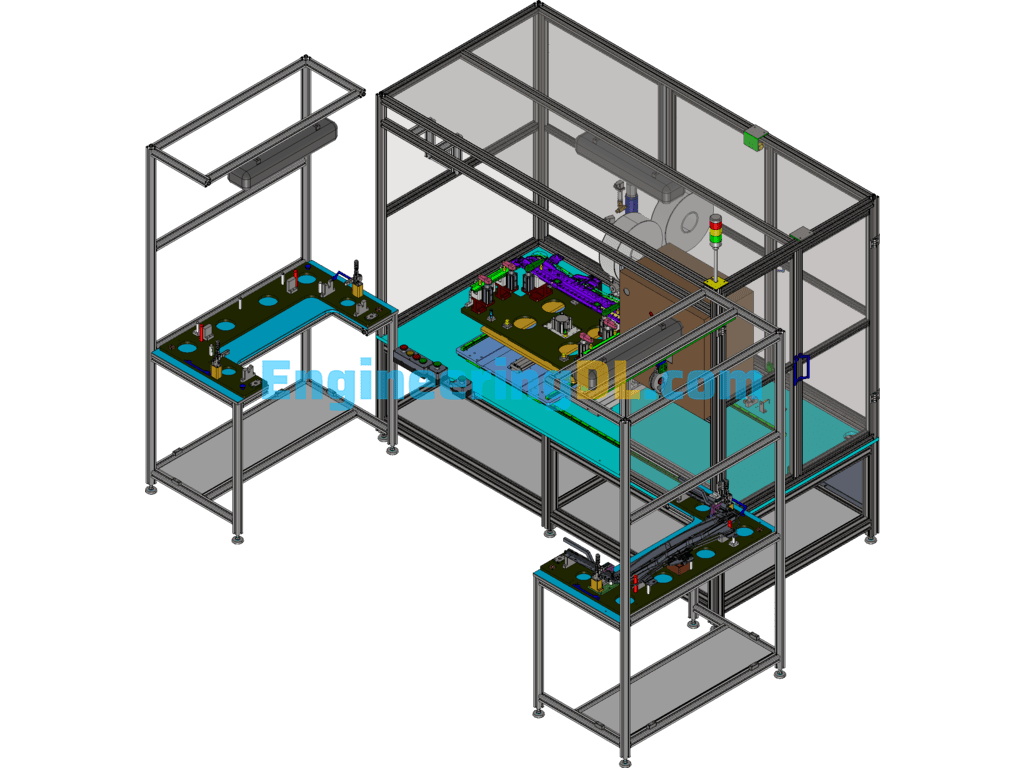

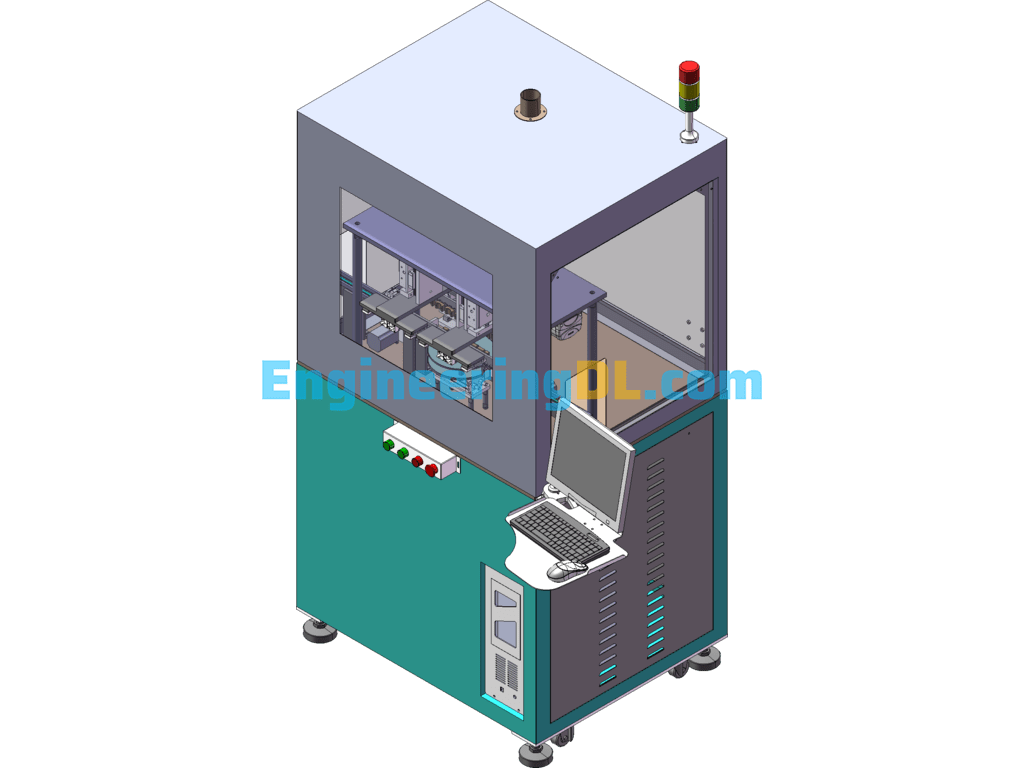

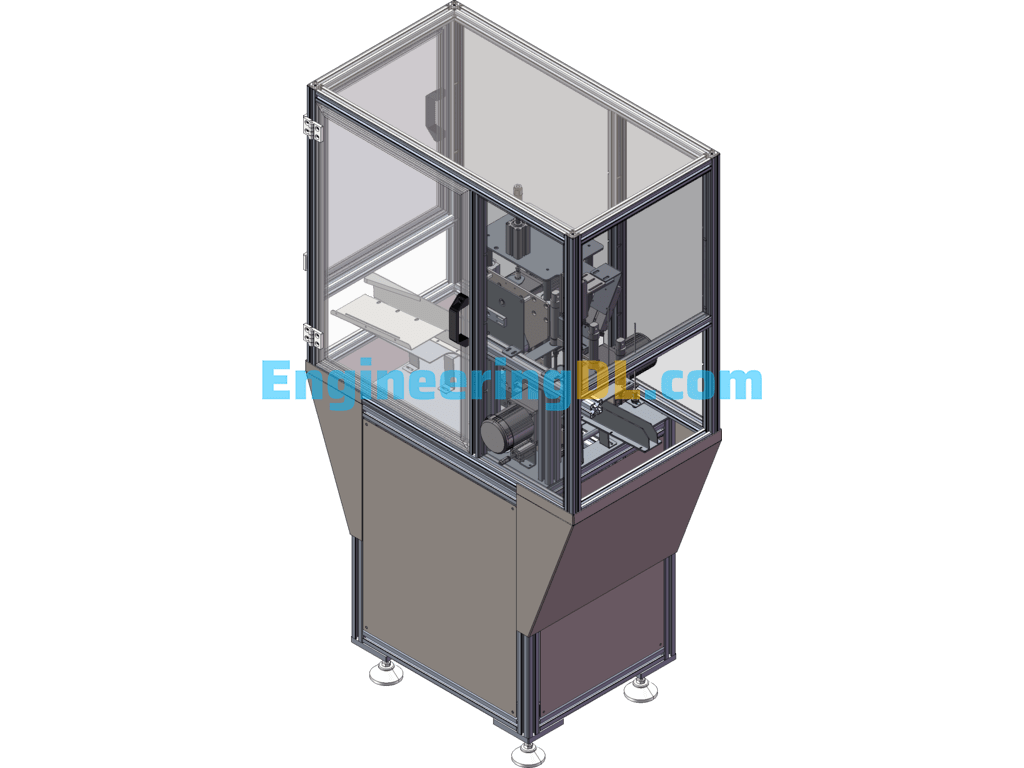

The automatic line welding machine for shaped steel cage mainly consists of a frame, a warp guiding mechanism, a longitudinal welding mechanism, a feeding mechanism, a transverse welding mechanism, a warp traction mechanism, a guide rail, a weft pushing mechanism and a transmission mechanism. The warp guide mechanism is fixed to the front of the frame, the welding mechanism is fixed to the frame and located directly above the warp guide mechanism, the feeding mechanism is located behind the longitudinal welding mechanism and fixed to the rear of the frame, the transverse welding mechanism is located on the side of the frame, the warp traction mechanism is arranged on the guide rail, the weft line pushing mechanism is located on the side of the warp guide mechanism and fixed to the inner side of the frame, the transmission mechanism is located inside the frame and makes the longitudinal welding mechanism The drive mechanism is located inside the frame and makes the longitudinal welding mechanism, feeding mechanism and weft line pushing mechanism linkage. Not only make it possible to shaped row welding, and with precision automatic, instead of manual labor, reduce the labor intensity and greatly improve the efficiency of shaped row welding, can be widely used in a number of fields such as engineering and construction.

1 – rack, 2 – warp steel, 3 – warp guide mechanism, 31 – guide hole, 4 – longitudinal welding mechanism, 41 – longitudinal electrode plate, 42 – longitudinal welding gun, 43 – welding gun support table, 44 – crank slider mechanism, 45-weft positioning stopper, 46-longitudinal welding support, 5-feeding mechanism, 51-slotted wheel mechanism, 52-feeding wheel, 521-feeding slot, 53-feeding box, 531-slanting plate, 532-mounting plate, 54-feeding guide frame, 541-upper guide frame, 542-lower guide frame, 543-spacing adjustment plate, 544-fixed plate, 545-adjustment spring, 546-bump, 55-drive shaft, 6-transverse welding mechanism, 61-transverse gun holder, 62-transverse gun, 63-transverse electrode plate, 64-transverse electrode plate holder, 65-welding contact switch, 66-hydraulic cylinder, 7-warp traction mechanism, 71-magnetic sleeve, 72-gear, 73-step motor, 74-traction mechanism contact switch, 75- warp locking contact switch, 76 – traction support, 8 – guide rail, 9 – control panel, 10 – weft pushing mechanism, 101 – cam mechanism, 102 – pushing rod, 103 – pushing rod holder, 104 – beveled slots, 105 – sliding rod, 11 – transmission mechanism, 111 – main motor, 112 – gearbox, 12 – weft reinforcement.

Specification: Automatic Line Welding Machine For Shaped Steel Cage (Mass Production) SolidWorks, 3D Exported

|

User Reviews

Be the first to review “Automatic Line Welding Machine For Shaped Steel Cage (Mass Production) SolidWorks, 3D Exported”

You must be logged in to post a review.

There are no reviews yet.